@droftarts Cool - looks like that 3 colour printer predates the Prusa MMU1 by quite a lot.

Posts made by dwuk3d

-

RE: Sovol SV08 Multiple Motion System Upgrade.posted in My Duet controlled machine

-

RE: Sovol SV08 Multiple Motion System Upgrade.posted in My Duet controlled machine

Z offset Tapping now working quite reliably as long as the print heads are clean.

Lots more work to do on timings and speed, and print head design - but printer starting to come together.

-

RE: Sovol SV08 Multiple Motion System Upgrade.posted in My Duet controlled machine

Printing getting better. I don't think the original problems with the flag in the video a few months ago were dimensional inaccuracies or alignment issues - rather the fact the it was cutting off some of the colours due to Axis limits.

-

RE: Sovol SV08 Multiple Motion System Upgrade.posted in My Duet controlled machine

Back to printer -

New Z Hopper motors arrived - bought full linear actuators - which I will take apart - as seems to be most cost effective way to source Nema 11 lead screw motors

Tap sensoring now working.

Logic is

1.Home All

2. G32 Z motor alignment

3. Then for each print head

4. Move other print heads 2mm up so that they are out of the way

5. Align Z hopper to just trigger optical sensor

6. Move head down about 0.02 mm to just past the trigger point.

7. Switch probes/endstops so that the Z axis now has the Z hopper end stop as its trigger. (inverted)

8. Move Z down until print head hits to bed and then pushes up slightly within the play of the print head to disable the triggered optical sensor.

9. Repeat for various points of the print bed,Short demo - showing tapping and play/flex - which might end up being a problem

https://youtu.be/5FGALqWV4t8Example Tap test macro.

;tap A.g M98.1 A"B On" ;reset probes to correct values M574 Z1 S2 K0; configure Z axis endstop M574 A1 P"122.io2.in" S1 ; configure A axis endstop G90 G1 Z3 F1000 G1 D{global.dOffset+2} F1000 G1 B{global.bOffset+2} F1000 var speed = 400 ;var w = {224, 224, 324, 324} ;var v = {310, 210, 210, 310} var w = {160, 200, 200, 160, 324} var v = {160, 160, 240, 240, 310} var point1 = -1 while iterations < 5 var iGrid = iterations G1 W{var.w[var.iGrid]} V{var.v[var.iGrid]} F10000 ;echo "W",var.w[iterations],"V",var.v[iterations] while iterations < 2 M574 Z1 S2 K0; configure Z axis endstop M574 A1 P"122.io2.in" S1 ; configure A axis endstop var aMax = 0 var aPos = 0 var aMin = 99 while iterations < 1 G1 A3 F{var.speed} M400 var aProbe = sensors.endstops[6].triggered if var.aProbe abort "A Probe already triggered" G1 H4 A-2 F{var.speed} set var.aPos = move.axes[6].machinePosition ;echo "D trigger pos",var.dPos if var.aPos > var.aMax set var.aMax = var.aPos if var.aPos < var.aMin set var.aMin = var.aPos var aProbe = false if var.aMax-var.aMin > 0.03 echo "variation",var.aMax-var.aMin,var.aMin,var.aMax while iterations < 4 ;echo "i",iterations G1 A{var.aPos-0.01*iterations} F{var.speed} M400 set var.aProbe = sensors.endstops[6].triggered if !var.aProbe abort "A Probe not triggered" else if iterations > 1 echo "lowered head ",0.01*iterations,"mm" break M574 A1 P"122.io3.in" S1 ; configure A axis to temporary Endstop M574 Z1 P"!122.io2.in" S1 ; configure Z Axis to A end stop inverted var zPos = 0 G1 Z{var.zPos+2} F500 M400 set var.aProbe = sensors.endstops[2].triggered if var.aProbe abort "AZ Probe already triggered" G1 H4 Z-7 F{var.speed} set var.zPos = move.axes[2].machinePosition if var.point1 == -1 set var.point1 = var.zPos echo "A zPos",var.zPos,"W",var.w[var.iGrid],"V",var.v[var.iGrid],"point",var.iGrid,"var",var.zPos-var.point1 G1 Z3 F1000 ;restore probes M574 Z1 S2 K0; configure Z axis endstop M574 A1 P"122.io2.in" S1 ; configure A axis endstop ; 122.io3.in - dummy endstop when A swapped out -

RE: G4 being executed by both motion systems [3.5.4]posted in MultiAxis Printing

@dc42 Thanks will switch to that version

-

G4 being executed by both motion systems [3.5.4]posted in MultiAxis Printing

I am having some trouble with layer shifts in motion system 1 on layer 2 - which I think is relating to something happening in Motion System 0.

