@FelixH Hello, I don't use pendant but I have noticed that sometimes when I am moving the machine on the Y axis it moves a little on the positive X axis and vice versa

Posts made by jhonf441

-

RE: CNC style Pendantposted in Hardware wishlist

-

can you suggest kinematics for multiple z axis?posted in General Discussion

Hi, I have a XY core printer with 600mm x 600mm printing area, currently the bed goes up and down, but since the bed is heavy I want to use a real self-leveling and I wanted to know what kinematic couplings they recommend or what they think of an XY core that up and down with the fixed bed.

I am going to use independent motors with linear guide

thanks in advance.

-

Tool changer question.posted in General Discussion

Hello, I was wondering if it is possible to have a tool changer?, but to have a row of tools in the back and another in the front.

-

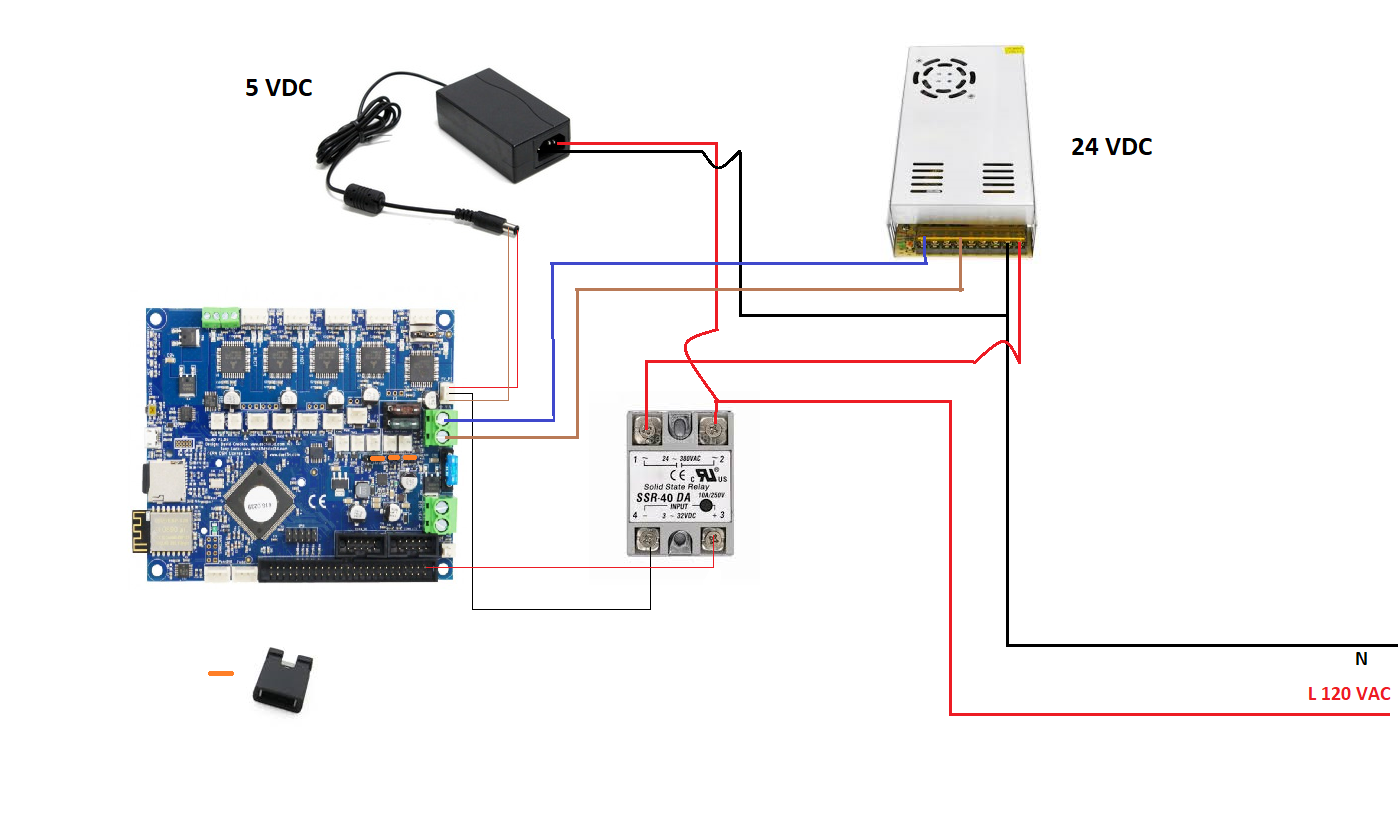

RE: Automatic shutdown without ATXposted in Duet Hardware and wiring

hi, i have something like this.

Duet and panelDue remain on after main power is turned off

-

Strange behavior I don't understandposted in General Discussion

i was trying to print and wanted to use micro steps to help adherence but i have noticed and this is not the first time the following

For example, the first layer and the current one had a height of 0.25mm and I wanted to help with micro steps by decreasing the separation between the bed and the extruder, but since there is no significant change, I reached -0.24mm of micro step and it turns out that the indicated height is z = 0.5mm, what am I missing?

attached image

I am using duet wifi with RepRapfirware 2.04, but I have seen that behavior in other firmware versions

-

RE: Printing Clay at the Resolution of Plasticsposted in My Duet controlled machine

@tom_lauerman hello I would like to know more about the correct calculations to take into account that a 50 mm filament is pushed through a nozzle of approximately 1 mm, how is the calculation?

