I revert the firmware to 2.05.1 (from 3.2) and its all working now! Thank you

Posts made by esobreiro

-

RE: Help - Trigger height Bed go down before printposted in General Discussion

-

RE: Bed leveling going to wrong side.posted in General Discussion

I revert the firmware from 3.2 to 2.05.1 and everything is working fine. Thank you!

-

RE: Bed leveling going to wrong side.posted in General Discussion

Downgrading the firmware... and test....

-

RE: Bed leveling going to wrong side.posted in General Discussion

Not so fast...

After following the belt schema now, I have half bed and the following errors:

G32

Warning: Skipping grid point (36.0, 36.0) because Z probe cannot reach it

Warning: Skipping grid point (66.0, 36.0) because Z probe cannot reach it

Warning: Skipping grid point (96.0, 36.0) because Z probe cannot reach it

Warning: Skipping grid point (126.0, 36.0) because Z probe cannot reach it

Warning: Skipping grid point (156.0, 36.0) because Z probe cannot reach it

Warning: Skipping grid point (186.0, 36.0) because Z probe cannot reach it

Warning: Skipping grid point (216.0, 36.0) because Z probe cannot reach it

Warning: Skipping grid point (246.0, 36.0) because Z probe cannot reach it

Warning: Skipping grid point (276.0, 36.0) because Z probe cannot reach it

Warning: Skipping grid point (276.0, 66.0) because Z probe cannot reach it

Warning: Skipping grid point (246.0, 66.0) because Z probe cannot reach it

Warning: Skipping grid point (216.0, 66.0) because Z probe cannot reach it

Warning: Skipping grid point (186.0, 66.0) because Z probe cannot reach it

Warning: Skipping grid point (156.0, 66.0) because Z probe cannot reach it

Warning: Skipping grid point (126.0, 66.0) because Z probe cannot reach it

Warning: Skipping grid point (96.0, 66.0) because Z probe cannot reach it

Warning: Skipping grid point (66.0, 66.0) because Z probe cannot reach it

Warning: Skipping grid point (36.0, 66.0) because Z probe cannot reach it

Warning: Skipping grid point (36.0, 96.0) because Z probe cannot reach it

Warning: Skipping grid point (66.0, 96.0) because Z probe cannot reach it

Warning: Skipping grid point (96.0, 96.0) because Z probe cannot reach it

Warning: Skipping grid point (126.0, 96.0) because Z probe cannot reach it

Warning: Skipping grid point (156.0, 96.0) because Z probe cannot reach it

Warning: Skipping grid point (186.0, 96.0) because Z probe cannot reach it

Warning: Skipping grid point (216.0, 96.0) because Z probe cannot reach it

Warning: Skipping grid point (246.0, 96.0) because Z probe cannot reach it

Warning: Skipping grid point (276.0, 96.0) because Z probe cannot reach it -

RE: Bed leveling going to wrong side.posted in General Discussion

@Phaedrux Thanks again.

I did that because of this problem... I just revert and no success.

Now its homed at X:60 Y:30 with same behaivour.Best regards,

Erick

-

RE: Bed leveling going to wrong side.posted in General Discussion

@droftarts i tried but was not good...

@Phaedrux following my homing files:

homeall.g

; called to home all axes

;

; generated by RepRapFirmware Configuration Tool v3.2.3 on Mon Mar 15 2021 16:16:13 GMT-0300 (Horário Padrão de Brasília)

G91 ; relative positioning

G1 H2 Z5 F6000 ; lift Z relative to current position

G1 H1 X305 Y305 F1800 ; move quickly to X or Y endstop and stop there (first pass)

G1 H1 X305 ; home X axis

G1 H1 Y305 ; home Y axis

G1 X-5 Y-5 F6000 ; go back a few mm

G1 H1 X305 F360 ; move slowly to X axis endstop once more (second pass)

G1 H1 Y305 ; then move slowly to Y axis endstop

G90 ; absolute positioning

G1 X310 Y22 F6000 ; go to first bed probe point and home Z X-155 Y-75 F6000

G30 ; home Z by probing the bed; Uncomment the following lines to lift Z after probing

