Oh man, I've chased that delta printer backlash down to ~0.05mm on my rostock metal max. I stopped chasing it after it got that low since it gets harder to identify the source the smaller the backlash gets.

Posts made by lord binky

-

RE: Delta bed leveling issuesposted in General Discussion

-

RE: Is it in the belts or stepper motor?posted in Tuning and tweaking

@norder Good Idea, I'll double check that this weekend, it's the same for each tower, there's a flat on the motor shafts and I have 2 screws on the pulleys, so it's probably not loose. Admittedly not the same as definitely not lose, and I've gone down rabbit holes overlooking simpler things than that.

-

Is it in the belts or stepper motor?posted in Tuning and tweaking

So I was about to keep chasing down rigidity in the arms of my delta printer and started poking around to see what else could have play in it. Linear rails, ball ends, arms are all really rigid, you tap on the carriage with your finger nail you feel it in each of the carriages like it was solid. Nothing stood out as a "wiggly". But then I realize I can move the effector, it returns to the same point, everything's connected well but there's play? I test it by using probing distance for reference. Turns out I can wiggle the effector over .5mm and even then unless I feel motors skip a step, the impact on the z probe is from 0.247 to 0.266. So outside of skipping a full step, it might (and usually did not when I was toying with it) mess up a microstep. So it's a spring like motion up to at least .5mm that returns effectively to the exact same spot. I feel around again, pushing on the effector even a slight bit you feel a corresponding movement in the belt up by the idlers. And this has me stumped, because nothing improves tightening a belt so it's not loose belts.

I feel like if I can address whatever "play" in the effector this is it would seriously help out on ringing. My gut says it is not in the belts, but it wouldn't be far fetched to say 9mm belts vs 6mm belts just don't do that. I feel like it is the stepper motors that are behind that movement, but I'm using 0.9 2.4A Nema17's ( Wantai 42BYGHM810) @ 2.4A. The play is not originating from the stepper motor shaft flexing (I have bearings stopping that).

I really like the performance I get from them otherwise so I'm stumped if I'll actually eliminate this flexible movement changing to a NEMA 23/24 and just taking the hit on motor specs (these ones have like 1.8mH inductance, nice for speeds on 24V). Would I have to go to closed loop steppers that'll actively counter that flex, but I'm not sure it'd even register since everything returns to normal after pressure is removed. And to rub it in, I feel like even if it's in the belts or steppers, how is this not prominent in those speedy CoreXY builds, they have long lengths of belts like my delta and nema17's (I think) are common components for them. Or is that just overlooked because it disappears when you go full servo.

My only options left in the sytem for the source of it is pulleys, belt, and stepper. I suppose pulleys could be the other issue, I don't have much for options on one half but I could swap idler pulleys to a large diameter and use a deflector pully to keep everything lined up. I'd love some input.

-

RE: Flsun Q5 delta printer, poor dimensional accuracyposted in Tuning and tweaking

@dog said in Flsun Q5 delta printer, poor dimensional accuracy:

Decided to go with altering the rod lengths, because that seemed to work and I kinda understood how it affects the print when it comes to dimensions. (measured length / desired length * rod length = new rod length ish) basically if the print is too small, shorten the rod, if too big, lengthen it.

I've used a piece of carbon paper over a piece of paper and did a heated nozzle tap (takes less force to mark) to do basically the same thing. It can speed up the process without doing a full print and having to account for anything other than just movement simply measuring from the outside of one dot to the inside of the other.

