Although I own a original duet laser filament monitor (v2) I also have a magnetic sensor on order. I have been playing with the various indirect filament monitor approaches lately with limited success and reliability.

FINALLY, I have something that works reliably:

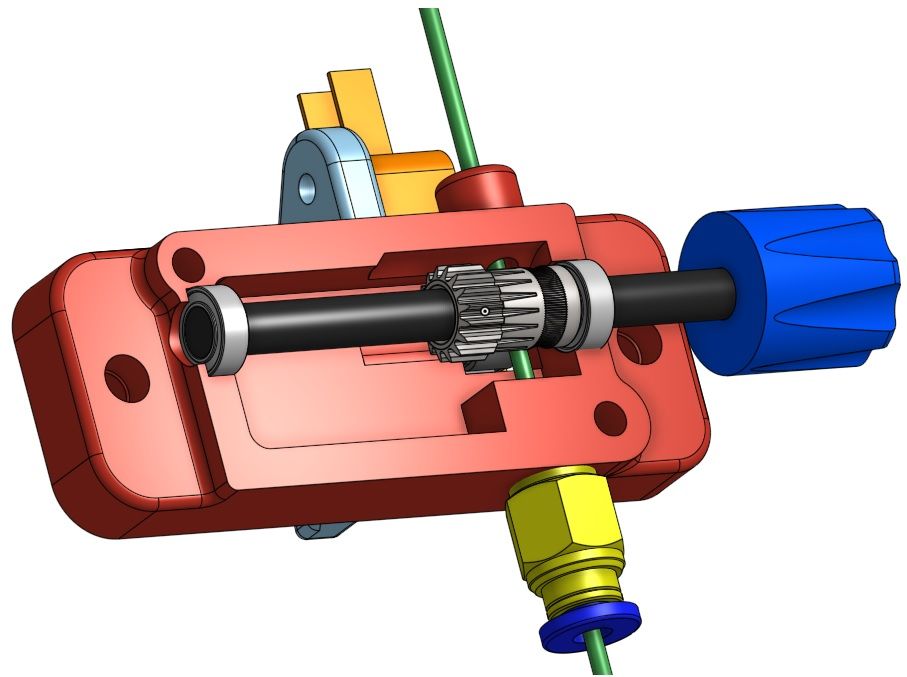

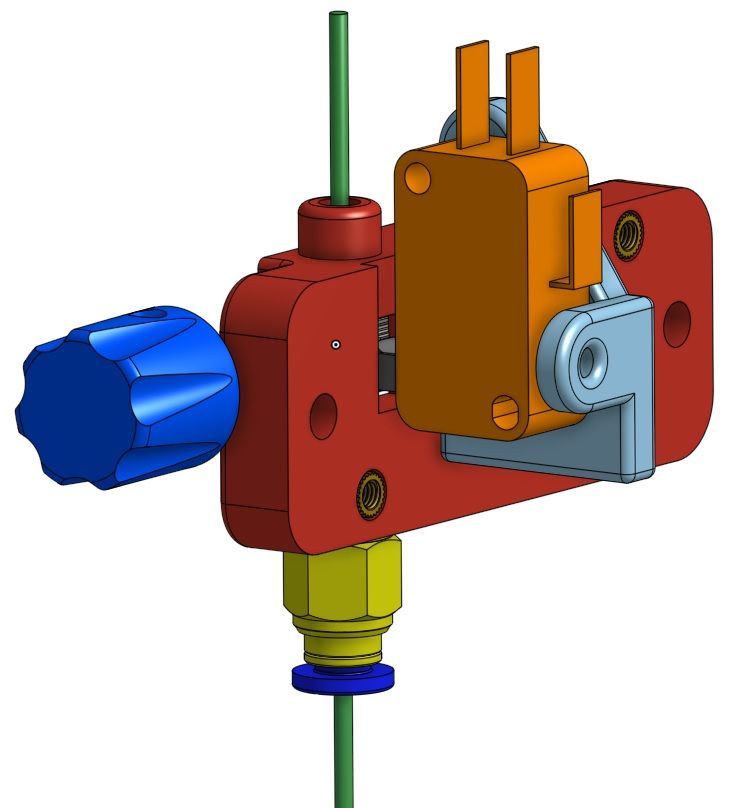

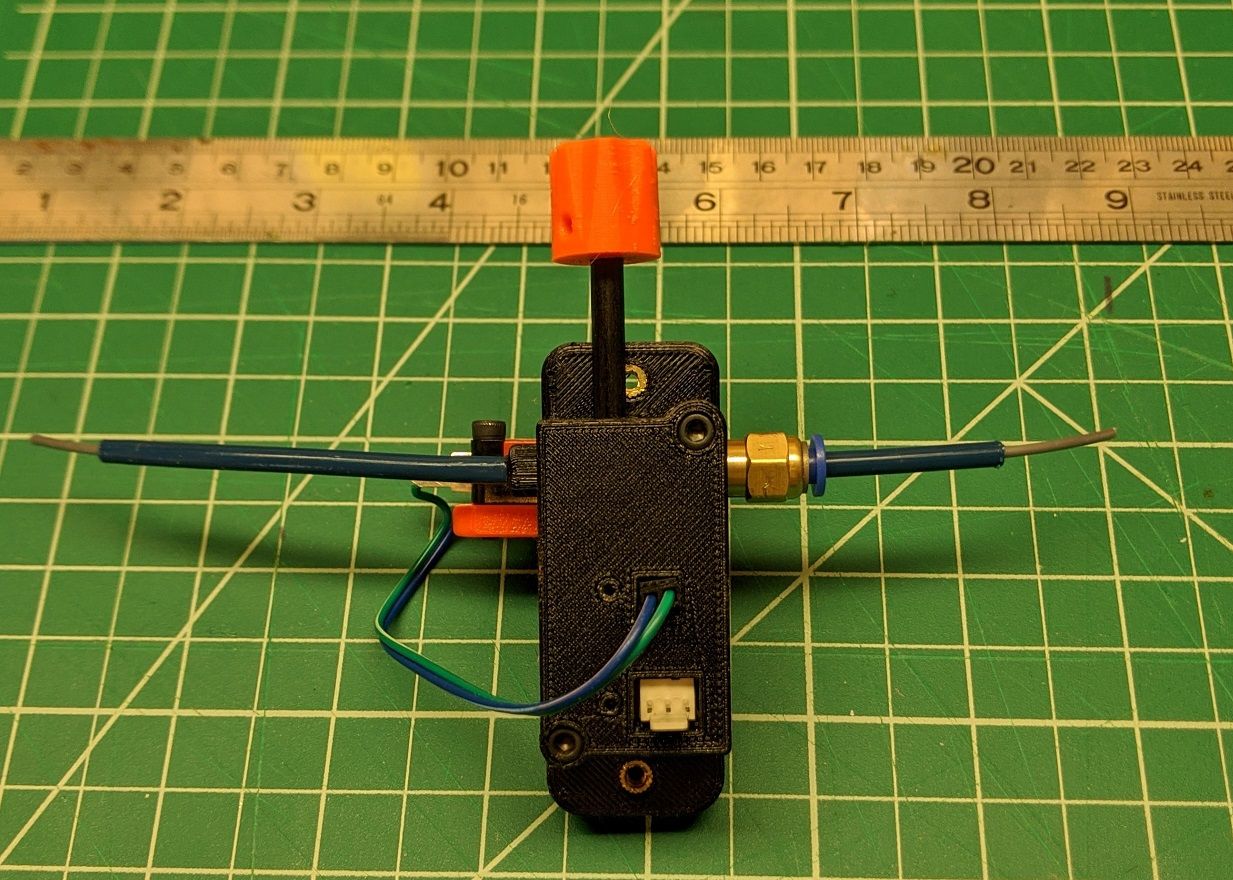

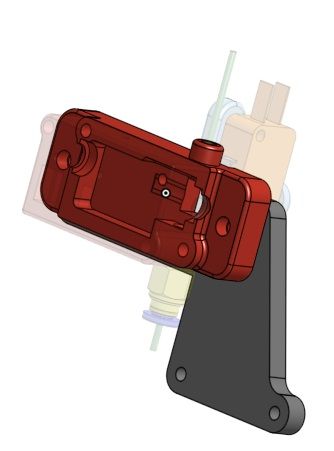

https://www.thingiverse.com/thing:4587312

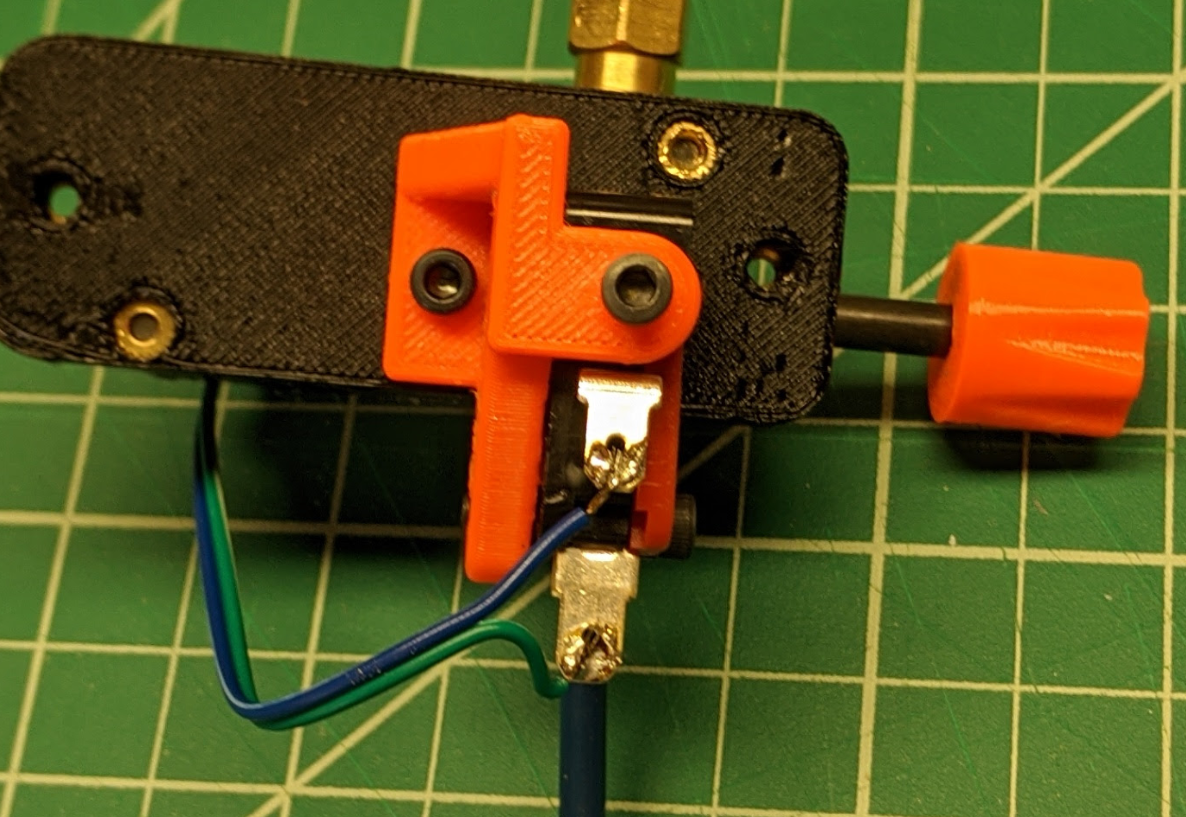

I have remixed the latest carbon fiber method with lots of tweaks as well as getting rid if the idler assembly and instead killing two birds by using a micro switch as the idler assembly.

The build was much easier than the original.