;G91 ; relative positioning

;G1 Z5 F100 ; lift Z relative to current position

;G90 ; absolute positioning

; homex.g

; called to home the X axis

;

; generated by RepRapFirmware Configuration Tool v3.2.3 on Mon Mar 15 2021 16:16:13 GMT-0300 (Horário Padrão de Brasília)

G91 ; relative positioning

G1 H2 Z5 F6000 ; lift Z relative to current position

G1 H1 X325 F1800 ; move quickly to X axis endstop and stop there (first pass)

G1 X-5 F6000 ; go back a few mm

G1 H1 X325 F360 ; move slowly to X axis endstop once more (second pass)

G1 H2 Z-5 F6000 ; lower Z again

G90 ; absolute positioning

; homey.g

; called to home the Y axis

;

; generated by RepRapFirmware Configuration Tool v3.2.3 on Mon Mar 15 2021 16:16:13 GMT-0300 (Horário Padrão de Brasília)

G91 ; relative positioning

G1 H2 Z5 F6000 ; lift Z relative to current position

G1 H1 Y325 F1800 ; move quickly to Y axis endstop and stop there (first pass)

G1 Y-5 F6000 ; go back a few mm

G1 H1 Y325 F360 ; move slowly to Y axis endstop once more (second pass)

G1 H2 Z-5 F6000 ; lower Z again

G90 ; absolute positioning

; homez.g

; called to home the Z axis

;

; generated by RepRapFirmware Configuration Tool v3.2.3 on Mon Mar 15 2021 16:16:13 GMT-0300 (Horário Padrão de Brasília)

G91 ; relative positioning

G1 H2 Z5 F6000 ; lift Z relative to current position

G90 ; absolute positioning

G1 X-155 Y-75 F6000 ; go to first probe point ???

G30 ; home Z by probing the bed; Uncomment the following lines to lift Z after probing

;G91 ; relative positioning

;G1 Z5 F100 ; lift Z relative to current position

;G90 ; absolute positioning -

RE: Bed leveling going to wrong side.posted in General Discussion

config overrride g: Is it right?

; config-override.g file generated in response to M500 at 2021-03-15 22:42

; This is a system-generated file - do not edit

; Heater model parameters

M307 H0 R0.315 C510.587:510.587 D7.27 S1.00 V23.6 B0

M307 H1 R3.445 C151.950:151.950 D6.86 S1.00 V23.8 B0

; Workplace coordinates

G10 L2 P1 X0.00 Y0.00 Z0.00

G10 L2 P2 X0.00 Y0.00 Z0.00

G10 L2 P3 X0.00 Y0.00 Z0.00

G10 L2 P4 X0.00 Y0.00 Z0.00

G10 L2 P5 X0.00 Y0.00 Z0.00

G10 L2 P6 X0.00 Y0.00 Z0.00

G10 L2 P7 X0.00 Y0.00 Z0.00

G10 L2 P8 X0.00 Y0.00 Z0.00

G10 L2 P9 X0.00 Y0.00 Z0.00

M486 S-1 -

RE: Bed leveling going to wrong side.posted in General Discussion

Hello @Phaedrux

Thanks!Its moving to the right and front

- Is exactly where it homing. Is it possible to change the probe position start manually? same as homing.

