@Phaedrux I fix the fan and now it's working. Thank

Posts made by Ladusse

-

RE: EZABL sensor mesh compensationposted in Third-party add-ons

-

RE: EZABL sensor mesh compensationposted in Third-party add-ons

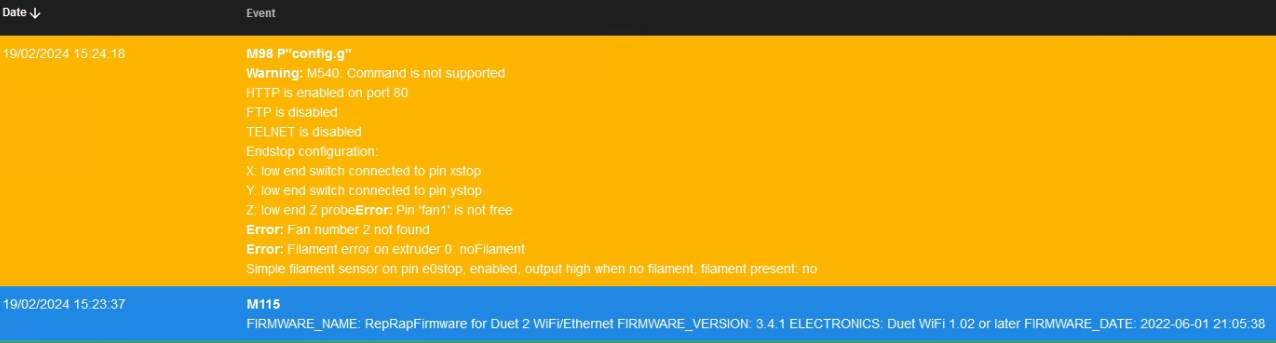

@droftarts, the Z: low end Z probeERROR: pin 'fan1' is not free line look weird to me

-

EZABL sensor mesh compensationposted in Third-party add-ons

I add the EZABL sensor on my printer. I can home the machine but as soon that I try to run the mesh compensation it won't work, I define the area and when it go to the first point it crash into the bed. Here is my config. Any tips?

