Sure. See below for those details. It's a Prusa P3 Steel, so the Z axis has 2 motors. It is level to the Y axis. The bed is leveled using a .1mm metal feeler gauge. It's a 3mm aluminum bed with Printbite on top. I have a 3 point leveling setup, and it is fairly level, not perfect like cast aluminum plate. The first layer as all layers are .2mm. I don't have any extra extrusion parameters. The extruder is calibrated, so I get 100mm when extruding 100mm. I am not using mesh compensation setup.

Home all

G91 ; relative positioning

G1 H2 Z5 F12000 ; lift Z relative to current position

G1 H1 X-205 Y-205 F1800 ; move quickly to X and Y axis endstops and stop there (first pass)

G1 H2 X5 Y5 F12000 ; go back a few mm

G1 H1 X-205 Y-205 F600 ; move slowly to X and Y axis endstops once more (second pass)

G90 ; absolute positioning

G1 X0 Y0 F6000 ; go to first bed probe point

G91 ; relative positioning

G1 H1 Z-305 F600 ; move Z down stopping at the endstop

G1 H2 Z3 F600 ; go back a few mm

G1 H1 Z-305 F120 ; move slowly to Z axis endstop once more (second pass)

G90 ; absolute positioning

G92 Z0.1 ; set Z position to axis minimum

Home X

G91 ; relative positioning

;G1 H2 Z5 F12000 ; lift Z relative to current position

G1 H1 X-205 F1800 ; move quickly to X axis endstop and stop there (first pass)

G1 H2 X5 F2400 ; go back a few mm

G1 H1 X-205 F600 ; move slowly to X axis endstop once more (second pass)

G90 ; absolute positioning

Home Y

G91 ; relative positioning

G1 H2 Z5 F12000 ; lift Z relative to current position

G1 H1 Y-205 F1800 ; move quickly to Y axis endstop and stop there (first pass)

G1 H2 Y5 F12000 ; go back a few mm

G1 H1 Y-205 F600 ; move slowly to Y axis endstop once more (second pass)

G1 H2 Z-5 F12000 ; lower Z again

G90 ; absolute positioning

Home Z

G91 ; relative positioning

G1 H1 Z-305 F600 ; move Z down stopping at the endstop

G1 H2 Z3 F600 ; go back a few mm

G1 H1 Z-305 F120 ; move slowly to Z axis endstop once more (second pass)

