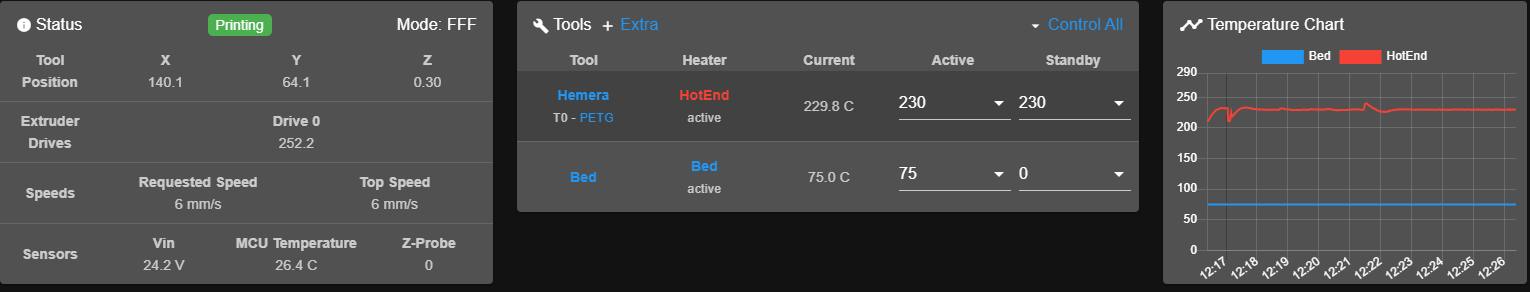

@mitch I got a response on the display. Happy printing.

Posts made by mitch

-

RE: Extra 7" panelposted in PanelDue

@elmoret I don't have a business selling anything. I just have an extra display that came off of a printer and thought it might be better to have someone get use out of it over sending it to the garbage. These are pretty low dollar items. Certainly not making any money on this.

I have always purchased authentic duet boards and sensors because I feel it is a safety case and I trust the workmanship.

But for displays I think I grabbed what was available at the time. Sorry if that offends anyone. Just trying to save perfectly good electronics from going to trash heap. I am looking at recycling options for some of the equipment as well. if anyone wants the display and case. Only asking for shipping.

-

Extra 7" panelposted in PanelDue

I have an extra working 7" panel and enclosure of anyone is interested. Wasn't sure where to post this. Apologies if I missed the buy/sell/trade forum. Kindly redirect.

7inch PanelDue 5i / 7i Integrated Paneldue Colour Touch Screen Controllers For DuetWifi Duet 2

-

RE: Klipper on Duet 3 Mainboardposted in Using Duet Controllers

@flopo76 I have recently built the Mercury One zeroG Hydra 1.1 conversion of an Ender 5. I have RPI driving Duet mini 5+ and a HUVUD tool board running CAN from duet USB-Can bridge.

Everything has flashed fine but I am having intermittent issues. When I try to move the bed in large movement all three Z stepper get way out of sync. I am wondering if the USB speed from RPI to Duet is limited and causing communication issues. I really want to use this board but it has been one headache after another.

-

RE: Duet2 wifi + ebmpapst fan wiringposted in Duet Hardware and wiring

@T3P3Tony Thanks. I had a more accessable ground going to my filament runout sensor so I ended up using that.

-

RE: FAN0 and FAN2 not workingposted in Duet Hardware and wiring

Well, I messed up and I think I need to replace some MOSFETS for Fans1 and 2.

I was trying to connect a 3 wire part cooling fan and I accidently shorted the GND of the 3 wire fan to the PWM GND of Fan1 and I saw a little smoke come out of the new 3 wire fan.

To try to determine what exactly I broke. I tested the fan fuse and it is fine.

I took a known good fan and connected it one at a time to

Fan0, used the M106 P0 S1 command and it turned on

Fan1, used the M106 P1 S1 command and it wouldn't turn on

Fan2, used the M106 P2 S1 command and it wouldn't turn onI saw this post where you indicated that the MOSFET most likely went out.

Am I correct to assume that means that I need to replace MOSFETs for both Fan1 and Fan2 with PMV20XNE?

I have a hot air station but I wouldn't say I am great at it. I could use some recommendations on temps for removing the existing part and putting the new one on.

Thanks in advance.