I introduced some delays in motion system 0 at various points so that I could try pin pointing exactly which command in motion system 0 is causing motion system 1's X&Y gantry to shift 10/5 mm's and cause the issue.

This resulted in some strange behaviour - where motion system 1 seemed to get stuck for a while.

I think I have figured out that all of the G4 delays I have put into motion system 0 are also being executed by motion system 1.

Some of the delays are in loops - but I assume the loop logic is probably being ignored and just the G4's are being picked up and executed - or maybe G4's in loops are being ignored.

When I reduce the length of the delays in motion system 0, then motion system 1 seemed to get delayed less.

I think I can work around this by using much smaller delays and putting them in loops - but it does help to explain a few strange delays.

Update: Putting delays into iterations didn't change the behaviour

So I have instead added an if statement to exit out of every macro that is likely to be called when multiple motion systems are active, plus in my general macro caller

if state.thisInput != null && inputs[state.thisInput].active == false M99 if exists(param.A) var P ="0:/macros/"^{param.A} if fileexists(var.P) M98 P{var.P} else var P2 =var.P^".g" if fileexists(var.P2) M98 P{var.P2} else echo "M98.1 Macro file not found",{var.P} else echo "M98.1 Macro Parameter A not found" -

RE: Sovol SV08 Multiple Motion System Upgrade.posted in My Duet controlled machine

@droftarts Yes I really like Fusion 360 too.

I did try doing a whole ship model in Blender - mainly due to the perspective corrector add-on - which is a really good way of tracing 3d objects when they are at an angle or have perspective distortion.

Ultimately though I gave up when print quality wasn't as good, plus having the spend ages wrestling will the models to correct model mesh errors.I'm still using a 2020 MacBook Air 8gb M1 - and it works pretty well - although it really started to struggle with this combined model - which I know would work easily in Blender. - I might upgrade to an M4 at some point with a larger screen for when I am away.

I got a PC too mainly for rendering of animations - which are about 60x faster on the 4070 Super/Ryzen7950X3D/32GB - vs the M1 GPU. Blender runs slightly quicker on Linux - but I usually do my rendering in windows 11.

Put up a couple more videos with a bit more detail, one of which got retweeted by Sovol - so fame building further. What would be really good though is if Sovol (or someone else) gets together with Bondtech to release a fully built, tested and supported INDX printer.

Free stuff might be nice - but I think it changes it from being a hobby - and starts putting pressure on to deliver. I haven't applied for the Bondtech Beta Programme as don't want to be sworn to secrecy.

PCBway have been in contact too about the triple headed printer videos - I guess having their logo on would add a certain amount of Kudos - but I don't think I need any custom PCBs - might need some CNC stuff though when I got to the rotary bed phase - but probably won't pursue it.Makerworld Boost points are pretty handy though for filament, plus Bambulab are selling quite a lot of parts too now. Plus might partially pay for an H2D if I decide to go for one. It's not until you try and create a printer do a major upgrade that you realise how much work must have gone into the X1C to make it so good.

-

RE: Sovol SV08 Multiple Motion System Upgrade.posted in My Duet controlled machine

@o_lampe thanks - do you mean G92's.

I don't think I have any of those in my macros that would be invoked mid print - the problem occurs mid layer 2 = when the printing switches back between T1 to T0. But I will check.

I think though that something is changing the endstop offsets for the Y and Y axis and then jumping them quickly to the new position.

I have noticed some unexpected behaviour when moving around between tools and mapped axis - but haven't really found a way to recreate the issue.

If I don't manage to resolve the problem I suppose I could try removing the X and Y mapping completely from the T1 and T2 tools definitions , and instead post process the G0-G3's to specify U,V & W instead when using T1 or T2.

Ps - the sequence is

Homing.z offsets

Motion system 1 - layer 1 - print T0 section ok

Motion system 0 - layer 1 - wait for pre-heat, delay, preheat, T1 print prime, wait for print T0 to finish, T1 print layer 1, move Z up to layer 2, T1 print layer 2.

