Hello. I would like to terminate any current moves (printing, running macro, movements from Dashboard etc) but without loosing current position (still being homed). M112 will stop all movements but also shut down Duet.

Example:

I am running series of macros for testing purposes, but I've started wrong macro that will crash on items on bed or take a long time to complete. I don't want to reset Duet because I still got data to extract and I don't want to set up everything again for testing.

I searched Forum and Wiki but all I found is that I can use trigger that will execute after all commands from buffer.

Any solution for that?

Best posts made by Mandragora

-

Terminate movement but not by M112posted in Gcode meta commands

-

RE: Firmware update on Duet 3 via USB and BOSSA - problemposted in Firmware installation

Ok, after successfully reinstalling firmware, I was able to connect to board with YAT via USB. After some debugging I created new configuration and web interface on new SD card - just to be sure (provided one was missing most of the files).

And BAM, DWC is present, now I can work from here.

-

RE: Max distance for control board from machine?posted in General Discussion

@dizzwold You can use online calculators or formulas to get resistance of a wire. What is important is to choose suitable cable size depending on motor current (RMS value) and cable length.

For example, 22 AWG (+- 0,326mm2) wire of 2m length (1m distance from Duet) has 0,1Ohm resistance in 30C. If you will pass 2A RMS it will result in 0,2V (U=IR) drop, and about 0,4W (P=UI or RII) of heat released, which isn't a lot, even on 3m from duet (6m of wire total for 1 phase of motor) 0,6V drop and 1,2W loss isn't that much. If you use 12V you might want to get a little thicker cable for smaller voltage drop.

Twisting wire pair for motor phase as @jay_s_uk said will reduce inductance which is important for high speeds, this is the same as most people are using low inductance motors.

I also put small ferrite cores on all 4 wires per motor close to duet, just in case of unwanted EMI. -

RE: inputshaping issueposted in Tuning and tweaking

I was fighting with my accelerometer yesterday - LIS3DSH.

1st it wasn't recognised on selected port, 680Ohm resistor onSDASDO line helped.

2nd I wanted to get some data to check if gravity is sensed but got similar error that I can't collect data. I didn't found any info on forum or wiki. Turned out that data can be collected after I homed the printer.

Latest posts made by Mandragora

-

RE: I'm confused about stepper motor voltageposted in Duet Hardware and wiring

I will add few cents to this discussion:

I supply 37V to my v1.0 6HC Duet:

https://forum.duet3d.com/topic/26758/32-4v-input-instead-of-32v/2?_=1659258404908If you want to know more about steppers, check this video out:

https://www.youtube.com/watch?v=lftsMrksdTA&list=PLWQs4VcXB7unGrcCVibcisuvt0Hamxb4d&index=21 -

RE: Weird motor vibrations after a "crash"posted in Duet Hardware and wiring

@phaedrux Nope, it did not. That was first thing that I suspected. I've checked leadscrews, linear rods and bearings, all is fine. Even if anything would be damaged, it doesn't explain noisy motors when I test them on my desk. Please check my videos.

-

RE: Weird motor vibrations after a "crash"posted in Duet Hardware and wiring

Here is second video with "new" motors:

Two Stepper motors in parallel - weird noise Part 2I think that new motors behaved the same way as ones before.

It is possible that back EMF from 2 motors is messing with current control of SpreadCycle, because when one motor stopped turning the other one went way quieter. But question remains, why it was ok before my "crash"?

It would be nice if anyone could reproduce testing of 2 or 3 motors connected in parallel. -

RE: Weird motor vibrations after a "crash"posted in Duet Hardware and wiring

@jumpedwithbothfeet Thanks for your reply. I've checked that all stepper motors TDS current rating is in RMS, in DWC we set peak value. So 2A peak is 1,418A RMS, this 80% max current is just to lower temperature of a motor. From my knowledge every motor max current is based on max winding temperature and heat dissipation. Every motor can be overloaded, sometimes as much as 5x.

