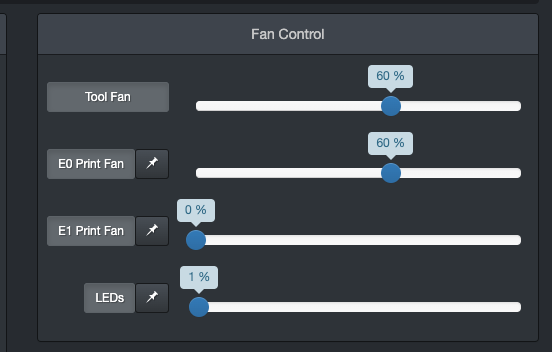

Hi,

I ams seeing a very strange phenomenon. When I combine multiple motors into a single axis, I have the first motor in the group run significantly hotter (measured) than the other motor(s). I first witnessed the issue on the X-axis, but then also on Z.

I am running a Modix3D Big60V3 that I upgraded to separate motor control with a Duex5 expansion. The machine comes stock with 2 X-axis and 4 Z-axis motors but all of them in series (or series/parallel on Z). In order to gain better control, accuracy and higher speeds I rewired all of them on to separate channels and developed a new config matching the physical layout. Tried to be diligent to read the GCODE pages on what order has to be followed when setting up the various parameters.

Attached the current config.g (work in progress).

Summary of changes:

- Broke out all motors on separate channels

- Eliminated the Bed PID controller and leveraged the K-type sensor and SSR to control the bed via Duet

- High power LED lighting via heater 6 on the Duex5

- Upgraded power supply

- Tuned extraction, temperatures, speed, acceleration & jerk, frequency, ...