-

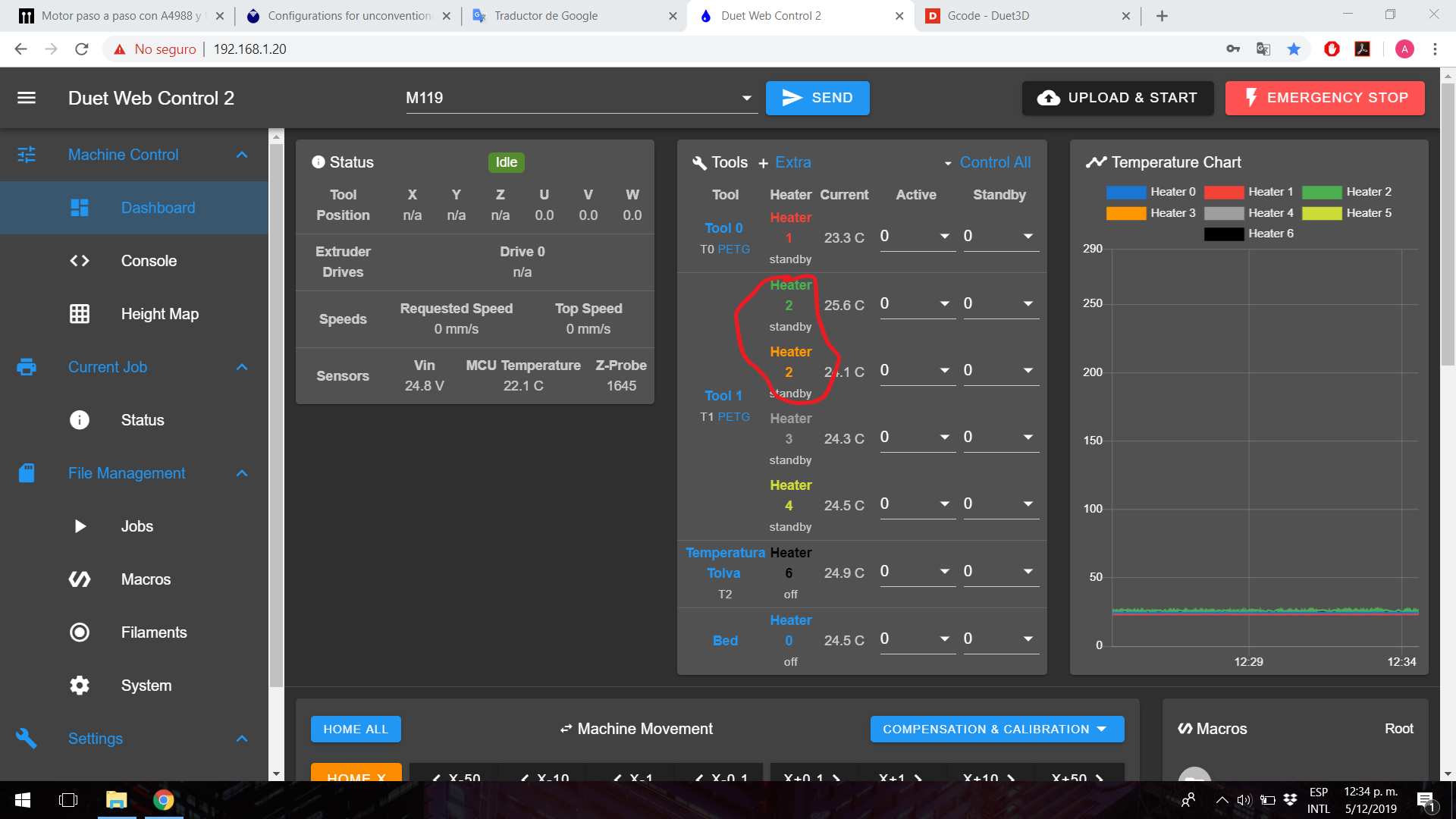

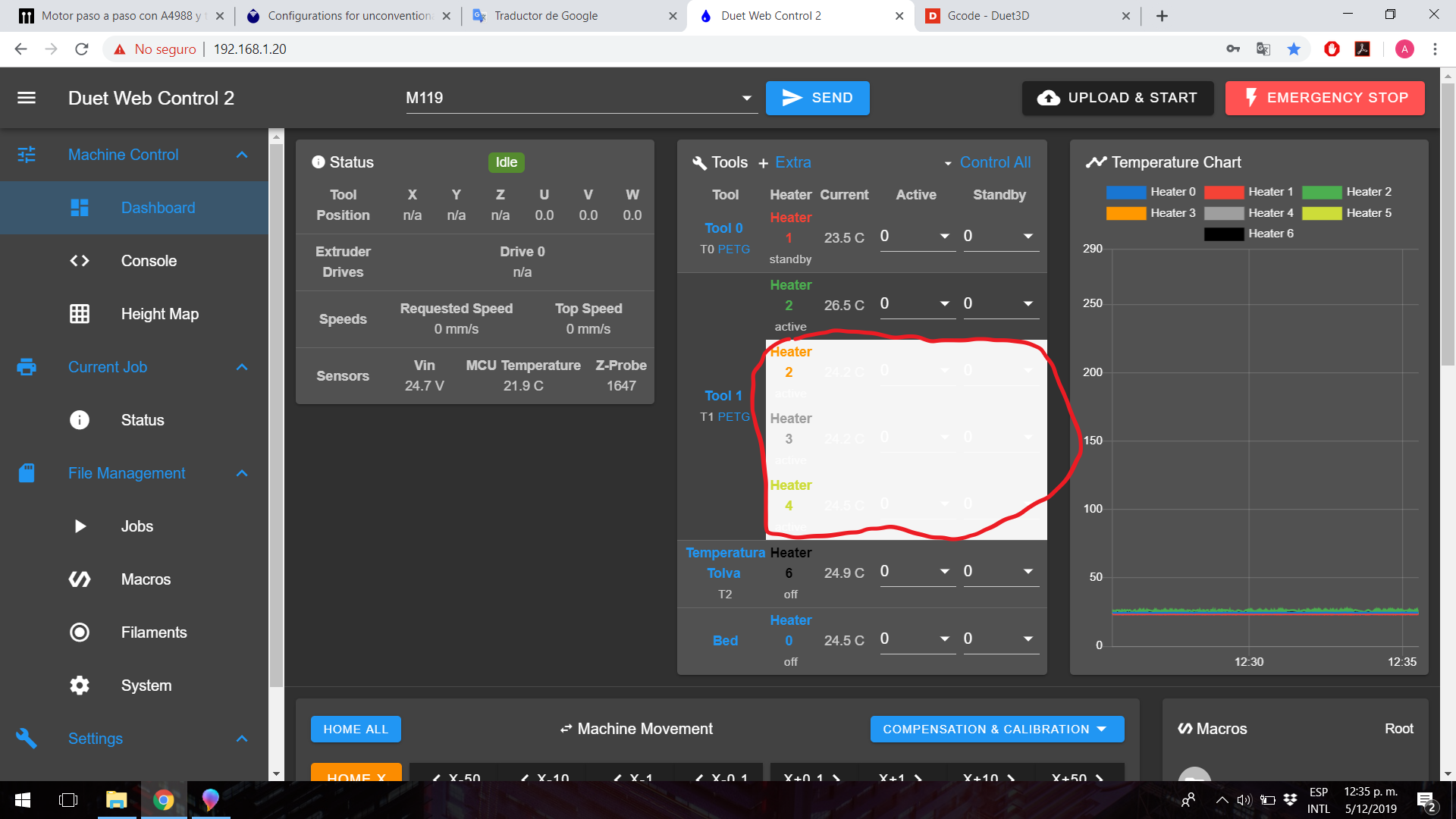

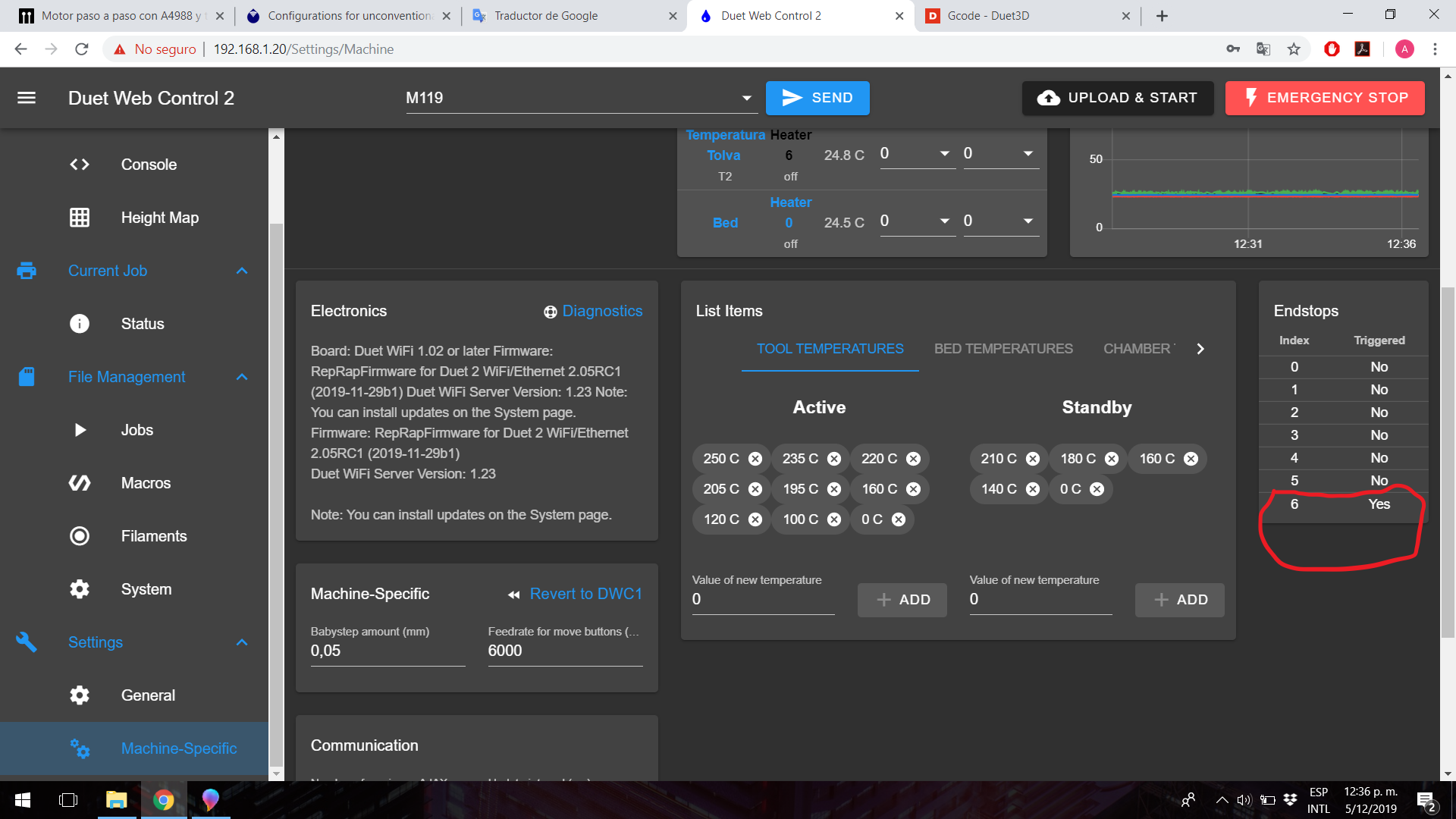

7-inch DWC and PanelDue anomaliesposted in Duet Web Control

I have the following configuration

Duet Web Control Version 2.0.4

FIRMWARE_NAME: RepRapFirmware for Duet 2 WiFi/Ethernet FIRMWARE_VERSION: 2.05RC1 ELECTRONICS: Duet WiFi 1.02 or later FIRMWARE_DATE: 2019-11-29b1; Configuration file for Duet WiFi (firmware version 1.21) ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v2 on Fri Mar 15 2019 23:53:22 GMT-0500 (hora estándar de Colombia) ; General preferences G90 ; Send absolute coordinates... M83 ; ...but relative extruder moves G21 ; G21 establece las unidades en mm / G20 establece las unidades en pulgadas ; kinematics type M669 K1 ; Select CoreXY mode ; Network M552 S1 ; Enable network M586 P0 S1 ; Enable HTTP M586 P1 S0 ; Disable FTP M586 P2 S0 ; Disable Telnet ; Drives M569 P5 S1 ; Drive 5 goes forwards axis X M569 P6 S0 ; Drive 6 goes forwards axis Y M569 P7 S1 ; Drive 7 goes forwards Extrusor M569 P8 S1 ; Drive 8 goes forwards Axis z M569 P9 S1 ; Drive 9 goes forwards Axis Z M569 P10 S1 ; Drive 10 goes forwards axis z M569 P11 S1 ; Drive 11 goes forwards axis z M584 X5 Y7 Z8:9:10:11 U9 V10 W11 E6 ; Apply custom drive mapping and four Z motors connected to driver outputs 8, 9, 10 and 11 Z M350 X16 Y16 Z16:16:16:16 I1 ; Configure microstepping with interpolation M350 E2 M350 U16 V16 W16 I1 M92 X80 Y80 Z400:400:400:400 E311;E2487 E155 E311 ; Set steps per mm M92 U400 V400 W400 M566 X900 Y900 Z30:30:30:30 E20 ; Set maximum instantaneous speed changes (mm/min) M566 U30 V30 W30 M203 X18000 Y18000 Z200:200:200:200 E600 ;E1500 ; Set maximum speeds (mm/min) M203 U200 V200 W200 M201 X4000 Y4000 Z100:100:100:100 E100 ;E1000 ; Set accelerations (mm/s^2) M201 U100 V100 W100 M84 S30 ; Set idle timeout ; define posiciones de los tornillos M671 X-321:-321:317:317 Y-144:184:184:-144 S4 ;agregar parametro F2 ; Axis Limits M208 X-267 Y-245 Z0 S1 ; Set axis minima M208 U0 V0 W0 S1 M208 X267 Y230 Z406 S0 ; Set axis maxima M208 U406 V406 W406 S0 ; Endstops Makerbot Mechanical Endstop v1.2 M574 X1 Y1 S0 ; S_ endstop-type: 0 = active low, 1 = active high, 2 = slice-direction-probe, 3 = motor load detection ; MicroSiwch ;M574 Z1 U1 V1 W1 S1 M574 Z1 U1 V1 W1 S1 ; Z-Probe ;M574 Z1 S2 ; Set endstops controlled by probe ;M307 H3 A-1 C-1 D-1 ; Disable heater on PWM channel for BLTouch ;M558 P9 H5 F120 T18000 A5 R0.2 B1 ;S0.03 R0.75 Set Z probe type to bltouch and the dive height + speeds ;G31 P25 X0 Y33 Z1.13 ; Set Z probe trigger value, offset and trigger height ;M557 X-265:265 Y-207:245 S53:113 ;Define mesh