-

Duet2 wifi + ebmpapst fan wiringposted in Duet Hardware and wiring

Printer: Ender 5 Pro,

Mainboard: Duet2 Wifi

Extruder/Hotend: E3D 24VDC Hemera Revo

Part Cooling Fan: 24VDC ebmpapst 5015, model RLF35-8/12N

Bed Sensor: BL TouchI have an ender5 Pro that I am updating to use this new fan duct design for the Hemera Revo + 5015 epmpapst blower.

https://rene-jurack.de/well-engineered-hemera-fan-duct-2/The part cooling fan that I am removing only had two leads (PWR & GND). The new fan has three leads, one for PWR (red), GND (black), and PWM (blue).

I found the following post that describes how to connect it to the Duet2:

https://duet3d.dozuki.com/Wiki/Connecting_and_configuring_fans#Section_Connecting_3_or_4_wire_fansMy current fan connections are:

PWM Fans V_FAN connected to Red PWR

PWM Fans FAN0(-) connected to Black GNDOn Duet 2, for 3-wire fans, the recommended connections are:

Red (PWR) of an always-on fan connector.

Black (GND)

Blue (PWM control) connect it to the FAN- pin of your chosen controlled fan connector.Question:

Before I start changing connections I wanted to ask about the GND. I am attempting to connect this new fan without fishing another wire up through the to the hotend. I am only missing the GND for the new fan connection. The only GND wire I have going to the Hemera that I could splice from looks like the GND going to the BL Touch.I know that for a two wire PWM fan the GND is the PWM control and you cannot bond that GND with other GND wires. However, for the three wire fans I believe it will be OK to bond the GND of the part fan with the GND on the BL Touch since it is truly acting as a standard GND. I wanted to get the forum's experienced opinion on the matter. Is it OK to bond the BL Touch GND with my three wire ebmpapst GND?

My new connections would be:

Always On Fans V_FAN connected to Red PWR of 5015

Splice the GND going to BL Touch and connect to GND (Black) of 5015

PWM Fans FAN0(-) connected to Blue (PWM Control) of 5015 -

RE: Can't touch the bed (bed leveling macro)posted in Tuning and tweaking

I ended up commenting out the "G31 Z0" near the top and changed the "G92 Z5" to "G92 G10" and now I have enough to get to the bed and complete the macro.

I am all for using built in leveling but I haven't found anything that seems to be as quick and accurate as something like this macro. I tried this process:

https://duet3d.dozuki.com/Wiki/Using_the_manual_bed_levelling_assistantNumerous times and it ends up being a giant game of go fish. Just no way to adjust a knob based on a fraction of rotation and get any kind of accuracy out of it. Just constantly missing the mark and the number of iterations takes far longer than just running a macro like this to tune it in. I am all for learning though. Perhaps with some clarification I might see how the M671 is supposed to be faster or more accurate?

-

RE: Can't touch the bed (bed leveling macro)posted in Tuning and tweaking

Appreciate the reply. This is going to be helpful to get to the bottom of this.

The Bed.g file actually defines that you are doing a four point bed calibration. It is the coordinates of your four adjustment screws and not defining that you have steppers at those screws from my understanding.

Please expand on the bed leveling built into the firmware. If you are referring to this:

https://duet3d.dozuki.com/Wiki/Using_the_manual_bed_levelling_assistantI haven't found that to be useful at all. After it completes it tells me some rough fraction of a turn on a knob which is anything but accurate. I find that it is far more convenient and accurate to actually adjust the knob until you get contact. Please elaborate if I am misunderstanding the built in feature but I have used it and haven't found it to be faster or more accurate. In fact, quite the opposite.

-

Can't touch the bed (bed leveling macro)posted in Tuning and tweaking

I have recently replaced some parts and need to bed level again.

I am running v3.4 firmware. I tried to run my trusty macro that I got from somebody on here (@Phaedrux ) perhaps. But for some reason, even after I have properly set my z-height, this macro won't let me touch the bed with the nozzle. Instead it lets me drop the Z down to 0 but zero is way above the bed. I commented out the reset Z height at the top and I still have the same problem. Can anyone spot what the issue is? Do I need a command at the top to ignore z height? If so, this confuses me because I believe the z-height to be correct already. Before I run this macro I can decrement my nozzle down to the bed manually and it touches the bed right at 0. What is this macro doing that raises the Z height so much when it runs?