Motion system 1 - layer 2 - wait for pre-heat, delay, preheat, T0 prime for layer 2, wait for T1 to finish, T0 head jumps to incorrect position, T0 print layer 2 - with layer shift -

RE: Sovol SV08 Multiple Motion System Upgrade.posted in My Duet controlled machine

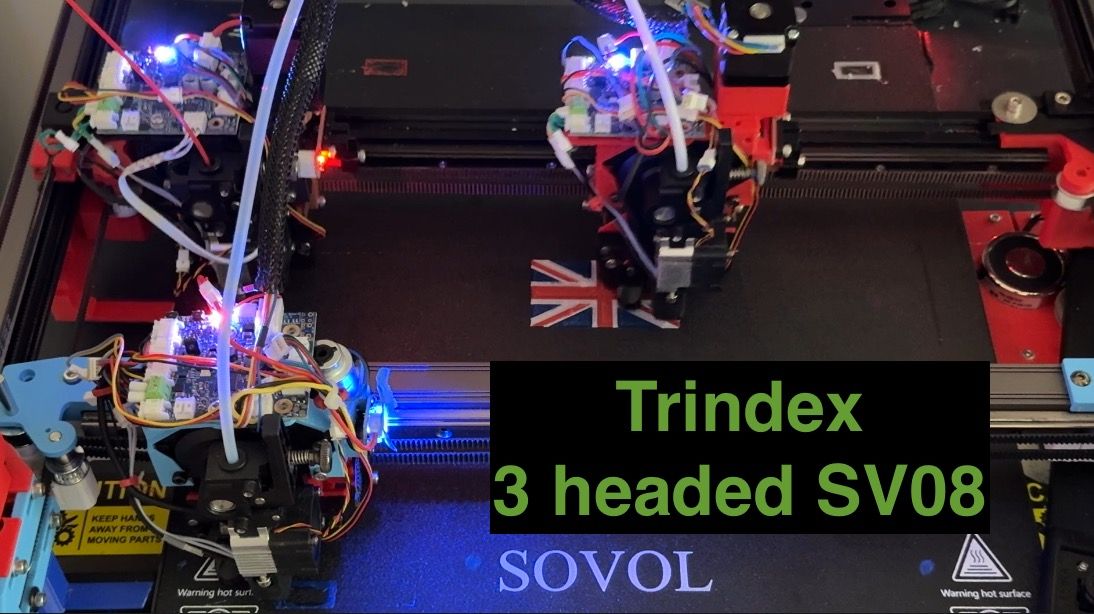

Started making some progress on the Trindex SV08 printer again.

Did some simple size test prints - and started getting issues with Z offsets.

I think I will have to improve my Z alignment - either by using 'voron tap' on all of the tools, or possibly using the ball probe Z offsets.

Plus a more serious issue.

When serial 3 headed printing - but with parallel print priming and colour switching between T1 (UV) and T0 (XY) - T0 consistently layer shifts about 10mm in the X and 5mm in the Y - and the layer shift if quite fast.

I had this issue a while ago and thought it was related to the Z hopper - but I have turned the Z hopping off on XY and are still getting the issue.

If I do similar prints with T2 (WV) and T0 (XY) - both of them print fairly well.

I have seen some oddities in normal alignment testing with X and Y sometimes jumping when I switch between tools - so not sure if it is an issue with my config, macros, slicer GCODE or a 3.5.4 problem.

Will continue investigating to try and get the problem to occur in a more simple gcode file without parallel printing.

Or might just try setting up another tool - T3 - and assign that to the UV - to see if I get the same issues.

-

RE: Sovol SV08 Multiple Motion System Upgrade.posted in My Duet controlled machine

@dwuk3d said in Sovol SV08 Multiple Motion System Upgrade.:

