Yes!

I understand now why the previous owner was reluctant the upgrade the firmware.

I'll get there eventually.

Just trying to bend the bed flat Again....

Posts made by magnets99

-

RE: hierarchy of control over gcodes, machine vs filament vs slicerposted in Tuning and tweaking

-

RE: better error reportingposted in Firmware wishlist

@moth4017

yeah i agree, i think it's on the feature list for the future.

just out of interest, why do you call out to other macros? -

RE: OK, not exactly wiring, but where can I buy wires in US??posted in Duet Hardware and wiring

@dc42 yikes!

So less of a standard... More of guidelines really... -

RE: better error reportingposted in Firmware wishlist

i'm assuming you've proved that it's not the config.g file, But that it's calling another file

Can you not comment out half the macros and then restart?

even with ten call outs you'd work it out which macro in around three tries. -

RE: Bent warped bed under the glassposted in Duet Hardware and wiring

thanks, i can't seem to find my plate for replacement.

I can find lots of the heating PCB but not the actual metal plate.

I've tried

bed plate

plate

heated plate

ultimaker 2

and HB13 which is silk-screened on the pcb heater underneath the plate

any ideas?i'm in australia

-

RE: better error reportingposted in Firmware wishlist

@moth4017

What happens if you add a comment line after 35?

like thisM584 Y0 X1 Z3:4:5 E2 M350 X16 Y16 I1 ;this is a comment to bump the line numbering M350 Z16 E16 M92 X80.00 Y80.00 Z320 E562then if the error moves to line 37 you know it is having trouble with that file.

Also, and i apologise if i'm teaching you to suck eggs, but:what happens if you split the m350's? like

M350 Z16

M350 E16any none printable characters in line 36?

I find the instructions a bit confusing, i see you have three motors driving Z and the notes say

Example: If you have two motors on your Z axis, physically connected to Z and E0 stepper drivers, configured with M584 Z2:3, set M350 Z16, not M350 Z16,16but in the examples for the extruders it's listing stepping for each

M350 Z1 ;set the Z-axis' driver to use full steps M350 E4:4:4 ;set extruders 0-2 to use quarter steps)though i guess they are independent extruders, not motors on the same axis.

