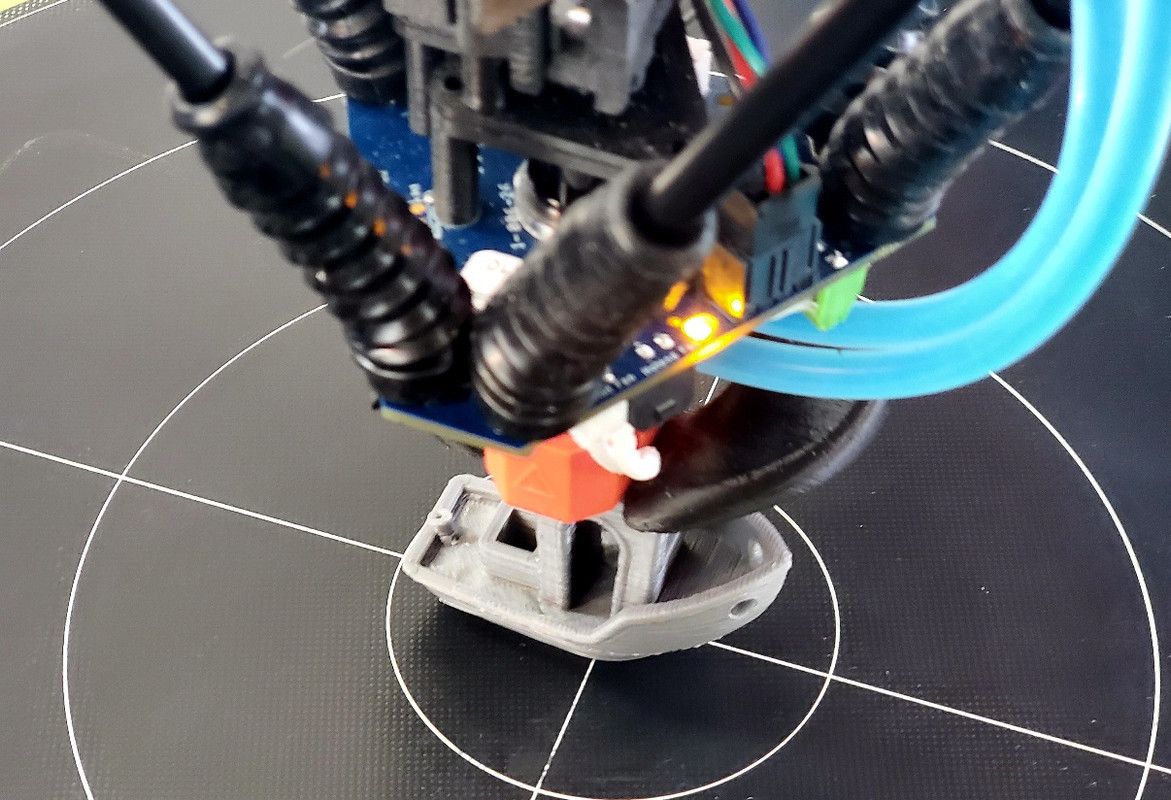

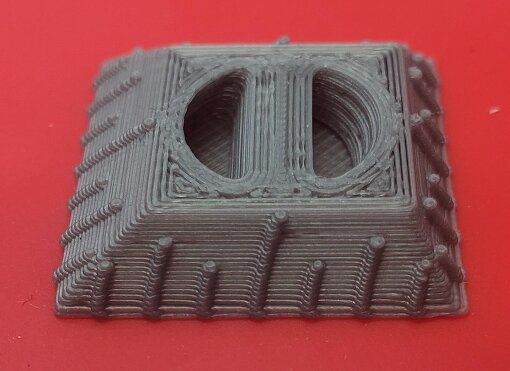

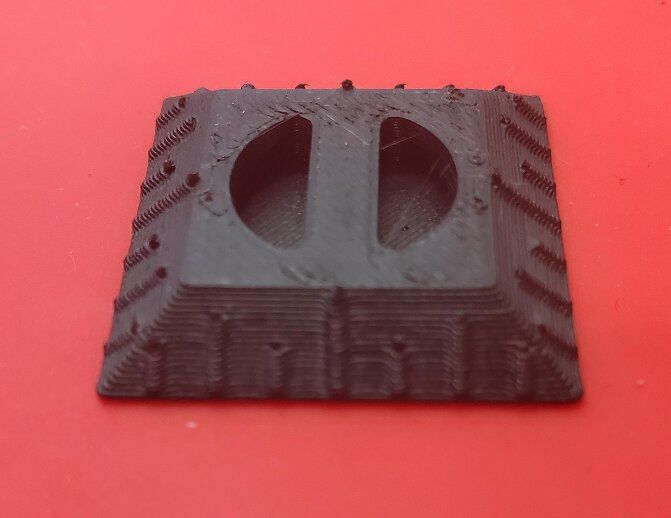

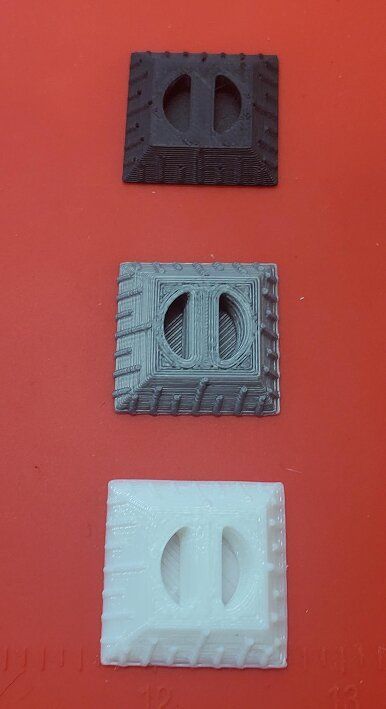

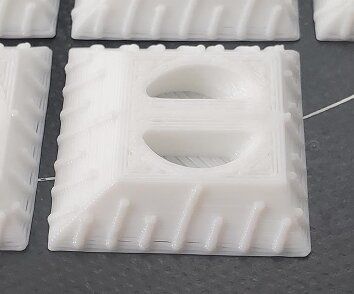

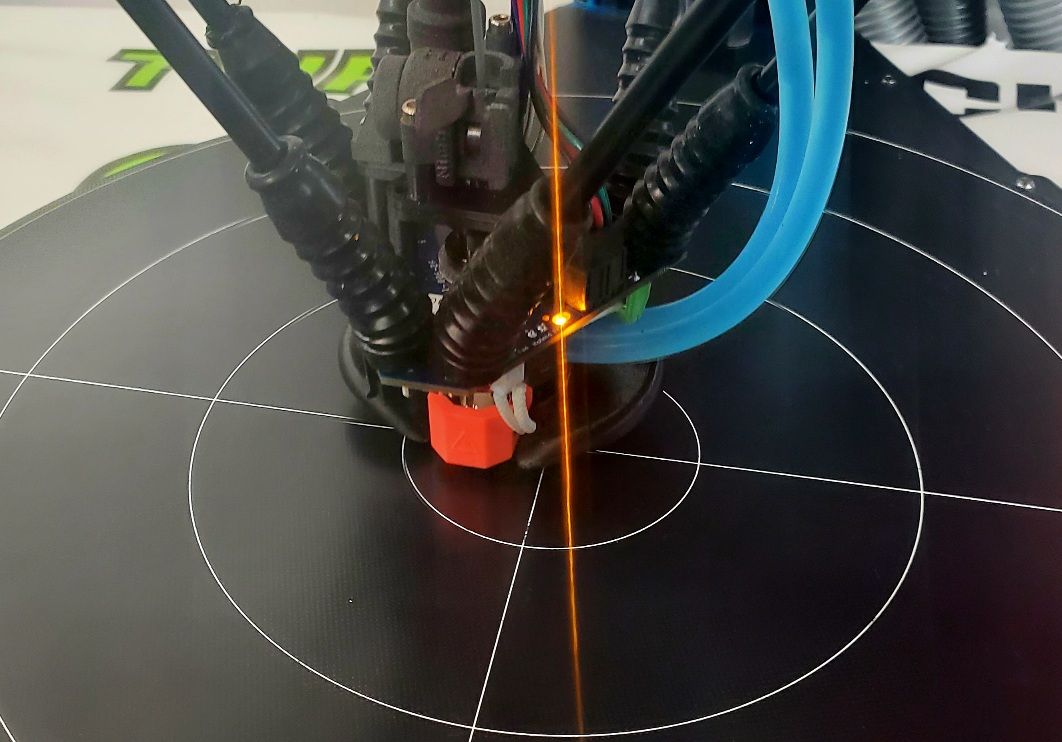

I finally did my first test print on my upgraded Anycubic Predator.

It still needs tons of tweaking, but I'm beyond excited that it even printed first try.

![20230508-074610[1].jpg](/assets/uploads/files/1683555724131-20230508-074610-1.jpg)

I was pretty intimidated to do my own home brew machine, but I love the predator footprint, but hated everything else. (Hotend, Control system, Delta Arms, cooling, etc.) So I decided to jump in the pool and try.

I want to first say thank you to the people on the forum that answered my questions. I was breaking lot of new ground here and was pretty intimidated, so thanks for getting me up and running when I got stuck.

Here is what I put together. Hayden Magarms, Zesty NImble V3 extruder, Duet3 mini 5+ wifi, liquid cooled hotend, Thermaltake liquid cooling system, Smart effector, PanelDue, relays controlling pump, and external fan controllers. I custom designed the cooling fan system based on a CFD duct system I saw on Youtube.

I am so jazzed to see it move. It felt like the eternal project and I hit a lot of roadblocks, but at least its running.

I realize now that I need to write an effective pre and post gcode, but that will be my next hurdle.

Anyway, just saying thank you, and can't wait to see this thing perform once I have the enclosure and gcode worked out.

Cheers,

Gumby