I actually have 2 more motors which are very similar, Model 17PM-K940-P7VS (motors on video are 17PM-K940-P6VS). According to a seller those motors are basically the same. I've used them on XY axis before with no issues. I will test them the same way on new video.Edit:

All 5 motors have the same phase resistance of around 1,65Ω. I've opened motor that was on left side of a printer, windings looked fine so I would rule out windings failure. The only thing that comes to mind how motor could be damaged is related do permanently disturbed magnetisation of rotor. But that would be hard to confirm. And those two motors tested work fine when they are alone. -

RE: Weird motor vibrations after a "crash"posted in Duet Hardware and wiring

Here is a video recorded today - sound effects of two motors connected in parallel: Two Stepper motors in parallel - weird noise

@jumpedwithbothfeet Z motors were connected to Driver 2 before and during crash. Before crash 3 motors together were working fine on F3000 and 5A. After crash they were loud. I tested them on driver 2 and later on driver 5 with no difference.

On video motors are tested on driver 2 of Duet.And I've forgot to mention, I got Duet 6HC, powered by 37,7V.

-

Weird motor vibrations after a "crash"posted in Duet Hardware and wiring

Hello everyone,

TL;DR: Motors started to vibrate weirdly after stall during lowering the bed. 3 motors were connected in parallel to one driver, and I've forgot to increase current in config for 3 motors instead of 1.

Full story:

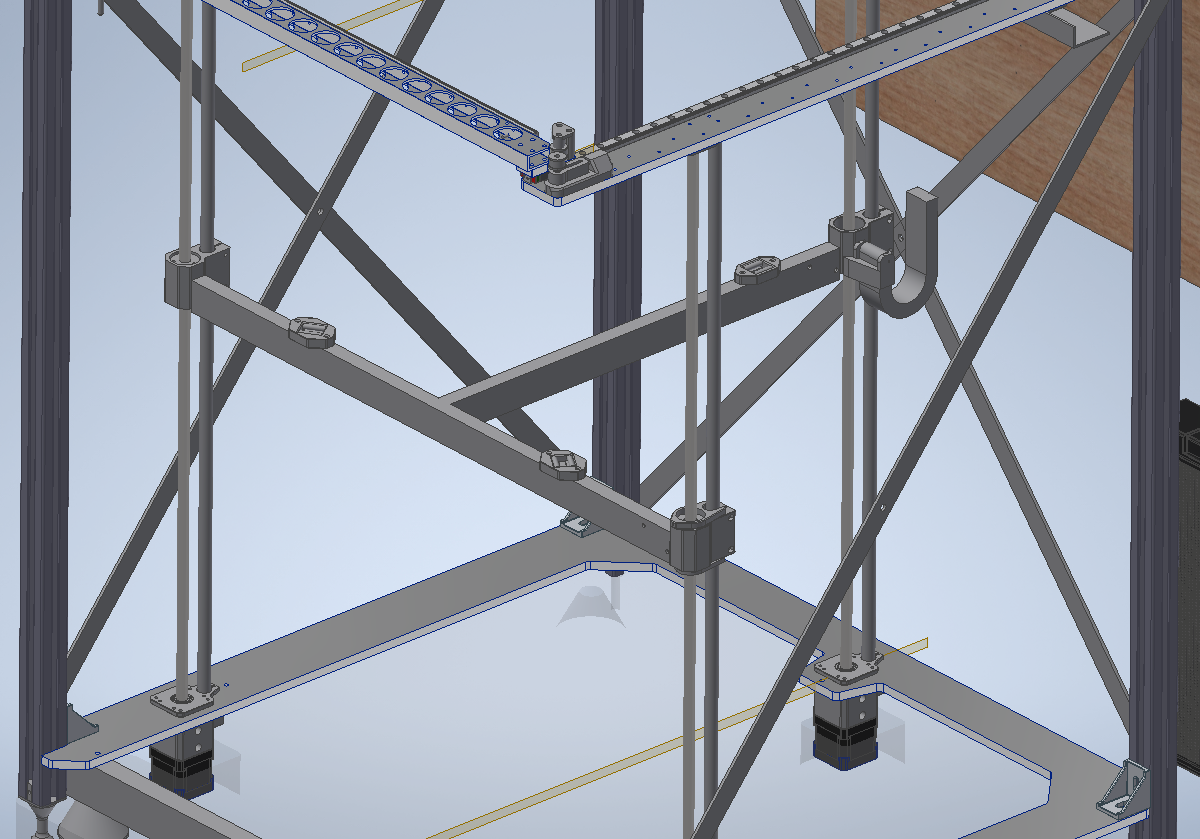

I was assembling lead screws and linear rods (triple Z axis, 700mm travel) for my printer. I hope you can see it well enough on picture below:

At first I've tested only 1 Z axis with 1 motor connected to driver. I've settled on F3000 (50mm/s) and 2A peak current (1,42A RMS). So it is fast enough to travel those 700mm and not so loud - except typical high pith noise of low quality motors . Motors are "Minebea", Model: 17PM-K940-P6VS, 1,8°, 1,5A, 0,45Nm and measured phase resistance of around 1,65Ω, unfortunately I couldn't find any documentation of this motor so inductance is unknown.

