@alankilian Thank you very much for sparing some time for printing the object. I am somehow relieved to see that it isn't specific to my printer only.

@3DPMicro The GCode looks perfectly fine when loaded on a GCode viewer. The walls are straight. The STL itself has no visible problems when loaded in Solidworks. It looks as it is intended to look.

@phaedrux The horseshoe shape can be a problem but that is the preferred method for all of the slicers I've tried. None of the slicers try to make that hole by retracting and going straight accross the hole. Maybe that is a fundamental error with the slicers themselves, who calculate the amount of plastic needed. The pressure advance might change how this looks but don't you think it is a huge amount of overextrusion for it to deal with? The pressure advance, especially on a direct drive extruder, isn't supposed to make that much of a change. While this part has been printed without pressure advance, I've used pressure advance in the past and I can still see the same artifacts.

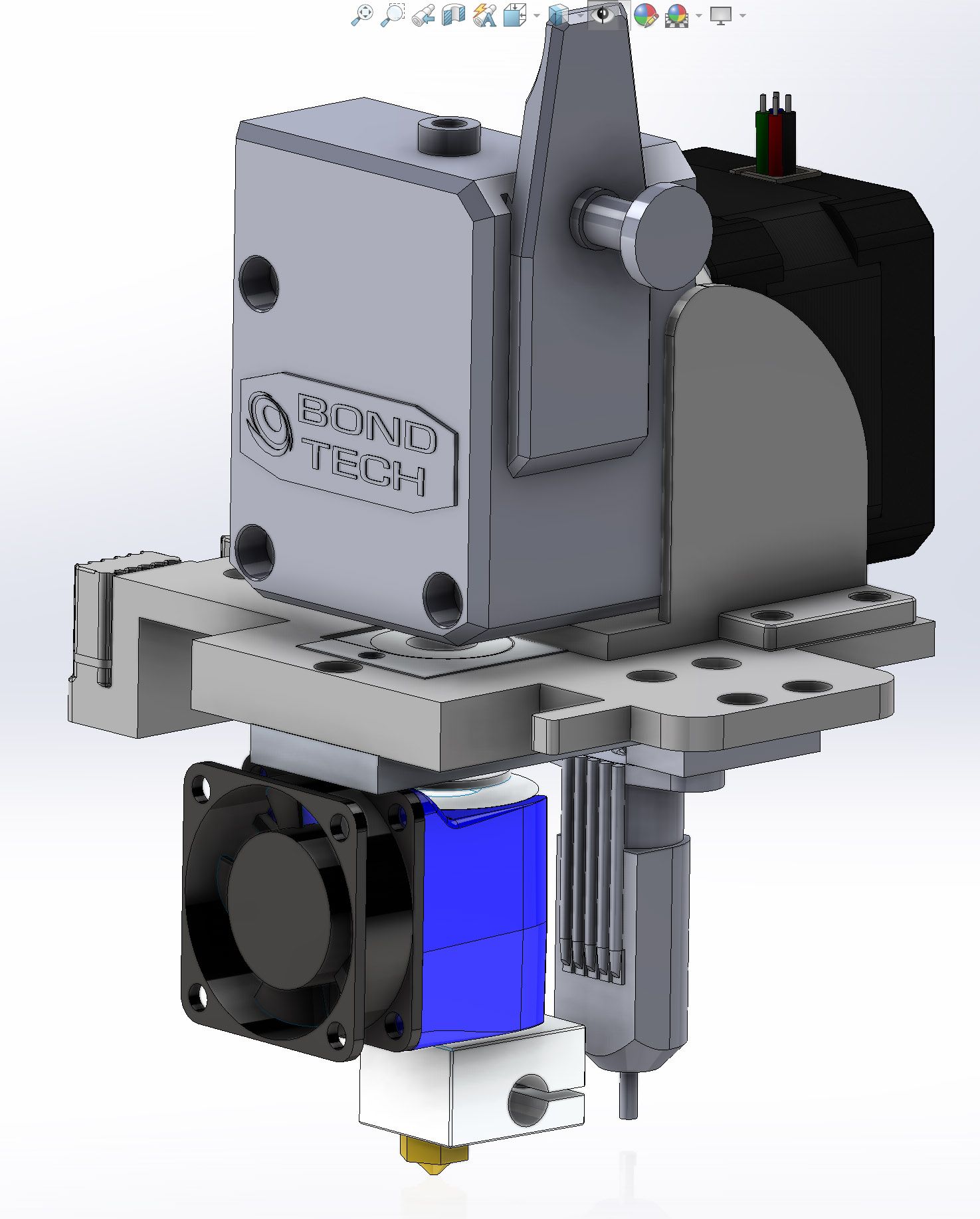

Some more information about my configuration: It is a custom cartesian printer with Duet Wifi 1.04, running firmware 3.2. Bondtech BMG extruder.

