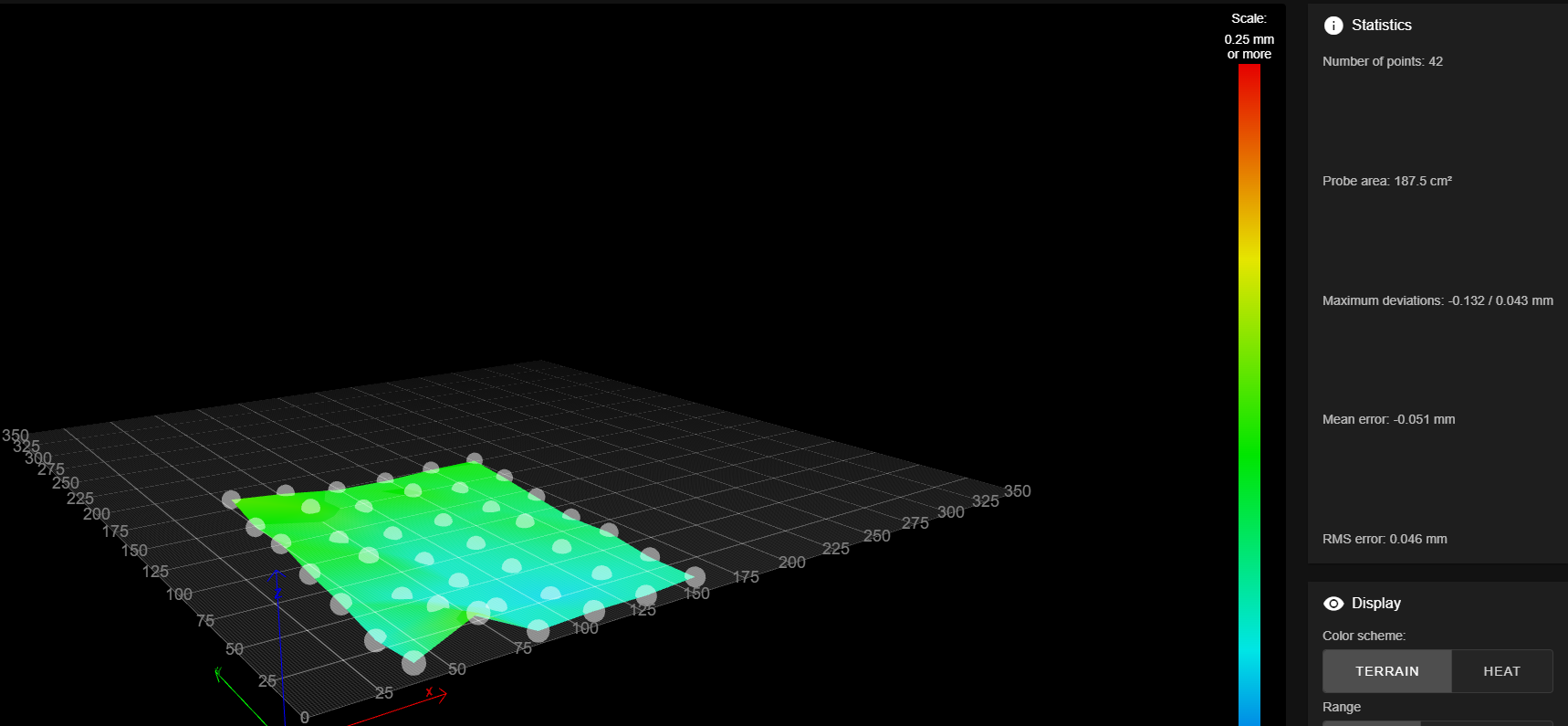

i am having issues with my initial layer z offset. i use g30 s-1 to get the probe offset and no matter what/when, its always about 4.1mm. that is what i have in my config.g

where the problem comes in is that when i print, i have to babystep to get my initial layer to stick. the amount i have to change it varies a lot and rapidly.

Example 1:

i can start a print at a -.8mm offset and it will print very well. i can then try to reprint and will have to adjust the offset to -1.3 or somewhere in between. nothing changes in between.