Since everything looked fine I've assembled all 3 Z axis and T frame with kinematic coupling for the head bed (as seen on picture). Next all 3 motors were connected in parallel to one driver. Did few more up-down travels of this assembly to check it out. All being fine I thought "ok, now lets throw my 516x516x10 aluminium on it and see hot it fits"And as you can guess, on first down move (I think order was 100mm) I've heard loud noise of stalled motors. I didn't have my E stop in hand so it lasted for 2 seconds. In reality all motors stalled in a sequence, cause bed was heavily tilted to one side (around 50mm). To correct my mistake, I've cut power, moved bed to kind of levelled state, restarter board and set higher current for Z to be 5A peak (3,54A RMS).

To my surprise motors were now loud as hell, whole printer was shaking. So I took bed of from T frame, but it didn't change anything. I did some test and it looks like something permanently changed.

When I power only 1 motor (F3000 (50mm/s) and 2A peak current) it works fine (at least as I can remember how it was before crash). But when 2 motors are connected in parallel, with 2x current, both of them are very loud and shaking. I lowered speed to F1000. This decreased noise a lot but when I was holding motor in hand I could feel irregular "grinding or crunching like" vibrations. But when the same motor is connected alone I don't feel this "grinding". I've teardown this motor but didn't found anything out of order, bearings were fine etc.My quick conclusion was that driver was damaged. So I've redo tests on different driver but no change was observed.

Next I've checked setting in config to see any changes, but all drivers are working in default spread cycle.I know that those motors aren't highest quality, and are for test purposes only (I am planning on getting my hands on something name brand later). But apart from that, what happened (very loud motors after crash) is a mystery for me and shouldn't happen. I would like to find the cause of this instead of "just get better motors".

I run latest firmware and DWC, my config below:

