Damn Layer Shift!, time to go Closed Loop?

-

Are you satisfied with how the outer wall of this part of the print varies far from smooth?

It looks pretty nonuniform compared to prints that come off my printer.

I think taking some time printing square or round towers along with other objects on the same build plate will help you understand how your printer is misbehaving and how to improve its print quality.

until you do that and can get quality prints imagining closed-loop control is a waste of time.

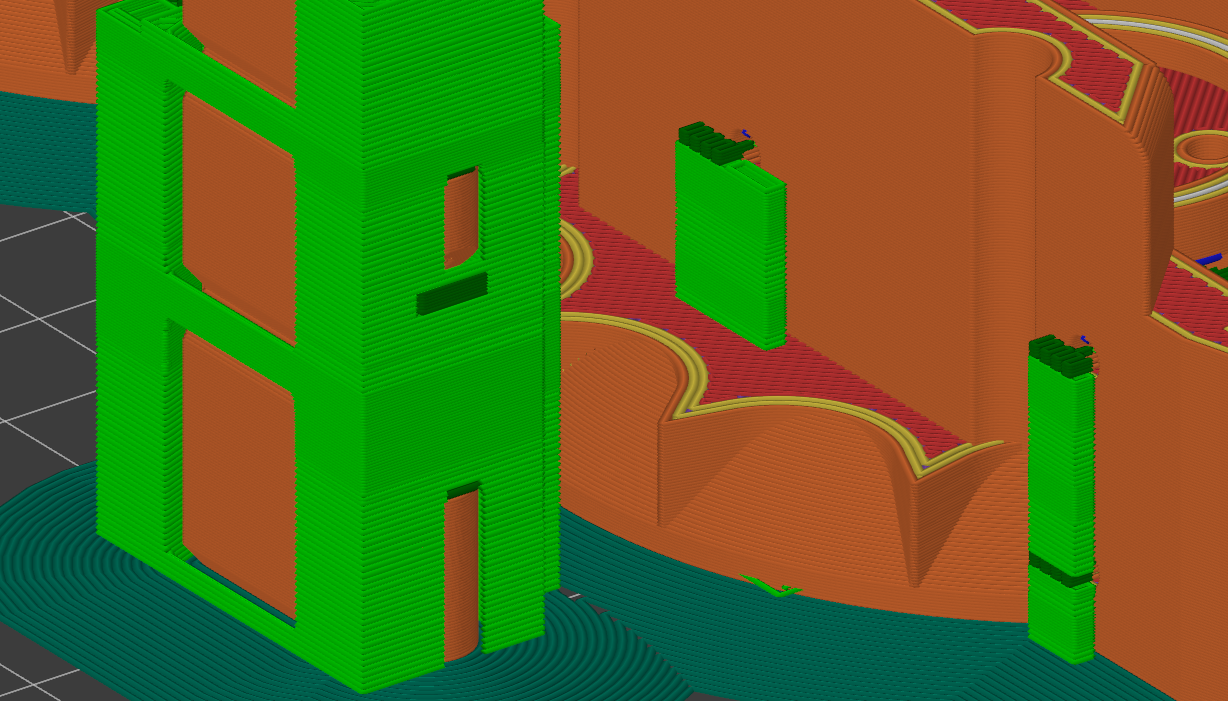

Just as an example, here's a print of part of a rocket nozzle I printed using my Duet2.

See how uniform the print is along the Z axis compared to how nonuniform your print is? That's the result of weeks of tuning the slicer settings. (Well, I have to admit I couldn't get the slicer to do a good enough job, so I wrote a program in C to directly generate GCODE to perform the moved to create this print, but I don't expect you do to that.)

Try getting your printer to produce nice smooth walls on your print and then if you absolutely cannot get it to do so, consider going to closed-loop.

If you don't do all the hard work first, you will never get good prints and will always be blaming something else.

-

@fcwilt to reduce the permiter count down from 3 to 2 with similar wall thickness

-

@alankilian the non uniform part is a support tower, I am not sure why but the support towers tend to looks less smooth than the actual part they are supporting

-

@alankilian that’s a clean print for sure. Was that in vase mode? What speed and layer heights was that done, just curious

-

@alankilian even in prusaslicer preview the supports have a rough non uniform appearance.