.

Here's my config.g:

; Configuration file for Duet WiFi (firmware version 3)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool v3.2.3 on Fri May 14 2021 14:28:05 GMT+0300 (GMT+03:00)

; General preferences

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

M550 P"Sigma 3D" ; set printer name

; Network

M552 S1 ; enable network

M586 P0 S1 ; enable HTTP

M586 P1 S0 ; disable FTP

M586 P2 S0 ; disable Telnet

; Drives

M569 P0 S0 ; physical drive 0 goes backwards

M569 P1 S0 ; physical drive 1 goes backwards

M569 P2 S1 ; physical drive 2 goes forwards

M569 P3 S0 ; physical drive 3 goes backwards

M584 X0 Y1 Z2 E3 ; set drive mapping

M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation

M92 X80.00 Y80.00 Z400.00 E830.00 ; set steps per mm

M566 X900.00 Y900.00 Z60.00 E1200.00 ; set maximum instantaneous speed changes (mm/min)

M203 X7200.00 Y7200.00 Z180.00 E2400.00 ; set maximum speeds (mm/min)

M201 X700.00 Y700.00 Z30.00 E700.00 ; set accelerations (mm/s^2)

M906 X1400 Y1500 Z1400 E900 I30 ; set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout

; Axis Limits

M208 X-20 Y0 Z0 S1 ; set axis minima

M208 X235 Y220 Z230 S0 ; set axis maxima

; Endstops

M574 X1 S1 P"!xstop" ; configure active-high endstop for low end on X via pin !xstop

M574 Y1 S1 P"!ystop" ; configure active-high endstop for low end on Y via pin !ystop

M574 Z0 P"nil" ; Z has no endstop

; Z-Probe

M950 S0 C"exp.heater3" ; create servo pin 0 for BLTouch

M558 P9 C"^zprobe.in" H5 F120 T4800 ; set Z probe type to bltouch and the dive height + speeds

G31 P500 X29 Y0 Z0.75 ; set Z probe trigger value, offset and trigger height

M557 X30:190 Y5:195 S20 ; define mesh grid

; Heaters

M308 S0 P"bedtemp" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin bedtemp

M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0

M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit

M140 H0 ; map heated bed to heater 0

M143 H0 S120 ; set temperature limit for heater 0 to 120C

M308 S1 P"e0temp" Y"thermistor" T100000 B4725 C7.06e-8 ; configure sensor 1 as thermistor on pin e0temp

M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1

M307 H1 R2.322 C219.7 D9.80 S1.00 V24.0 ; disable bang-bang mode for heater and set PWM limit

M143 H1 S300 ; set temperature limit for heater 1 to 300C

; Fans

M950 F0 C"fan0" Q500 ; create fan 0 on pin fan0 and set its frequency

M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off

M950 F1 C"fan1" Q500 ; create fan 1 on pin fan1 and set its frequency

M106 P1 S1 H1 T45 ; set fan 1 value. Thermostatic control is turned on

M950 F2 C"fan2" Q500 ; create fan 2 on pin fan2 and set its frequency

M106 P2 S1 H-1 ; set fan 2 value. Thermostatic control is turned off

; Tools

M563 P0 D0 H1 F0:2 ; define tool 0

G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets

G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C

; Custom settings are not defined

; Miscellaneous

M575 P1 S1 B57600 ; enable support for PanelDue

T0 ; select first tool

Here are some settings for the print that I've copied from the GCode:

; generated by PrusaSlicer 2.3.1+win64 on 2021-05-15 at 16:38:11 UTC

;

; external perimeters extrusion width = 0.45mm

; perimeters extrusion width = 0.45mm

; infill extrusion width = 0.45mm

; solid infill extrusion width = 0.45mm

; top infill extrusion width = 0.40mm

M107

G10 S210 ; set temperature

;TYPE:Custom

M561;Clear bed transforms

G28 XY; Home X and Y axis

M280 P3 S10 I1; BLTouch Pin down

G1 X100 Y100; Go to 100

G28 Z;