-

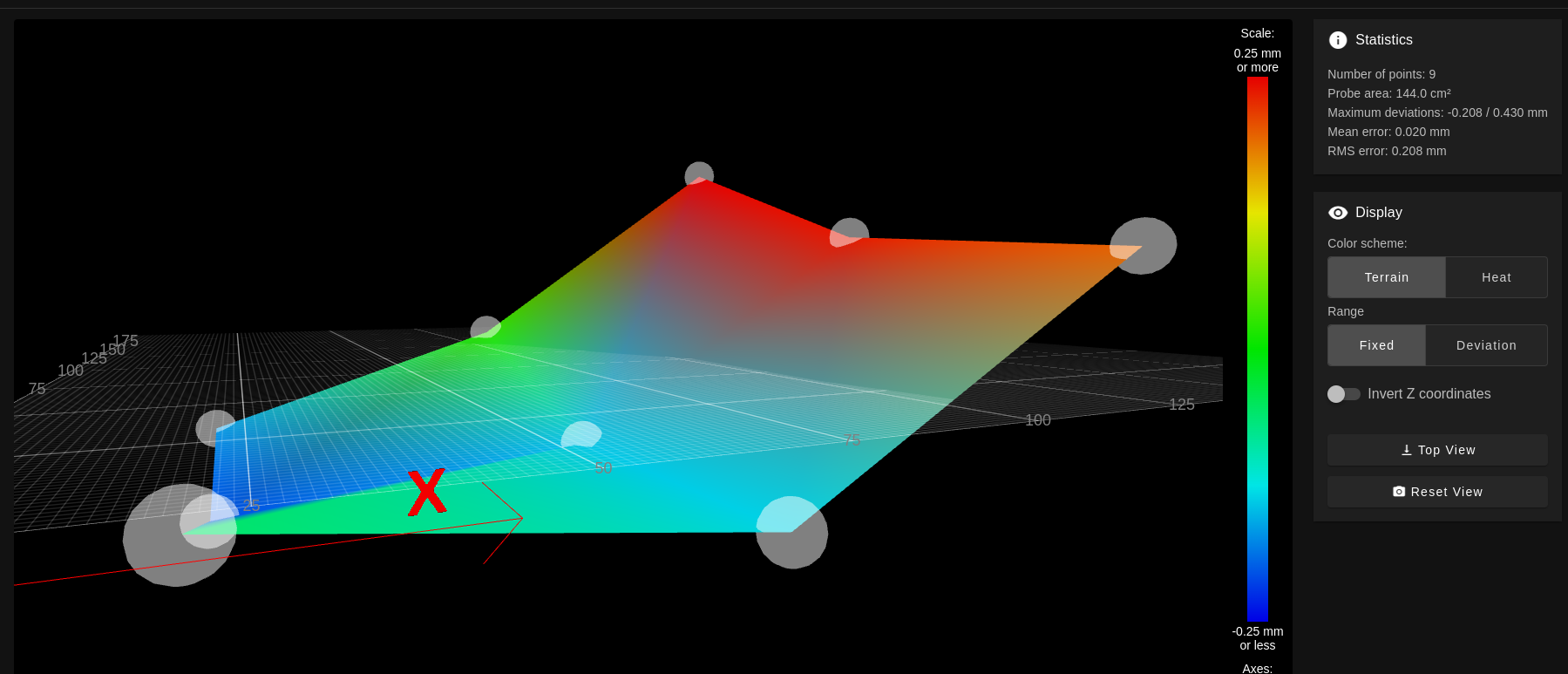

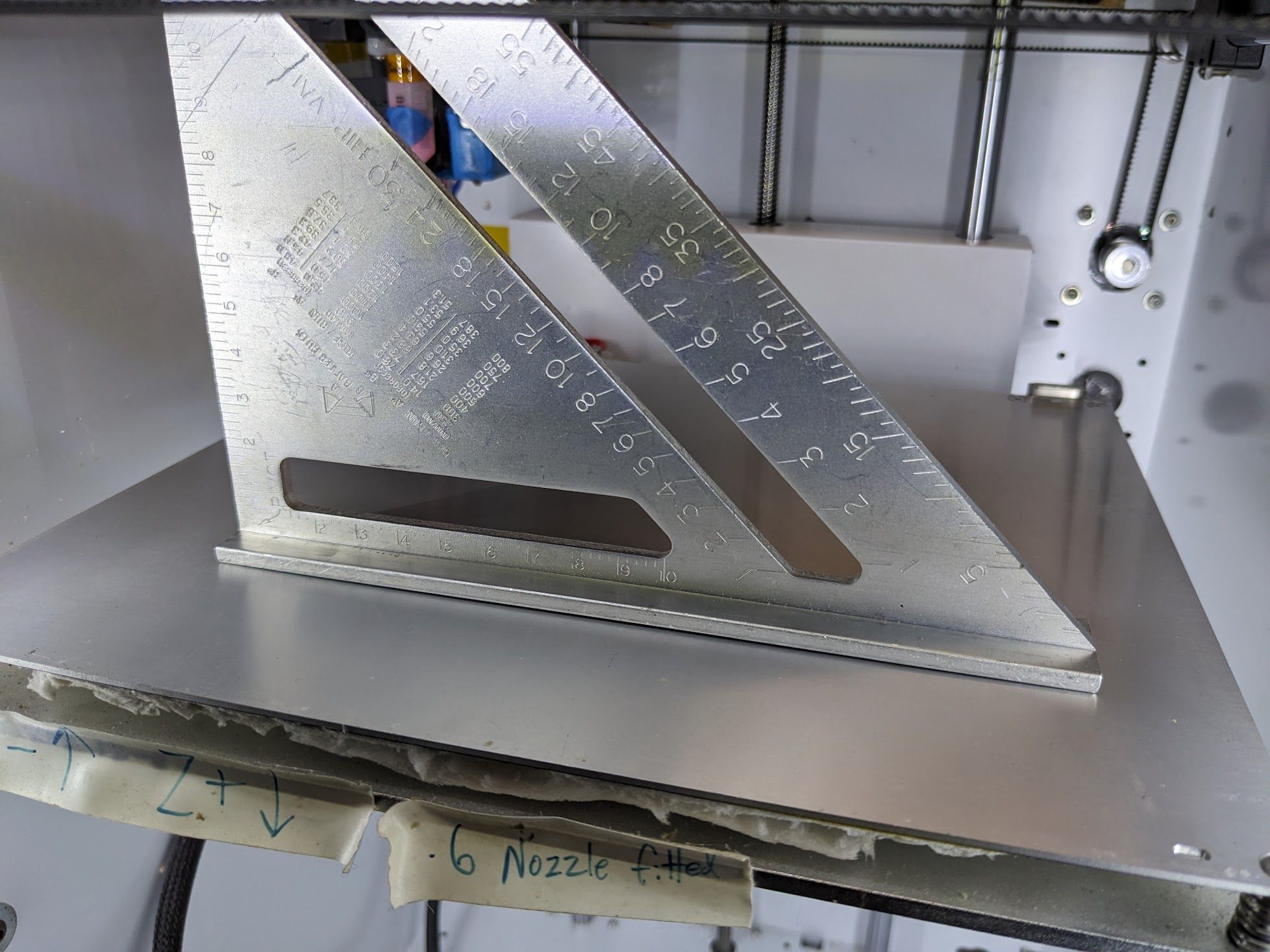

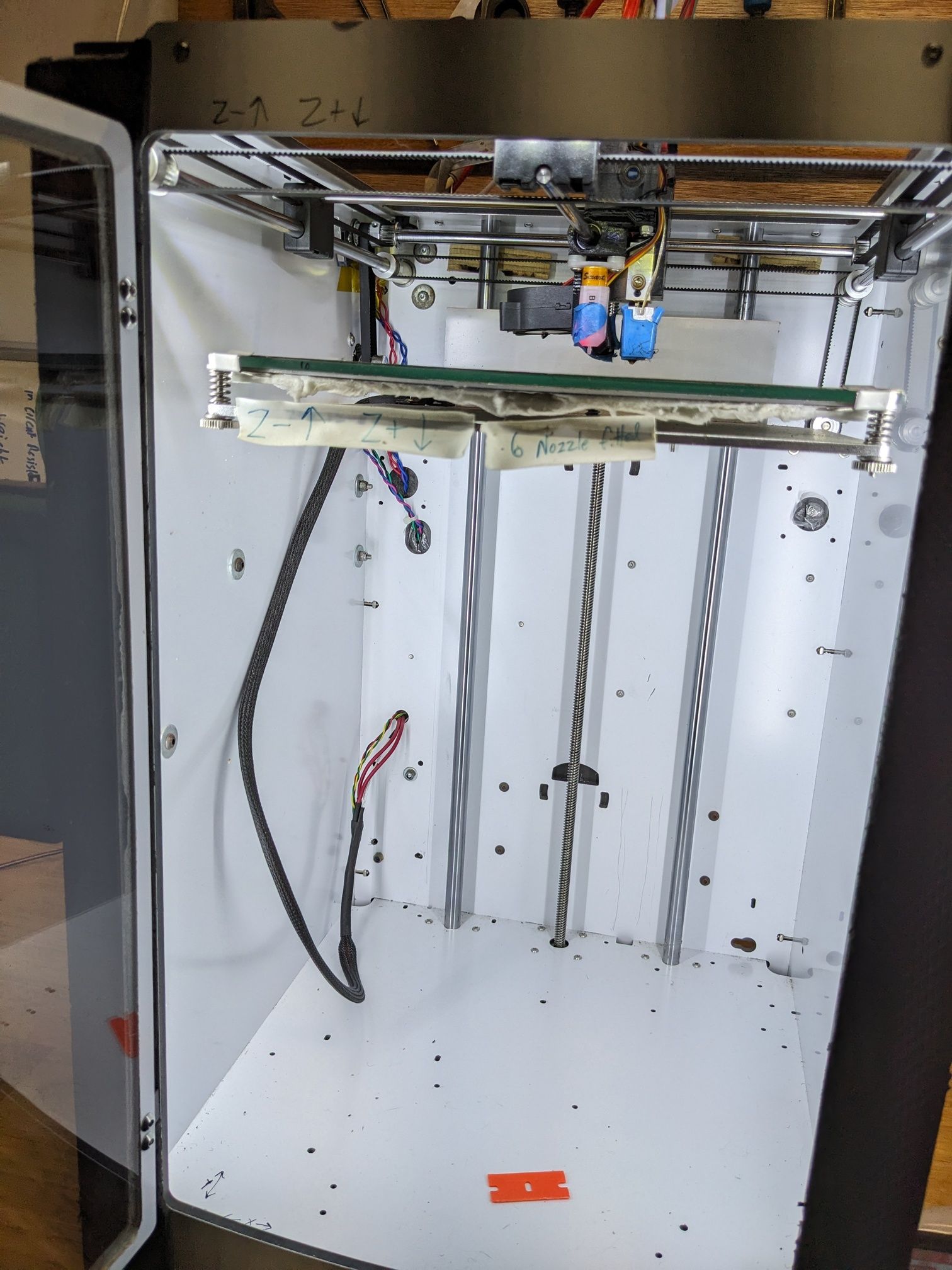

Bent warped bed under the glassposted in Duet Hardware and wiring

Hi All, I need to replace my PEI sheet which sits on glass which sits on a heated bed.