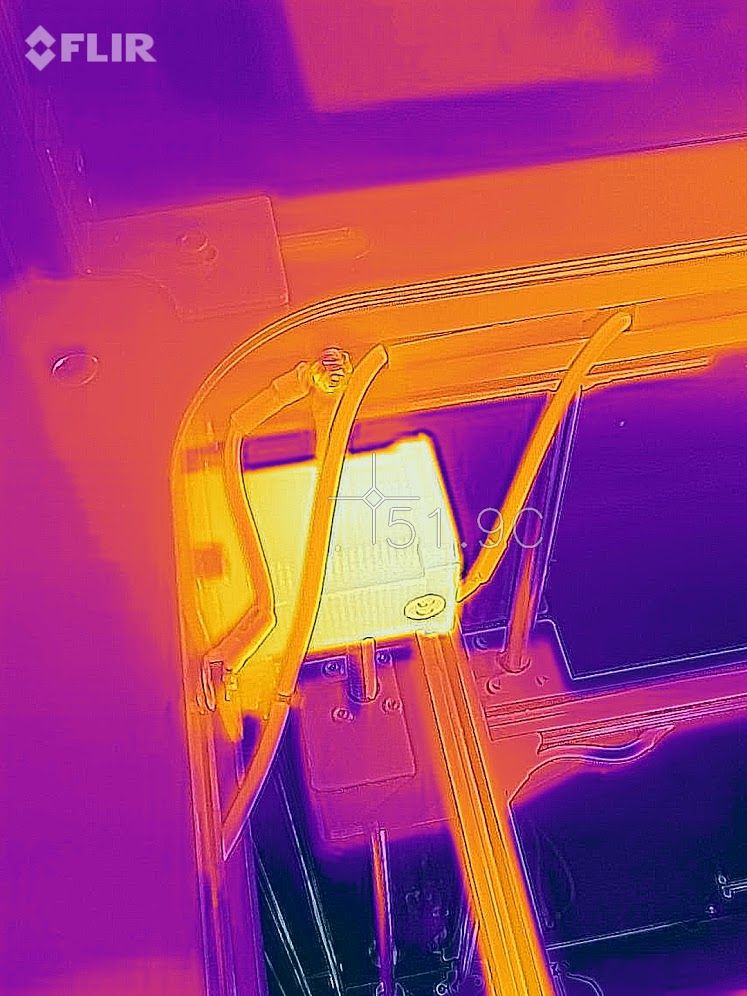

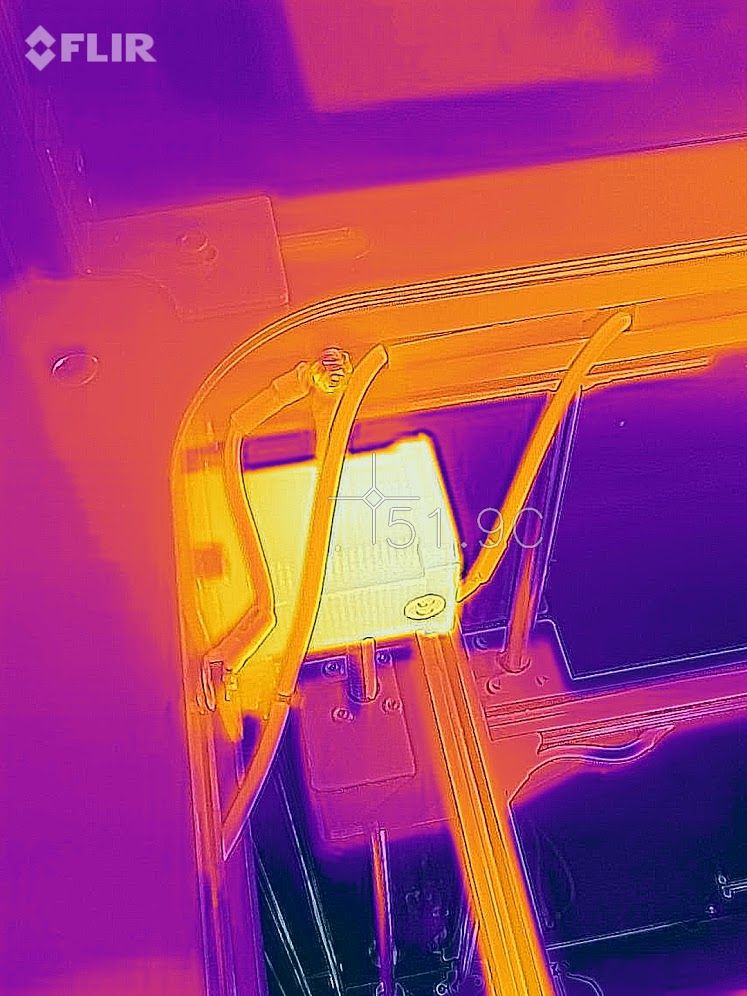

For both the X (X1 & X2) and Z axis (ZL1, ZL2, ZR1 & ZR2) I see as much as 15-20C temperature difference between the first motor in the group (X1 & ZL1) (hotter) and the rest of the group. The first motors are on the Duet2 Wifi and the others are all on the Duex5.

The Duet2 Wifi and the Duex are connected (bridged) at their power connectors via 10AWG silicone wire to ensure stable voltage.

I am setting up the motor groups first, then later the amperage and the likes of steps...

When running, the first motors also have higher torque compared to the rest. When tuning for stall detection, it is always the Duex5 attached motors (X2, ZL2, ZR1 & ZR2) that stall early.

These are all 2000mA motors, originally setup to 1800mA but now setup to run at 2000mA.

I am also attaching two heat camera shots that show the difference between X1 and X2 after approx 12 hours of printing inside the enclosure with a filter-fan pulling out the warm air (in this case testing with PLA - would recycle for the likes of ABS).

Can't figure out what I am missing. I have not yet upgraded to 3.X as I wanted to get everything up and running and tuned first before introducing another significant change.

Diagnostics:

M122

=== Diagnostics ===

RepRapFirmware for Duet 2 WiFi/Ethernet version 2.05 running on Duet WiFi 1.02 or later + DueX5

Board ID: XXXXX-XXXXX-XXXXX-XXXXX-XXXXX-XXXXX

Used output buffers: 3 of 24 (14 max)

=== RTOS ===

Static ram: 25712

Dynamic ram: 94140 of which 0 recycled

Exception stack ram used: 472

Never used ram: 10748

Tasks: NETWORK(ready,628) HEAT(blocked,1176) DUEX(suspended,160) MAIN(running,1300) IDLE(ready,160)

Owned mutexes:

=== Platform ===

Last reset 04:58:20 ago, cause: software

Last software reset at 2020-06-08 16:06, reason: User, spinning module GCodes, available RAM 10732 bytes (slot 0)

Software reset code 0x0003 HFSR 0x00000000 CFSR 0x00000000 ICSR 0x0441f000 BFAR 0xe000ed38 SP 0xffffffff Task 0x4e49414d

