Hollow shaft extruder

-

I've verified my NEMA08 motor temp-curve and the rated current of 0.6A is quite reasonable. For PLA printing the motor-surface temp at 0.5A is a bit too high.

The filament got soft when I extruded very slow (0.5mm/s). At normal print speeds I don't expect problems, but the first layer speed is usually slower and might fail.

Will try with 0.45A for longer periods and add some airflow over the stepper by designing an intake fan shroud for the hotend fan.I also noticed that 20° cant angle doesn't self-lock the filament motion completely, but that is part of my pacemaker strategy. Luckily I've written the code for the remote torque_push motor in such way, that it goes idle without incomming steps.

-

@fma said in Hollow shaft extruder:

@rqthree very cute extruder!

Do you have some more informations about the motors and all vitamins used? Would you share your 3D models?

Thanks,

Frederic, here you go. Change the file extension to .zip from .doc. This forum does not accept zip files.

-

@rqthree Thank you very much!

-

Those rollers that were on funssor store on AliExpress a month or so ago finally showed up. They don't look anywhere near as bad as far as machining quality goes compared to the pictures. Id be hard to pressed to make better ones on the lathe. I'll send some pictures later today, gotta get to bed so I can watch some college football today.

-

@breed I have them on my watchlist, but wait until the price drops.

If it's good enough with one flanged bearing (according to @rqthree ) it doesn't make sense to use three long threaded rods.

I was thinking if making them conical in both directions would be better? But the contact area is so small, it doesn't matter... -

@rqthree There is a problem with these files: Carrier_Assy.FCStd and Knife_Bearing.FCStd ; I'm unable to open them, neither other people at my hackerspace (they freeze or crash FreeCAD).

Could you save them as STEP files?

Thanks, -

@fma said in Hollow shaft extruder:

@rqthree There is a problem with these files: Carrier_Assy.FCStd and Knife_Bearing.FCStd ; I'm unable to open them, neither other people at my hackerspace (they freeze or crash FreeCAD).

Could you save them as STEP files?

Thanks,The files are fine, but were generated with a very high definition version of FreeCad. They will eventually open, but may take many minutes on a pretty high power workstation. In any case, the two files you reference are not at all important, and just show the over-all arrangement of parts.They don't contain any critical dimensions or data not seen in the other files.

-

@rqthree Ok, I see!