Example 2:

i can start a print and get a -.8mm offset, then pause the print, resume and the offset is no longer correct.

Things i have checked:

- bed is not lose

- extruder is not lose

- the z motors do not seem to be skipping

- bltouch seems to be working fine as no matter what, G30 s-1 results in 4.1mm

- bltouch mount is solid as well.

Info about printer:

print is a customer corexy printer with dual z axis motors for bed leveling. Bltouch for bed meshing. this issue has always been a thing but before, i didnt have to change the offset much between prints.

im at a lose at what to do. ideas?

config.g files

; Configuration file for Duet WiFi (firmware version 3)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool v3.2.3 on Wed Jul 21 2021 18:08:02 GMT-0400 (Eastern Daylight Time)

; General preferences

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

M550 P"My Printer" ; set printer name

M669 K1 ; select CoreXY mode

; Network

M552 S1 ; enable network

M586 P0 S1 ; enable HTTP

M586 P1 S0 ; disable FTP

M586 P2 S0 ; disable Telnet

; Drives

M569 P0 S1 ; physical drive 0 goes backwards

M569 P1 S1 ; physical drive 1 goes backwards

M569 P2 S1 ; physical drive 2 goes forwards

M569 P3 S1 ; physical drive 3 goes forwards

M569 P4 S1 ; physical drive 4 goes forwards

M584 X0 Y1 Z2:4 E3 ; set drive mapping

M671 X200:200 Y-133:567 S15 ; locations of lead screws relative to 0:0

M350 X16 Y16 Z16 E64 I1 ; configure microstepping without interpolation

M92 X80 Y80.00 Z400 E391 ; set steps per mm

M566 X10 Y10 Z300 E600 ; set maximum instantaneous speed changes (mm/min)

M203 X18000.00 Y180000.00 Z600 E4800.00 ; set maximum speeds (mm/min)

M201 X2000 Y2000 Z100 E1000 ; set accelerations (mm/s^2)

M906 X1500 Y1500 Z800 E1500 I30 ; set motor currents (mA) and motor idle factor in per cent

M84 S50 ; Set idle timeout

; Axis Limits

M208 X0 Y0 Z-2.0 S1 ; set axis minima

M208 X350 Y350 Z400 S0 ; set axis maxima

; Endstops

M574 X1 S1 P"xstop" ; configure active-high endstop for low end on X via pin xstop

M574 Y1 S1 P"ystop" ; configure active-high endstop for low end on Y via pin ystop

M574 Z1 S2 ; configure Z-probe endstop for low end on Z

; Z-Probe

M950 S0 C"exp.heater3" ; create servo pin 0 for BLTouch

M558 P9 C"^zprobe.in" H5 F100 T12000 R.1 ; set Z probe type to bltouch and the dive height + speeds

G31 P500 X27.6 Y18.7 Z4.1 ; set Z probe trigger value, offset and trigger height Z1.92 for .8mm nozzle 1.99 for .8mm nozzle

M557 X25:175 Y25:175 S25 ; define mesh grid

; Heaters

;M140 H-1 ; disable heated bed (overrides default heater mapping)

M308 S0 P"e0temp" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin e0temp

M950 H0 C"e0heat" T0 ; create nozzle heater output on e0heat and map it to sensor 0

M307 H0 B0 R1.857 C155.2 D5.66 S1.00 V24.1 ; disable bang-bang mode for heater and set PWM limit

M143 H0 S300 ; set temperature limit for heater 0 to 300C

M308 S1 P"bedtemp" Y"thermistor" T25000 B3950 ; configure sensor 1 as PT1000 on pin bedtemp

M950 H1 C"bedheat" T1 ; create bed heater output on bedheat and map it to sensor 1

M307 H1 B0 R0.757 C145.9 D1.90 S1.00 ; enable bang-bang mode for the bed heater and set PWM limit