Also, before someone asks, I am aware of the following:

https://duet3d.dozuki.com/Wiki/Using_the_manual_bed_levelling_assistantBut it also seems to be out of date as those macros do not work either and I get errors when trying to run them.

If anyone has a handy dummy proof manual bed leveling macro to use with a BL touch I would be much appreciated.

For ref:

bed.g

; bed.g ; called to perform automatic bed compensation via G32 ; ; generated by RepRapFirmware Configuration Tool v2.1.8 on Sun Feb 09 2020 08:41:29 GMT-0600 (Central Standard Time) ;M561 ; clear any bed transform ;G29 ; probe the bed and enable compensation G28 ; Home M401 ; deploy Z probe ; Probe adjustment screw locations G30 PO X26 Y195 Z-99999 ; Probe at adjustment screw #1 (back left) G30 P1 X177 Y195 Z-99999 ; Probe at adjustment screw #2 (back right) G30 P2 X177 Y25 Z-99999 ; Probe at adjustment screw #4 (front right) G30 P3 X26 Y25 Z-99999 S4 ; Probe at adjustment screw #3 (front right) and report adjustments needed M402 ; retract probeBed Level Macro

; Helps guide leveling the bed mechanically, and calibrate the ZProbe trigger height before running a grid bed compensation routine.. ; ; Preamble to tell the user to prepare the printer before continuing ; ;M291 P"Before proceeding make sure the printer is mechanically sound and properly functioning." R"Prepare printer for leveling routine" S3 ; User must click OK ;M291 P"ZProbe should be configured and working. Clear the print bed of any obstacles or debris." R"Prepare printer for leveling routine" S3 ; User must click OK ;M291 P"This routine will take about 10-20 minutes and heat both the bed and nozzle." R"Prepare printer for leveling routine" S3 ; User must click OK ;M291 P"You will need a piece of paper. Filament will be unloaded." R"Prepare printer for leveling routine" S3 ; User must click OK ;M291 P"Make sure you have successful Gcodes logged to the console before proceeding." R"WARNING" S3 ; User must click OK or cancel ;M291 P"Make a note of your M558 Z value and backup current heightmap before proceeding." R"WARNING" S3 ; User must click OK or cancel M929 P"bedlevellog.txt" S3 ; start logging ; Clear compensation map and Zprobe trigger height ; M291 P"Grid bed compensation map will be disabled. Ok or Cancel?" R"WARNING" S3 ; User must click OK or cancel. M561 ; Disable any current bed compensation G29 S2 ; Clear mesh bed compensation perameters ;G31 Z0 ; Reset zprobe trigger height ; Heat up bed and nozzle to PLA temps in prep for filament removal and probing ; M291 P"Bed and nozzle will preheat and home all axis." R"Preheat and Home" S3 T0 ; User must click OK or cancel M104 S130 ; Set nozzle to 130 and release M140 S55 ; Set bed to 55 and release ; home all axis ; G28 XY G28 Z ; Home all axis G90 ; Absolute positioning T0 ; Activate first tool ; Set lower speeds for Z homing and lower Z motor current ; M566 Z10 ; Set maximum instantaneous speed changes (mm/min) (Jerk) M203 Z400 ; Set maximum speeds (mm/min) M201 Z100 ; Set maximum accelerations (mm/s^2) M913 Z40 ; Drop motor current to prevent damage in case of head crash ; Move nozzle forward for filament removal ; ;M291 P"Moving nozzle to the front for filament removal and cleaning." T0 ;G1 X50 Y5 Z100 ; Moves print head to front left and drops the bed down for easy access ;M109 S130 ; Set nozzle to 130 and wait ; Tone to get user attention ; M400 ; Clear movement buffer so tones play reliably M300 S666 P500 G4 P501 M300 S1111 P300 G4 P301 ; Unload filament and clean nozzle ; ;M291 P"Unload filament if loaded and clean nozzle, then press OK to continue" R"Unload Filament" S3 T0 ; User must click OK or cancel M702 ; Unload Filament ; Preheat to probing temps ; M291 P"Preheating the bed to 60 and nozzle to 210 for accurate probing" T0 M104 S210 ; Set nozzle to 210 and release M190 S60 ; Set bed to 60 and wait M109 S210 ; Set nozzle to 210 and wait ; Tone to get user attention ; ;M400 ; Clear movement buffer so tones play reliably ;M300 S666 P500 ;G4 P501 ;M300 S1111 P300 ;G4 P301 ; Move nozzle to center of bed at Z10 and drop to Z1 ; M291 P"Nozzle will now move to center of bed and move close to the bed" T0 M98 P"/macros/general/1_Center_Nozzle" ;P move to bed center ; Reset z to 8 to allow jogging up to touch bed to nozzle ; G92 Z8 ; Dialog to allow user to job z to touch nozzle to bed gently and then move Z down 10 ; M291 P"Carefully Jog the Z Axis until the bed and nozzle are touching and click OK" R"Setting Z=0" Z1 S3 G92 Z0 ; set z = 0 ; Move nozzle to leveling points and prompt user to level bed at each ; M291 P"Nozzle will now move to the 4 leveling points twice." S1 T2 ; Move to leveling point 1 G1 Z2 ; move to z2 for travel G1 X26 Y25 F6000 ; Move to front left corner M400 M291 P"Adjust point 1 by using jog to lower nozzle to 0, then use the bed height knobs and a piece of paper to tweak tension." R"Adjustment Point 1" S2 Z1 ; Move to leveling point 2 G1 Z2 ; Move to Z2 for clearance G1 X195 Y195 F6000 ; Move to rear right corner M400 M291 P"Adjust point 2 by using jog to lower nozzle to 0, then use the bed height knobs and a piece of paper to tweak tension." R"Adjustment Point 2" S2 Z1 ; Move to leveling point 3 G1 Z2 ; Move to Z2 for clearance G1 X195 Y25 F6000 ; Move front right corner M400 M291 P"Adjust point 3 by using jog to lower nozzle to 0, then use the bed height knobs and a piece of paper to tweak tension." R"Adjustment Point 3" S2 Z1 ; Move to leveling point 4 G1 Z2 ; Move to Z2 for clearance G1 X26 Y195 F6000 ; Move rear left corner M400 M291 P"Adjust point 4 by using jog to lower nozzle to 0, then use the bed height knobs and a piece of paper to tweak tension." R"Adjustment Point 4" S2 Z1 ; Repeat to verify ; M291 P"The adjustment sequence will now repeat for fine adjustment." S1 T2 ; Move to leveling point 1 G1 Z2 ; move to z2 for travel G1 X26 Y25 F6000 ; Move to front left corner M400 M291 P"Adjust point 1 by using jog to lower nozzle to 0, then use the bed height knobs and a piece of paper to tweak tension." R"Adjustment Point 1" S2 Z1 ; Move to leveling point 2 G1 Z2 ; Move to Z2 for clearance G1 X195 Y195 F6000 ; Move to rear right corner M400 M291 P"Adjust point 2 by using jog to lower nozzle to 0, then use the bed height knobs and a piece of paper to tweak tension." R"Adjustment Point 2" S2 Z1 ; Move to leveling point 3 G1 Z2 ; Move to Z2 for clearance G1 X195 Y25 F6000 ; Move front right corner M400 M291 P"Adjust point 3 by using jog to lower nozzle to 0, then use the bed height knobs and a piece of paper to tweak tension." R"Adjustment Point 3" S2 Z1 ; Move to leveling point 4 G1 Z2 ; Move to Z2 for clearance G1 X26 Y195 F6000 ; Move rear left corner M400 M291 P"Adjust point 4 by using jog to lower nozzle to 0, then use the bed height knobs and a piece of paper to tweak tension." R"Adjustment Point 4" S2 Z1 ; Move nozzle to center of bed at z10 ; M291 P"Nozzle will now move to center of bed to reset Z0" S3 G1 Z1 ; Drop bed for nozzle clearance ;G1 X112.5 Y112.5 Z2 F4000 ; Move to bed center M98 P"/macros/general/1_Center_Nozzle" ; Reset z to 5 to allow jogging up to touch bed to nozzle ; G92 Z5 ; Dialog to allow user to jog z to touch nozzle to bed gently and then move Z down 10 ; M564 S0 ; To allow movement lower than where the firmware thinks Z=0 is. M291 P"Jog the Z Axis until the bed and nozzle are touching and click OK" R"Setting Z=0" Z1 S3 G92 Z0 ; Set z = 0 G1 Z1 ; Drop bed for nozzle clearance M291 P"The bed has been mechanically leveled and Z0 set." S2 ; Tone to get user attention ; M400 ; Clear movement buffer so tones play reliably M300 S666 P600 G4 P601 M300 S1511 P300 G4 P301 M291 P"Probing complete. Turning off heaters and homing axis." ; Turn off heaters ; M104 S0 ; Set nozzle to 0 and release M140 S0 ; Set bed to 0 and release G28 XY ; Home XY ; Set normal settings after stall detection probing ; M98 P"/macros/general/1_Center_Nozzle" ;P define the parameter and is not part of the name ; Tone to get user attention M400 ; Clear movement buffer so tones play reliably M300 S666 P600 G4 P601 M300 S1511 P300 G4 P301 M291 P"Run Trigger Height Macro to determine trigger height" M929 S0 ; stop logging -