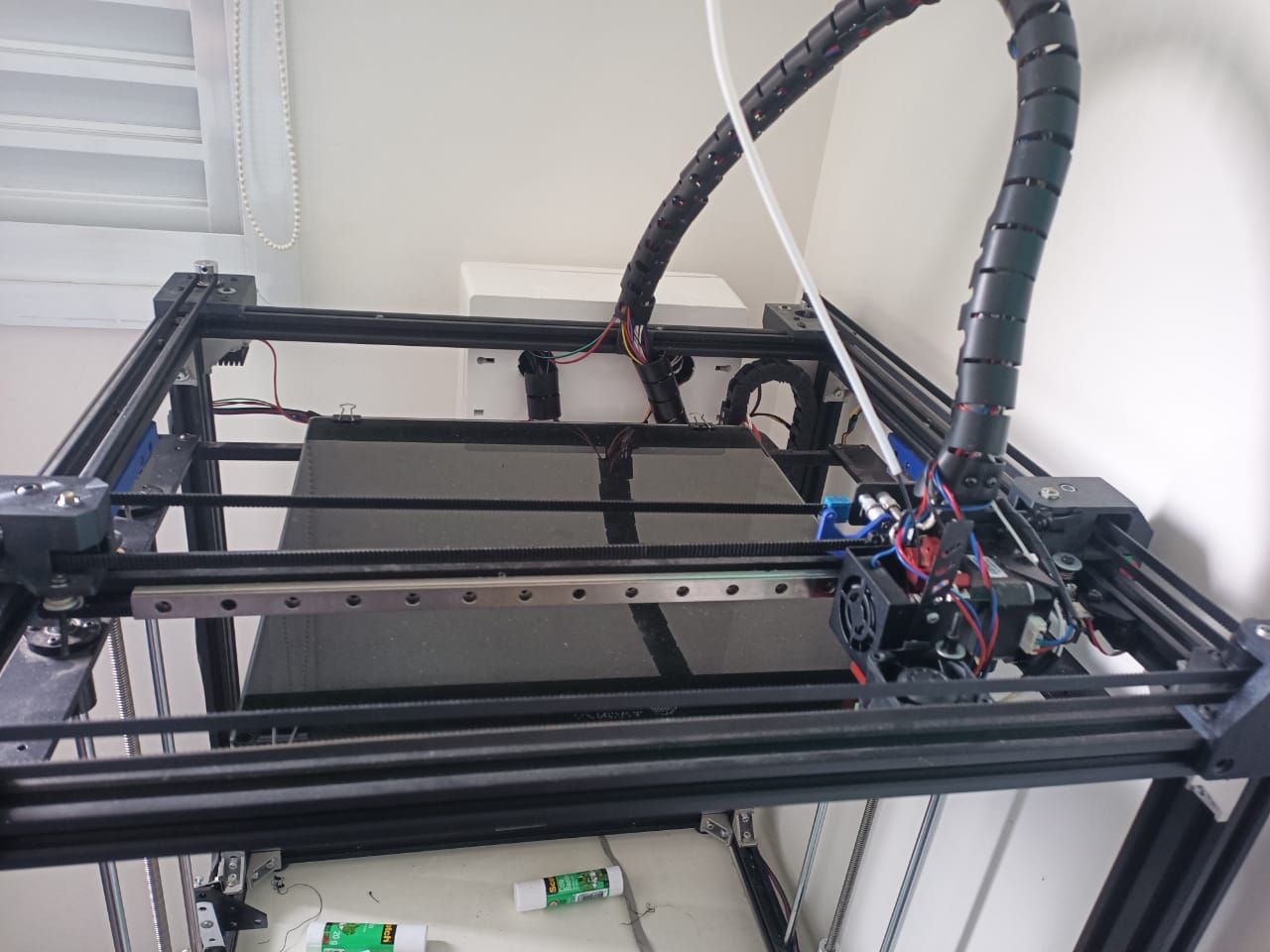

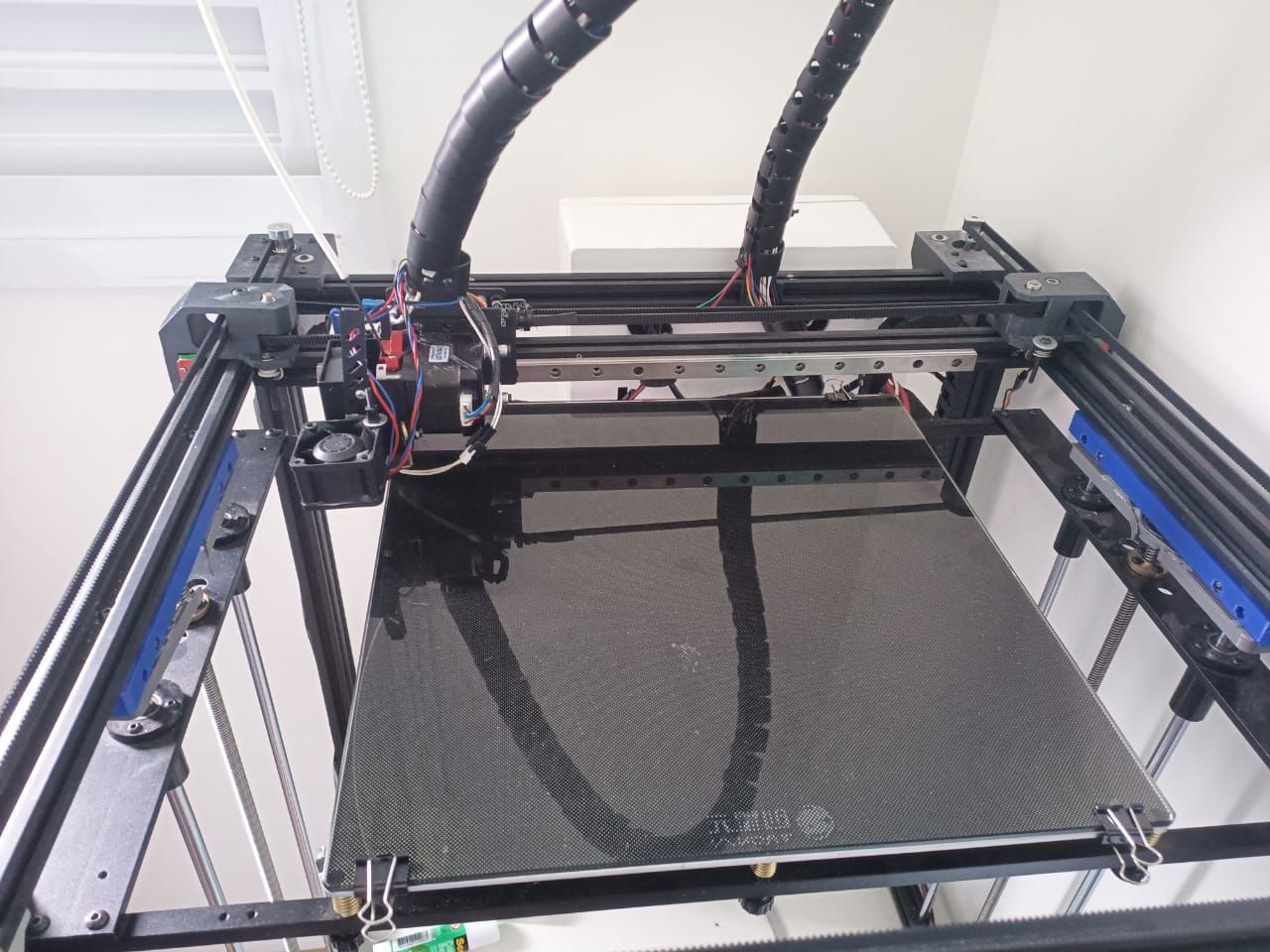

- Is exactly where it homing. Is it possible to change the probe position start manually? same as homing.Picture 1:

HomingPicture 2:

Probing start

-

Bed leveling going to wrong side.posted in General Discussion

Hello,

Despite the printer homing and moves well the bed leveling is not working. The printer seems find the correct start point, however, the head moves to the oposite side, out of the bed. Need help, thanks. Moving from left to rigth, should be the oposite.

Following my config.g:

General preferences

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

M550 P"My Printer" ; set printer name

M669 K1 ; select CoreXY mode; Network

M552 S1 ; enable network

M586 P0 S1 ; enable HTTP

M586 P1 S0 ; disable FTP

M586 P2 S0 ; disable Telnet; Drives

M569 P0 S1 ; physical drive 0 goes forwards

M569 P1 S1 ; physical drive 1 goes forwards

M569 P2 S0 ; physical drive 2 goes backwards

M569 P3 S0 ; physical drive 3 goes backwards

M584 X0 Y1 Z2 E3 ; set drive mapping

M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation

M92 X80.00 Y80.00 Z400.00 E420.00 ; set steps per mm

M566 X900.00 Y900.00 Z60.00 E120.00 ; set maximum instantaneous speed changes (mm/min)

M203 X6000.00 Y6000.00 Z180.00 E1200.00 ; set maximum speeds (mm/min)

M201 X500.00 Y500.00 Z20.00 E250.00 ; set accelerations (mm/s^2)