-

RE: Help on custom Delta printer buildposted in 3D Printing General Chat

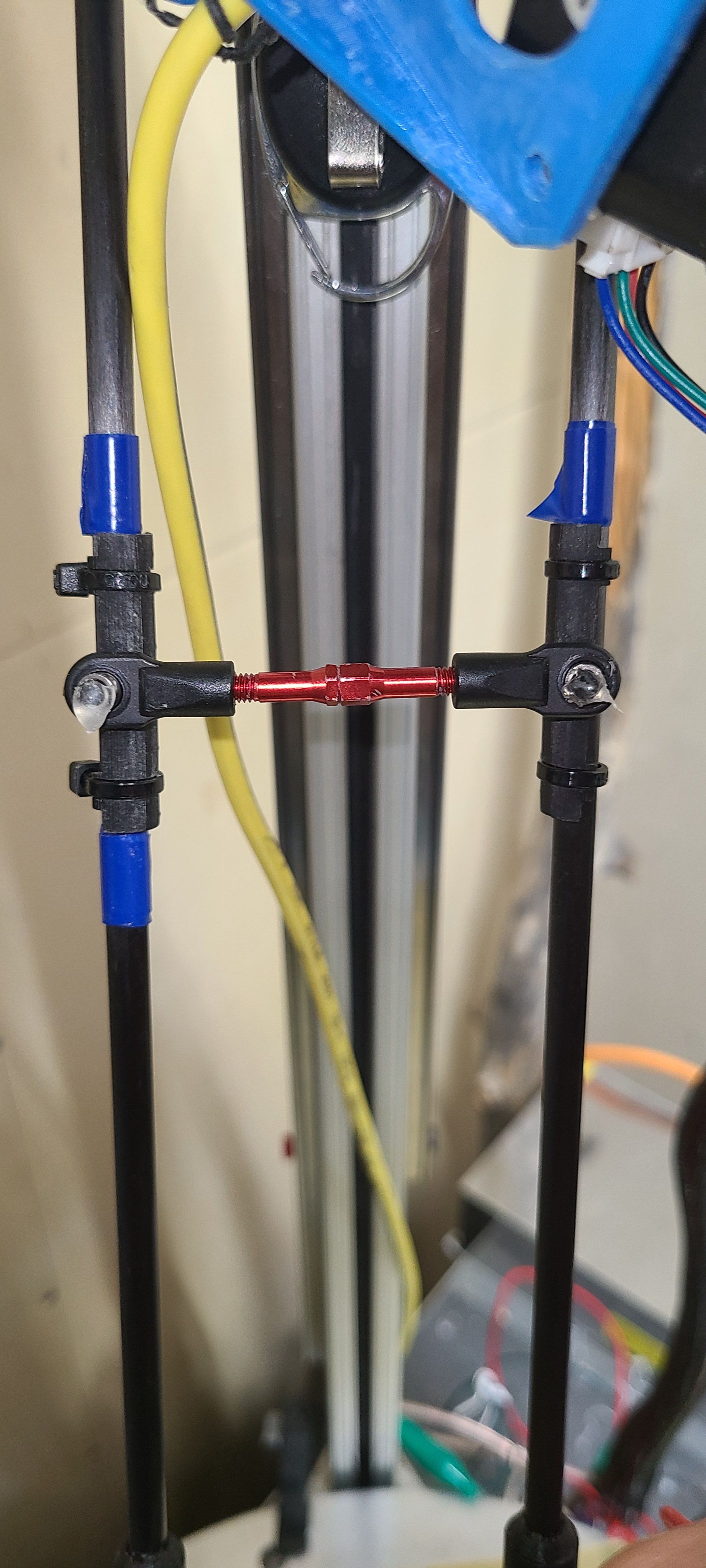

If your making your own arms, I did a test (yes i haven't shared it before now but i had another trick up my sleeve i wanted to test out and grab comparison data from the accelerometer) and got improvements on ringing/ on 360mm arms by reinforcing them midway. It does not affect the arms as long as the articulation is centered on the arms.

-

RE: Help on custom Delta printer buildposted in 3D Printing General Chat

@yiannis i used the openscad delta simulator to maximize my stability for my delta over the print area when designing the parts : effector carriages, and arm spacing. The frame is a rostock max metal, and the arms are 360mm haydn magball arms. I did get improvements in my printer optimizing for stability so it's what i'd recommend using for any variables you don't have locked down.