M140 H1 ; map heated bed to heater 1

M143 H1 S125 ; set temperature limit for heater 1 to 300C

; Fans

M950 F0 C"fan0" Q500 ; create fan 0 on pin fan0 and set its frequency

M106 P0 S1 H-1 ; set fan 0 value. Thermostatic control is turned off

M950 F1 C"fan1" Q500 ; create fan 1 on pin fan1 and set its frequency

M106 P1 S1 H0 T60 ; set fan 1 value. Thermostatic control is turned off

; Tools

M563 P0 D0 H0 F0 ; define tool 0

G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets

G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C

; Custom settings are not defined

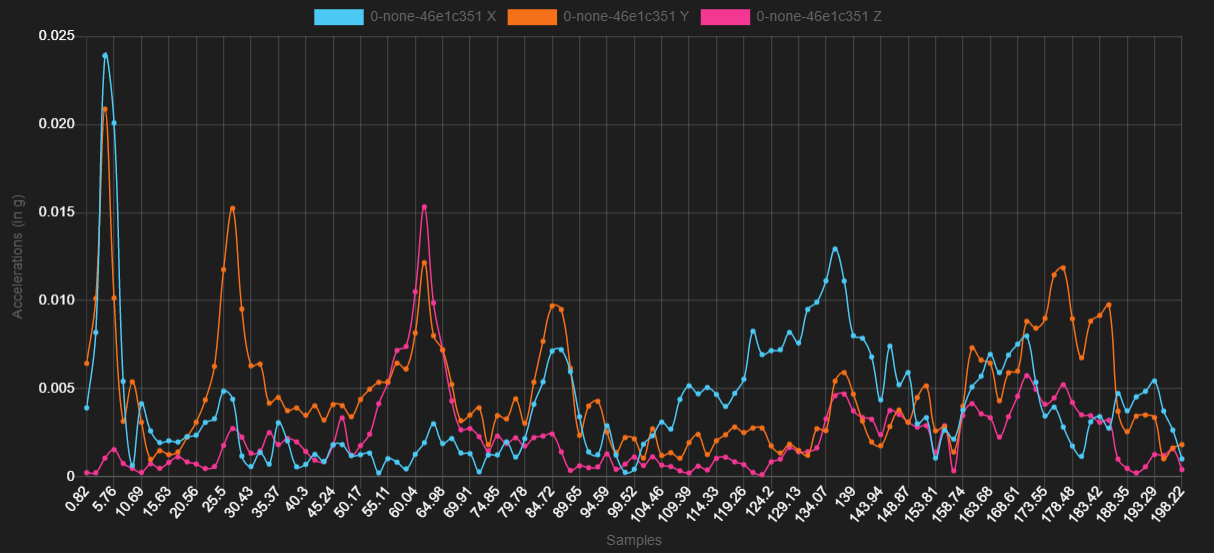

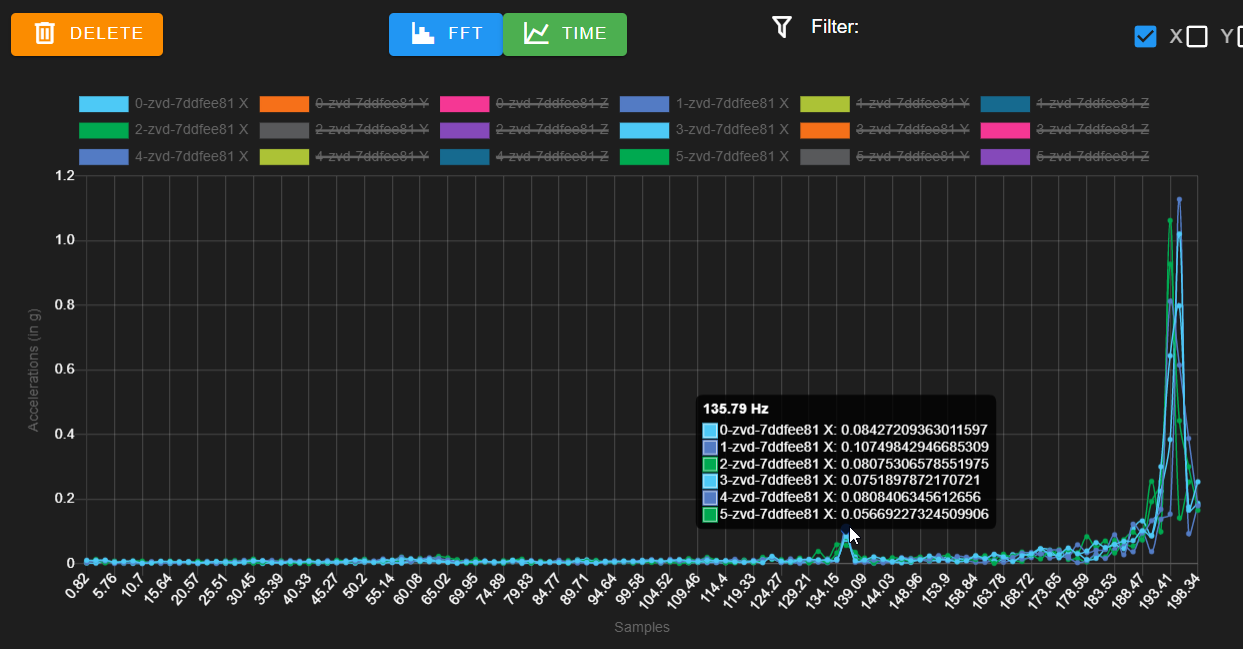

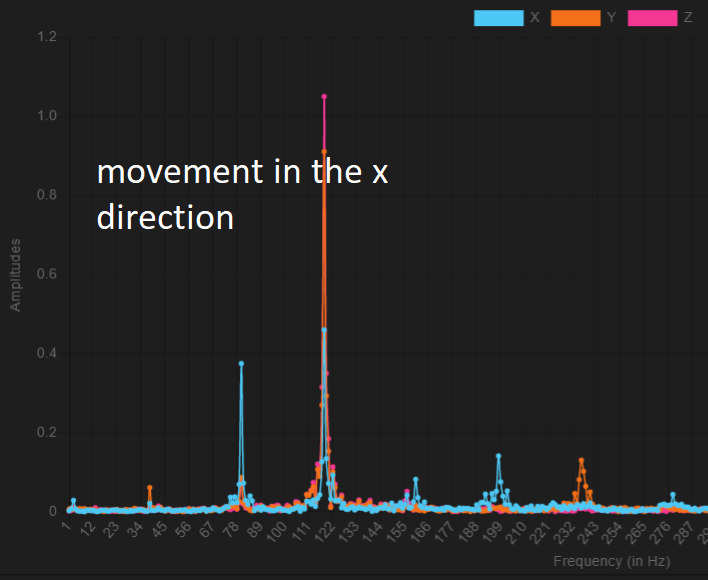

M955 P0 I45 C"spi.cs3+spi.cs4"

bed.g

; bed.g

; called to perform automatic bed compensation via G32

;

; generated by RepRapFirmware Configuration Tool v3.2.3 on Wed Jul 21 2021 18:08:02 GMT-0400 (Eastern Daylight Time)

M561 ; clear any bed transform

;G28 ;

G30 P0 X100 Y20 Z-99999 ; probe near a leadscrew, half way along Y axis

G30 P1 X100 Y180 Z-99999 S2 ; probe near a leadscrew and calibrate 2 motors

G30 P0 X100 Y20 Z-99999 ; probe near a leadscrew, half way along Y axis

G30 P1 X100 Y180 Z-99999 S2 ; probe near a leadscrew and calibrate 2 motors

G29 ; probe the bed and enable compensation

homez.g

; homez.g

; called to home the Z axis

;

; generated by RepRapFirmware Configuration Tool v3.2.3 on Wed Jul 21 2021 18:08:02 GMT-0400 (Eastern Daylight Time)

G91 ; relative positioning

G1 H2 Z5 F3600 ; lift Z relative to current position

G90 ; absolute positioning

G1 X100 Y100 F3600 ; go to first probe point

G30 ; home Z by probing the bed

G32 ;

g30 s-1;

G29 s1;

; Uncomment the following lines to lift Z after probing

;G91 ; relative positioning

;G1 Z2 F100 ; lift Z relative to current position

;G90 ; absolute positioning