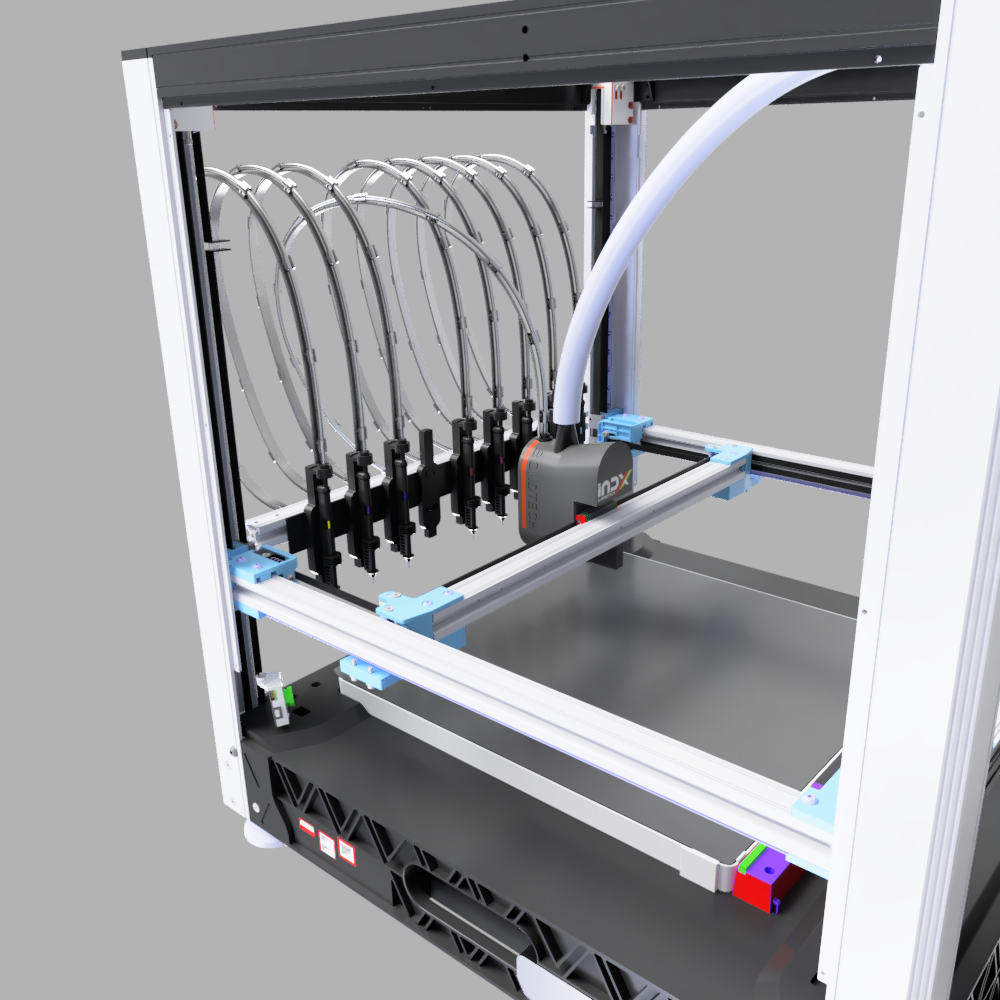

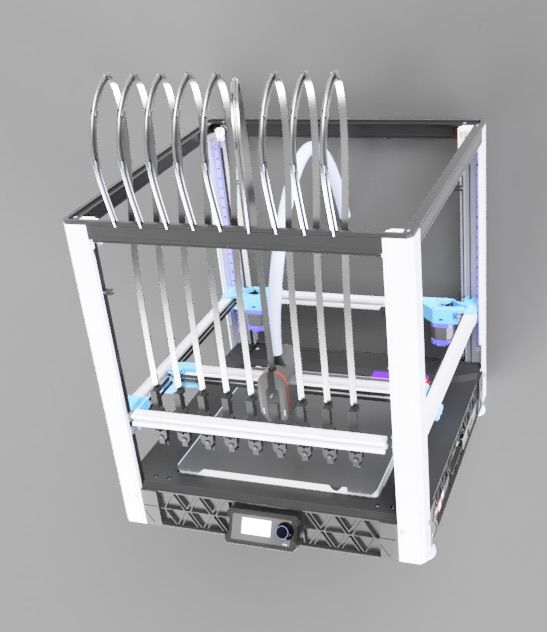

@droftarts Will be interesting to see if the video gets much pick up as it is certainly a very elegant design and could completely remove the need for me to add single nozzle multiplexing on top of tool changing - plus also remove the need for lots of electronics and motors etc. for the extra tools and multiplexer

Might do a better version of the video with a few animations of the different options next.

