@droftarts Thank you.

Posts made by br7408

-

RE: IR Height Sensorposted in Duet Hardware and wiring

@droftarts Yes, it is Duet. Bought it through filastruder April 22nd 2023.

-

RE: IR Height Sensorposted in Duet Hardware and wiring

I take that back.

I went to calibrate the probe and I am getting errors, because it is not triggering properly. How do I initiate obtaining a replacement?

Here you can see it is initially triggering way low, and then nothing, and then triggering again high. Getting 2 red blinks on startup, as it should.

Specifically: "No trigger on probe after full movement" error in Klipper. Both other IR sensors in the other two identical machines work just fine.

-

RE: IR Height Sensorposted in Duet Hardware and wiring

HMMM. Strangely it seemed to fix itself somehow. I wonder if the EBB 42 woke up stupid or something.

-

IR Height Sensorposted in Duet Hardware and wiring

I finally got around to building my third printer. All 3 are exactly identical printers. I am noticing a weird issue with the 3rd IR height sensor. It boots into digital mode just fine, but it seems to trigger at 2 different heights. The first height is well off the bed, second height is about normal. Never seen this before. Is this unit defective?

-

RE: IR Height Sensor with Klipperposted in IR Height Sensor

Excellent. I actually did more digging around last night and found one of your posts in another forum from many years ago recommending this. I will try it and report back. Your sensor is absolutely the best one out there in my opinion, so I will be happy to get it working on this machine.

UPDATE: That did the trick David. It is now booting in digital mode. Thank you.

-

IR Height Sensor with Klipperposted in IR Height Sensor

I am doing a second build of a similar printer to my first (Duet 3 wifi), running Klipper on a BTT Octopus 1.1 instead. I wanted to use the IR Height sensor on this build as well because it works really well with my heated bed (strong magnets).

I notice on startup, I get 4 pulses (analog) instead of 2 (digital). I do have the pullup signal activated, but I read somewhere about the signal from the board not engaging in time, or similarly needing to add an additional resistor to provide the proper current to activate digital mode.

I cannot find any consistent information anywhere, though. Are there any known fixes for this?

The (seemingly) most feasible solution I have read is from the original IR Sensor website that discusses adding a 470 ohm pulldown resistor from the sensor pin to the ground pin.

-

RE: strange error en 3.5.1posted in General Discussion

Is this issue confirmed fixed with the update? I'm on 3.5.1.

I did an M600, where I had my printhead move into position for a filament change on my filament-change.g

For filament-change.g I have an M291 to resume, followed by an M24.

I tested it on a small 7 layer test print to verify, and it worked flawlessly.

On a very large and expensive print, after filament change, on resume it returned to 5mm above the resume point, then dove the extruder deep into the print and then stopped. Time and expensive material wasted.

Also got the "Error in GCode file line XXXX" and "Axis X is already in use by a different motion system. "

Those errors were not present on the test print either.

-

RE: Input Shaping and Accelerometer, how do I make it useful?posted in General Discussion

@gnydick So you are running an upper and lower rail on your x gantry? What model printer? I only ask because I have contemplated running dual x rails myself on my corexy.

Of the things you fixed, which of the fixes do you think was the most influencing change, in regards to solving your resonance issue?

Are you running damper plates on your stepper motors? I found that those quieted mine down immensely.

-

RE: Jerk/M566 how to find the ideal setting?posted in General Discussion

@Chriss said in Jerk/M566 how to find the ideal setting?:

@br7408 Thanks... that sounds like a very cool way to find the right values. .... I will give it a try....

I literally reconfirmed this again yesterday.

I was printing a partially radiused object (120 mm fan shroud), and I figured I'd lower the jerk a little just to see if I could get a slower start on the straight edges, to help the IS work a little sooner. As soon as I dropped outside wall jerk to 540, I could hear the steppers ratcheting on radius moves, and the outside wall of the radius was choppy. Went back to 600 and it was fine again.

I think jerk is literally one of the only settings that my printer really can consistently tell me what the minimum acceptable setting is.

Now this is a 4 motor corexy.... I don't know if that would make a difference.