-

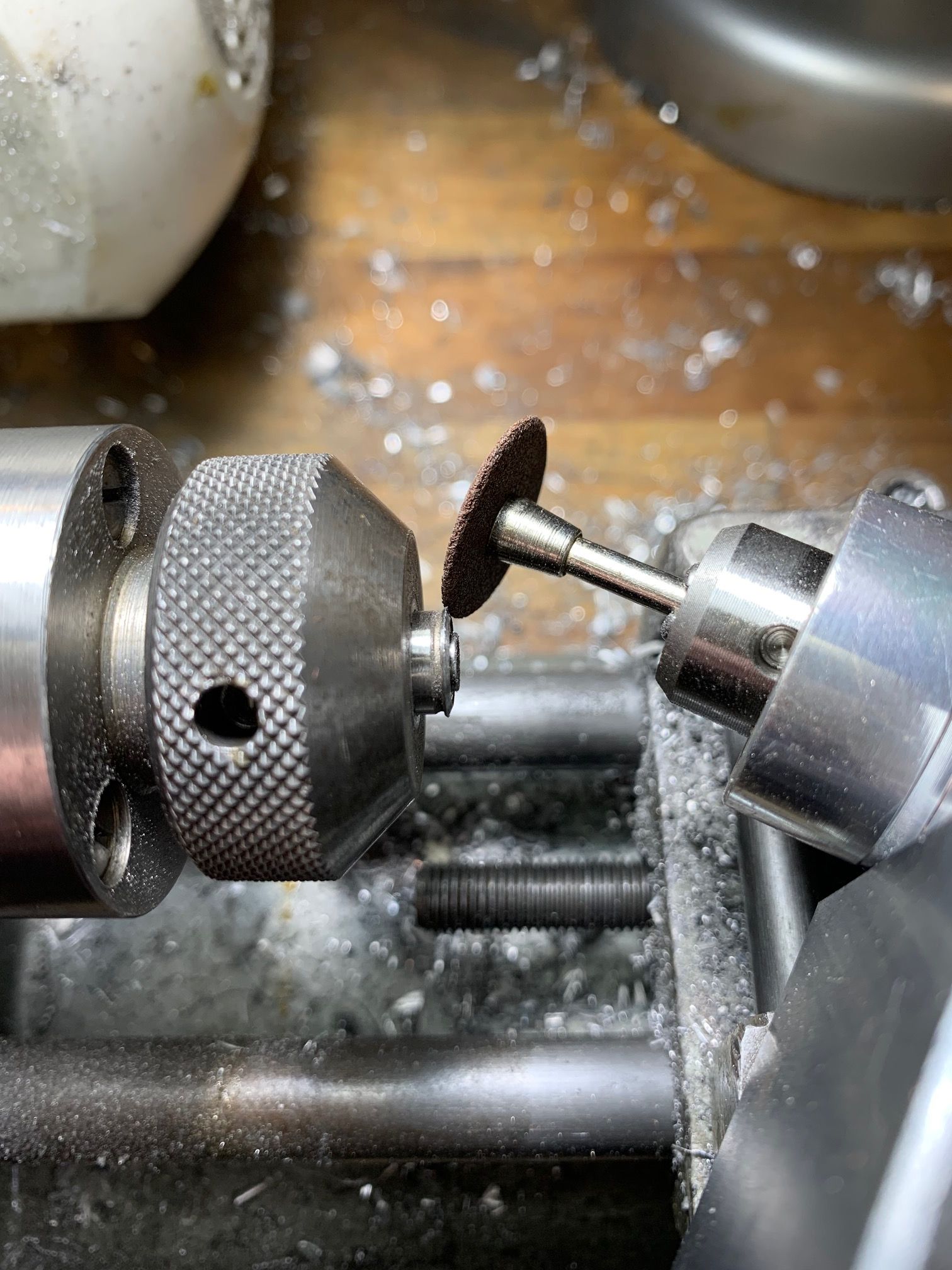

@rqthree BTW, how do you get the sharp edge on the flanged bearing? With a lathe?

-

@fma , yes, I use a collet chuck in a jewelers lathe, with an abrasive disc on a rotary tool. Others, like Tom Brazier, have come up with clever methods that don't require a lathe.

-

@rqthree Thanks, I'll read the entire thread again to see how other guys do...

-

@o_lampe said in Hollow shaft extruder:

@rqthree The left/right rotation is a good idea.

Otherwise It is a bit similar to my dual motor approach, but I'll put a Bowden tube between the two. No weight panelty and free choice for the remote motor.I'm also a bit worried about temperatures and sketched up a thin watercooling plate to fit between your motors. A bit more weight doesn't make much of a difference, you already fouled there anyway

The dual motor Push-Me-Pull-You VDE works fine at 0.2 amps driving two paralleled NEMA 11 motors. The motors get slightly warm after several hours of continuous operation, but nothing that affects even PLA.

-

@rqthree I vote we call this push pull version VDE337.

-

@tombrazier said in Hollow shaft extruder:

@rqthree I vote we call this push pull version VDE337.

Tom, I have to ask...??? I know there is always a method to your madness, but I have wracked my brains on this one.

EDIT: Never mind, you Cessna driver. VDE337 it is!

-

Some updates from me...

I have experimented further with the LDO motor. For everything other than ridiculously fast printing it's great. The primary limitations I have found are that continuous current much above about 600mA will eventually cause it to get too hot for PLA and at any current E jerk needs to remain quite low (e.g. max 7mm/s) for the VDE which has quite a high steps/mm ratio. On the other hand it has great acceleration and speed, I can get 1000mm/s/s even with the high step/mm count of VDE and top speed is about 60mm/s (with no load) and over 10mm/s driving filament into the hot end.

One day I might figure out how to get TMC CoolStep to help with the current. And I have dreams of implementing a jerk-less version of Linear Advance in Marlin which would pretty much remove the jerk limit as an issue.

In other news, I have uploaded a video about the bearing grinder jig.

And, further news, with a PLA printed carrier the 3 back-to-back bearing pairs version of the extruder seems to work pretty well. I have used a bite of 0.07mm for this version. @o_lampe it works a lot better than with your printed carriers which leaves me wondering whether something like material flexibility might be an issue. I am also coming to the conclusion that it's best to grind the bearings first and then measure them and print a carrier to match their edge diameter. That's a lot easier than grinding an edge down to the exact diameter.

-

@tombrazier said in Hollow shaft extruder:

grinding an edge down to the exact diameter.

Both precedures aren't mass-production friendly. The skrewder wraps the screws around the filament which results in adjustable bite and fast changeable filament ability.

If we could change the VDE100 design to be wrappable, it would be best of both worlds. -

@o_lampe said in Hollow shaft extruder:

@tombrazier said in Hollow shaft extruder:

grinding an edge down to the exact diameter.

Both precedures aren't mass-production friendly. The skrewder wraps the screws around the filament which results in adjustable bite and fast changeable filament ability.

If we could change the VDE100 design to be wrappable, it would be best of both worlds.I must respectfully disagree on both counts. Holding sub-micron tolerances is common practice in manufacturing these days, and the VDE does not need "adjustable bite" and "fast changeable filament ability". It already does these things by design, albeit perhaps serendipitously.

I believe that one must be very conscious of the goals of a particular idea, declare victory when achieved and then move on, rather than try to force fit what has worked before into what is needed now.

Personally, I believe that increases in FDM printing speeds will only come from smaller diameter filament. All existing extruders (the VDE included) are limited in their extrusion rate by how quickly you can melt a column of plastic 1.75mm in diameter.

-

@rqthree "being done is a decision" that must be made. Kudos!

-

@oliof said in Hollow shaft extruder:

@rqthree "being done is a decision" that must be made. Kudos!

Yeah, rq3's comments struck a chord with me too.

-

Hi All,

I’ve just finished for the holiday break and wanted to look at the hollow shaft extruder, is there a good consolidated reference material somewhere on the web?I specifically want to order some flanged bearings to go with the carriers I already have but I can’t find the specs… unfortunately I don’t have time to dig into the thread befor Xmas but I want to order parts to grind the flanges and tinker with between Xmas and new year.

Any thoughts would be greatly appreciated.

Many thanks

Barry M