-

RE: Bed leveling using strain gauges as endstops/probesposted in General Discussion

I used the FSR and johnsl board on my delta for awhile and it did pretty well after working out some kinks in my mounting. Mapping a bed for delta autocal isn't so great since there is some deviation in response simply since the force varies between 3 sensors based on where you touch, but for leveling it was more than sufficient. Main reason i went contact-less on any sensor i could. Using a brass nozzle to touch the bed would deform the hole eventually, enough to irk me on a calibration cube (well, immediately if i crashed as you'd expect). The johnsl board would likely do great on sensitivity if the fsr's weren't loaded by a weight like the bed depending how you arrange it too.

-

RE: Best Choice of Motor for a Delta Printerposted in Duet Hardware and wiring

I'll also add for me if you exclude bearing issues in motors or pulleys (I've blown the tiny bearings in idler pulleys multiple times which is why i used flanged bearings now). The next issue of high belt tension is going to be eating up the belts and teeth when your hotend or carriage eventually crashes. I think it's easy enough to tension a little more and recalibrate starting low and then go high until nothing improves.

-

RE: Best Choice of Motor for a Delta Printerposted in Duet Hardware and wiring

@ignacmc i just push the carriages all the way up and tension to an equal frequency using an app. I ballpark the base tension at the idler pulley for tight but not too tight and tune from there. You have a lot more wiggle room than you'd expect, just make sure they're the same.

I've been using deltas for years (my first was a the seemecnc rostock max v2) and I've found it isn't as necessary to hit a specific tension than it is to just maintain a reasonable and equal tension on the towers. I've done all sorts of gauges and tricks for targeting a specific tension and it just hasn't mattered. That goes for pretty much all aspects of a delta though, carriage resistance, arm lengths, rod spacing, etc. The more each tower responds the same the less weird stuff you chase and are able to compensate with a setting change in software for or identify the root cause like joints.

-

RE: Extruder cable shielding improved surface finish (slightly).posted in Tuning and tweaking

So i couldn't recreate the issue with another cable..Frustrating when trying to show shielding fixed the issue, but I'm still confident that was what helped...mostly. Still, I had another test print showing what i have moved away from when EMF was an issue regardless of the solution ( cable pathing or shielding). I adjusted contrast so the visibility was clear even if the colors are looking a little artificial. The surface issue was apparent in any print with the outer layer lower than 60mm/s.