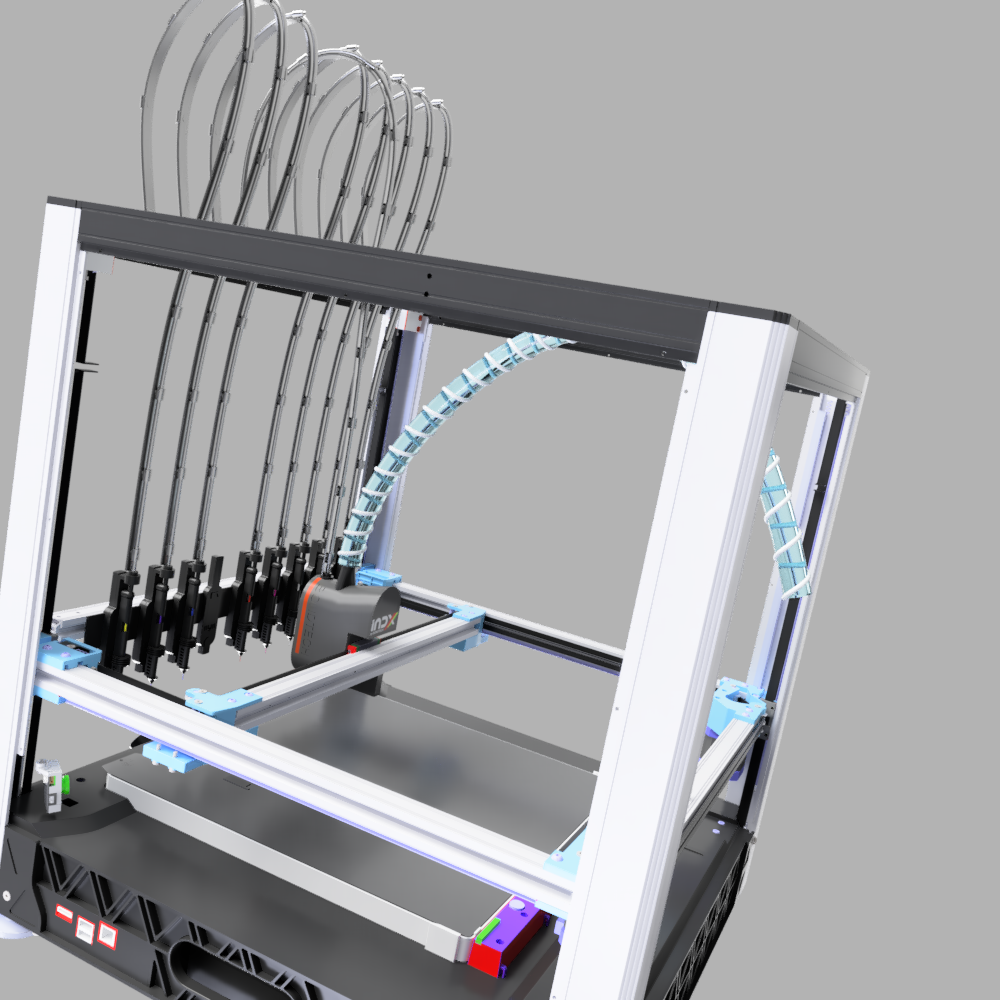

Finally got round to starting on some INDX/SV08 animations - which will eventually include my currently planned 2 Gantry, 3 Toolhead, rotating bed version - with some full multi colour ship print simulations.

Blender is very powerful - but I find it very hard to use compared to Fusion - I find I have to google at least half of the commands, including ones I have used only a few minutes ago - due to the odd keystrokes with combinations of modifier keys.

Doesn't help too that I am using a Mac - whereas most of the documentation and explanation videos use the windows versions of the keystroke modifier keys.

The INDX on SV08 renders I did last week got retweeted by both SOVOL and BONDTECH which was good.

-

RE: Sovol SV08 Multiple Motion System Upgrade.posted in My Duet controlled machine

Having trouble getting the same Hanpose Nema11 x 28 lead screw motors for last extruder in a reasonable time.

Considered ordering normal Nema11's, couplers and lead screws.

But decided to go for these instead - will have to take them apart and cut down the lead screw - but delivery in a few days.

I also get a free linear rail and carriage which might be useful -Also ordered a second ball probe for dimensional alignment

-

RE: Multiple motion system call macro in the second motion systemposted in General Discussion

@pouryatorabi thought so - do you still get the problem?

Macro's work ok for me in multiple motion systems - especially when you run them as job,

What is in the macro?

I found that without the M606 it will only run a few commands in parallel.

I usually do T0 or T1 after most of my M596's

-

RE: Multiple motion system call macro in the second motion systemposted in General Discussion

@pouryatorabi For M596 the documentation says use P rather than S.

Also to make things work in parallel if you have a lot of commands I have found sometimes M606 S1 is needed.

-

RE: Sovol SV08 Multiple Motion System Upgrade.posted in My Duet controlled machine

Still away - so no progress on actual printer.