grid ; Heaters M305 P0 T100000 B4138 R4700 ; Set thermistor + ADC parameters for heater 0 M143 H0 S120 ; Set temperature limit for heater 0 to 120C M305 P1 T100000 B4725 C7.060000e-8 R4700 ; Set thermistor + ADC parameters for heater 1 M143 H1 S250 ; Set temperature limit for heater 1 to 250C M912 P0 S-6.5 ; ajuste el calentador 1 ajuste electronico del monitor de temperatura en grados centigrados ;m571 consultar ;Extrusora de tornillo M305 P2 T100000 B4100 R4700 ; Set thermistor + ADC parameters for heater 1 M143 H2 S250 ; Set temperature limit for heater 1 to 250C M305 P3 T100000 B4100 R4700 ; Set thermistor + ADC parameters for heater 1 M143 H3 S250 ; Set temperature limit for heater 1 to 250C M305 P4 T100000 B4100 R4700 ; Set thermistor + ADC parameters for heater 1 M143 H4 S250 ; Set temperature limit for heater 1 to 250C M305 P5 T100000 B4100 R4700 ; Set thermistor + ADC parameters for heater 1 M143 H5 S250 ; Set temperature limit for heater 1 to 250C M305 P6 T100000 B4100 R4700 ; Set thermistor + ADC parameters for heater 1 M143 H6 S250 ; Set temperature limit for heater 1 to 250C ; Fans ;M106 P0 I0; invertir PWM del ventilador 1 M106 P0 S0 F500 H-1 ; Set fan 0 value, PWM signal inversion and frequency. Thermostatic control is turned off M106 P1 S0 I0 F500 H-1 ; Set fan 1 value, PWM signal inversion and frequency. Thermostatic control is turned on M106 P2 S127 I1 F500 H-1 ; Set fan 2 value, PWM signal inversion and frequency. Thermostatic control is turned off ; Tools M563 P0 D0 H1 S"Extrusora volcano" ; Define tool 0 G10 P0 X0 Y0 Z0 ; Set tool 0 axis offsets G10 P0 R0 S0 M563 P1 D0 H2:3:4:5 S"Extrusora de Tornillo" G10 P1 X0 Y0 Z0 ; Set tool 0 axis offsets G10 P1 R0:0:0:0 S0:0:0:0 ; Set initial tool 0 active and standby temperatures to 0C M563 P2 H6 S"Temperatura Tolva" G10 P2 X0 Y0 Z0 ; Set tool 0 axis offsets G10 P2 R0 S0 ; Avance de presión unidad extrusora ;M572 D0 S0.06 ; Automatic saving after power loss is not enabled M911 S21 R23 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; Set voltage thresholds and actions to run on power loss ; Custom settings are not configured ; activar bltouch ;M280 P3 S160 I1 ; Alarm Release and Push-Pin UP ;M280 P3 S140 I1; modo 5v logic zmin M929 P"eventlog.txt" S1; iniciar el registro en el archivo eventlog.txt ;LEDs ;M307 H4 A-1 C-1 D-1 ;M307 H5 A-1 C-1 D-1 ;M307 H6 A-1 C-1 D-1 ;M307 H7 A-1 C-1 D-1 ; GUI config ;M404 N1.75 ; display for users nominal-filament-diameter/width of setup, in this case 1.75mm ; seleccionar herramienta T0 ; Load any saved values from last use, that were saved with M500 command M501 ; Ensure that M501 is at the end of config.g in order for the values in config-override.g to be loaded at startup ; config done ;M291 P"Config done" S2 T3 ; send message ;M300 S300 P1000 ; beep ;M292 ; Hide the message M80The PanelDue the heaters overlap with the macros, it would be better to leave the macros by default only available in the macro button.