-

RE: Best Choice of Motor for a Delta Printerposted in Duet Hardware and wiring

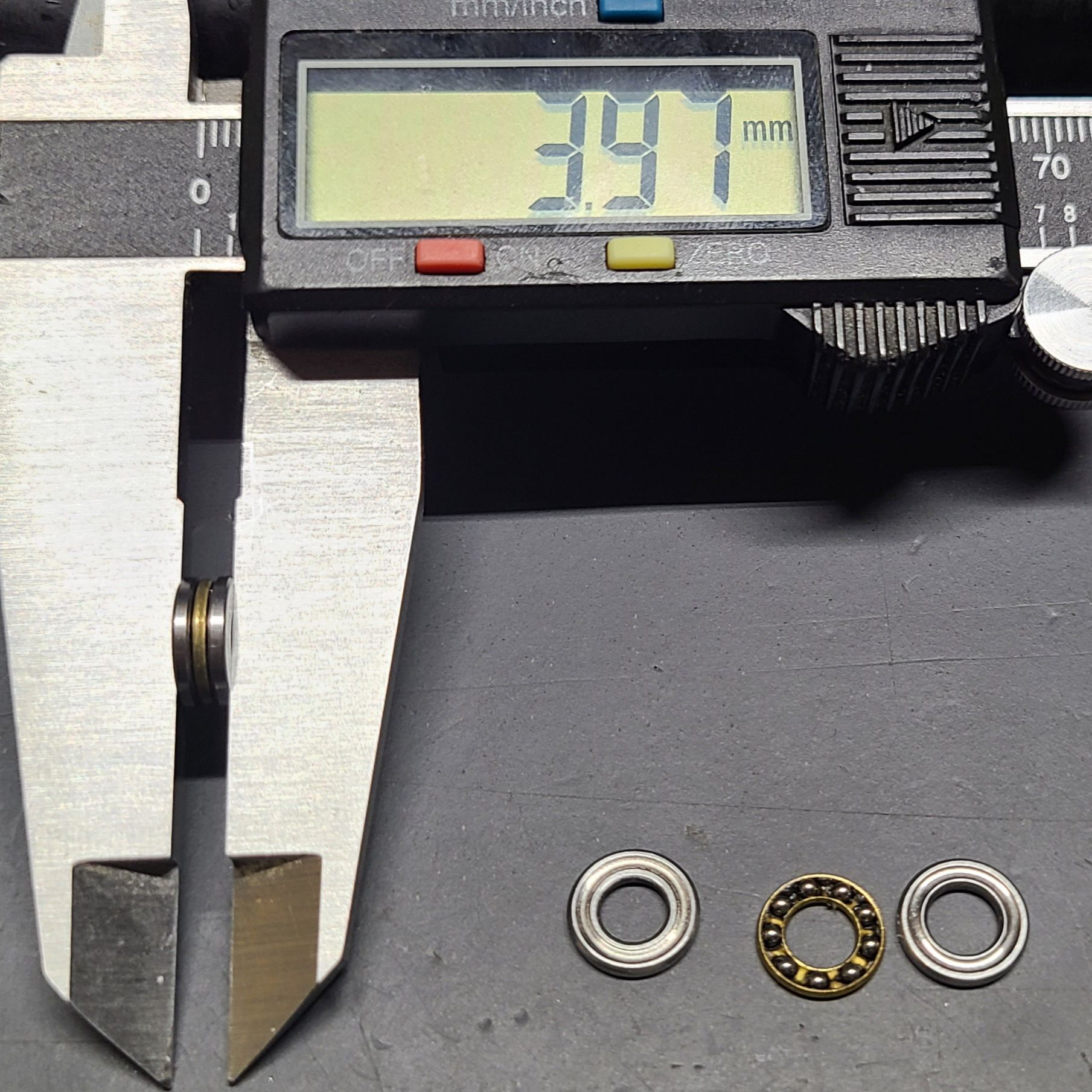

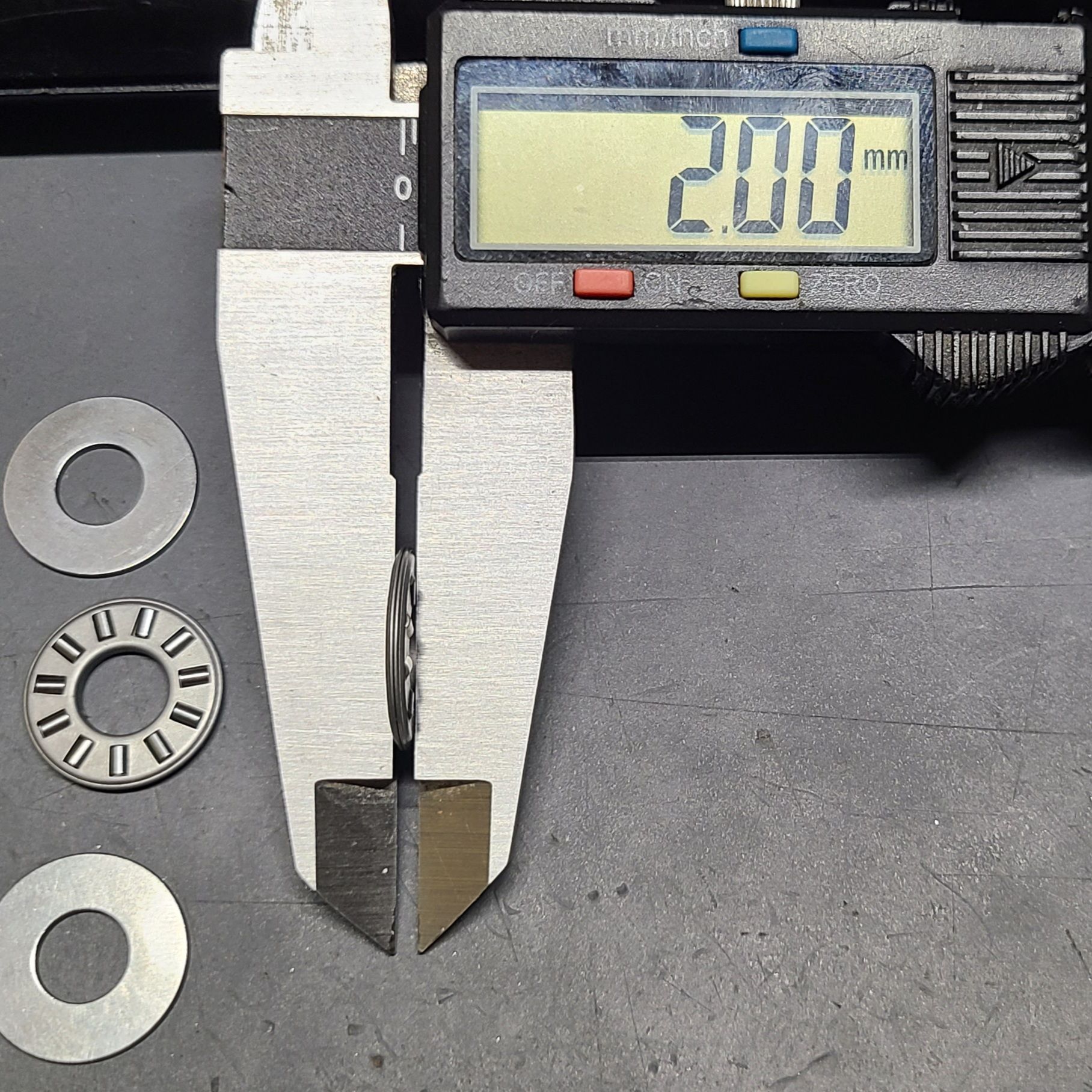

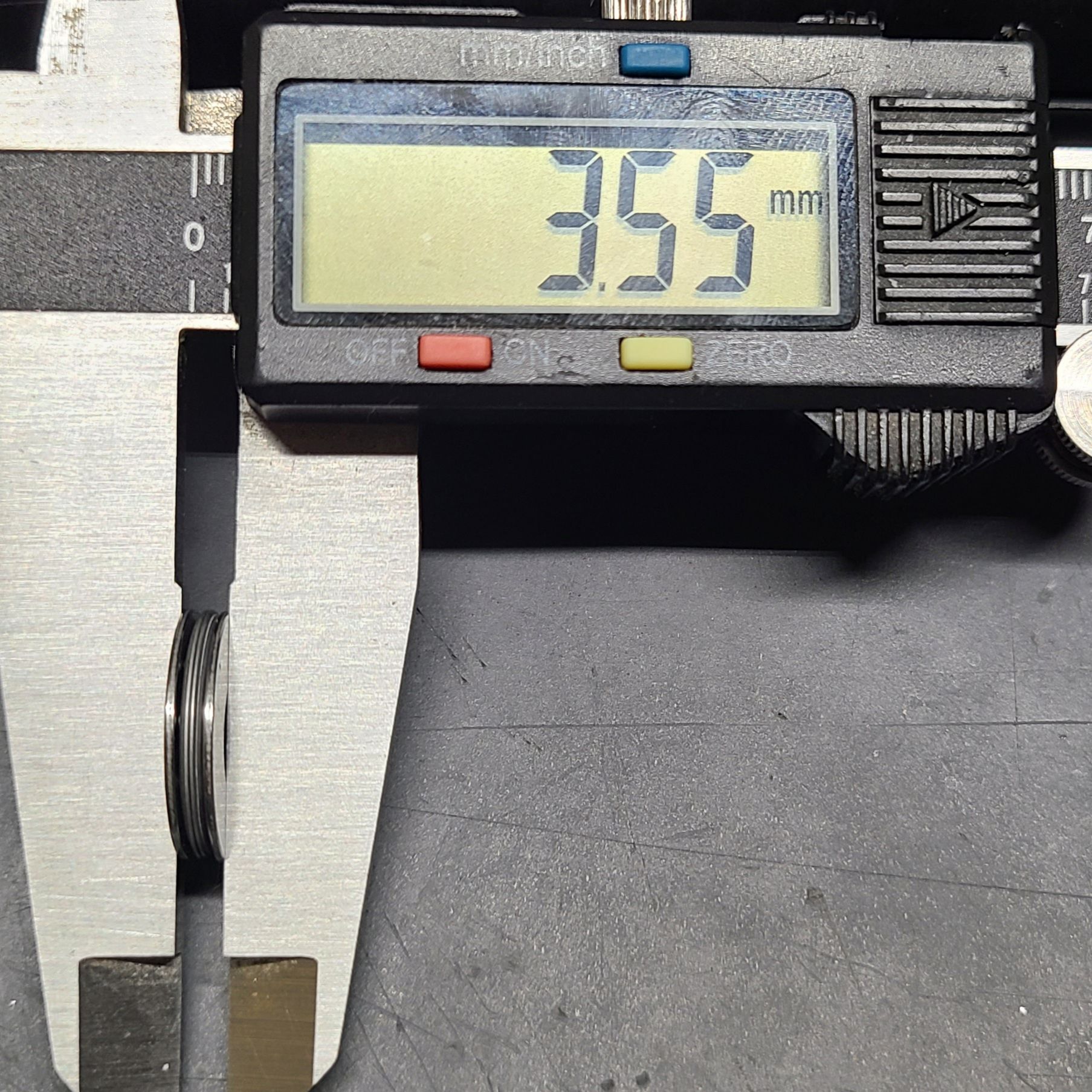

Ok, here's some pics. The first is an example of the setup. The others show thickness, the needle bearing you have options depending on the surface of the motor face, the ball bearing set while the ID being the same as the motor shaft is nice i prefer the needle bearings for contact area against the pulley.

-

RE: Best Choice of Motor for a Delta Printerposted in Duet Hardware and wiring

@ignacmc this is right, snug the pulley against the thrust bearing will limit the amount of deflection on the motor shaft. Next time you have the chance watch closely before and after tensioning motors on a delta for me the amount of force for visible deflection on the shaft is actually very little when tensioning directly against the motor (especially if you use dampers!). At the temps we are comfortable running the motors I'd wager bearing wear is in the top two motor issues after a year of use.

-

RE: Best Choice of Motor for a Delta Printerposted in Duet Hardware and wiring

@bberger said in Best Choice of Motor for a Delta Printer:

Wantai 42BYGHM810

I use the Wantai 42BYGHM810 on my delta. I don't use dampers and the motors are basically silent. I have gone through 3 different sets of dampers and after chasing every other mechanical issue I could and tuning the drivers, they very much were unnecessary and only added to ghosting. Whatever your choice if you don't have a pillow block (most printers don't) then I highly recommend putting a roller bearing between the pulley and the motor case (my current preference is the needle bearings). You have to measure the space available and account for possibly adding some washers to keep your pulley centered. What this does it reduce the tension on the motor shaft, the tension on the pulley instead is applied to the thrust bearing and motor to the motor case saving your internal motor bearings. Before I started doing this my previous motors needed replacement every 2-3 years because of bearing issues on my deltas, and I feel like it helps on ghosting and tension too (that's just an added bonus so wasn't worth testing for me).