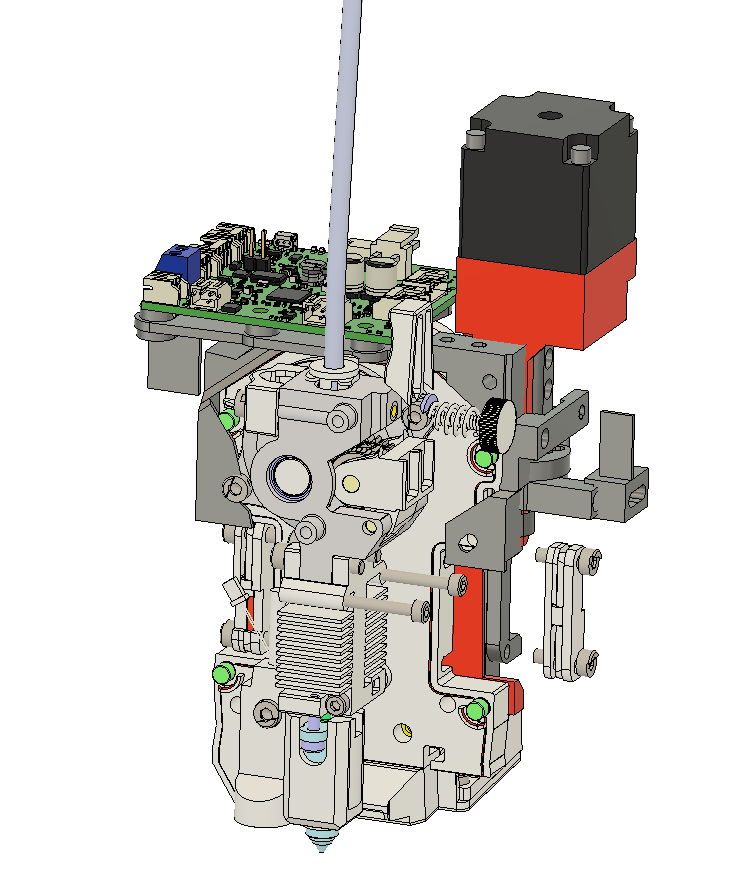

A few more Bondtech INDX diagrams (Renders from Autodesk Fusion) - with some options of where to place the PTFEs.

Might actually be better turning the whole thing around and having the PTFEs on the back with the head reversed on the rear gantry.With the front gantry having the IDEX Sovol print heads on it.

With PTFE's starting at the front of the flying gantry.

with PTFE's starting at the top.

With improved modelling of the air pipe.

-

RE: More heater for a tool in copy modeposted in MultiAxis Printing

Dual IDEX sounds really interesting, I saw a brief glimpse of your printer on Instagram and it looks really good and congratulations on your award.

You might want to consider upgrading to a 6hc board - so that you can run different gcode on the two gantries in parallel.

Would be interested in finding out more about your design - such as the kinematics your are using, bed probing, head alignment etc.

-

RE: MMU-owners: tip forming or cutting?posted in General Discussion

@o_lampe tip forming pretty unreliable in my experience, even if it saves a bit of waste. Cutting pretty reliable and easy with a blade - i've done 10's of 1000s of colour changes on my Bambulab printers and so far have never needed to change the blade.

Long retractions also an issue with the MMU2/3. The Bambulab approach of rewinding spools much more reliable - although slow and complex, or the shorter multiple PTFE approach of AMS lite quicker for a limited number of colours.

Separate nozzle (if necessary hot end and extruder) much more preferable than any multiplexing approach both in terms of waste and speed.

-

RE: Disable Axis Travel Smoothnessposted in General Discussion

@pouryatorabi i presume you already have the feedrate set at 800 before the extrude move - otherwise if its was previously a different speed I believe it will gradually accelerate up or down to 800 throughout the move.

-

RE: Sovol SV08 Multiple Motion System Upgrade.posted in My Duet controlled machine

@o_lampe thanks good idea about doubling up - that slip ring has 6 connections and I only need 4 - so I can double up the heater ones - 20A 230v would be masses more than I need.

I haven't done enough actual printing on the SV08 to find any heat bed issues - but it seems to maintain temps ok - although I did get a failure with the PID tuning,

Point taken about the project approach.

One of the advantages of not having a sponsor is not being restricted to specific goals, dates or budgets.

But you might be right that there is a risk of me losing interest in the project - especially as I've just booked a QM2 cruise - so really want to do a model of that ship before I go - so that I can get some comparison photos.

So far all of my changes are just reordering things that were already in the plan (or when better technology like INDX vs Stealthchanger comes along).

On this subject though I am about to change around my bed slinger approach a fair bit to not have a longer bed - but instead just move about 150mm - and add the ability to link multiple SV08's with this ability together - to get 350x700 or 350x1050 for example - with the build plates slightly overlapping the heated beds.