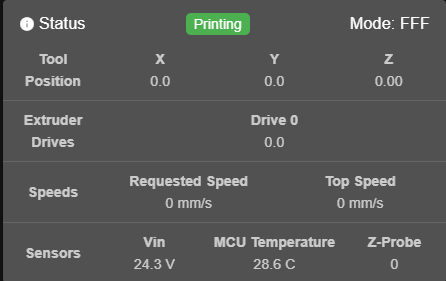

My test run yielded very reliable results:

9/3/2020, 12:48:32 PM M591 D0

Duet3D laser filament monitor v2 with switch on pin e0stop, disabled, allow 70% to 130%, check every 3.0mm, version 2, quality 223, brightness 255, shutter 92, measured min 228% avg 247% max 268% over 2450.8mm

M591 D0

Duet3D laser filament monitor v2 with switch on pin e0stop, disabled, allow 70% to 130%, check every 3.0mm, version 2, quality 223, brightness 255, shutter 89, measured min 228% avg 247% max 268% over 2273.6mm

M591 D0

Duet3D laser filament monitor v2 with switch on pin e0stop, disabled, allow 70% to 130%, check every 3.0mm, version 2, quality 223, brightness 255, shutter 88, measured min 229% avg 247% max 267% over 609.2mm

I have also asked DC to include the L parameter into the the M591 command so that we can tune the ratio to normalize the output and he is making the change per v3.2:

M591 D0 P6 C"e0stop" R70:130 L0.4 E3.0 S0

Lnn (firmware 3.2 and later) Calibration factor, default 1.0. The filament movement reported by the laser sensor is multiplied by this value before being compared with the commanded extrusion. Intended for use with sensors that use the laser to read movement of a wheel that is turned by the filament.

I would estimate this indirect setup would L0.4 based on the test runs.

The microswitch has a tuner screw to fine tune the operating distance on the switch by simply turning the set screw.