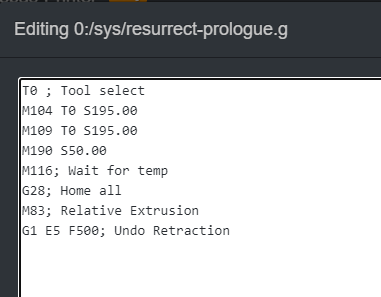

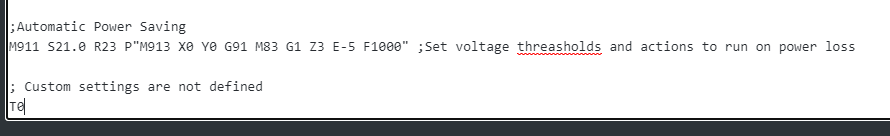

; Drives M569 P0 S0 ; physical drive 0 goes backwards M569 P1 S0 ; physical drive 1 goes backwards M569 P2 S0 ; physical drive 2 goes backwards M569 P3 S1 ; physical drive 3 goes forwards M584 X0 Y1 Z2 E3 ; set drive mapping M350 E128 I0 ; configure microstepping without interpolation M350 X16 Y16 Z16 I1 ; configure microstepping with interpolation M92 X80.50 Y80.50 Z399.4 E3228.80 ; set steps per mm M566 X1200.00 Y1200.00 Z24.00 E300.00 ; set maximum instantaneous speed changes (mm/min) M203 X9000.00 Y9000.00 Z180.00 E6000.00 ; set maximum speeds (mm/min) M201 X500.00 Y500.00 Z100.00 E5000.00 ; set accelerations (mm/s^2) M906 X800 Y800 Z800 E1000 I50 ; set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout ; Axis Limits M208 X0 Y0 Z0 S1 ; set axis minima M208 X235 Y235 Z260 S0 ; set axis maxima ; Endstops M574 X1 S1 P"xstop" ; configure switch-type (e.g. microswitch) endstop for low end on X via pin xstop M574 Y1 S1 P"ystop" ; configure switch-type (e.g. microswitch) endstop for low end on Y via pin ystop ;M574 Z1 S1 P"zstop" ; configure switch-type (e.g. microswitch) endstop for low end on Z via pin zstop M574 Z1 S2 ; Zprobe stop M574 E0 S1 P"e0stop" ; run out filament ; Z-Probe M558 P5 C"!zprobe.in" H3 F900 T12000 G31 P25 X30 Y12 Z2.0 M557 X80:235 Y50:200 P3:3 ; Heaters M308 S0 P"bedtemp" Y"thermistor" T98801 B4185 ; configure sensor 0 as thermistor on pin bedtemp M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0 M307 H0 B1 S1.00 ; enable bang-bang mode for the bed heater and set PWM limit M140 H0 ; map heated bed to heater 0 M143 H0 S110 ; set temperature limit for heater 0 to 110C M308 S1 P"e0temp" Y"thermistor" T100000 B4092 ; configure sensor 1 as thermistor on pin e0temp M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1 M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit M143 H1 S275 ; set temperature limit for heater 1 to 275C ; Fans M950 F0 C"fan0" Q500 ; create fan 0 on pin fan0 and set its frequency M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off M950 F1 C"fan1" Q500 ; create fan 1 on pin fan1 and set its frequency M106 P1 S1 X0.4 H1 T45 ; set fan 1 value. Thermostatic control is turned on M950 F2 C"fan1" Q500 ; create fan 2 on pin fan1 and set its frequency M106 P2 S1 X0.4 H1 T45 ; set fan 2 value. Thermostatic control is turned on ; Tools M563 P0 D0 H1 F0 ; define tool 0 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C ;Automatic Power Saving M911 S21.0 R23 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ;Set voltage threasholds and actions to run on power loss ; Custom settings are not defined T0 ; Select tool 0 M501 ; Enable EEPROM support M591 D0 P2 C"e0_stop" S1 ; filament monitor connected to E0 endstop M591 D0 ; display filament sensor parameters for extruder drive 0 -

RE: problem update from 3.0 to 3.4.1posted in Firmware installation

@phaedrux I restart the card and now it's working.

-

problem update from 3.0 to 3.4.1posted in Firmware installation

I do the update from 2.X to 3.0 without a problem. I start the update from 3.0 to 3.4.1 and now I'm not able to connect via my browser. Did I need to remove the SD and modify the WIFI setting into the config file?

-

RE: Laser sensor calibration infoposted in Filament Monitor

@alankilian thanks for the explication it's now more clear.

-

RE: Laser sensor calibration infoposted in Filament Monitor

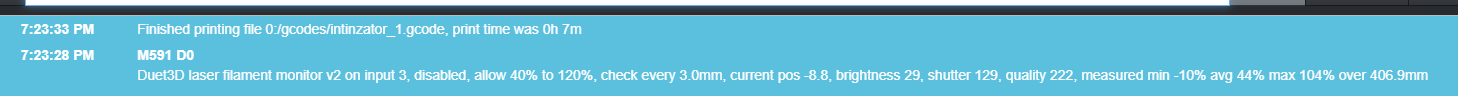

@Phaedrux yes I seen it I don't understand the R value the minimum and maximum permitted measured movement as a percentage of commanded movement. As the example calibration reports 43% to 115% then you might choose R30:130.

Why it choose R30:130 with the reports of 43% to 115%?

-

Laser sensor calibration infoposted in Filament Monitor

Hi I just installed my laser sensor and I don't now what I should for the ''R" value. here is my result.

Thanks

-

RE: Configuring Stall Detectionposted in General Discussion

@jay_s_uk thanks. I ask this question because when I home my Z axis it isn't very constant with my limit switch. Do you have a tip to be more constant like speed, proximity switch instead of limit switch?

-

Configuring Stall Detectionposted in General Discussion

Can we configuring stall detection for the Z axis?

-

RE: 1.8 vs 0.9 degre motorposted in General Discussion

@Veti thanks for the answer. I know how to change the steps but the current I not sure how.

-

1.8 vs 0.9 degre motorposted in General Discussion

If I change my existing motor 1.8 deg to 0.9 deg motor, did I need to change someting in my settings?

-

RE: resuming jobposted in General Discussion

After trying and trying some stuff I found the problem. Before trying to restart I have to be sure that my T0 was select. I was assuming that the tool was select because I wrote it down in my config but it wasn't. So I have to be sure that the tool was select and I restart the print as it should.

Regards

-

RE: resuming jobposted in General Discussion

When I type M916 in the console they start to heat, home and extrude filament and don't move were it stop. Did I have to do something else or it should re-start to print?