G90 ; absolute positioning

G92 Z0.1 ; set Z position to axis minimum

Config.g

; General preferences

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

M550 P"P3 Steel" ; set printer name

; Network

M552 S1 ; enable network

M586 P0 S1 ; enable HTTP

M586 P1 S0 ; disable FTP

M586 P2 S1 ; enable Telnet

; Drives

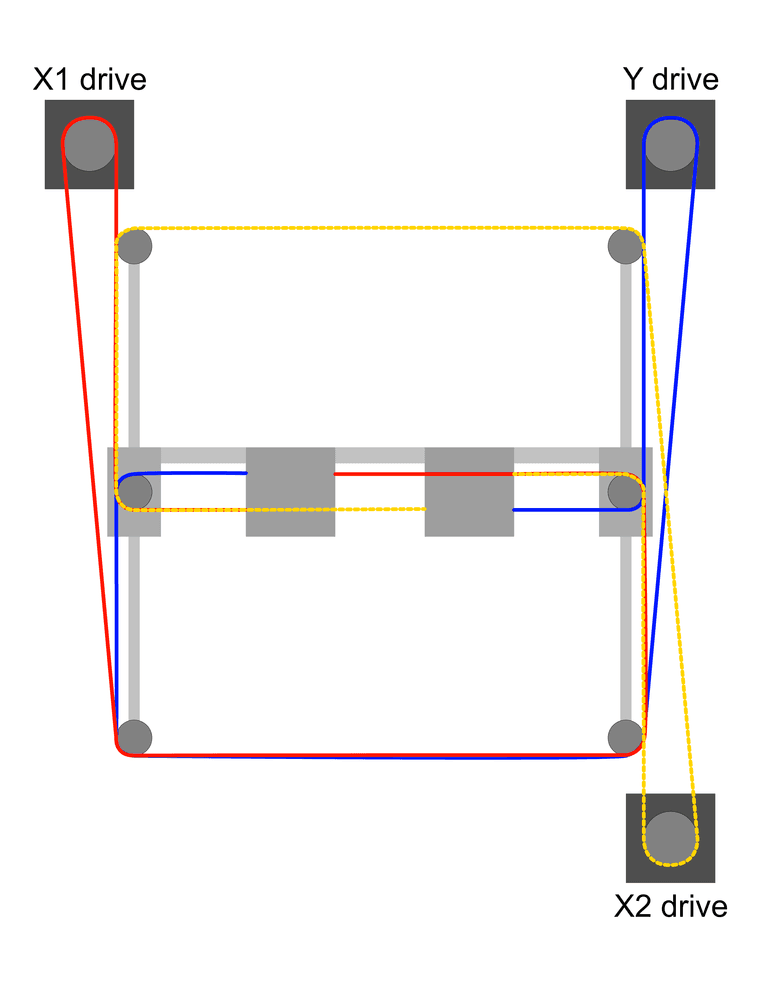

M569 P0 S1 ; physical drive 0 goes forwards

M569 P1 S1 ; physical drive 1 goes forwards

M569 P2 S0 ; physical drive 2 goes backwards

M569 P3 S1 ; physical drive 3 goes forwards

M584 X0 Y1 Z2 E3 ; set drive mapping

M350 X128 Y128 Z128 E128 I0 ; configure microstepping without interpolation

M92 X640.00 Y640.00 Z3200.00 E2335.5 ; set steps per mm

M566 X900.00 Y900.00 Z12.00 E1500.00 ; set maximum instantaneous speed changes (mm/min)

M203 X12000.00 Y12000.00 Z180.00 E12000.00 ; set maximum speeds (mm/min)

M201 X1400.00 Y1400.00 Z50.00 E9000.00 ; set accelerations (mm/s^2)

M906 X1200 Y1200 Z1000 E1400 I30 ; set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout

; Axis Limits

M208 X0 Y-13 Z0 S1 ; set axis minima

M208 X200 Y195 Z300 S0 ; set axis maxima

; Endstops

M574 X1 S1 P"!xstop" ; configure active-high endstop for low end on X via pin xstop

M574 Y1 S1 P"!ystop" ; configure active-high endstop for low end on Y via pin ystop

M574 Z1 S1 P"!zstop" ; configure active-high endstop for low end on Z via pin zstop

; Z-Probe

M558 P0 H2 F120 T6000 ; disable Z probe but set dive height, probe speed and travel speed

M557 X0:200 Y0:200 S1 ; define mesh grid

; Heaters

M308 S0 P"bedtemp" Y"thermistor" T100000 B4066 C9.264103e-8 ; configure sensor 0 as thermistor on pin bedtemp

M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0

M143 H0 S120 ; set temperature limit for heater 0 to 120C

M307 H0 A62.4 C118.9 D3.0 B0 S1.00 ; disable bang-bang mode for the nozzle heater and set PWM limit

M308 S1 P"e0temp" Y"thermistor" T100000 B4725 C7.06e-8 ; configure sensor 1 as thermistor on pin e0temp

M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1

M143 H1 S300 ; set temperature limit for heater 1 to 300C

M307 H1 A387.2 C120.9 D3.1 B0 S1.00 ; disable bang-bang mode for the nozzle heater and set PWM limit

; Fans

M950 F0 C"fan0" Q500 ; create fan 0 on pin fan0 and set its frequency

M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off

M950 F1 C"fan1" Q500 ; create fan 1 on pin fan1 and set its frequency

M106 P1 S1 H-1 ; set fan 1 value. Thermostatic control is turned off

M950 F2 C"fan2" Q500

M106 P2 S1 H1 T100

; Tools

M563 P0 D0 H1 F0 ; define tool 0

G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets

G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C

; Custom settings are not defined

M207 S3 R-0.1 F6000 T6000 Z0.1 ; Firmware retraction F is retract mm/m and T is detract mm/m

M572 D0 S0.8 ; pressure advance

; Miscellaneous

M911 S10 R11 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; set voltage thresholds and actions to run on power loss