uxcell TC512 Thrust Needle Roller Bearings with Washers 5/16" Bore 3/4" OD 5/64" Width 5pcs

https://www.amazon.com/gp/product/B07VZXWSG6/uxcell F5-10M Thrust Ball Bearings 5mm x 10mm x 4mm Chrome Steel Single Direction 4pcs

https://www.amazon.com/gp/product/B07QKKYKR8/ -

RE: CPAP blower fan?posted in Duet Hardware and wiring

@clearlynotstef i used a "UMLIFE DC 6-60V 400W BLDC Three-Phase DC Brushless Motor Controller PWM Hall Motor Control Driver Board 12V 24V 48V" i got from amazon and tested a cpap motor i plan to use for my hotend cooling. It tested fine using potentiometer control (since i simply want the fan always on). The pwm control on that unit is stated to work 2.5V to 5V in case i wanted to try using it for cooling. This seems unlikely though since my berd air pump can change the print finish from glossy to flat if it goes above 50%, so i have headroom to pipe more cooling if I need to. My delta can't chase those high speeds too though... until i get to work on a 3 arm per tower mod to add the constraint/rigidity (more triangles!).

-

RE: Extruder cable shielding improved surface finish (slightly).posted in Tuning and tweaking

@mrehorstdmd Link below to the sleeve i used, I've used grounding strap before as well but that was much larger than necessary although cheaper. The extruder motor cable crossed a few other cables perpendicular to them so i thought interference would be low and ran up a couple feet parallel to other cables about 8 inches away from hotend wiring (fans, probe, thermistor, heater). I have twisted the stepper wire pairs before but haven't this time, i needed the length.

Still, none of the power hungry hotend components were active when I identified the issue, so i suspect the extruder wires running across the duet near the motor drivers is where it picked up noise. Ideally making a new duet enclosure and shielding that in a safe manner would reduce noise on anything else unshielded too. I don't see any indication of EMI issues elsewhere though...well besides the occasional heatbed mosfet singing. That'll have to wait till i finish with replacing the hotend fans with a cpap blower though.

If you have concerns about bare metal sleeving floating about, gutting paracord is an inexpensive way to get some nonconductive (nylon) sleeve to run the shielding. As to the specifics, i just popped out the pins of the connector on one end and ran all 4 wires in the sleeve (taped them together while sleeveing). Grounded it initially with an alligator clip between the sheath and input ground.

Electriduct 1/8" Tinned Copper Metal Braid Sleeving Flexible EMI RFI Shielding Wire Mesh (0.08" Diameter) - 25 Feet https://www.amazon.com/dp/B01BIBQBCK/ref=cm_sw_r_awdo_7CQKEEDRMG84QEZYV47S?psc=1

-

RE: Extruder cable shielding improved surface finish (slightly).posted in Tuning and tweaking

@oliof I plan to do this, i had fixed it right before i got started doing a bunch of gardening prints for my wife and i wasn't delaying justification for my hobby. I'll get before and after prints comparison probably saturday unless my son does the impossible and goes to bed on time tonight.