-

RE: Tuning Macros Menus (Accel, Jerk, Retraction, Pressure Advance)posted in Tuning and tweaking

These macros have been a great aid. I wrote additional macros for all of the IS algorithms in single steps 30-50 Hz. I found it useful for real-time tweaking freqs during actual printing. I can upload them somewhere if anyone wants them.

-

RE: Input Shaping and Accelerometer, how do I make it useful?posted in General Discussion

You can put in and record your own moves with IS if needed, if you want to utilize moves other than what is available on the IS interface in DWC.

For example, on a corexy machine, it can be useful to run opposite xy diagonal moves to check the variance on belt tension, in a similar manner that Klipper does. I run a code such as this. These moves will show up as move 4 and 5 in the input shaper graph after refreshing the screen. I then compare the xy frequency peaks of each move to verify.

G1 X-150 Y-150 G4 S3 M956 P120.0 S1000 A0 F"5-X64-191-0-none.csv" G4 P10 G1 X150 Y150 F10000 G1 X150 Y-150 G4 S3 M956 P120.0 S1000 A0 F"4-X64-191-0-none.csv" G4 P10 G1 X-150 Y150 F10000Obviously you will need to modify the code for your own machine, and depending on where your xy origin is.

-

Test Bed corexyposted in General Discussion

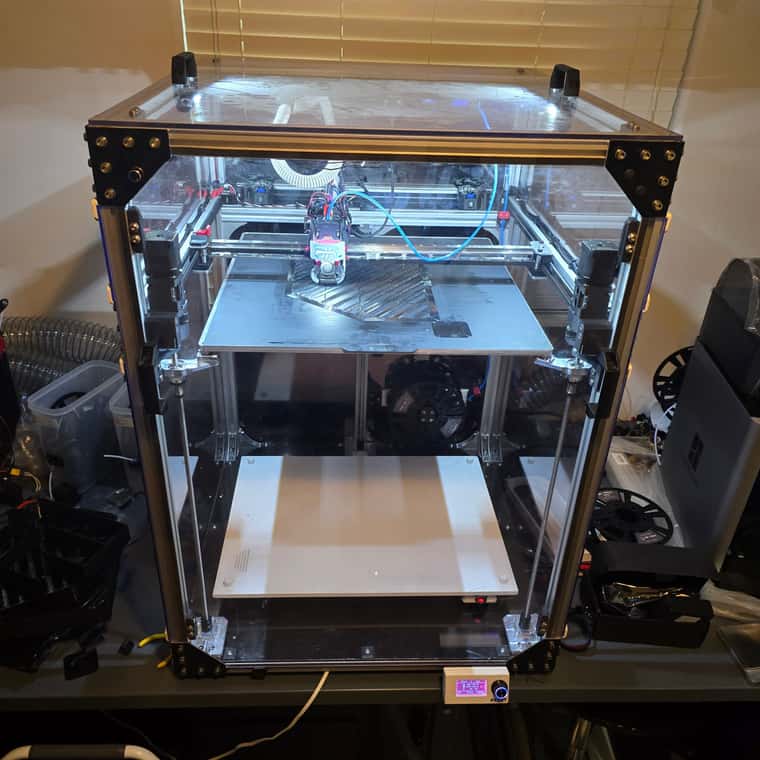

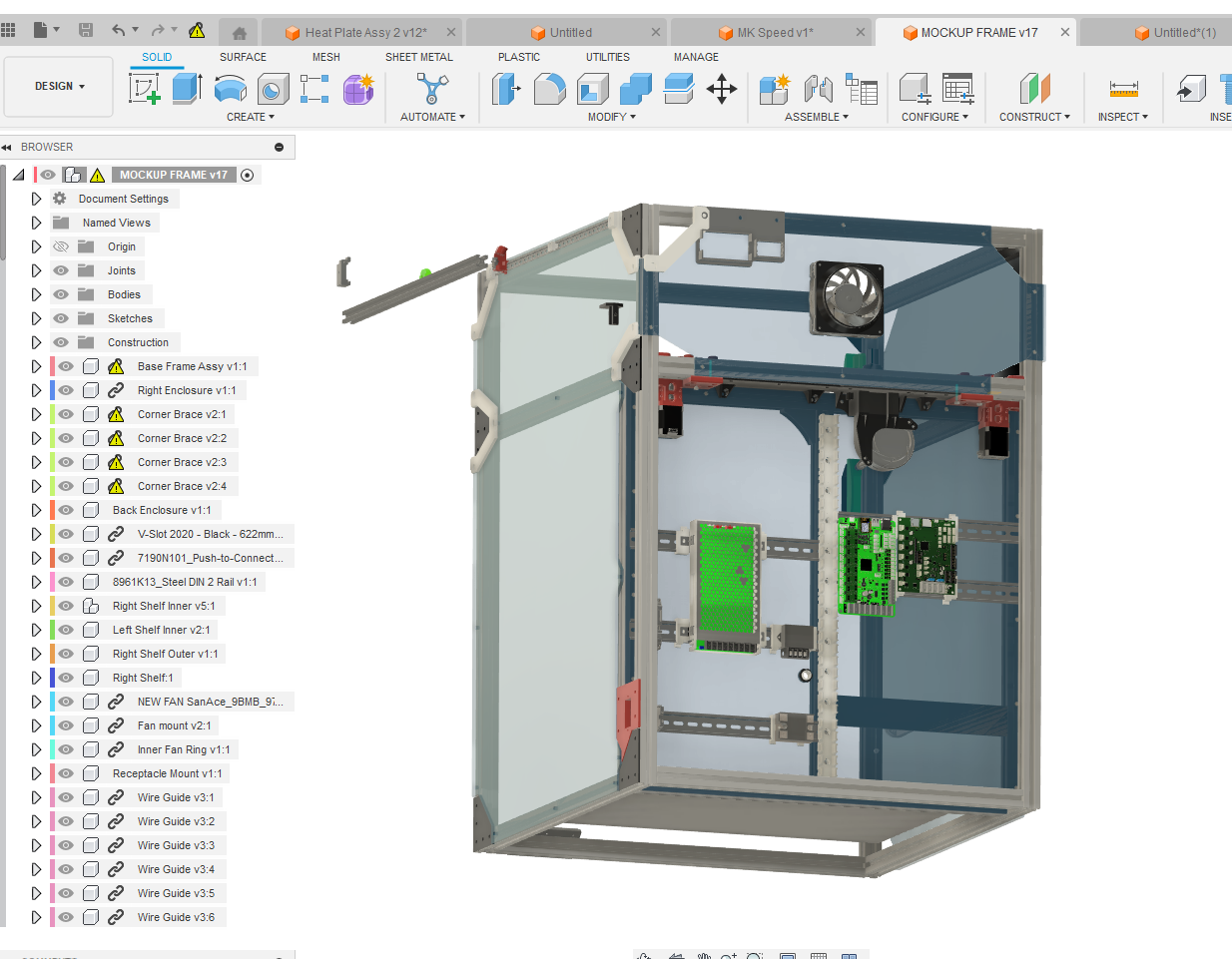

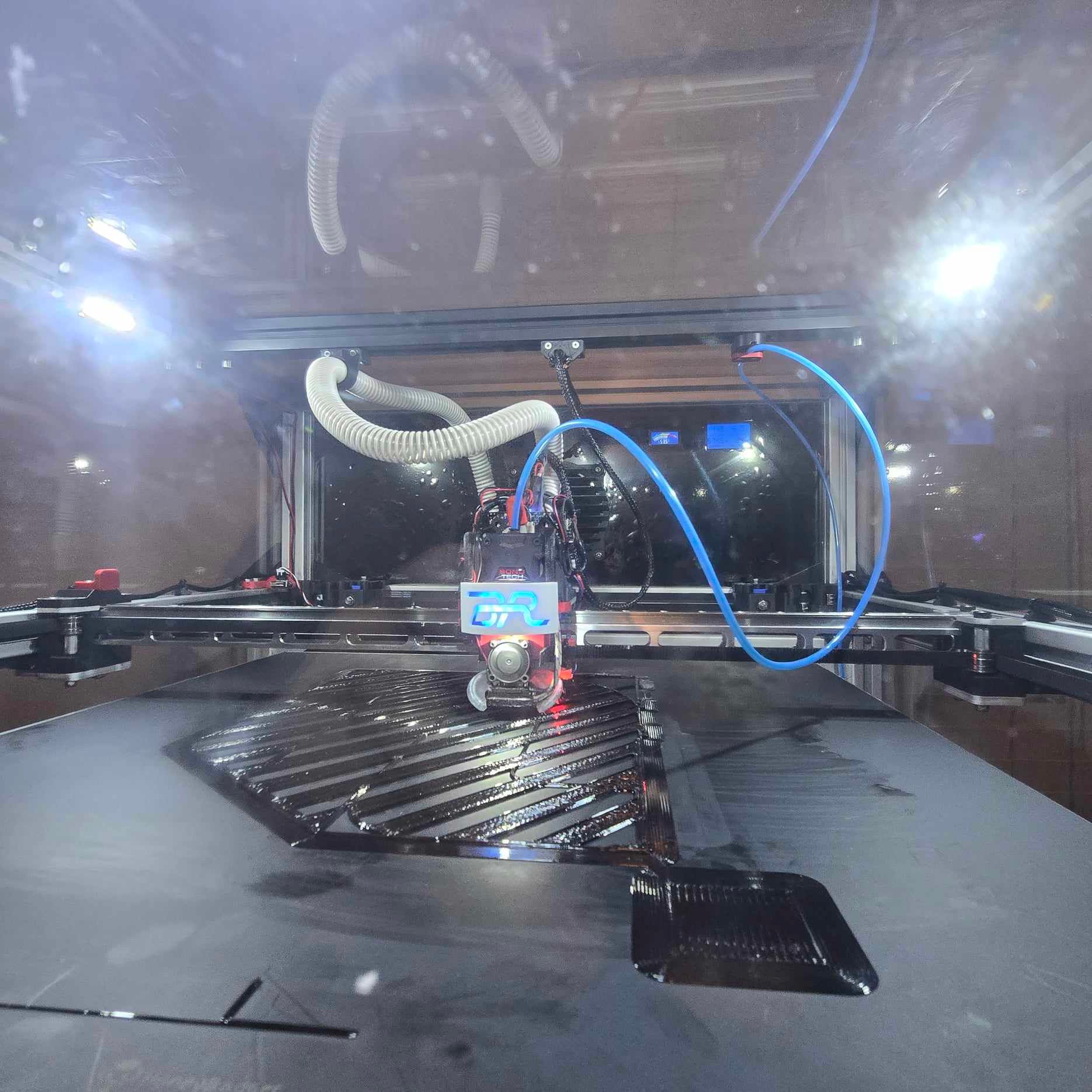

I have been revising and perfecting this first printer build for over a year now through a culmination of knowledge experimentation and research driven mostly by passion. It's a large Ratrig Vcore 3.1 based 500x500mm bed corexy running AWD, and a pogo pin manually interchangeable tool head that I designed. It also has an active heating chamber/ forced air external fume extraction system and high velocity air part cooling system that I designed. All mechanical components are top of the line; this printer performs very well. I am running it with a Duet 3 wifi board, 1LC, as well as Duet's infrared bed sensor and scanning probe. I am no engineer (I hate math), but I am a perfectionist. I usually print ASA and Polycarbonate.

I just started to build printer #2. This printer will be identical mechanically, except running a BTT Octopus board with Klipper through Raspberry Pi. I figure this would create a great opportunity to test bed two mechanically exact identical printers using two different firmware/operating systems side by side.

Its pretty clear that corexy printers are the current performance standard, and larger scale models are in huge demand as they will meet the near future consumer demands of FDM 3D printing.

I'm more than willing to offer my time to work with or help duet engineers later on for side by side testing and comparison, if this configuration will be of any benefit to you.