Error status: 0

Free file entries: 8

SD card 0 detected, interface speed: 20.0MBytes/sec

SD card longest block write time: 48.4ms, max retries 0

MCU temperature: min 37.6, current 40.2, max 41.2

Supply voltage: min 23.8, current 23.9, max 24.2, under voltage events: 0, over voltage events: 0, power good: yes

Driver 0: ok, SG min/max 246/1023

Driver 1: ok, SG min/max 48/1023

Driver 2: ok, SG min/max 74/1023

Driver 3: ok, SG min/max 0/1023

Driver 4: standstill, SG min/max not available

Driver 5: ok, SG min/max 81/1023

Driver 6: ok, SG min/max 141/1023

Driver 7: ok, SG min/max 121/1023

Driver 8: ok, SG min/max 140/1023

Driver 9: standstill, SG min/max not available

Date/time: 2020-06-08 21:04:25

Cache data hit count 4294967295

Slowest loop: 75.47ms; fastest: 0.07ms

I2C nak errors 0, send timeouts 0, receive timeouts 0, finishTimeouts 0, resets 0

=== Move ===

Hiccups: 0, FreeDm: 153, MinFreeDm: 103, MaxWait: 1753764ms

Bed compensation in use: mesh, comp offset -0.044

=== DDARing ===

Scheduled moves: 28571, completed moves: 28552, StepErrors: 0, LaErrors: 0, Underruns: 0, 0

=== Heat ===

Bed heaters = 0 -1 -1 -1, chamberHeaters = -1 -1

Heater 0 is on, I-accum = 0.0

Heater 1 is on, I-accum = 0.7

=== GCodes ===

Segments left: 1

Stack records: 2 allocated, 0 in use

Movement lock held by null

http is idle in state(s) 0

telnet is idle in state(s) 0

file is doing "G1 X188.375 Y199.424 E0.10137" in state(s) 0

serial is idle in state(s) 0

aux is idle in state(s) 0

daemon is idle in state(s) 0

queue is idle in state(s) 0

autopause is idle in state(s) 0

Code queue is empty.

=== Network ===

Slowest loop: 87.08ms; fastest: 0.00ms

Responder states: HTTP(0) HTTP(0) HTTP(0) HTTP(0) FTP(0) Telnet(0) Telnet(0)

HTTP sessions: 1 of 8

- WiFi -

Network state is running

WiFi module is connected to access point

Failed messages: pending 0, notready 0, noresp 0

WiFi firmware version 1.23

WiFi MAC address xx:xx:xx:xx:xx:xx

WiFi Vcc 3.37, reset reason Turned on by main processor

WiFi flash size 4194304, free heap 24416

WiFi IP address 192.168.xx.xx

WiFi signal strength -48dBm, reconnections 0, sleep mode modem

Socket states: 0 0 0 0 0 0 0 0

=== Filament sensors ===

Extruder 0 sensor: ok

Extruder 1 sensor: ok

config.g:

; Generated by Modix - 1.3

; Modified by fxstein 2020-05-31

;

; Changelog:

; Duet2Wifi Only:

; - Converted bed heater to Duet controller via k-coupler daughter board

; - Force join wireless network to support hidden SSID

; - Increased extruder max speed from 1200mm/min to 12000mm/min for quicker retractions

; - Increased extruder max acceleration from 250mm/s^2 to 8000mm/s^2 for quicker retractions

; - Increased extruder max instantaneous speed change from 120mm/min to 3000mm/min for quicker retractions

; Quicker retractions aid in elimination of Volcano stringing

; - Equalize X and Y max instantaneous speed change from 300/500 to 300/300 to avoid inner wall separation during high infill speeds

; - Increase X and Y max speed to 12000mm/min or 200mm/s

; - Increase Z max speed from 200mm/min to 300mm/min or 5mm/s for quicker z-hops

; - Recalibrated extruder steps per mm

;

; Duet2Wifi + Duex5 (work in progress)

; - Split x-axis to individual drives 0+5

; - Setup stall control for both X and Y axis - now with individual motor control possible

; - Increase max speed for X & Y to 18000 or 300mm/s

; - Increase max acceleration for X & Y to 2000 mm/s^2

; - Increase max travel acceleration to 2000 mm/s^2

; - Increase X & Y max instantaneous speed change to 400 mm/min

; - Add Duet and Duex PWM fans

; - Switch permanent cooling tool cooling fans to temperature control

; - Increase max amperage for X & Y motors to 2000mA

; - Increase acceleration for X & Y to 4000mm/s^2 for testing

;

; Modix Big-60, Dual Printhead

; General preferences

G90 ; Send absolute coordinates...