it has annoying metal tabs which either hold the plate firm or lets the sheet sit flat (not both!)So i've bought a kit with a magnetic sticky sheet and some pei sheets sandwiched between sprung steel

(this link, i chose the second one, with base)Problem is, the heated metal bed under the base is visibly warped

Here is the map

Screenshot taken after removing the glass then doing a bed level compensation.And you can see in the picture it bows in the middle under the straight edge

my thoughts are:

- take the bed off and try and bend it flat, i'm not sure if i'm skilled enough or if i need special equipment.

- stick the magnetic sheet to the glass, this has the disadvantage of keeping the metal tabs, longer bed heat times and there is still a gap under the glass meaning uneven heating.

I have tried:

heating the bed up in case it was just contraction causing it to bow.

Any advice on what i should do here?

-

RE: OK, not exactly wiring, but where can I buy wires in US??posted in Duet Hardware and wiring

@gnydick

i'm afraid i don't know enough about stepper motors to say why. Are all nmea17's the exact the same? with the exact same connector? -

RE: OK, not exactly wiring, but where can I buy wires in US??posted in Duet Hardware and wiring

@gnydick

I'm not sure but i would guess that because stepper motors use sine waves the rated current will be RMS not Peak. so you can add another 30% (terrible rule of thumb but it's good enough) which takes 2A to 2.6 peak, then a bit of headroom where the connector manufacture is being pessimistic and the motor manufacturer is optimistic.or...

I'm not sure where you got those figures from.

the connector is a jst-vh (not ph) and is rated to 10amp with 16awg. But i would guess the limiting factor is more likely to be the trace on the board not the cabling or the connector. -

RE: The Plastic Sturgeon (Watercooled franken printer)posted in Example setups and prints

@droftarts

I did buy the Califlower, it's printed out really well. Thought my calipers only go to one decimal place, i'm pretty happy that that values are the same in each direction though,

it recommended m556 s100 x-0.033

which i'll test again after i've finished the other tunings. before adding it. -

RE: OK, not exactly wiring, but where can I buy wires in US??posted in Duet Hardware and wiring

that's odd, are you looking for the cables or the crimps?

16awg is pretty chunky and i'm suprised you're having trouble.

this is the datasheet for the headers used on the board

https://www.jst-mfg.com/product/pdf/eng/eVH.pdfthe notes say

"The 4 wire motor and OUT1, OUT2 and OUT3 are JST VH series connectors. They require a minimum of 22AWG wire (20AWG or 0.5mm2 recommended. Most NEMA17 size stepper motor wire will will not be thick enough to use in the normal way; but you can double the stripped part of the wire back on itself to bulk it up, and put a small length of heatshrink sleeving over the insulation to bulk up the insulation. You will need a suitable crimping tool for the crimp pins, for example Engineer PA21 (use the 2.2mm jaw opening to crimp the bare wire and the 2.5mm on to crimp the insulation). Alternatively you can solder the wire to the crimp pin"If you are desperate and want it done now, that molex cables in your PC power supply for the older style hard drives are typically good quality 20awg stranded.

I often see PC's on council chuck out days to harvest.

Failing that i'd use mouser or RS.

Amazon or ebay will also provide what you need...but you roll the dice on quality. -

RE: hierarchy of control over gcodes, machine vs filament vs slicerposted in Tuning and tweaking

Thank you all,

some great advice there.I'm going to stick with orca slicer, so with that in mind i shall:

try and avoid override_config (i've moved my heater pid settings over)

not use the filamanet section on the duet and instead use the slicer filament settings

check that my slicer isn't messing about with static settings (as i do want to do pressure advance and input shaping).

@droftarts

I took the little silicon jacket of the HotEnd and i agree with you that it's a volcano-175-AS. that's really good info about the stringing as i'm currently doing teachingtechs benchmark for temperature

https://teachingtechyt.github.io/calibration.html#temp

and i can't even get one bridge working. But at least i feel a bit more confident now about why. -

hierarchy of control over gcodes, machine vs filament vs slicerposted in Tuning and tweaking

Hi,

So i'm trying to tune my printer and it's very slow going.

i've got the basics sorted and i'm happy with my config.g code but now i'm trying to reduce stringing, increase speed and quality etc.What is the best practice for gcode location and run order?