-

RE: Jerk/M566 how to find the ideal setting?posted in General Discussion

@droftarts I found I was able to get it the smoothest right around minimum 600 jerk. Speed wise it obviously depends on the nozzle size and material, but with a .6 and ASA getting nice smooth outer walls around 160 mm/s with 36hz mzv on the resonance tower. Inside walls I can print up to 200. Accel generally around 4-6k.

-

RE: Jerk/M566 how to find the ideal setting?posted in General Discussion

My method for jerk setting...

I generally print a stepped series of radials (or a cone) and watch what the printhead is doing as it prints the outer radial. With jerk too low, you will see small corner artifacts on the outer wall and you will see & hear the printhead making abrupt movements. As you raise the jerk, the radial wall will smooth out and the printhead will move much smoother. I usually raise the jerk during the print using M566 in small intervals just to where the printhead/radial just starts to smooth out, and that setting seems to work great.

It also really also depends on how your printer does with resonance and whether or not you need input shaping. With less jerk, I find the input shaper tends to work a little better. Excessive jerk can also elicit resonances right after sharp corners.

-

RE: Plug-in Ideaposted in General Discussion

@o_lampe I need to run a minimum jerk of 10 in order to print radials smoothly. I find it could come into play at short corner moves... That or even a way to reduce jerk on short moves. I doubt IS would fix it, as you say.

Then again my only remaining issue with resonance is on the Y axis. I believe it is due to a tiny amount of belt stretch, as this is a big printer.

-

Plug-in Ideaposted in General Discussion

I know Dave is already hard at work on the newest input shaper, because I've already seen the 3.6 references in the Duet library.

I had a thought... not sure how realistic it is.

So typically the slicer will import the print g-code to DWC.

What if there was a DWC plug-in that conditionally analyzed the G-code of the imported project,

and filtered each short move below x value, and reduced the F value of that particular move? I guess it could even have filterable variables to discriminate short move distance and axis range of the move... Instead of IS simply not being applied, the feed rate simply slows down instead to minimize ringing during short moves.Is something like this possible? It seems like it would be rather easy to someone who is good with conditional coding.

-

Stealthchop & Speadcycleposted in General Discussion

Running an AWD setup on a large corexy. I am on RRF 3.5.

It is my understanding that under this software version, my steppers by default are full-time on speadcycle?

...Or are they still using stealthchop and switching over to spreadcycle at a given speed?

-

RE: New to Input Shapingposted in Tuning and tweaking

Correction, I had it backwards... I am using M203 to gradually increase speed. As I increase the speed, the resonant frequency increases on the X axis on a single X axis move. The Y resonant frequency remains the same at all speeds on y axis moves. amplitude varies with speed for both.

I also do not understand the entire logic behind the option of capturing data during or after the move. I have been mostly capturing during the move. If I capture data after the move, I only get significant peaks in the Y axis, with a minimal amount on X. It would be great if there were a more in-depth explanation of this feature.

I am also confused as to why the motion profile only allows input for negative to positive axis movement for each move, but not the reverse of that.

I have both a 1LC and a Scanning Probe board on my printhead, and both accelerometer readings are similar and consistent on all tests.

One of my main print resonance issues seems to stem mostly from stepper vibration (big AWD corexy). I am primarily concerned with finding an outer wall print speed that will minimize this resonance. My theory behind this was to find an axis feed rate that evokes the lowest amplitude of resonance on the accelerometer at a practical printing axis feed rate, and then also apply IS to the frequency as well. My printer evokes very little resonance at higher axis feed rates, but these speeds are not practical speeds for printing under all circumstances. This is where I found the resonant frequency on the X axis varying based on axis feed rate. Trying to utilize a practical axis feed rate to read accelerometer amplitude and compare with what I see visually seems like it could be of some benefit.

Perhaps I'm off in that thought process, but until the developers provide a more comprehensive explanation of how Duet IS and motion profiles work and how it can be practically applied... I have scoured the internet for weeks for any answers I can find and I am good at figuring things out. There are still many great unanswered IS questions in this forum and I find the explanation given on the Duet website not sufficient enough to fully understand it.

What would also be phenomenal is some sort of implementation for using accelerometer data to compare and check belt tension on corexy printers, similar to what Klipper uses.