M906 X800 Y800 Z800 E800 I30 ; set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout; Axis Limits

M208 X10 Y10 Z5 S1 ; set axis minima

M208 X310 Y310 Z350 S0 ; set axis maxima; Endstops

M574 X2 S1 P"!xstop" ; configure active-high endstop for high end on X via pin !xstop

M574 Y2 S1 P"!ystop" ; configure active-high endstop for high end on Y via pin !ystop

M574 Z2 S2 ; configure Z-probe endstop for high end on Z; Z-Probe

M558 P1 C"zprobe.in" H5 F120 T6000 ; set Z probe type to unmodulated and the dive height + speeds

;M558 H30 ;*** Remove this line after delta calibration has been done and new delta parameters have been saved

G31 P500 X180 Y100 Z1.5 ; set Z probe trigger value, offset and trigger height

M557 X40:310 Y40:310 S30 ; define mesh grid; Heaters

M308 S0 P"bedtemp" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin bedtemp

M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0

M307 H0 B1 S1.00 ; enable bang-bang mode for the bed heater and set PWM limit

M140 H0 ; map heated bed to heater 0

M143 H0 S120 ; set temperature limit for heater 0 to 120C

M308 S1 P"e0temp" Y"thermistor" T100000 B4138 ; configure sensor 1 as thermistor on pin e0temp

M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1

M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit

M307 H0 R0.316 C358.3 D8.10 S1.00 V23.6

M143 H1 S280 ; set temperature limit for heater 1 to 280C; Fans

M950 F0 C"fan0" Q500 ; create fan 0 on pin fan0 and set its frequency

M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off

M950 F1 C"fan1" Q500 ; create fan 1 on pin fan1 and set its frequency

M106 P1 S1 H1 T45 ; set fan 1 value. Thermostatic control is turned on; Tools

M563 P0 D0 H1 F0 ; define tool 0

G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets

G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C; Custom settings are not defined

; Miscellaneous

M575 P1 S1 B57600 ; enable support for PanelDue -

RE: Help - Trigger height Bed go down before printposted in General Discussion

UPDATE 2

15/03/2021 13:13:19 G30 S-1

Error: Z probe was not triggered during probing move

15/03/2021 13:12:46 G30 S-1

Error: Z probe was not triggered during probing move

15/03/2021 13:12:06 G92 Z0

15/03/2021 13:11:37 M564 S0 -

RE: Help - Trigger height Bed go down before printposted in General Discussion

Yes, shoud be 1.0 - Let me test here and check if the problem still persists.

ThanksUPDATE:

The problem still persists....

-

Help - Trigger height Bed go down before printposted in General Discussion

Hello,

Despite the use of M564 S0 (https://duet3d.dozuki.com/Wiki/Using_mesh_bed_compensation) my print (final stages of finishing) is lowereing the bed before start print.

What could be wrong?

; Drives

M569 P0 S1 ; physical drive 0 goes forwards

M569 P1 S1 ; physical drive 1 goes forwards

M569 P2 S0 ; physical drive 2 goes backwards

M569 P3 S0 ; physical drive 3 goes forwards

M584 X0 Y1 Z2 E3 ; set drive mapping

M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation

M92 X80.00 Y80.00 Z400.00 E420.00 ; set steps per mm

M566 X900.00 Y900.00 Z60.00 E120.00 ; set maximum instantaneous speed changes (mm/min)

M203 X6000.00 Y6000.00 Z180.00 E1200.00 ; set maximum speeds (mm/min)

M201 X500.00 Y500.00 Z20.00 E250.00 ; set accelerations (mm/s^2)

M906 X800 Y800 Z800 E800 I30 ; set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout; Axis Limits

M208 X30 Y30 Z20 S1 ; set axis minima

M208 X310 Y300 Z360 S0 ; set axis maxima; Endstops

M574 X1 S1 P"!xstop" ; configure active-high endstop for low end on X via pin !xstop

M574 Y1 S1 P"!ystop" ; configure active-high endstop for low end on Y via pin !ystop

M574 Z2 S2 ; configure Z-probe endstop for high end on Z; Z-Probe

M558 P1 C"zprobe.in+zprobe.mod" H5 F120 T6000 ; set Z probe type to unmodulated and the dive height + speeds