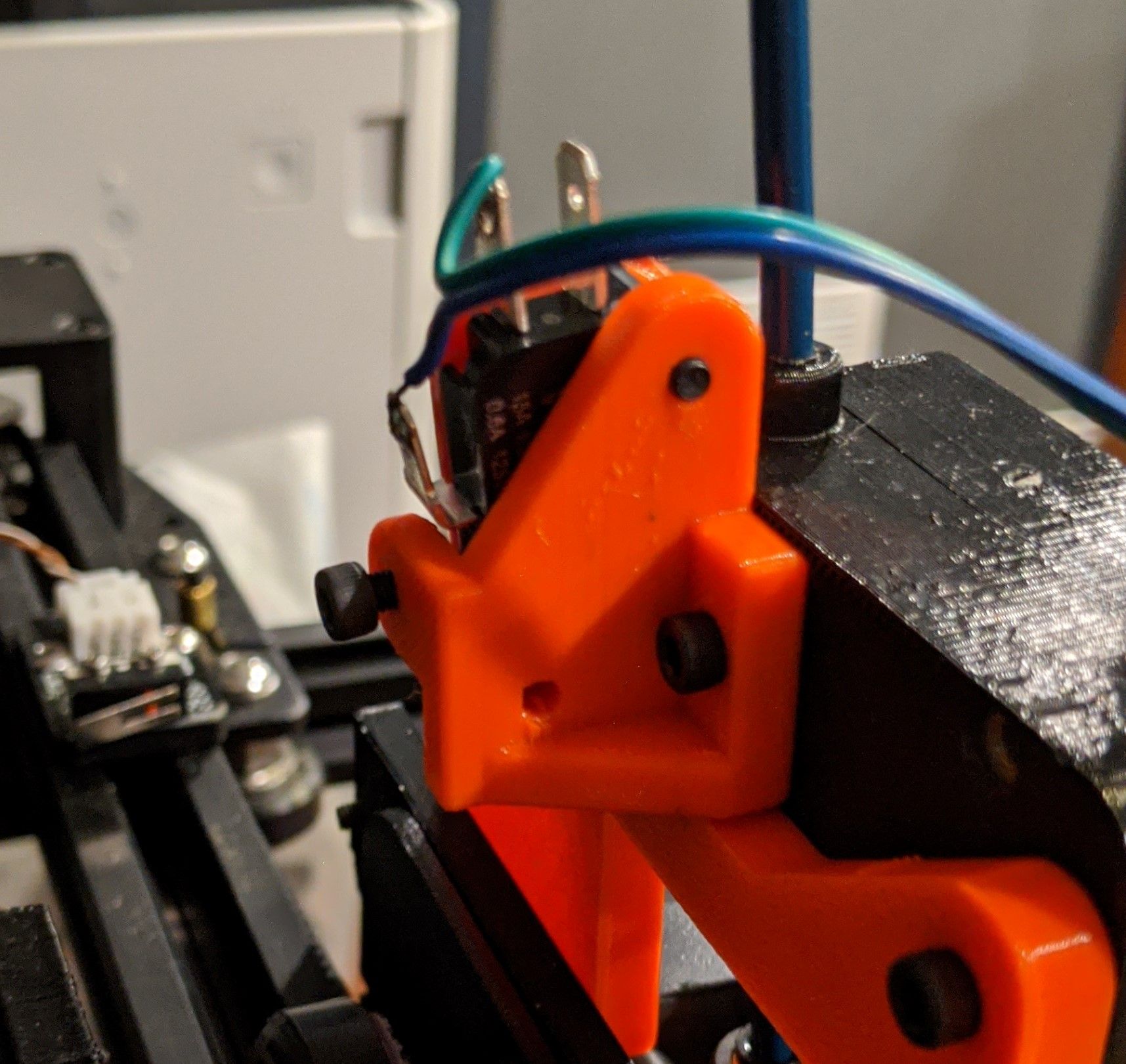

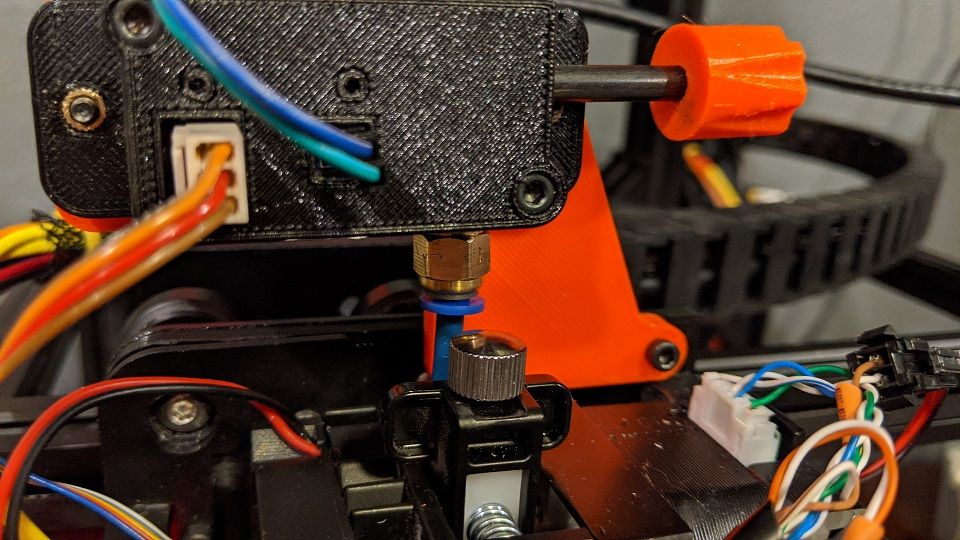

I am printing on a modified Ender 5 with a direct drive Hemera. I have also included a bracket (orange) to make this a rigid mount to make loading and unloading easier. Right now I just push in the filament and it feeds through pretty easily and provides enough clearance to engage/disengage the hemera tension lever.

The real trick was playing with the different hob gear options. The original used a gear that was just to "slick" and didn't have a concave channel to keep the filament centered and create more friction. I had to move to a Mk3 gear in black to get the best performance.