RE: 3.4 RC assign how to assign PS_ON?posted in Firmware installation

@mitch said in 3.4 RC assign how to assign PS_ON?:

PS_ON

In case anyone else had the same question:

M81 C"pson" ; Turn off 24VDC power on start up and enable control in the UI M950 J0 C"^exp.e6stop" ; create GPIO input pin 0 attached to Estop6 expansion connector - Senses Power Button, Low=Button Pressed M950 P1 C"!exp.31" ; create GPIO output pin 1 attached to heater7 on expansion connector - Controls Duet2 On=S1 (default), Off=S0 M581 P0 S1 T2 C0 ; When E6 goes Low, execute trigger2.g to complete shutdown -

3.4 RC assign how to assign PS_ON?posted in Firmware installation

Prior to the 3.4RC upgrade I had been using the following configuration for 3.4Beta1.

I saw the release note regarding:

"There is no longer a power supply control pin assigned by default (in previous firmware versions, PS_ON was assigned by default). Therefore, M80 and M81 will not work until you have assigned a power control pin. If you want to control the power supply, you should use assign a pin using either M80 or M81 with the C parameter in config.g. Use M80 if you want to start with power on, or M81 if you provide separate 5V power and you want to start with VIN power off."However, it is still unclear to me what I need to do to define PS_ON.

This is what I was prev using on 3.4Beta1:

; Soft Power Control M81 ; Turn off 24VDC power on start up and enable control in the UI M950 J0 C"^exp.e6stop" ; create GPIO input pin 0 attached to Estop6 expansion connector - Senses Power Button, Low=Button Pressed M950 P1 C"!exp.31" ; create GPIO output pin 1 attached to heater7 on expansion connector - Controls Duet2 On=S1 (default), Off=S0 M581 P0 S1 T2 C0 ; When E6 goes Low, execute trigger2.g to complete shutdown -

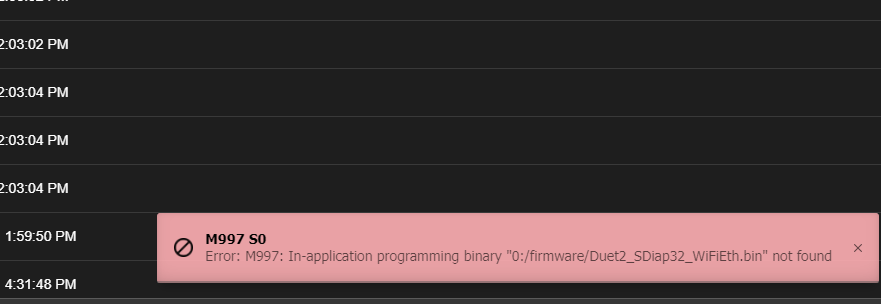

3.4beta7 upgraded failsposted in Firmware installation

Attempts to upgrade via the web interface from 3.4Beta1 to 3.4beta7 fail with an error stating that the Duet2_SDiap32_WiFiEth.bin file is missing from the firmware directory.

Looking in the firmware directory I only see two files:

PanelDueFirmware.bin

Duet20CombinedFirmware.binI found a copy of the missing file in my sys folder, copied it into the firmware directory and then attempted the upgrade again. No errors this time, but it doesn't seem to have upgraded.