G31 P500 X0 Y0 Z500 ; set Z probe trigger value, offset and trigger height

M557 X80:310 Y30:260 S30 ; define mesh grid; Heaters

M308 S0 P"bedtemp" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin bedtemp

M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0

M307 H0 B1 S1.00 ; enable bang-bang mode for the bed heater and set PWM limit

M140 H0 ; map heated bed to heater 0

M143 H0 S120 ; set temperature limit for heater 0 to 120C

M308 S1 P"e0temp" Y"thermistor" T100000 B4138 ; configure sensor 1 as thermistor on pin e0temp

M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1

M307 H1 B0 S1.0 ; disable bang-bang mode for heater and set PWM limit era B0

M143 H1 S280; Fans

M950 F0 C"fan0" Q500 ; create fan 0 on pin fan0 and set its frequency

M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off

M950 F1 C"fan1" Q500 ; create fan 1 on pin fan1 and set its frequency

M106 P1 S1 H1 T45 ; set fan 1 value. Thermostatic control is turned on; Tools

M563 P0 D0 H1 F0 ; define tool 0

G10 P0 X5 Y5 Z10 ; set tool 0 axis offsets

G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C; Custom settings are not defined

; Miscellaneous

M575 P1 S1 B57600 ; enable support for PanelDue

M501

Homeall:

G91 ; relative positioning

G1 H2 Z5 F6000 ; lift Z relative to current position

G1 H1 X-285 Y-285 F1800 ; move quickly to X or Y endstop and stop there (first pass)

G1 H1 X-285 ; home X axis

G1 H1 Y-285 ; home Y axis

G1 X5 Y5 F6000 ; go back a few mm

G1 H1 X-285 F360 ; move slowly to X axis endstop once more (second pass)

G1 H1 Y-285 ; then move slowly to Y axis endstop

G90 ; absolute positioning

G1 X80 Y30 F6000 ; go to first bed probe point and home Z

G30 ; home Z by probing the bed; Uncomment the following lines to lift Z after probing

G91 ; relative positioning

;G1 Z5 F50 ; lift Z relative to current position

;G90 ; absolute positioningThank you!

-

RE: Z endstop switch + Mini height sensor ir boardposted in General Discussion

@jay_s_uk thank you!

Is it possible home with the endstop and leveling with the sensor?

-

RE: Z endstop switch + Mini height sensor ir boardposted in General Discussion

Thanks.

Ok, but in this case the low endstop will stop work. Is ir right?

-

Z endstop switch + Mini height sensor ir boardposted in General Discussion

Hello,

How to combine endstop switch and the mini heigth sensor board as low and high limits?

So far the homing performs well using the low z endstop as reference, but when I start the bed leveling the optical sensor is activate but the bed keeps rising - not triggering.

Board: Duet 2 WiFi (2WiFi)

Firmware: RepRapFirmware for Duet 2 WiFi/Ethernet 3.2.2 (2021-02-11)

Duet WiFi Server Version: 1.25config.g

; Drives

M569 P0 S1 ; physical drive 0 goes forwards

M569 P1 S1 ; physical drive 1 goes forwards

M569 P2 S0 ; physical drive 2 goes backwards

M569 P3 S0 ; physical drive 3 goes forwards

M584 X0 Y1 Z2 E3 ; set drive mapping

M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation

M92 X80.00 Y80.00 Z400.00 E420.00 ; set steps per mm

M566 X900.00 Y900.00 Z60.00 E120.00 ; set maximum instantaneous speed changes (mm/min)

M203 X6000.00 Y6000.00 Z180.00 E1200.00 ; set maximum speeds (mm/min)

M201 X500.00 Y500.00 Z20.00 E250.00 ; set accelerations (mm/s^2)

M906 X800 Y800 Z800 E800 I30 ; set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout; Axis Limits

M208 X5 Y5 Z5 S1 ; set axis minima

M208 X300 Y300 Z360 S0 ; set axis maxima; Endstops

M574 X2 S1 P"!xstop" ; configure active-high endstop for high end on X via pin !xstop

