@alankilian Thanks for your time, I really appreciate it.

Posts made by kzamani

-

RE: Need Help Wiring SureServo SVA-2100 to Duet 2 Ethernetposted in Duet Hardware and wiring

-

RE: Need Help Wiring SureServo SVA-2100 to Duet 2 Ethernetposted in Duet Hardware and wiring

@alankilian I've connected DI-1 and DI-6 ~ DI-8 to the internal 24v power supply at "VCC". The servo drive screen shows "0"

-

RE: Need Help Wiring SureServo SVA-2100 to Duet 2 Ethernetposted in Duet Hardware and wiring

@alankilian I do not. As I understand it, you can turn off the drive enable signal through the menu on the servo drive.

Same goes for DI 6 - DI 8

Everything is disabled.

-

RE: Need Help Wiring SureServo SVA-2100 to Duet 2 Ethernetposted in Duet Hardware and wiring

Here's the overall wiring diagram for the system. It doesn't really drill down into how to wire the step / direction inputs for the servo drive, so I used my best judgement.

-

RE: Need Help Wiring SureServo SVA-2100 to Duet 2 Ethernetposted in Duet Hardware and wiring

I should note, I have the wiring as follows:

Duet 2 -> Duet Breakout Board

Drive 9:Step + -> "Pulse"

Step - -> "/Pulse"

Dir + -> "Sign"

Dir - -> "/Sign"Furthermore: The drive is configured to run in Pt mode, and is wired according to the diagram shown on page 20: https://cdn.automationdirect.com/static/manuals/sureservomanual/ch2.pdf

-

Need Help Wiring SureServo SVA-2100 to Duet 2 Ethernetposted in Duet Hardware and wiring

Hello everyone!

I am in the process of installing an MDPE-10 extruder onto an existing printer system. The system uses a Duet 2 Ethernet controller, sending step / dir signals to servo motors mounted on each axis.

The new MDPE-10 extruder requires the use of a Sure Servo SVA-2100 servo drive. There's a plethora of information for the servo drive located here: https://cdn.automationdirect.com/static/manuals/sureservomanual/sureservomanual.html

I can drive the servo motor using the controls on the servo drive, however the step / dir signals sent from the Duet are not turning the motor. Current motor configuration looks like this:

; Drives M584 X5:6 Y7 Z8 E9 P:4 ; Set drives for all axes to be driven from I/O port and CONN/LCD ports M671 X-320:1566 Y603:603 S60 ; Set ball screw positions for probing routines, maximum error correction is 60mm or 3 rotations of the ball screw. M569 P5 S1 T2:1:0.25:0 ; Drive 5 goes forwards - X axis 1 - timings for all motors based on clearpath servo drives M569 P6 S1 T2:1:0.25:0 ; Drive 6 goes forwards - X axis 2 M569 P7 S1 T2:1:0.25:0 ; Drive 7 goes forwards - Y Axis 1 M569 P8 S0 T2:1:0.25:0 ; Drive 8 goes backwards - Z Axis 1 M569 P9 S1 T5:5:5:5 ; Drive 9 goes backwards - Extruder Drive M350 X16 Y16 Z16 E16 I1 ; Configure microstepping with interpolation M92 X320 Y320 Z320.00 E50 ; Set steps per mm M566 X600 Y600 Z300 E80 ; Set maximum instantaneous speed changes (mm/min) M203 X24000 Y24000 Z2400 E12700 ; Set maximum speeds (mm/min) M201 X750 Y1250 Z500 E250 ; Set accelerations (mm/s^2) M906 X800.00 Y800.00 Z800.00 E800.00 I30 ; Set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeoutThe 5:5:5:5 timing is there strictly as a test, since I am unclear on the timings for this particular servo drive.

Any help would be greatly appreciated.

-

RE: Endstop as controllable switch?posted in General Discussion

Perfect. Thanks for the information!

-

RE: Endstop as controllable switch?posted in General Discussion

Does the PWM capability matter if I need to switch on a relay or power a solenoid?