M83 ; ...but relative extruder moves

; Network

M550 P"BIG60V3" ; Set machine name

; See secrets.g for setting passwords and sensitive information

; Set secrets and passwords

M98 P"secrets.g"

; Logging

M929 P"eventlog.txt" S1 ; Start logging to file eventlog.txt for e.g. stalls and other significant events

; Finish network setup

M552 P"IoT Network" S1 ; Enable network and force join (if hidden) network

M586 P0 S1 ; Enable HTTP

M586 P1 S0 ; Disable FTP

M586 P2 S0 ; Disable Telnet

; Drives

M569 P0 S1 ; Physical drive 0 goes forwards. X-Axis. X1

M569 P1 S0 ; Physical drive 1 goes backwards. Y-Axis.

M569 P2 S0 ; Physical drive 2 goes backwards. Z-Axis. ZL1

M569 P3 S1 ; Physical drive 3 goes forwards. E0-Extruder.

M569 P4 S0 ; Physical drive 4 goes backwards. E1-Extruder.

; Duex5 expansion must come before M350 and M906

M569 P5 S0 ; Physical drive 5 goes backwards. X-Axis. X2

M569 P6 S0 ; Physical drive 6 goes backwards. Z-Axis. ZL2

M569 P7 S0 ; Physical drive 7 goes backwards. Z-Axis. ZR1

M569 P8 S0 ; Physical drive 8 goes backwards. Z-Axis. ZR2

; Setup combined axis

M584 X0:5 ; combine drive 0 (X1) and 5 (X2) for X-Axis

M584 Z2:6:7:8 ; combine drives 2 (ZL1), 6 (ZL2), 7 (ZR1), 8(ZR2) for Z-Axis

; Continue Drives setup

M350 X16 Y16 Z16 E16 I1 ; Configure microstepping with interpolation

M92 X100 Y100 Z2000 E399 ; Set steps per mm

M906 X2000 Y2000 Z1800 E1000 I30 ; Set motor currents (mA) and motor idle factor in %

M84 S30 ; Set idle timeout

;M915 X Y S5 H200 F1 R2 ; Stall detection. For X & Y axis. Pause print

;M915 X Y S20 H200 F0 R1 ; Stall detection. For X & Y axis. Just log it.

M915 X S15 H200 F0 R2 ; Stall detection. For X axis. Pause print

M915 Y S17 H200 F0 R2 ; Stall detection. For Y axis. Pause print

M915 Z S20 H200 F0 R2 ; Stall detection. For Z axis. Pause print

; Speed Settings

M201 X3000 Y3000 Z150 E8000 ; Set maximum accelerations (mm/s^2) *

M203 X18000 Y18000 Z900 E12000 ; Set maximum speeds (mm/min) *

M204 P1000 T2000 ; Set print and travel accelerations (mm/s^2) *

M566 X600 Y600 Z30 E3000 ; Set maximum instantaneous speed changes (mm/min) *

M593 F30 ; Cancel ringing at 30Hz *

; Axis Limits

M208 X0 Y0 Z0 S1 ; Set axis minima

M208 X600 Y600 Z660 S0 ; Set axis maxima

; Endstops

M574 X1 Y2 S1 ; Set active low and disabled endstops

; Z-Probe

M574 Z2 S2 ; Set endstops controlled by probe

;M307 H3 A-1 C-1 D-1 ; Disable heater on PWM channel for BLTouch

M307 H7 A-1 C-1 D-1 ; Disable heater on PWM channel for BLTouch via PWM5 (Heater 7) on Duex5

;M558 P9 H5 F120 T6000 A1 R0.7 ; Set Z probe type to bltouch and the dive height + speeds

M558 P9 H2 F120 T18000 A1 R0 ; Set Z probe type to bltouch and the dive height + speeds

G31 P500 X-13 Y-18 Z2.546 ; Set Z probe trigger value, offset and trigger height(Z-Offset)