the DWC sometimes the temperatures are not plotted and when I activate the tool T1 in dark mode it turns white, and the heater is repeated.

according to me I don't have a probe, but an activated one appears in the interface

It seems that the M80 command is generating a problem, after turning it off and on (M80) it stays in a state where it cannot be used, the same happens if it is sent from the console, it stays charging and does not receive any other command .

-

RE: how to move a stepper motor constantly?posted in General Discussion

@Danal said in how to move a stepper motor constantly?:

Not at present. There is only one movement queue (with some exotic exceptions), and G0 G1 with multiple axis perform "coordinated linear motion", ensuring that all axis arrive a the specified point at the same instant in time.

Future releases will contain both conditional g-code and multiple movement queues, and these MIGHT do what you want.

What is the use case? There could be a potential range of solutions that involve an IO pin that can be manipulated by gcode on the Duet, that pin then driving an arduino or similar to drive the stepper.

The use case is a 3mm filament coil extruder, when I am not printing I am manufacturing filament.

@3mm said in how to move a stepper motor constantly?:

There is a way to do it using additional hardware. Using additional hardware would enable a stepper motor to turn continuosly, and the circuitry to do so could be arranged in many different ways. One strategy might use DUET fan IO pin, (controllable by codes) to gate on/off a nano-arduino driving an A4988 step-stick hooked up to a stepper motor. Another, might use a LM555 timer chip arranged as an astable multivibrator, again gated (drive the RESET line up/down by a DUET fan I/O pin). The output of the timer would be connected to an A4988 stepstick. If you need to control the direction of spin, use another fan pin.

There is almost always a way to do things. The DUET controllers are excellent.

See:

https://www.instructables.com/id/555-TIMER-CIRCUIT-TO-DRIVE-a-STEPPER-MOTOR/

https://www.makerguides.com/a4988-stepper-motor-driver-arduino-tutorial/

These are just a few ideas. If you look around a bit I'm fairly certain you are likely to find an actual step-by-step solution, although there is enough information in the above URLs to implement your own solution.

