@jay_s_uk Yes Exactly that, I have or am trying to get a 2 filament option to work,

I have 3 extruders,

Hot end Extruder 0

Y Splitter

Colour Feed A - Extruder 1

Colour Feed B - Extruder 2,

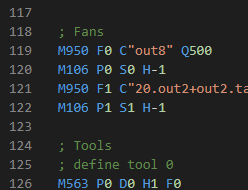

I have 2 tools defined

M563 P0 D0:1 H1 F0 S"Colour - 1" ; define tool 0

M563 P1 D0:2 H1 F0 S"Colour - 2" ; define tool 1

All 3 extruders are Bondtech BMG, and I have a selection arm similar to the ERCF selector which disengages the drive cogs on the feeding Extruders when not needed.

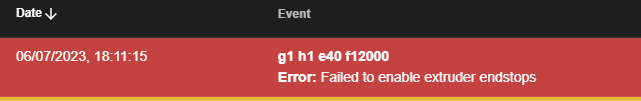

I want to feed quickly to the hot end and detect the stall, at that point I know the filament has hit the hot end and I can deselect the feed extruder with the servo and issue a M567 E1:0 to stop the feed extruder from pushing.

All seems to work ok, but I cant for the life in me work out what I am doing wrong with configuring the end stop for the extruder for Stall detection.

so any help I can get is much appreciated.

I would have gone out and got a ERCF, but I had all these bits in.

Regards

Michael.