M122 === Diagnostics === RepRapFirmware for Duet 2 WiFi/Ethernet version 3.4.0beta1 (2021-07-10 16:20:05) running on Duet Ethernet 1.02 or later Board ID: 08DGM-917DA-G4MSJ-6J1F4-3S06M-99PZB Used output buffers: 1 of 24 (23 max) === RTOS === Static ram: 23924 Dynamic ram: 75204 of which 0 recycled Never used RAM 15288, free system stack 190 words Tasks: NETWORK(ready,24.3%,237) HEAT(delaying,0.0%,326) Move(notifyWait,0.1%,340) MAIN(running,73.9%,467) IDLE(ready,1.8%,29), total 100.0% Owned mutexes: === Platform === Last reset 00:00:50 ago, cause: power up Last software reset at 2021-07-20 18:03, reason: User, GCodes spinning, available RAM 11776, slot 0 Software reset code 0x0003 HFSR 0x00000000 CFSR 0x00000000 ICSR 0x0041f000 BFAR 0xe000ed38 SP 0x00000000 Task MAIN Freestk 0 n/a Error status: 0x00 Aux0 errors 0,0,0 Step timer max interval 0 MCU temperature: min 25.8, current 27.5, max 28.1 Supply voltage: min 0.4, current 24.5, max 24.5, under voltage events: 0, over voltage events: 0, power good: yes Heap OK, handles allocated/used 0/0, heap memory allocated/used/recyclable 0/0/0, gc cycles 0 Driver 0: position 0, standstill, SG min/max not available Driver 1: position 0, standstill, SG min/max not available Driver 2: position 0, standstill, SG min/max not available Driver 3: position 0, standstill, SG min/max not available Driver 4: position 0, standstill, SG min/max not available Driver 5: position 0 Driver 6: position 0 Driver 7: position 0 Driver 8: position 0 Driver 9: position 0 Driver 10: position 0 Driver 11: position 0 Date/time: 2022-02-12 14:41:31 Cache data hit count 1879040214 Slowest loop: 149.57ms; fastest: 0.13ms I2C nak errors 0, send timeouts 0, receive timeouts 0, finishTimeouts 0, resets 0 === Storage === Free file entries: 10 SD card 0 detected, interface speed: 20.0MBytes/sec SD card longest read time 1.6ms, write time 0.0ms, max retries 0 === Move === DMs created 83, maxWait 0ms, bed compensation in use: none, comp offset 0.000 === MainDDARing === Scheduled moves 0, completed moves 0, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1 === AuxDDARing === Scheduled moves 0, completed moves 0, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1 === Heat === Bed heaters = 0 -1 -1 -1, chamberHeaters = -1 -1 -1 -1 Heater 1 is on, I-accum = 0.0 === GCodes === Segments left: 0 Movement lock held by null HTTP is idle in state(s) 0 Telnet is idle in state(s) 0 File is idle in state(s) 0 USB is idle in state(s) 0 Aux is idle in state(s) 0 Trigger is idle in state(s) 0 Queue is idle in state(s) 0 LCD is idle in state(s) 0 Daemon is idle in state(s) 0 Autopause is idle in state(s) 0 Code queue is empty. === Filament sensors === Extruder 0: pos 0.00, errs: frame 0 parity 0 ovrun 0 pol 0 ovdue 0 === Network === Slowest loop: 22.02ms; fastest: 0.01ms Responder states: HTTP(0) HTTP(0) HTTP(0) HTTP(0) FTP(0) Telnet(0), 0 sessions HTTP sessions: 1 of 8 Interface state active, link 100Mbps full duplex -

RE: PT100 sensor on Duet2 sporadically hunting for target tempposted in Tuning and tweaking

Well, so far so good. I ran a twisted pair and terminated new connectors. One of the two seemed to have fixed this issue for now. Thanks for the help.

-

RE: PT100 sensor on Duet2 sporadically hunting for target tempposted in Tuning and tweaking

@Veti Ok, doing that now. I know I read something somewhere about 4wire vs 2wire on the PT100. Right now I am just running a straight 2wire.

Running a separate twisted 2wire now.

-

RE: PT100 sensor on Duet2 sporadically hunting for target tempposted in Tuning and tweaking

The PT100 wire is not twisted pair. It is just a straight through cable. However, all of the motor cables are in fact twisted pair.

Is tearing this wire bundle apart and using twisted pair for the PT100 sensor a necessity? If that would eliminate this issue I have not problem doing it. But it is quite the task if it isn't usually necessary.

-

RE: PT100 sensor on Duet2 sporadically hunting for target tempposted in Tuning and tweaking

I am attempting to run a print right now. The blips in the graph are heater faults I have had to clear. The temp just seems to stay on and then drift, clear it, it works again. Not spikes to 2000 or anything like that.