Good Luck,

3mm

Thank you for your answers as well as they have given me ideas, surely use a GPIO pin to control a microcontroller with some...

@zapta said in how to move a stepper motor constantly?:

How long is 'constantly' ? A day? a year? 100 years?

You can have a very long macro file with a larger number of move operations.

some hours no more than one day.

-

how to move a stepper motor constantly?posted in General Discussion

Does Duet have a command or set of them that makes a stepper motor move constantly?

-

RE: Duet 2 Wifi Expansion board IO useposted in Duet Hardware and wiring

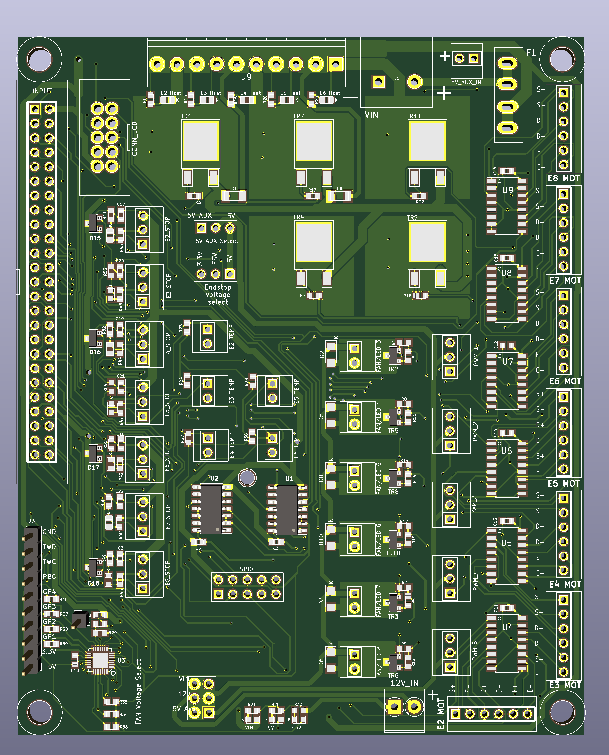

I want to be able to have the sales of a duex, that is to say, heaters, fans, but with the freedom to use external stepper motors, I previously worked on a expansion board, which connects to the expansion head just like a duex uses the chip sx1509B, but with level converters for external stepper motors, which leads me to have to modify the firmware by changing the IC2 address of the chip, and I wanted to know if this is already implemented, with what I can do the circuit and put Everything to work.

this is the image of the circuit, similar to duex5 but in ulgar of tcm2660 it carries the breakoutboard level converters for 7 stepper motors.

I have tried to build the firmware for myself to make the change but I have not been able, after several attempts, and if I do it myself, this forces me to have to modify the firmware every time there is a new update.

Your help will be greatly appreciated. -

Duet 2 Wifi Expansion board IO useposted in Duet Hardware and wiring

Re: Duet 2 Wifi Expansion board IO usage

Hello, here we talk about duex0, I would like to know where I can find some of this, or if the firmware is already programmed to accept this card, with what I could design and use without modifying anything.

I want to organize my wiring and get the most out of the expansion head.

-

RE: Configurations for unconventional extruders and materialsposted in My Duet controlled machine

@JustD said in Configurations for unconventional extruders and materials:

Why? spray it... or get a tape... a injektion with some color.. use a big Edding... etc.

Because it is an unconventional extruder, the plastic that it uses comes in a presentation as in the attached image, the steps are probably a process of error testing and moving the extrusion multiplier

@JoergS5 said in Configurations for unconventional extruders and materials:

@jhonf441 I am interested in whether you consider mixing the pellet with color also? E. g. using color pigments which are used to produce oil and water colors. Then one could produce true color prints.

when working with pellets, obtaining a specific color is very simple, pigment for pellets is used, it consists of a kilogram of pellet with a concentration of one color, its price is about 3 dollars and a single kilo can be enough to give color to 25Kg of virgin pellet, so while it is being extruded, some colored grains can be added and the molten plastic will have color, attached pigment image, but there are also other advantages, mixing pellets of different types of polymers, to obtain a new polymer with one or several physical and mechanical properties of several polymers.

@dc42 said in Configurations for unconventional extruders and materials:

@jhonf441, you don't need to reduce the speed you set in S3D. All you need to do is set the maximum extruder speed in your M203 command in config.g correctly, then the firmware will slow down moves when necessary to satisfy that limit. Of course, the print time estimated by S3D will be even less accurate than usual.

You could consider reducing microstepping below x16 to reduce the required step rate.

That is something that had not occurred to me, it has given me a light on my way I hope to test it and show progress, I am also working on the extruder so that I can make 3mm gauge filament with a feedback controller measuring in filament thickness and varying the speed of the engine to reduce the error and adjust itself, I would like to do it by gcode but I think that would need a gcode loop so that the motor can rotate until some external event breaks the cycle and stops the process; This is so that when the machine is not printing it is making filament for prints that need a lot of quality in the finish and require smaller nozzles.

Thanks to everyone for your replies.

-

RE: Duet 3d did not considerposted in Duet Hardware and wiring

I use this type of motors that need an external driver to make the closed control loop, if I want to use duet 3, I would need to buy part of the main board, buy expansion boards even when I only use 6 motors.

-

RE: Duet 3d did not considerposted in Duet Hardware and wiring

Of course, but this means that you must buy expansion cards by obligation and not by necessity, it does not seem the most just solution.

-

Duet 3d did not considerposted in Duet Hardware and wiring

I am a user of duet and its excellent service, with the arrival of duet 3 I wonder if there is the possibility of updating hardware for users who use on one or more axes, servomotors or closed loop stepper motors, which necessarily require drivers of external.