-

RE: Endstop as controllable switch?posted in General Discussion

Hi,

Can the endstops be configured similar to how fans can be configured as switches? In the current firmware, I can use the following command to define a GPIO pin which can be controlled with m42:

M950 F2 C"nil" ; disable fan 2, free pin to be controlled by m42 command M950 p3 C"fan2" ; setup fan 2 to be controlled by GPIO port 3Can something similar be done with endstops?

-

Endstop as controllable switch?posted in General Discussion

Hello! Long time user of the Duet 2 ethernet, moving to firmware 3 now. One issue I have not explored is whether or not an endstop can be used as a g-code controllable switch? Looking towards future expansion in some of my printers, it would be useful to control E0 / E1 endstop pins as switches.

Thanks,

Kevin -

RE: Duet controlled micro millposted in My Duet controlled machine

@3DPMicro This build looks really great! Is there any chance I could take a peak at a BOM or exploded view? I've been wanting to build something like this for machining watch cases / main plates but I haven't found the time.

Thanks!

-k -

RE: Wiring NEMA 34 + Stepper Drivers to the Breakout Expansion Boardposted in Duet Hardware and wiring

More progress:

Timings set to 4:2:0.5:0.5 and now things are moving! Not sure why this mattered but, here we go.

-k

-

RE: Wiring NEMA 34 + Stepper Drivers to the Breakout Expansion Boardposted in Duet Hardware and wiring

I've made some progress! I purchased a similar driver from Pololu which offers the same driver chip and a USB interface to initialize the chip. Using the USB interface, I was able to setup the driver chip to run in a STEP/DIR mode and set motor currents. From what I can tell, the wiring is correct for my current setup, but there is still no motion in the stepper motor, nor is the status LED on the driver chip changing. Per the user guide, the light should be blinking in some fashion, indicating it is receiving step / direction signals.

I believe I have a wiring issue and / or a timing issue which I do not know how to resolve. Any trouble shooting advice or corrections would be greatly appreciated.

Additional testing notes:

- I can drive the motors directly from the Duet(when plugged into the X/Y/Z MOT connectors) , however they will not move the carriages at slower speed and the will lose steps.

*I have tested the same configuration with a known good Duet from another machine, running the same firmware and the issue persists.

*I have tried a few different timing configurations, but according to the documentation, 4:2:0.5:0.5 seems to be correct

Here is the current config.g for the machine.

- I can drive the motors directly from the Duet(when plugged into the X/Y/Z MOT connectors) , however they will not move the carriages at slower speed and the will lose steps.

-

RE: Wiring NEMA 34 + Stepper Drivers to the Breakout Expansion Boardposted in Duet Hardware and wiring

@kzamani said in Wiring NEMA 34 + Stepper Drivers to the Breakout Expansion Board:

Pamoco P85-2H-2-B-400-4

After some further reading it looks like the driver chips need to be initialized via SPI which I did not realize. A few more follow-up questions:

-Can the Duet initialize these DRV8711 driver chips via SPI? If so, can I wire all 4 of the chips to the same SPI0 / 1 bus to activate them?

-How do I adjust the motor currents if I am using external drivers via SPI? Is this done via M-codes?Thanks!

-k -

Wiring NEMA 34 + Stepper Drivers to the Breakout Expansion Boardposted in Duet Hardware and wiring