M574 Y2 S1 P"!ystop" ; configure active-high endstop for high end on Y via pin !ystop

M574 Z1 S1 P"!zstop" ; configure active-high endstop for low end on Z via pin !zstop; Z-Probe

M558 P2 C"zprobe.in+zprobe.mod" H5 F120 T6000 ; set Z probe type to unmodulated and the dive height + speeds (p2)

G31 P500 X20 Y20 Z1.0 ; set Z probe trigger value, offset and trigger height (era 500)

M557 X15:215 Y15:195 S20 ; define mesh grid; Heaters

M308 S0 P"bedtemp" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin bedtemp

M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0

M307 H0 B1 S1.00 ; enable bang-bang mode for the bed heater and set PWM limit

M140 H0 ; map heated bed to heater 0

M143 H0 S120 ; set temperature limit for heater 0 to 120C

M308 S1 P"e0temp" Y"thermistor" T100000 B4138 ; configure sensor 1 as thermistor on pin e0temp

M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1

M307 H1 B0 S1.0 ; disable bang-bang mode for heater and set PWM limit era B0

M143 H1 S280; Fans

M950 F0 C"fan0" Q500 ; create fan 0 on pin fan0 and set its frequency

M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off

M950 F1 C"fan1" Q500 ; create fan 1 on pin fan1 and set its frequency

M106 P1 S1 H1 T45 ; set fan 1 value. Thermostatic control is turned on; Tools

M563 P0 D0 H1 F0 ; define tool 0

G10 P0 X5 Y5 Z10 ; set tool 0 axis offsets

G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C; Custom settings are not defined

; Miscellaneous

M575 P1 S1 B57600 ; enable support for PanelDue

M501

homeall.g

G91 ; relative positioning

G1 H2 Z5 F6000 ; lift Z relative to current position

G1 H1 X295 Y295 F1800 ; move quickly to X or Y endstop and stop there (first pass)

G1 H1 X295 ; home X axis

G1 H1 Y295 ; home Y axis

G1 X5 Y5 F6000 ; go back a few mm

G1 H1 X295 F360 ; move slowly to X axis endstop once more (second pass)

G1 H1 Y295 ; then move slowly to Y axis endstop

G1 H1 Z335 F360 ; move Z down stopping at the endstop

G90 ; absolute positioning

G92 Z360 ; set Z position to axis minimum (you may want to adjust this); Uncomment the following lines to lift Z after probing