-

RE: Configurations for unconventional extruders and materialsposted in My Duet controlled machine

links are marked as spam

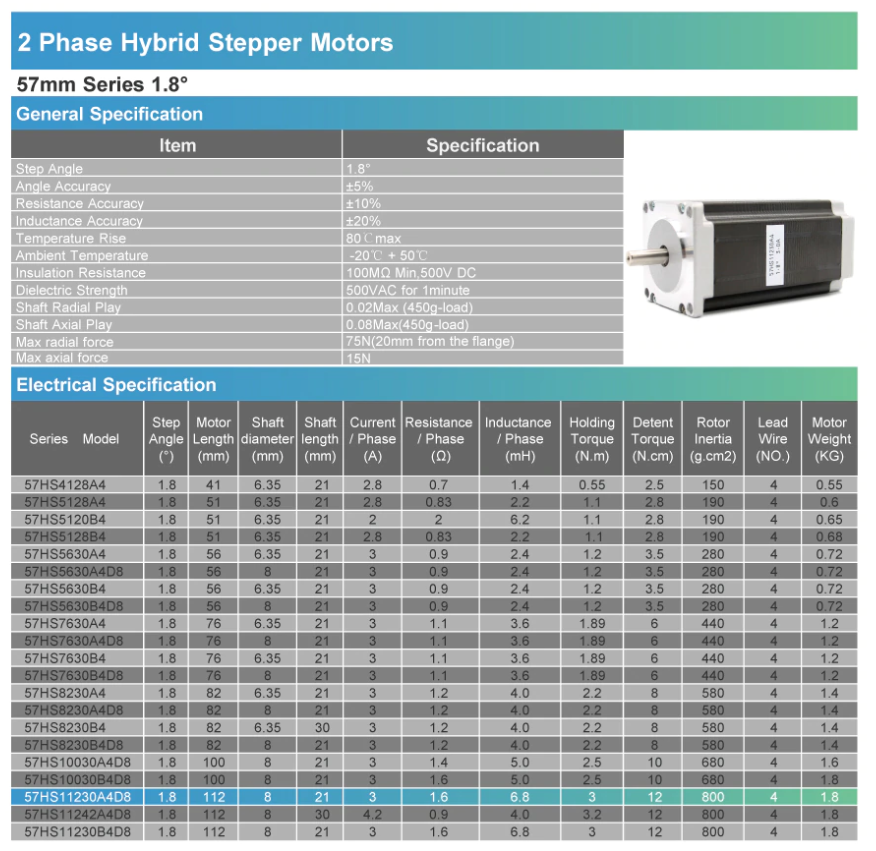

Motor

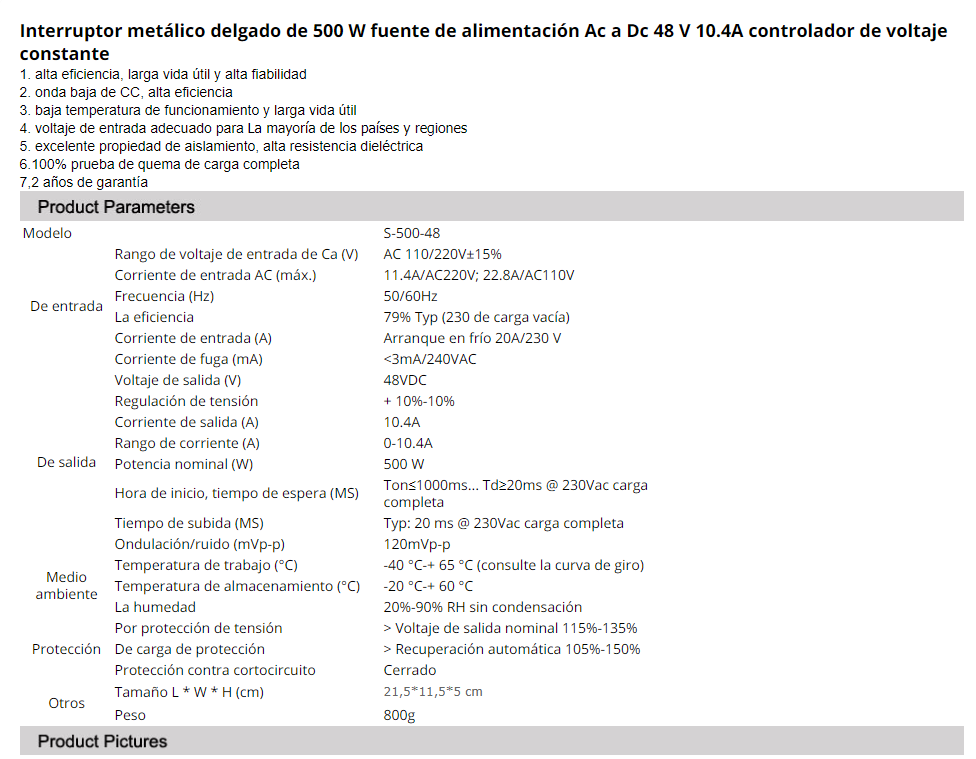

Power supply

this is the configuration file

; Configuration file for Duet WiFi (firmware version 1.21) ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v2 on Fri Mar 15 2019 23:53:22 GMT-0500 (hora estándar de Colombia) ; General preferences G90 ; Send absolute coordinates... M83 ; ...but relative extruder moves G21 ; G21 establece las unidades en mm / G20 establece las unidades en pulgadas ; kinematics type M669 K1 ; Select CoreXY mode ; Network M550 PScorexy ; Set machine name M552 S1 ; Enable network M586 P0 S1 ; Enable HTTP M586 P1 S0 ; Disable FTP M586 P2 S0 ; Disable Telnet ; Drives M569 P5 S0 ; Drive 5 goes forwards axis X M569 P6 S1 ; Drive 6 goes forwards axis Y M569 P7 S1 ; Drive 7 goes forwards Extrusor M569 P8 S1 ; Drive 8 goes forwards Axis z M569 P9 S1 ; Drive 9 goes forwards Axis Z M569 P10 S1 ; Drive 10 goes forwards axis z M569 P11 S1 ; Drive 11 goes forwards axis z M584 X5 Y6 Z8:9:10:11 U10 V11 E7 ; Apply custom drive mapping and four Z motors connected to driver outputs 8, 9, 10 and 11 Z M350 X16 Y16 Z16:16:16:16 E16 I1 ; Configure microstepping with interpolation M350 U16 V16 W16 I1 M92 X80 Y80 Z400:400:400:400 E2487; ; Set steps per mm M92 U400 V400 W400 M566 X900 Y900 Z30:30:30:30 E120 ; Set maximum instantaneous speed changes (mm/min) M566 U30 V30 W30 M203 X18000 Y18000 Z200:200:200:200 E1000 ; Set maximum speeds (mm/min) M203 U200 V200 W200 M201 X4000 Y4000 Z100:100:100:100 E200 ; Set accelerations (mm/s^2) M201 U100 V100 W100 M84 S30 ; Set idle timeout ; define posiciones de los tornillos M671 X-321:-321:317:317 Y-144:184:184:-144 S4 ;agregar parametro F2 ; Axis Limits M208 X-267 Y-245 Z0 S1 ; Set axis minima M208 U0 V0 W0 S1 M208 X267 Y230 Z406 S0 ; Set axis maxima M208 U406 V406 W406 S0 ; Endstops Makerbot Mechanical Endstop v1.2 M574 X1 Y1 S0 ; S_ endstop-type: 0 = active low, 1 = active high, 2 = slice-direction-probe, 3 = motor load detection ; MicroSiwch M574 Z1 U1 V1 W1 S1 :M574 Z1 U1 V1 S1 ; Z-Probe ;M574 Z1 S2 ; Set endstops controlled by probe ;M307 H3 A-1 C-1 D-1 ; Disable heater on PWM channel for BLTouch ;M558 P9 H5 F120 T18000 A5 R0.2 B1 ;S0.03 R0.75 Set Z probe type to bltouch and the dive height + speeds ;G31 P25 X0 Y33 Z1.13 ; Set Z probe trigger value, offset and trigger height ;M557 X-265:265 Y-207:245 S53:113 ;Define mesh grid ; Heaters M305 P0 T100000 B4138 R4700 ; Set thermistor + ADC parameters for heater 0 M143 H0 S120 ; Set temperature limit for heater 0 to 120C ;M305 P1 T100000 B4725 C7.060000e-8 R4700 ; Set thermistor + ADC parameters for heater 1 ;M143 H1 S250 ; Set temperature limit for