-

@adamfilip said in Damn Layer Shift!, time to go Closed Loop?:

@fcwilt to reduce the permiter count down from 3 to 2 with similar wall thickness

Thanks.

Frederick

-

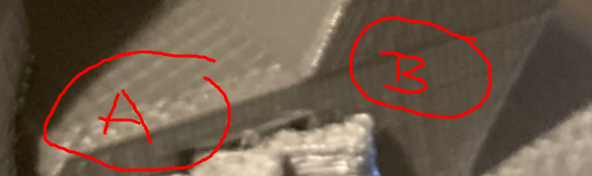

Looking at your example, there are two areas that imply some additional tuning may be required -- if not for this print, then maybe for future ones.

In A, there seems to be roughness on short infill, which may be an indication that it's worth tuning retracts and PA a tiny bit more.

In B we see kind of a line, which is similar to the infamous Benchy Hull Line which appears where the plastic cools down differently due to a geometry change such as in your part. B is very difficult to tune out completely, and your filament is an excellent choice to point out any and all flaws that may not even be as visible or even relevant in the real world. If the transition point feels smooth, it's probably fine to ignore.

Especially A could lead to either the nozzle or a low mounted Z probe snagging on filament that curled up. B just indicates that tuning for overhangs/and or part cooling might improve the print overall.

If your current printer setup does not allow for more cooling, printing slower may be an option. Sometimes it's surprising how well reducing terminal speeds by 30 to 50 percent helps without adding more than 10 to 20 percent to the print time (since jerk and acceleration affect overall print time considerably). I understand that this may be undesirable on a multi day print, but it's still better than having to have multiple attempts. Printing slower also means more uniform printing which leads to more a) uniform surface finish, which may or may not be relevant depending on whether you plan to fill/sand/paint the part or not and b) better interlayer adhesion.

-

@adamfilip the EXP1HCL has been released for a while and is available from some of our resellers, for example Filastruder and E3D.

-

As with anything there are multiple causes of layer shifts in a print. Some may and some may not be solved with closed loop. Open loop is the wrong way to run a machine but it's cheap and does work. Other forms of cnc machines all have some form of positional feedback either motor mounted encoder, linear scale both relative or absolute. Closed loop won't necessarily fix a layer shift problem if it's backlash in the system due to a mechanical tolerance being too large. I can't however think of any reason why it would be worse than open loop besides price.

-

Howdy sir. My apologies - I didnt mean to come off like that, and perhaps my good willed intentions didnt come through in my post. for that I apologize. I know the last thing you need when struggling to get your printer working after hours of config and testing and struggles - is some clown on the interwebz giving you flack.

Didnt mean to be rude ... sorry if it came off that way. Was hoping to prevent you from spending $$$ unnecessarily. Thats all. Thought I saw some print tuning issues from your pics - perhaps I was mistaken.

Good luck with getting this sorted. Hope it gets worked out soon.

-

@adamfilip I can think of a few more things to ask about and one thing to try (FWIW).

- Is the layer shift always happening in the same direction? (I am wondering if it is always associated with a particular stepper?).

2.) When I had this problem with my previous printer, the nozzle was getting hung up on a protruding piece of plastic ( Z hop would often help but wasn't a reliable solution for me). This would happen when either:

-

the layers would start to curl up which was due to insufficient cooling (which sometimes just meant that the layer time was so brief that the previous layer had not sufficiently cooled when the next layer was extruded on top of it

-

or plastic built up on the nozzle and at some point the glob would stick to the print ( less likely with PLA because any PLA building up on the nozzle should melt vs for example a PET-G which is more like a gel when extruded)

-

or I was using some PLA filament that wasn't well suited for 3d printers.

You didn't sat what brand filament you are using, but if you are in the US, try eSun PLA+. You will want to run it at a higher temperature. It is not very expensive and very consistent roll to roll. I have thrown away almost full rolls of some PLAs because I couldn't count on them to behave in a predictable fashion.

All of the other points that folks have brought up are also great ideas to chase down.

Good luck hunting down the problem!