G29 S1 ; Bed leveling with already recorded height map

M280 P3 S90 I1; BLTouch pin up

G10 S210 ; set temperature

M116 ; wait for temperature to be reached

G21 ; set units to millimeters

G90 ; use absolute coordinates

M83 ; use relative distances for extrusion

; Filament gcode

; filament used [mm] = 2126.85

; filament used [cm3] = 5.12

; total filament used [g] = 0.00

; total filament cost = 0.00

; estimated printing time (normal mode) = 57m 56s

; avoid_crossing_perimeters = 0

; avoid_crossing_perimeters_max_detour = 0

; bed_custom_model =

; bed_custom_texture =

; bed_shape = 0x0,200x0,200x220,0x220

; bed_temperature = 0

; before_layer_gcode =

; between_objects_gcode =

; bottom_fill_pattern = monotonic

; bottom_solid_layers = 2

; bottom_solid_min_thickness = 0

; bridge_acceleration = 0

; bridge_angle = 0

; bridge_fan_speed = 100

; bridge_flow_ratio = 1

; bridge_speed = 60

; brim_width = 0

; clip_multipart_objects = 1

; color_change_gcode = M600

; complete_objects = 0

; cooling = 0

; cooling_tube_length = 5

; cooling_tube_retraction = 91.5

; default_acceleration = 0

; default_filament_profile =

; default_print_profile =

; deretract_speed = 0

; disable_fan_first_layers = 3

; dont_support_bridges = 1

; draft_shield = 0

; duplicate_distance = 6

; elefant_foot_compensation = 0.2

; end_filament_gcode = "; Filament-specific end gcode \n;END gcode for filament\n"

; end_gcode = M104 S0 ; turn off temperature\nM140 S0 ; turn off bed\nG28 X0 ; home X axis\nM84 ; disable motors\n

; ensure_vertical_shell_thickness = 0

; external_perimeter_extrusion_width = 0

; external_perimeter_speed = 50%

; external_perimeters_first = 0

; extra_loading_move = -2

; extra_perimeters = 1

; extruder_clearance_height = 20

; extruder_clearance_radius = 20

; extruder_colour = ""

; extruder_offset = 0x0

; extrusion_axis = E

; extrusion_multiplier = 1

; extrusion_width = 0

; fan_always_on = 1

; fan_below_layer_time = 60

; filament_colour = #29B2B2

; filament_cooling_final_speed = 3.4

; filament_cooling_initial_speed = 2.2

; filament_cooling_moves = 4

; filament_cost = 0

; filament_density = 0

; filament_diameter = 1.75

; filament_load_time = 0

; filament_loading_speed = 28

; filament_loading_speed_start = 3

; filament_max_volumetric_speed = 0

; filament_minimal_purge_on_wipe_tower = 15

; filament_notes = ""

; filament_ramming_parameters = "120 100 6.6 6.8 7.2 7.6 7.9 8.2 8.7 9.4 9.9 10.0| 0.05 6.6 0.45 6.8 0.95 7.8 1.45 8.3 1.95 9.7 2.45 10 2.95 7.6 3.45 7.6 3.95 7.6 4.45 7.6 4.95 7.6"

; filament_settings_id = "PLA No Heated Bed"

; filament_soluble = 0

; filament_spool_weight = 0

; filament_toolchange_delay = 0

; filament_type = PLA

; filament_unload_time = 0

; filament_unloading_speed = 90

; filament_unloading_speed_start = 100

; filament_vendor = (Unknown)