heater 1 to 250C M912 P0 S-6.5 ; ajuste el calentador 1 ajuste electronico del monitor de temperatura en grados centigrados ;m571 consultar ;Extrusora de tornillo M305 P1 T100000 B4100 R4700 ; Set thermistor + ADC parameters for heater 1 M143 H1 S250 ; Set temperature limit for heater 1 to 250C M305 P2 T100000 B4100 R4700 ; Set thermistor + ADC parameters for heater 1 M143 H2 S250 ; Set temperature limit for heater 1 to 250C M305 P3 T100000 B4100 R4700 ; Set thermistor + ADC parameters for heater 1 M143 H3 S250 ; Set temperature limit for heater 1 to 250C M305 P4 T100000 B4100 R4700 ; Set thermistor + ADC parameters for heater 1 M143 H4 S250 ; Set temperature limit for heater 1 to 250C M305 P5 T100000 B4100 R4700 ; Set thermistor + ADC parameters for heater 1 M143 H5 S250 ; Set temperature limit for heater 1 to 250C ; Fans ;M106 P0 I0; invertir PWM del ventilador 1 M106 P0 S0 F500 H-1 ; Set fan 0 value, PWM signal inversion and frequency. Thermostatic control is turned off M106 P1 S0 I0 F500 H-1 ; Set fan 1 value, PWM signal inversion and frequency. Thermostatic control is turned on M106 P2 S127 I1 F500 H-1 ; Set fan 2 value, PWM signal inversion and frequency. Thermostatic control is turned off ; Tools ;M563 P0 D0 H1 ; Define tool 0 M563 P0 D0 H1:2:3:4 S"Extrusora de Tornillo" G10 P0 X0 Y0 Z0 ; Set tool 0 axis offsets G10 P0 R0:0:0:0 S0:0:0:0 ; Set initial tool 0 active and standby temperatures to 0C M563 P1 H5 S"Temperatura Tolva" ; indicador G10 P1 X0 Y0 Z0 ; Set tool 1 axis offsets G10 P1 R0 S0 ; Avance de presión unidad extrusora ;M572 D0 S0.06 ; Automatic saving after power loss is not enabled M911 S21 R23 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; Set voltage thresholds and actions to run on power loss ; activar bltouch ;M280 P3 S160 I1 ; Alarm Release and Push-Pin UP ;M280 P3 S140 I1; modo 5v logic zmin M929 P"eventlog.txt" S1; iniciar el registro en el archivo eventlog.txt ;LEDs ;M307 H4 A-1 C-1 D-1 ;M307 H5 A-1 C-1 D-1 ;M307 H6 A-1 C-1 D-1 ;M307 H7 A-1 C-1 D-1 ; GUI config ;M404 N1.75 ; display for users nominal-filament-diameter/width of setup, in this case 1.75mm ; seleccionar herramienta T0 ; Load any saved values from last use, that were saved with M500 command M501 ; Ensure that M501 is at the end of config.g in order for the values in config-override.g to be loaded at startup ; config done ;M291 P"Config done" S2 T3 ; send message ;M300 S300 P1000 ; beep ;M292 ; Hide the message M80according to what I could understand and the basis for the calculations these are the screw distances

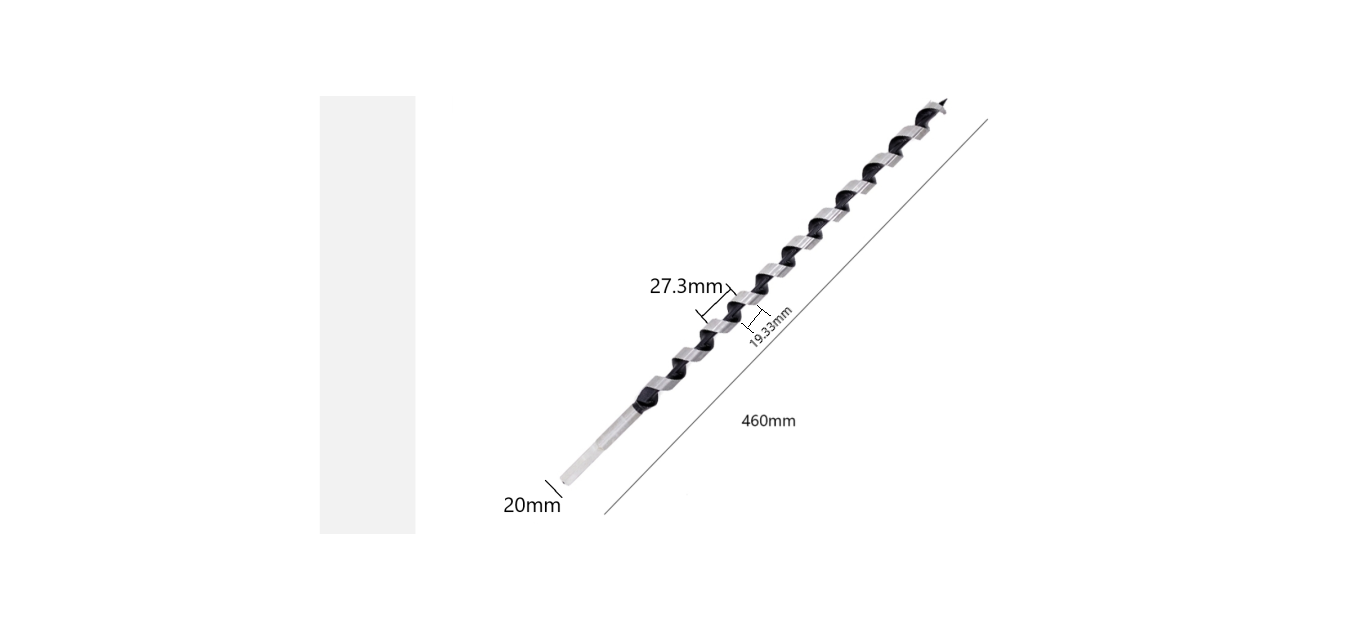

200 * 16 * 15 / 19.3 = 2487 steps per mm

@fcwilt said in Configurations for unconventional extruders and materials:

Hi,

I don't have access to Simplfy3D at the moment. Where are you entering this "speed limit"?