The machine runs it's own gcode when it starts called

sys/config.gbut then, it can override that with sys/config-override.g

then there is a filament folder and it has a config.g file in which will override the sys/config.g; and presumably it will override config-override.g too. but only if i click it or always if it's loaded?

My Slicer, Orca, also has a section called Machine G-Code for the selected printer and that has bits like

G21; metric values G90; absolute positioning M82 ; set extruder to absolute mode M107; start with the fan offThen, Orca Slicer has a filament profile with a section called Setting Overrides

i think i could even put codes in there that would then override the orca machine code section which would override the myfilament/config.g which would override the config-override.g which would then override config.g!

So what is the best practice for where g-code goes? Is there a handy flow chart guide about what type of code goes where?

should i not use the filament folder on the machine at all and just use the slicer filament profile since the the slicer has both model and filament?

Should i try to reduce any and all 'static settings' in the slicers printer template otherwise if i change slicer half of my config.g will revert to sys/config.g and might not be correct?

I'm having trouble with tuning and i really don't want to end up with a whole load of changes that i can't track or worse... are having no affect because i didn't know something else is overwriting them.

How are you managing this? -

RE: The Plastic Sturgeon (Watercooled franken printer)posted in Example setups and prints

@droftarts

Thanks for the info Ian,

That's really helpful stuff.

I'm using orca slicer as reddit feels it give the best results and i liked the interface.

i'm working my way through these

https://teachingtechyt.github.io/calibration.html#flow

calibration settings, though my partner made a very good point, i could shave 30 minutes off the print time, but if it wasn't a good result or failed 3 in 10 i'd be just as efficient leaving it at 2 hours print time.I'm looking forward to playing with the feed forward, and i'm going to buy an accelerometer. a bit frustrating that i have a box of ADXL345's but it doesn't support that one. Still it's a very awesome OSS project!

-

RE: The Plastic Sturgeon (Watercooled franken printer)posted in Example setups and prints

@droftarts

Ooo thanks for the info, yes I think the previous owner was printing nylon a fair bit.I'm quite new to this so how fast is fast?

I ran a benchy on it and it took 2hours and 10mins.My speeds are based on the original config.g I found on the SD card so i have no idea if they are super conservative or if that's a typical benchy print?