M557 X0:580 Y0:580 P8:8 ; Define mesh grid. 64 Points

M376 H10 ; Height (mm) over which to taper off the bed compensation

; Z leadscrew positions - mainly when used with Duex5 expansion and individual z motor drivers

M671 X0:0:600:600 Y0:600:0:600 ; Z leadscrews are approx at (0,0), (0,600), (600,0) and (600,600)

; Heaters

;Bed:

;M140 H-1 ; To disable heated bed

M305 P0 X150 ; Add K-type thermocoupler for bed heater

M140 H0 ; Enable heated bed

M143 H0 S120 ; Set temperature limit for heater 0 to 120C

;M307 H0 A# C# D# V# S1.0 B0 ; PID calibration template

M307 H0 A19 C26 D4 V24 S1.0 B0 ; PID calibration from macro run

;E0:

M305 P1 T100000 B4725 C7.060000e-8 R4700 ; Set thermistor + ADC parameters for heater 1

M143 H1 S285 ; Set temperature limit for heater 1 to 285C

;M307 H1 A# C# D# V# S1.0 B0 ; PID calibration template

;M307 H1 A19 C26 D4 V24 S1.0 B0 ; PID calibration from macro run

;E1:

M305 P2 T100000 B4725 C7.060000e-8 R4700 ; Set thermistor + ADC parameters for heater 2

M143 H2 S285 ; Set temperature limit for heater 2 to 285C

;M307 H2 A# C# D# V# S1.0 B0 ; PID calibration template

;M307 H2 A19 C26 D4 V24 S1.0 B0 ; PID calibration from macro run

; Fans

M106 P0 S0 I0 F500 H-1 C"E0 Print Fan" ; Set fan 0 value, PWM signal inversion and frequency. Thermostatic control is turned off

M106 P1 S0 I0 F500 H-1 C"E1 Print Fan" ; Set fan 1 value, PWM signal inversion and frequency. Thermostatic control is turned off

; Duex5 expansion

M106 P2 T35:65 B10 H100:101:102 C"Duet Fan" ; Thermostatic fan to cool the Duet2

M106 P3 T35:65 B10 H100:101:102 C"Duex Fan" ; Thermostatic fan to cool the Duex5

M106 P4 T40:50 B10 H1 C"E0 Cool Fan" ; Thermostatic fan for cool side of E0 only when tool is heated

M106 P5 T40:50 B10 H2 C"E1 Cool Fan" ; Thermostatic fan for cool side of E1 only when tool is heated

; Tools

M563 P0 S"E0" D0 H1 F0 ; Define tool 0

G10 P0 X0 Y0 Z0 ; Set tool 0 axis offsets

G10 P0 R190 S210 ; Set initial tool 0 active and standby temperatures to 0C

M563 P1 S"E1" D1 H2 F1 ; Define tool 1

G10 P1 X0 Y51.5 Z0 ; Set tool 1 axis offsets

G10 P1 R190 S210 ; Set initial tool 1 active and standby temperatures to 0C

; Automatic power saving

M911 S22.5 R29.0 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; Set voltage thresholds and actions to run on power loss. Power Failure Pause

; LED Lights - Duex5

M307 H6 A-1 C-1 D-1 ; Use heater 5 for LED lights on Duex5

M42 P6 S1.0 ; Set full bright

; Custom settings

;M564 H0 S0 ; Negative movements are allowed

G29 S1 ; Load the height map from file and activate bed compensation

;M915 P1 S4 H400 F1 R2 ; Stall detection. For Y motor. Pause print moved to drive section

M591 D0 P1 C3 S1 ; Regular filament sensor for E0

M591 D1 P1 C4 S1 ; Regular filament sensor for E1

;M581 E2 S1 T0 C0 ; Optional external switch for emergency stop

;M593 F40 ; Cancel ringing at 40Hz

;M592 D0 A0.01 B0.0005 L0.25 ; The amount of extrusion requested is multiplied by (1 + min(L, A*v + B*v^2)) where v is the requested extrusion speed (calculated from the actual speed at which the move will take place) in mm/sec.

;M592 D1 A0.01 B0.0005 L0.25 ; The amount of extrusion requested is multiplied by (1 + min(L, A*v + B*v^2)) where v is the requested extrusion speed (calculated from the actual speed at which the move will take place) in mm/sec.

X1 heat signature (51.9C):

X2 heat signature (38.1C):

I have probably missed some important information - please let me know if I did.

Your help is very much appreciated.