; fill_angle = 45

; fill_density = 20%

; fill_pattern = grid

; first_layer_acceleration = 0

; first_layer_bed_temperature = 0

; first_layer_extrusion_width = 0

; first_layer_height = 0.2

; first_layer_speed = 30

; first_layer_temperature = 210

; full_fan_speed_layer = 0

; gap_fill_speed = 20

; gcode_comments = 0

; gcode_flavor = reprapfirmware

; gcode_label_objects = 0

; high_current_on_filament_swap = 0

; host_type = octoprint

; infill_acceleration = 0

; infill_anchor = 600%

; infill_anchor_max = 50

; infill_every_layers = 1

; infill_extruder = 1

; infill_extrusion_width = 0

; infill_first = 0

; infill_only_where_needed = 0

; infill_overlap = 25%

; infill_speed = 60

; interface_shells = 0

; ironing = 0

; ironing_flowrate = 15%

; ironing_spacing = 0.1

; ironing_speed = 15

; ironing_type = top

; layer_gcode =

; layer_height = 0.2

; machine_limits_usage = emit_to_gcode

; machine_max_acceleration_e = 10000,5000

; machine_max_acceleration_extruding = 1500,1250

; machine_max_acceleration_retracting = 1500,1250

; machine_max_acceleration_x = 9000,1000

; machine_max_acceleration_y = 9000,1000

; machine_max_acceleration_z = 500,200

; machine_max_feedrate_e = 120,120

; machine_max_feedrate_x = 500,200

; machine_max_feedrate_y = 500,200

; machine_max_feedrate_z = 12,12

; machine_max_jerk_e = 2.5,2.5

; machine_max_jerk_x = 10,10

; machine_max_jerk_y = 10,10

; machine_max_jerk_z = 0.2,0.4

; machine_min_extruding_rate = 0,0

; machine_min_travel_rate = 0,0

; max_fan_speed = 100

; max_layer_height = 0

; max_print_height = 200

; max_print_speed = 80

; max_volumetric_speed = 0

; min_fan_speed = 100

; min_layer_height = 0.08

; min_print_speed = 10

; min_skirt_length = 0

; notes =

; nozzle_diameter = 0.4

; only_retract_when_crossing_perimeters = 0

; ooze_prevention = 0

; output_filename_format = [input_filename_base].gcode

; overhangs = 1

; parking_pos_retraction = 92

; pause_print_gcode = M601

; perimeter_acceleration = 0

; perimeter_extruder = 1

; perimeter_extrusion_width = 0

; perimeter_speed = 50

; perimeters = 3

; physical_printer_settings_id =

; post_process =

; print_settings_id = Sigma 3D

; printer_model =

; printer_notes =

; printer_settings_id = Sigma 3D

; printer_technology = FFF

; printer_variant =

; printer_vendor =

; raft_layers = 0

; remaining_times = 0

; resolution = 0

; retract_before_travel = 0.5

; retract_before_wipe = 0%

; retract_layer_change = 0

; retract_length = 0.8

; retract_length_toolchange = 10

; retract_lift = 0

; retract_lift_above = 0

; retract_lift_below = 0

; retract_restart_extra = 0

; retract_restart_extra_toolchange = 0

; retract_speed = 40

; seam_position = aligned

; silent_mode = 1

; single_extruder_multi_material = 0

; single_extruder_multi_material_priming = 1

; skirt_distance = 4

; skirt_height = 1

; skirts = 4

; slice_closing_radius = 0.049

; slowdown_below_layer_time = 5

; small_perimeter_speed = 20

; solid_infill_below_area = 5

; solid_infill_every_layers = 0

; solid_infill_extruder = 1

; solid_infill_extrusion_width = 0

; solid_infill_speed = 20

; spiral_vase = 0

; standby_temperature_delta = -5

; start_filament_gcode = "; Filament gcode\n"

; start_gcode = M561;Clear bed transforms\nG28 XY; Home X and Y axis\nM280 P3 S10 I1; BLTouch Pin down\nG1 X100 Y100; Go to 100\nG28 Z;\nG29 S1 ; Bed leveling with already recorded height map\nM280 P3 S90 I1; BLTouch pin up\n

; support_material = 0

; support_material_angle = 45

; support_material_auto = 0

; support_material_buildplate_only = 0

; support_material_contact_distance = 0.2

; support_material_enforce_layers = 0

; support_material_extruder = 1

; support_material_extrusion_width = 0

; support_material_interface_contact_loops = 0

; support_material_interface_extruder = 1

; support_material_interface_layers = 1

; support_material_interface_spacing = 0

; support_material_interface_speed = 100%

; support_material_pattern = rectilinear

; support_material_spacing = 3

; support_material_speed = 60

; support_material_synchronize_layers = 0

; support_material_threshold = 45

; support_material_with_sheath = 0

; support_material_xy_spacing = 50%

; temperature = 200

; template_custom_gcode =

; thin_walls = 1

; threads = 8

; thumbnails =

; toolchange_gcode =

; top_fill_pattern = monotonic

; top_infill_extrusion_width = 0

; top_solid_infill_speed = 30

; top_solid_layers = 3

; top_solid_min_thickness = 0

; travel_speed = 90

; use_firmware_retraction = 0

; use_relative_e_distances = 1

; use_volumetric_e = 0

; variable_layer_height = 1

; wipe = 0

; wipe_into_infill = 0

; wipe_into_objects = 0

; wipe_tower = 0

; wipe_tower_bridging = 10

; wipe_tower_no_sparse_layers = 0

; wipe_tower_rotation_angle = 0

; wipe_tower_width = 60

; wipe_tower_x = 180

; wipe_tower_y = 140

; wiping_volumes_extruders = 70,70

; wiping_volumes_matrix = 0

; xy_size_compensation = 0

; z_offset = 0

I was wondering, if more people are willing to print this object and post a picture.