-

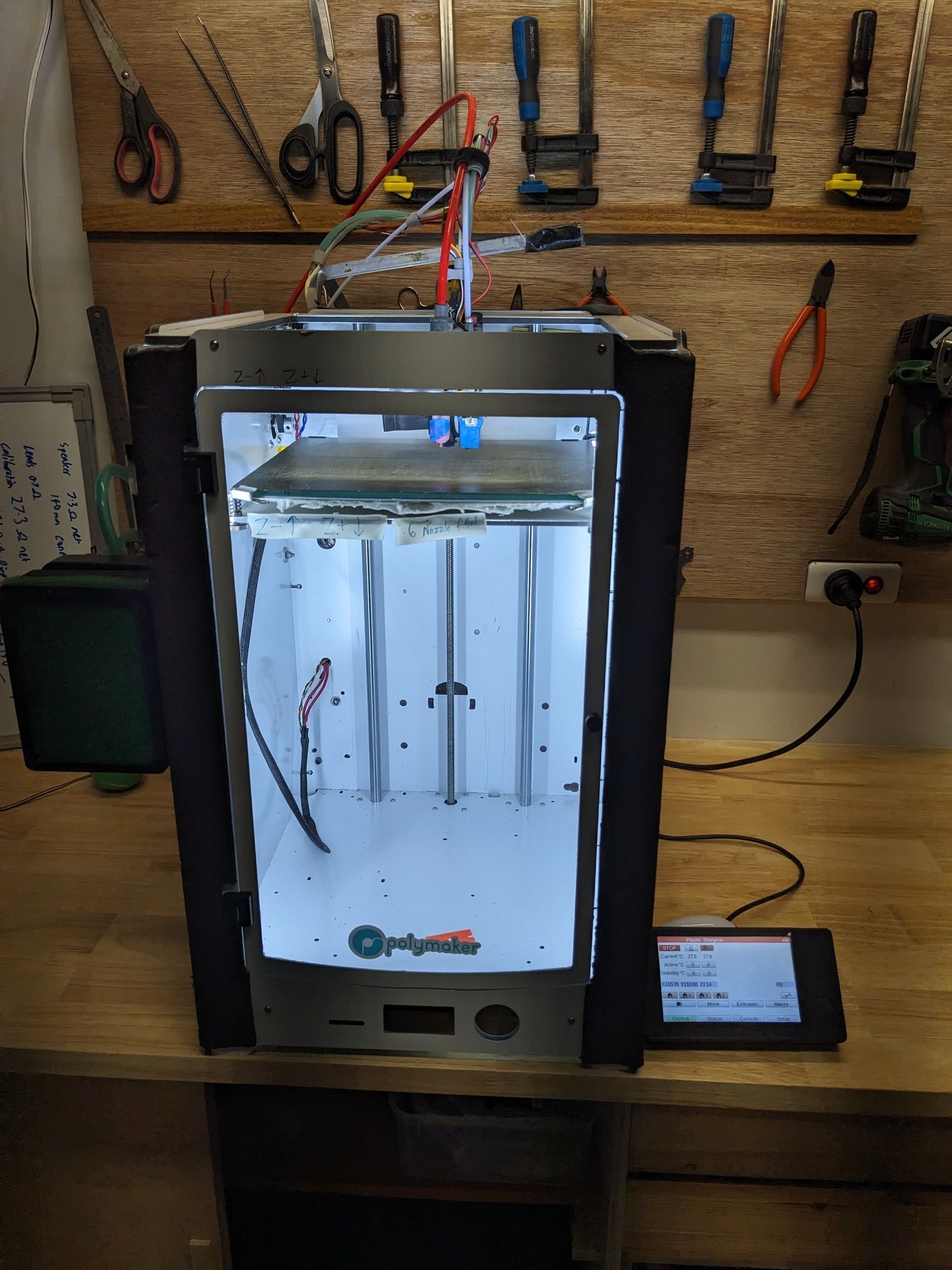

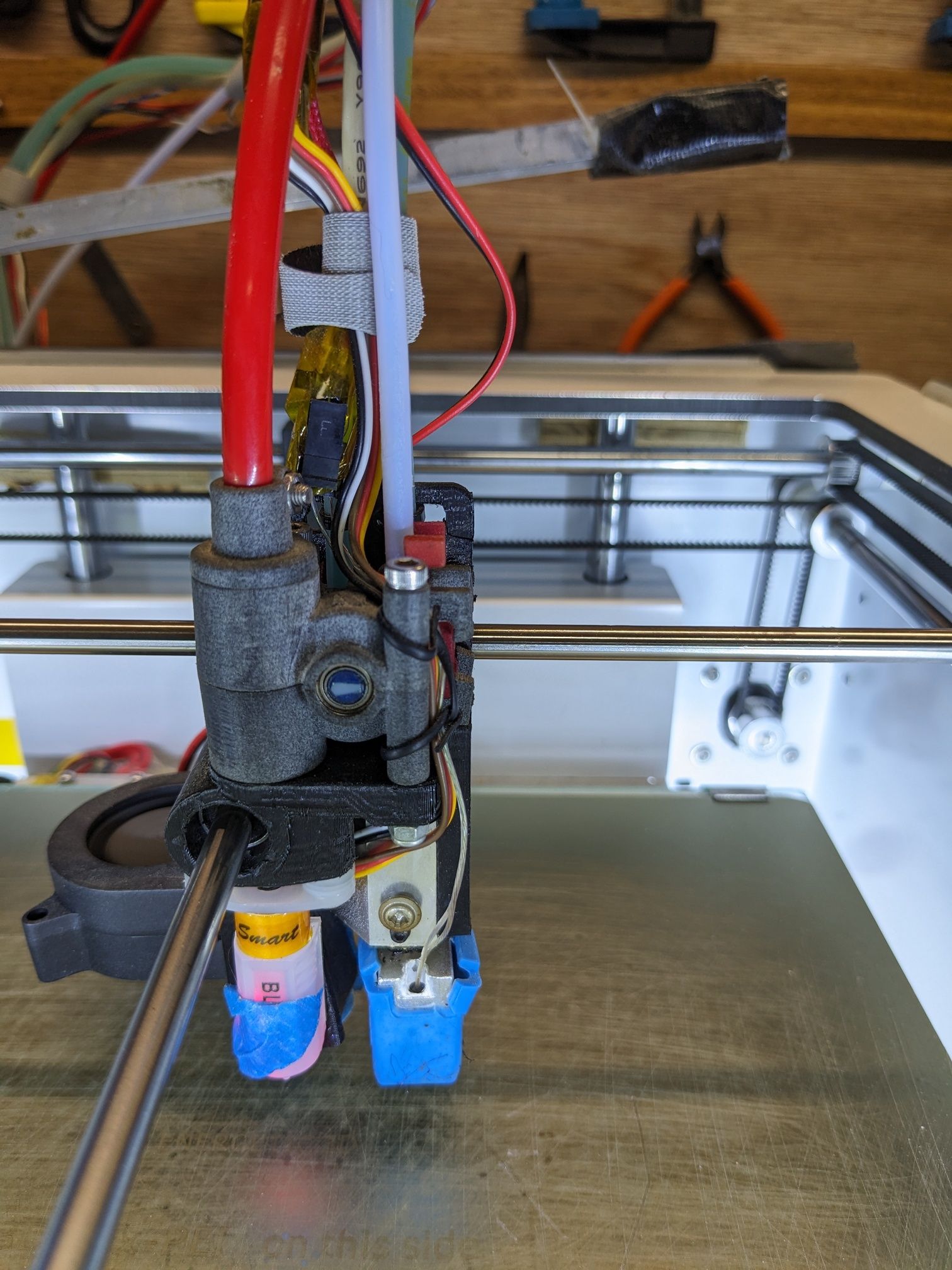

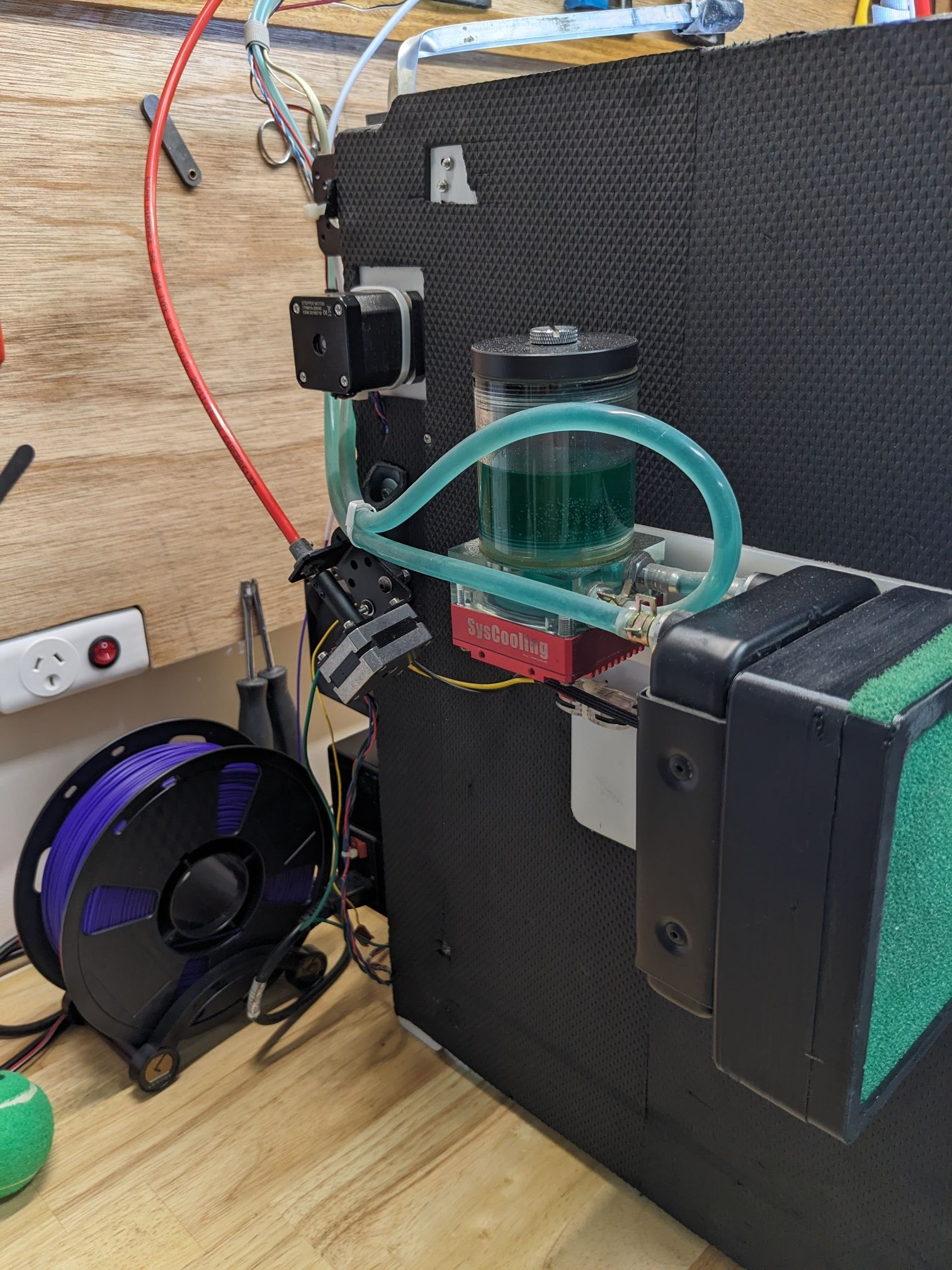

The Plastic Sturgeon (Watercooled franken printer)posted in Example setups and prints

Hi All,

I'm now in the tuning phase of my inherited 3d printer.

It hadn't been updated since 2019 and i think hadn't been used in a few years.

I'm new at 3d printers but old at electronics and noodling.

So i spent the last few days and (with your help) got it printing ok.

I'm now trying to make it fasterHere are some pictures, i think it's a fairly unusual printer because of the water cooling and the extruder drive system.

I think it uses an ulitmaker 3 enclosure.

It has a build space of 200x200 and at least 300 (probably more).

It has a watercooled head

it has a remote flex drive extruder called a Zesty Nimble by Zesty Tech (no longer around)

no idea what head it has, it has a .6 nozzle allegedly.and PEI plate on the heated bed.

-

RE: M280: Probe already triggered at start of probing move BLTouchposted in General Discussion

@Phaedrux

I think because i was doing basic stuff it was ok, but yes, it did get a few things wrong:*3. Test Manual Pin Movement