Will probably do dual gantry - but only single heads on the second SV08.

That will then deliver my original plan (and most popular video so far) - see Prusa Multi Mini.

My immediate plans (which I may change)

- Get 3 headed build working well - with fully parallel, faster printing

- Rotating bed

- Angled extruder on rotating bed

- 150mm bed slinging

- 2nd linked or independent SV08 with 150mm bed slinging

- 4th print head - probably on stealthchanger to allow for offloading.

- iNDX - which may slot in earlier if previous steps go past December.

-

RE: Sovol SV08 Multiple Motion System Upgrade.posted in My Duet controlled machine

@o_lampe the bed is already mains with an SSR - so I was planning on putting the SSR output through the slip ring, plus the temperature sensor.

Are you saying that would be ok - or that I should look at a better quality slip ring?

I suppose continuous rotation would only be a novelty feature - I wouldn't need a slip ring for 90,180,270,180,90,0 rotation - which is the main reason fir me adding it.

So I could drop it if a good quality one is going to be massively expensive,

I could always disconnect the cables and use a bambulab cool plate for continuous rotation demo's.

-

RE: Sovol SV08 Multiple Motion System Upgrade.posted in My Duet controlled machine

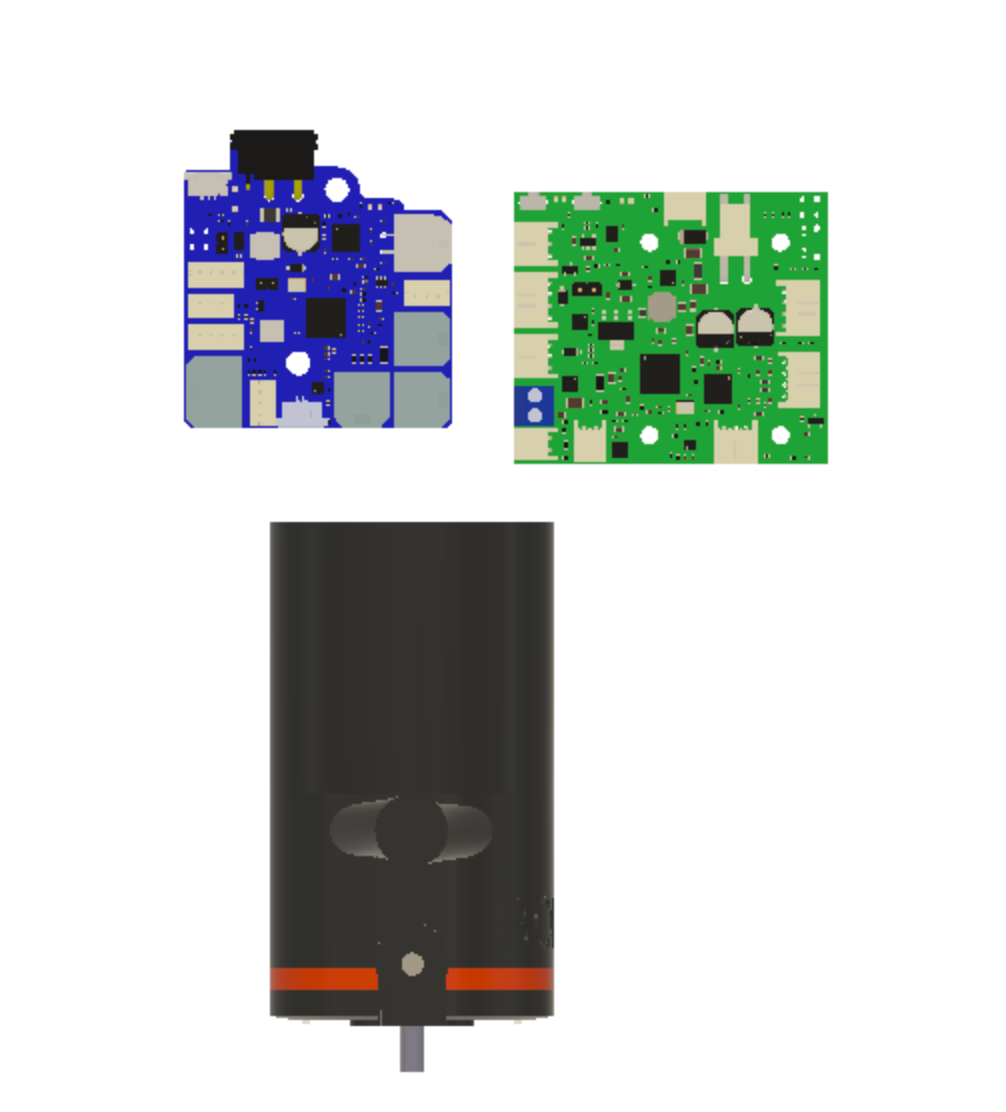

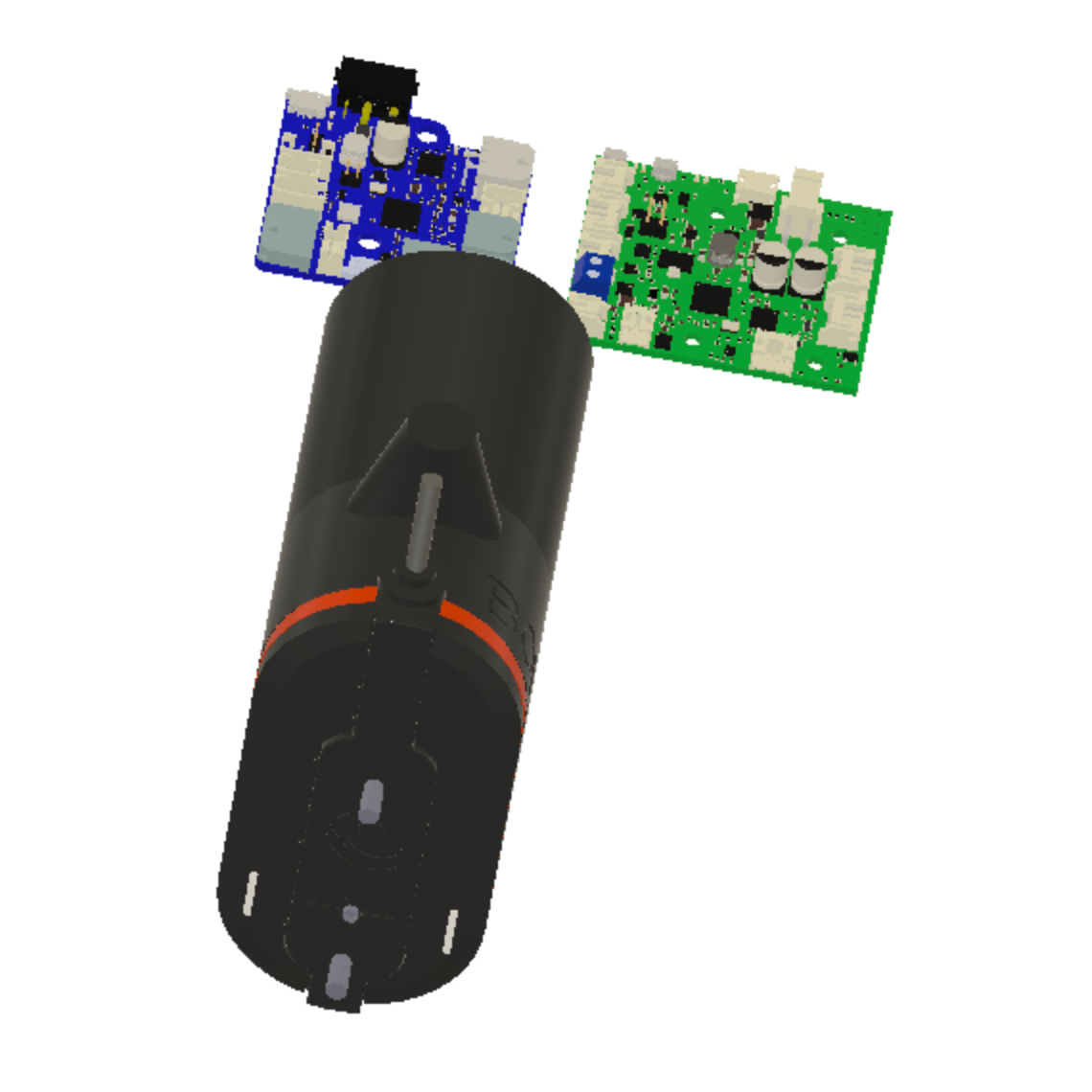

Think I might need a Roto toolboard for when I add an INDX to my front gantry.

Nb/ my picture of the INDX toolhead is slightly bigger than the real thing according to Bondrech.

Might get one now as it could also help with reducing the width on my rear right extruder too - although I suppose I could just rotate the 1LC upwards so that it doesn't take up so much space.