-

Extruder cable shielding improved surface finish (slightly).posted in Tuning and tweaking

Long story short, all three axis stepper motor cables are shielded (EMI mesh sleeve) on my delta printer (although this could apply to any style) so I skipped doing it on the extruder. Half-assing it bit me again and it may be what got rid of the irregular surface ripple that kind of looked like a salmon skin/moire pattern that you only really see when the surface is glossy. Yeah, that really fine one that drives some of us crazier than massive ghosting does. Until this point I had no indication my electronics had any glaring issues and wrote it off thinking I had that well in hand. I just glared at the delta my mechanics blaming them as the source leaving me completely stumped for what the real cause was though. Anything that seemed a plausible mechanical source I reached out to fix hoping it would be the thing to remove those tiny artifacts even though it didn't match up with anything obvious math wise.*

I discovered this while I was playing with the new input shaping plug-in. My hotend fans are normally always on and I unplugged them while using the accelerometer to decrease the noise level on it. Then while toying with the plug-in I heard extruder noise that was almost a whine that I couldn't hear over the hotend fans. I noticed it while homing and then dead quite after homing was done made it stand out though. So I homed again and reached over to feel the motor, and it's vibrating with some oscillation when the axis motors are going. I just sat for a minute with my face in my hand and wishing I could give past-me a slap to the back of the head for stopping 3/4 of the way through on shielding the motor cables. I wanted to share my success on this in case it can help anyone else frustrated with calming the waves in the specular reflections even if it is also a facepalm moment of shame.

*- That isn't to say there aren't other things causing it in another build. I just have happened to already done my best to mitigate them in previous rabbit holes on belts, pulleys, eccentricities on anything round and rotating, arm lengths, arm joints, arm spacing, then arm rigidity, all the extruder bits, fan vibration, frame vibration, bearings (both the linear slides and stepper motor bearings), chasing this stupid pattern.

-

RE: Input Shaping - why (not effective on some parts at all)posted in Tuning and tweaking

@bberger I had meant 40 mm/s (M205-> max instantaneous speed change in mm/sec or 3000.0 using M566). I don't think that's a low jerk setting. As for the input shaping M593 Snnn (optional) Damping factor of ringing to be cancelled, default 0.1. The way I read that is increase/decrease this if you know you nailed your frequency but input shaping is too much/little.

-

RE: Input Shaping - why (not effective on some parts at all)posted in Tuning and tweaking

@bberger I found input shaping a little frustrating with my delta so good luck! I tuned out my ringing (37 Hz +/- 5 Hz for me), then i get the lip at the corners which is worse to me than the ringing. The only variable to fix that was taking my jerk above 40 mm/s (M205) ... at which point i get my ringing back. To lower the ringing after that i had to increase the amplitude of the IS... and then it sounds scary as the motors are doing their IS work... so I decided to shelve tuning it for a bit until i figure out what mechanical bit will need help.

-

Fixed my high pitched fan (electrical) noiseposted in Duet Hardware and wiring

So I have a super annoying high pitch whine on a pair of Sunon 12v fans (MF25101V1) in a push/pull on a mosquito clone. While I'm replacing the hot-end heater I figure it should be an easy thing to either fix or identify why my fans have this high pitched induction coil whine that slowly claws at your soul. Might as well fix while things are torn down... and into the rabbit hole i dove. Threw my scope on it since I felt like it was some electrical noise was carrying through to the fan motors. Of course I did, I'm using switched mode supplies. Regular 12v rail had all kinds of electrical noise at 500Hz, 1kHz, and 100kHz.

Well, somethings causing it right? Let's start with filtering some culprits out. I try a capacitor to filter it... nothing. Ok well, a temporary voltage offset on the noise but the waveform didn't change at all? Fine...grab a toroid and do a simple choke...scream.. multiple LC filters ...and still no response...Am I a ghost now? WTF is this sorcery?!

So eventually I snip a fan out and blissful silent air flow... So it turns out that the issue was running two fans off the same cable right up to their own leads... Noise is gone soon as each fan gets it's own wires back to the terminal strip (they're wired always on).

I'm just happy the noise is gone and won't question why I've never had an issue wiring this way before. Still I thought I'd share in case someone has a whine / high pitched noise they can't get rid of, then here's one possibility.

TLDR; Parallel DC Fans sharing a power cable can cause high pitched feedback sometimes, intermittently, and in just the right way to test your sanity.