Manually deploy the probe pin and push it gently into the housing while sending:gcode

Copy code

M119

If the probe doesn't register as triggered when pushed, the issue may be:

A wiring problem.

A faulty BLTouch.

A configuration issue with the signal pin.*Which would be good advice if i was using it as an end stop, but i wasn't.

But got me looking at the wiring... -

RE: M280: Probe already triggered at start of probing move BLTouchposted in General Discussion

@Phaedrux

Thanks, in the end there was lots wrong, i'm not sure how i got it so wrong to start with.

original:; Probes M558 K0 P9 C"^exp.thermistor6" H5 F120 T6000 ; configure BLTouch probe via slot #0 G31 P500 X-19.7 Y-8.4 Z2.2 ; set Z probe trigger value, offset and trigger height M950 S0 C"exp.heater7" ; create servo #0 for BLtouchFinal fixed one:

; Z-Probe Configuration M950 S0 C"exp.heater7" ; Assign Heater7 (pin 31) for BLTouch control M558 P9 C"^zprobe.in" H5 F120 T6000 ; Configure Z-Probe signal pin G31 P500 X-19.7 Y-8.4 Z2.2 ; Set trigger value, offsets, and trigger height M574 Z1 S2 ; Set Z endstop controlled by the probeIssues were (as i went along):

assumed 3 wire config not 5 wire.

wrong pin for sensor

missing ^ (pullup) on zprobe.inI actually found chatGPT pretty good for getting me to check stuff, it seems to know rrf 3+ pretty good.

-

RE: Duet 2 wifi don't connect to androidposted in Duet Web Control

@Siim

when you say you can "read the news with my home network ip"

can you eleborate?If you mean:

When i enable tailscale on my phone it gets an ip that is in the same range as my home network and i can visit news.bbc.co.ukthen that's not a very good test as tailscale supports split tunnelling meaning your phone could be connecting and getting an ip on your LAN range but then not routing anywhere and then your phone is using the mobile data connection to get to news.bbc.co.uk directly.

I really think you are better off posting on a tailscale forum or reddit group. I do not believe your issue is with the DWC server.

Or in other words, if you can reach the DWC from within your lan, it is working.

-

RE: Filament drive counting backwardsposted in Duet Web Control

@Aurimas

Wow that is a monster!

you could probably lost pla cast a whole engine block with that!