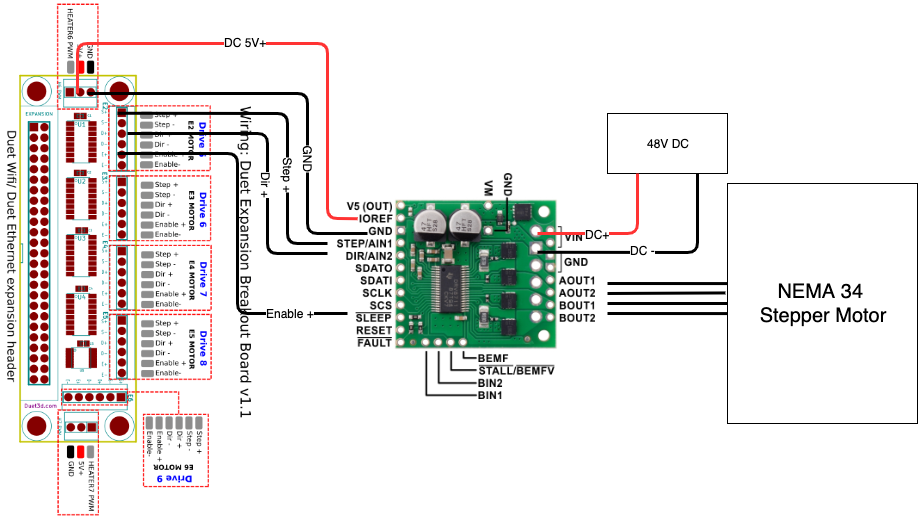

Hello All! I am retrofitting a large delta style 3D printer which uses NEMA 34 motors. The motors (Pamoco P85-2H-2-B-400-4) require a 48V 4A current, hence the need for the external stepper drivers. Using the Breakout Expansion board in conjunction with the Pololu 36v4 board, I'd like to drive these stepper motors. Based on my understanding of the documentation, I I believe I have the wiring correct. Documentation is here: https://www.pololu.com/product/3730

Can someone confirm if this wiring is correct?

I am away from my desk at the moment, but I can share config.g files on Monday.

Thanks!

-Kevin -

Duet Ethernet and RS-485posted in Duet Hardware and wiring

Hello all!

We are revising our electronics and I would like to use an OMRON PID in conjunction with the Duet3D to control the temperature of an extruder. The PID supports communication via a proprietary protocol & RS-485. I am curious if the Duet has the ability to send bits via the GPIO pins on the expansion header? If so, can the bits be configured via gcode? It would be great if I could poll the PID for temperature or set the temperature from the Duet.

Unfortunately I can't use the Duet to directly control the temperature as the noise coming from the thermocouple was causing temperature spikes which I was never able to fully diagnose / remedy. :C

Link to the communication protocol manual: https://assets.omron.eu/downloads/manual/en/v1/h175_e5_c_communications_manual_en.pdf

Thanks!

-kevin

-

RE: Maximum possible number of servos and endstops?posted in Duet Hardware and wiring

Thanks everyone! I'll look into these solutions.

-

RE: Maximum possible number of servos and endstops?posted in Duet Hardware and wiring

Hi @dc42

When designing the original printer, I placed an end stop at home position of the X and Y axis and an inductive probe at the Z-axis. This works well in concept, however I'd like to add extra limit switches to the bottom of the Z-travel to keep the machine from hitting the frame -- it's an issue we are currently experiencing. If we lower the Z-bed to remove a print and then re-home the machine, the default behavior is to lower the print bed and then to home X/Y before homing the machine. This is where we experience failures and where I would like to install a few z-min end stops, one for each lead screw.

With regards to your second question: we are using servos to drive all of our axes. The machine was designed with the understanding that we may change out extruders or controllers in the future. Clearpath servos were chosen for their ability to substitute for stepper drivers and for the extra overhead power available.

We use the built-in bed leveling in the firmware now with two servos. I'd like to add a third servo in our next design to allow for true bed leveling.

If we use the break-out board to drive our servos, how do we tap into the expansion connector? I suppose that was the intent of my original question -- how to use the break out board to drive servos, but to also wire up a few extra limit switches (in case we need more than 5?)

Thanks for the wonderful support forum!

-

Maximum possible number of servos and endstops?posted in Duet Hardware and wiring

Hello all!

We are working on a v2 of our larger printer and the question came up whether we could use Min/Max switches for each axis. With that in mind, we would like to use 3 servos on our Z axis as well as 2 servos for the X-axis and a single screw for the Y-axis. That leaves an additional servo for the extruder. If we use the breakout board, we can drive all 7 servos without any issues.

My question is thus: is it possible to use the breakout board to drive 7 servos while also using more than the 5 end stops allocated on the Duet 2 Ethernet / Wifi board?

Thanks!

-

RE: Fan Issueposted in Duet Hardware and wiring

@phaedrux Given the hassle with wiring something new into the Duet, I'll go with lower draw fans. They might set me back a few bucks but it's not a big deal.

Also the blade fuse isn't bad, so I think I'm in the clear!

Thanks for the help! Also, I love your avatar. Hyper Light Drifter is one of my favorite games.