;G91 ; relative positioning

G1 Z5 F300 ; lift Z relative to current position

;G90 ; absolute positioningMany thanks,

Erick

-

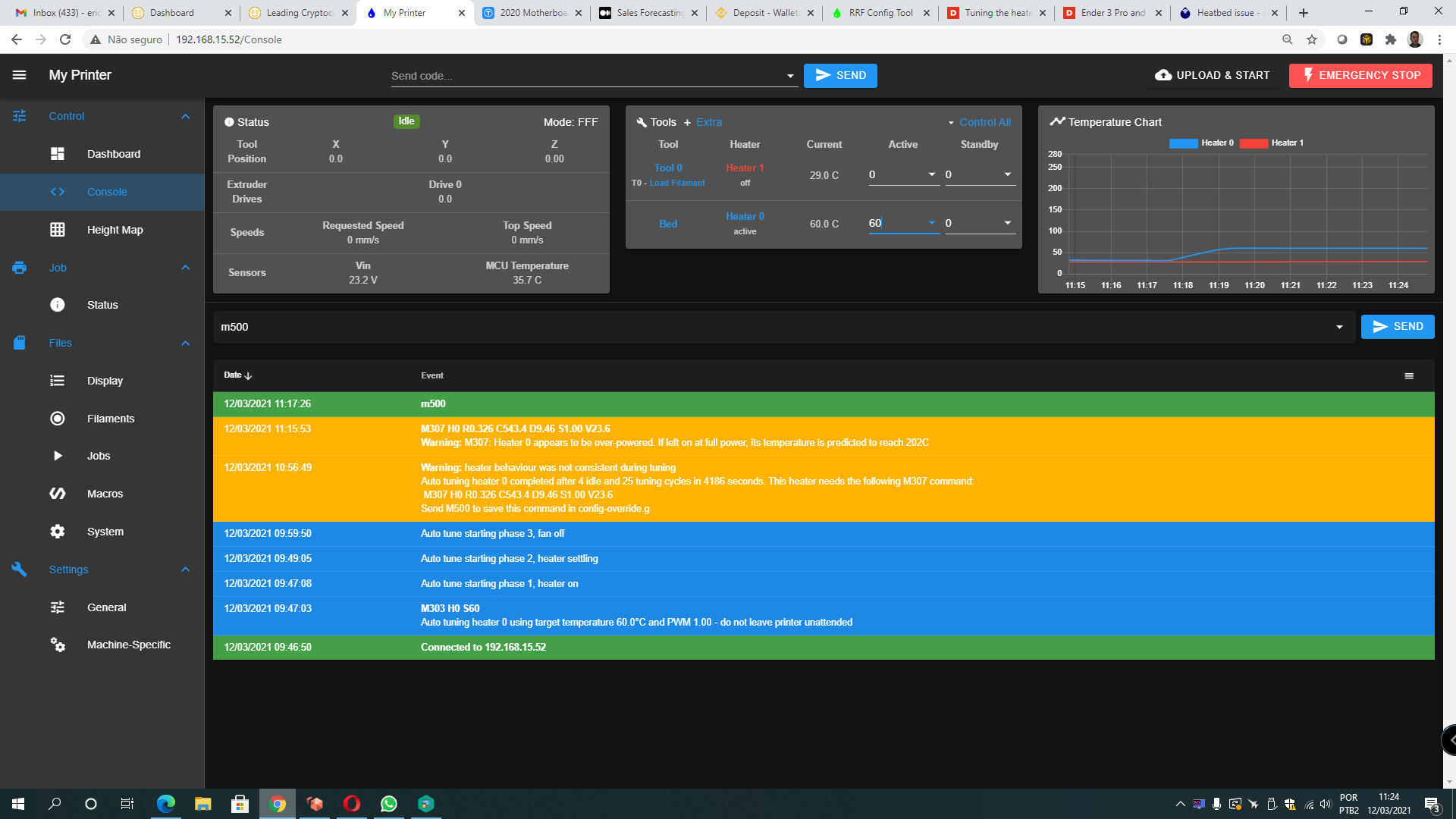

RE: Heatbed issue - Heater 0 fault (...)posted in General Discussion

Thank you!

Warning: heater behaviour was not consistent during tuning

Auto tuning heater 0 completed after 4 idle and 25 tuning cycles in 4186 seconds. This heater needs the following M307 command:

M307 H0 R0.326 C543.4 D9.46 S1.00 V23.6

Send M500 to save this command in config-override.gDespite the error, the results seems ok:

-

Heatbed issue - Heater 0 fault (...)posted in General Discussion

Here we go...

Heater 0 fault: temperature rising much more slowly than the expected 1.6°C/sec - Heatebed.

Its a big heatbed originally from Tronxy X55 printer (30cmx30cm).

Following my config.g heater commands:

; Heaters

M308 S0 P"bedtemp" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin bedtemp

M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0

M307 H0 B1 S1.00 ; enable bang-bang mode for the bed heater and set PWM limit

M140 H0 ; map heated bed to heater 0

M143 H0 S120 ; set temperature limit for heater 0 to 120C

M308 S1 P"e0temp" Y"thermistor" T100000 B4138 ; configure sensor 1 as thermistor on pin e0temp

M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1

M307 H1 B0 S1.0 ; disable bang-bang mode for heater and set PWM limit era B0

M143 H1 S280Its a 600w 24v power source.

Board: Duet 2 WiFi (2WiFi)

Firmware: RepRapFirmware for Duet 2 WiFi/Ethernet 3.2.2 (2021-02-11)

Duet WiFi Server Version: 1.25Thank you very much!

Regards,

Erick

-

RE: Duet Wifi heater issue - board resetposted in 3D Printing General Chat

Nobreak = Computer Uninterruptible Power Supplies (UPS)

-

RE: Duet Wifi heater issue - board resetposted in 3D Printing General Chat

The printer was connected to a nobreak. I changed to a direct socket and...

it works! Thanks