Have you specified the max extruder speed in your Duet config file?

Once I have set the max extruder speed in the config file, I simply check prints for under extrusion. If I see that during printing the extruder is hitting it's max limit then I reduce the printing speed.

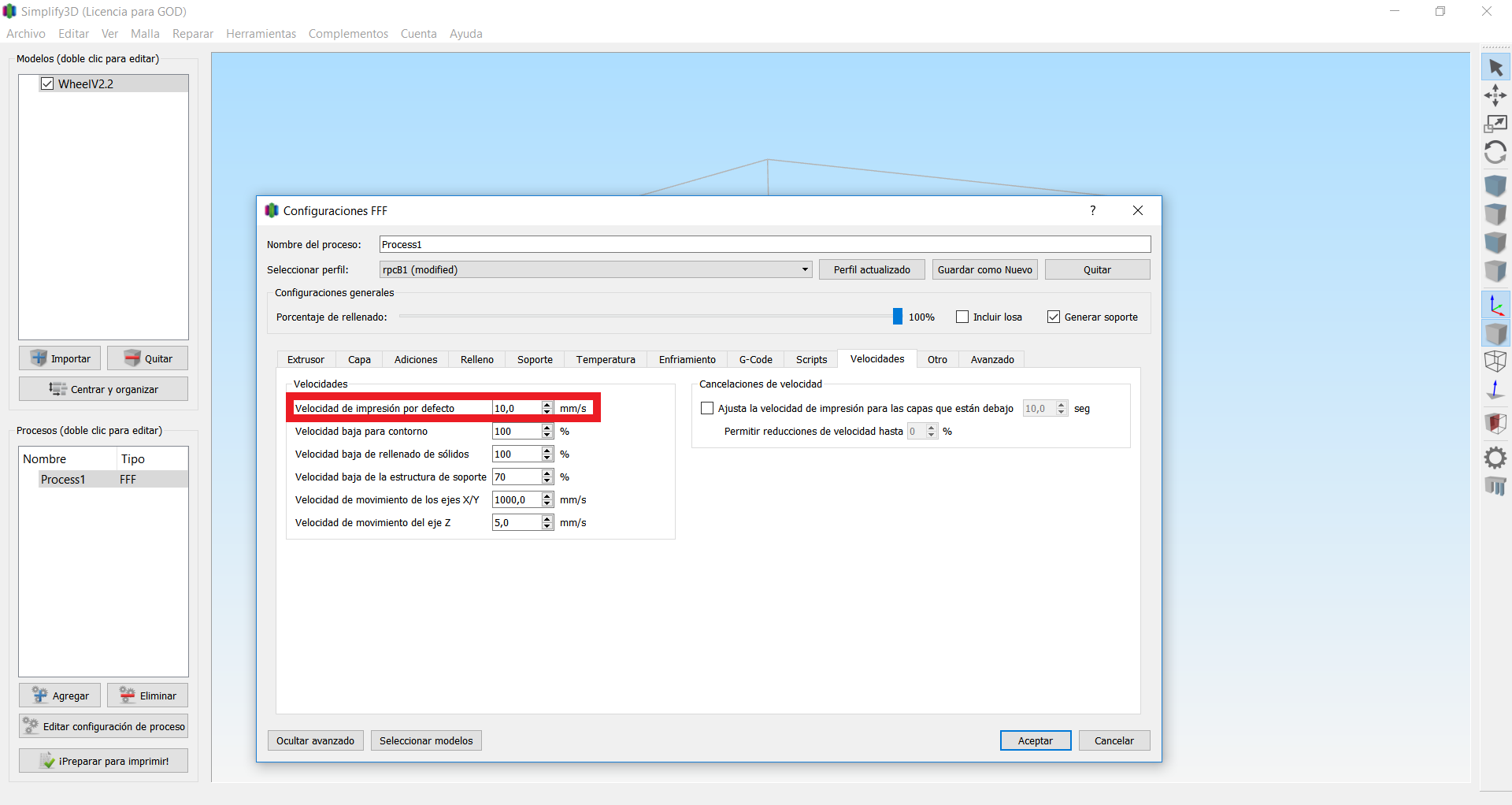

FrederickThis is a parameter where I set the maximum speed, any value above this will generate commands G1 X9.392 Y4.504 E0.5595 F600 with speeds higher than F600 and cause the engine to not move

-

Configurations for unconventional extruders and materialsposted in My Duet controlled machine

Hello,

I have been working in a pellet extruder for some time to print directly, my motivations are: large impressions in short times, and the economic one without doubts.

This is an interim job, since it is a hobby in addition to other things, work and study.

Theoretically I have found a limit that is worrying to me, I use a nema 23 engine with a torque of 425 ozin and I use an endless screw speed reducer with a 15: 1 ratio, use an external driver of DQ542MA, and here comes the calculations:

16 microstepping

200 steps per lap

15: 1 reducer

drill bit 19.3mm200 * 16 * 15 / 19.3 = 2487 steps per millimeter

The nozzle I use is 1.8mm in diameter but the extruded filament is 2mm or sometimes a little more depends on how fast the motor rotates, in some tests I have done with the extruder controlled directly from Duet 2, the maximum speed that I can move the extruder without losing steps or stopping, is 10mm / s, that is, this is a real practical and mechanical limit, so when going to the slicing software, in this case Simplify3D, I must indicate this speed, but I don't know if this or all of the chargers do the same, when I generate Gcode I get things like this

G1 X9.392 Y4.504 E0.5595 F600which means that not only the extruder is going to move at 10mm / s but also all other axes, thus making printing very slow.

I would like to hear them, and specifically I would like to know the opinions of those who work with something similar, or clays, chocolate, that do not use a conventional extruder.

-

RE: Printing Clay at the Resolution of Plasticsposted in My Duet controlled machine

Hello, @tom_lauerman I would like to know what software you use to cut your STL's, since as I currently understand the prints are calculated from solid mm of filament and in your case you use clay, what parameters do you move or what is the configuration and how do you find it?