; Configuration file for Duet 3 (firmware version 3) ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v3.1.10 on Fri Dec 11 2020 19:50:46 GMT+0100 (Central European Standard Time) ; General preferences G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"Arato" ; set printer name M669 K1 ; select CoreXY mode M955 P0 I25 S1600 R16 C"spi.cs3+spi.cs2" ; all wires connected to temp DB connector - Accelerometer creation ; Network M552 P0.0.0.0 S1 ; enable network and acquire dynamic address via DHCP M586 P0 S1 ; enable HTTP M586 P1 S0 ; disable FTP M586 P2 S0 ; disable Telnet ; Drives M569 P0.0 S1 ; physical drive 0.0 goes forwards lewy motor M569 P0.1 S1 ; physical drive 0.1 goes forwards prawy motor M569 P0.2 S0 ; physical drive 0.2 goes backwards Z motors tymczasowo M569 P0.3 S0 ; physical drive 0.3 goes backwards Extruder? M569 P0.5 S1 ; T locking pin ; test drivera Z ;M569 P0.5 S0 ; physical drive 0.2 goes backwards M584 X0.0 Y0.1 Z0.2 E0.3 ;C0.5 ; set drive mapping ; test drivera Z ;M584 X0.0 Y0.1 Z0.5 ;E0.3 ;C0.5 ; set drive mapping M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation M350 C16 I1 M92 X100.00 Y100.00 Z1600.00 E1376 C100 ; set steps per mm M566 X2000.00 Y2000.00 Z60.00 E120.00 C20 ; set maximum instantaneous speed changes (mm/min) ;M203 X60000.00 Y60000.00 Z200.00 E2400.00 C6000 ; set maximum speeds (mm/min) M203 X30000.00 Y30000.00 Z1000.00 E3000.00 C600 ; set maximum speeds (mm/min) ;M201 X40000.00 Y40000.00 Z40.00 E10000.00 C1000 ; set accelerations (mm/s^2) M201 X4000.00 Y4000.00 Z120.00 E10000.00 C500 ; set accelerations (mm/s^2) ;M204 P30000 T50000 ; set accelerations (mm/s^2) P- printing T- travel M204 P3000 T5000 ; set accelerations (mm/s^2) P- printing T- travel M906 X4000 Y4000 Z2000 E850 C600 I30 ; set motor currents (Peak mA) and motor idle factor in per cent M84 S1 ; Set idle timeout ; Axis Limits ;M208 X0 Y0 Z0 S1 ; set axis minima ;M208 X568 Y565 Z500 S0 ; set axis maxima ; Print area (0,0) - (500,500) M208 S1 X-34 Y-4 Z0 ; set axis lower limits M208 S0 X534 Y562 Z500 ; set axis upper limits ; Endstops M574 X1 S1 P"io0.in" ; configure active-high endstop for low end on X via pin io0.in M574 Y1 S1 P"io1.in" ; configure active-high endstop for low end on Y via pin io1.in M574 Z1 S2 ; configure Z-probe endstop for low end on Z ; M574 C1 S3 ; Z-Probe M558 P5 C"^io2.in" H5 F600 T30000 ; set Z probe type to switch and the dive height + speeds G31 P500 X0 Y0 Z2.5 ; set Z probe trigger value, offset and trigger height M557 X0:500 Y0:500 S250 ; define mesh grid ;Stall Detection ; M915 C S6 F0 H200 R0 ; Coupler ; Heaters M308 S0 P"temp0" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin temp0 M950 H0 C"out0" T0 ; create bed heater output on out0 and map it to sensor 0 M307 H0 B1 S1.00 ; enable bang-bang mode for the bed heater and set PWM limit M140 H0 ; map heated bed to heater 0 M143 H0 S120 ; set temperature limit for heater 0 to 120C M308 S1 P"temp1" Y"thermistor" T100000 B4138 ; configure sensor 1 as thermistor on pin temp1 M950 H1 C"out1" T1 ; create nozzle heater output on out1 and map it to sensor 1 M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit M143 H1 S280 ; set temperature limit for heater 1 to 280C ; Fans M950 F0 C"out4" Q500 ; create fan 0 on pin out4 and set its frequency M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off M950 F1 C"out5" Q500 ; create fan 1 on pin out5 and set its frequency M106 P1 S1 H-1 ; set fan 1 value. Thermostatic control is turned off ; Tools M563 P0 D0 H1 F0 ; define tool 0 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C ; Custom settings are not defined M950 J1 C"io8.in" ; E STOP - stopping movements M581 P1 T0 S1 R0 ; -

RE: 4 stepper motors for Z-axis, amperageposted in Duet Hardware and wiring

It depends on if you want to control all 4 motors individually for bed traming. If yes, every motor needs to be connected to individual stepper driver. So each will have its own set of parameters, which will be identical if you use the same kind of motors.

Other option is that all motors will be working together as one and bed traming will be done manually by turning screws of each motor. In this scenario all motors could be connected to 1 stepper driver. There are actually 3 ways to connect 4 motors to 1 driver.- All motors are connected in series. That way they will be seen as one 1,8A motor but with 4x higher inductance and resistance. It might work on low inductance motors and or high supply voltage, so you can actually create enough torque for desired speeds. Each motor will get exactly same current = same torque.

- All motors in parallel. They will act as 7,2A motor which is to much for most boards unless you will decrease actual current by a lot. Another issue is that current for each motor might not be equal due to differences in resistance and inductance - manufacturer tolerances. This might result in different torque of each motor, so if actual torque will be to close to actual required, some motors might loose steps - very bad.

- Mixed set up. You connect in parallel 2 sets of motors, where a set of motors are 2 motors connected in series. This way you get "best of 2 worlds". Current of 3,6A but not so high required voltage for supply.

I personally have 3 motors, each on separate driver which is best. I experimented on three 1,8A motors connected in parallel on 6HC board which worked on dry runs (but I also work on 37V supply). I don't know about that during printing.

I hope that will give you general idea.

-

RE: Failed to start accelerometer data collectionposted in Beta Firmware

There was a topic on forum about different wiring the accelerometer when using daughter board because this board shifts few pins around. Try look for that.

-

RE: Pause/continue movementposted in Using Duet Controllers

I asked about similar feature here:Terminate movement but not by M112

-

RE: inputshaping issueposted in Tuning and tweaking

@sinole You are right, it is SDO, as documentation says here:

https://docs.duet3d.com/User_manual/Connecting_hardware/Sensors_Accelerometer

I've miss typed, gonna edit my post above.