@infiniteloop said in Energizing a relay using the expansion header:

Can I use the E1 heater output for coil pins?

That depends. The E1 heater output switches to GND, but provides VIN on the other pin by default. So return to the data sheet and assure that your relay’s version has a matching ”Coil code”: ”24” for a VIN of 12V, ”25” for a VIN of 24V.

A note of caution from the documentation:

There are no on-board flyback diodes on these outputs, so if you connect a high-current inductive load, you must use an external flyback diode.

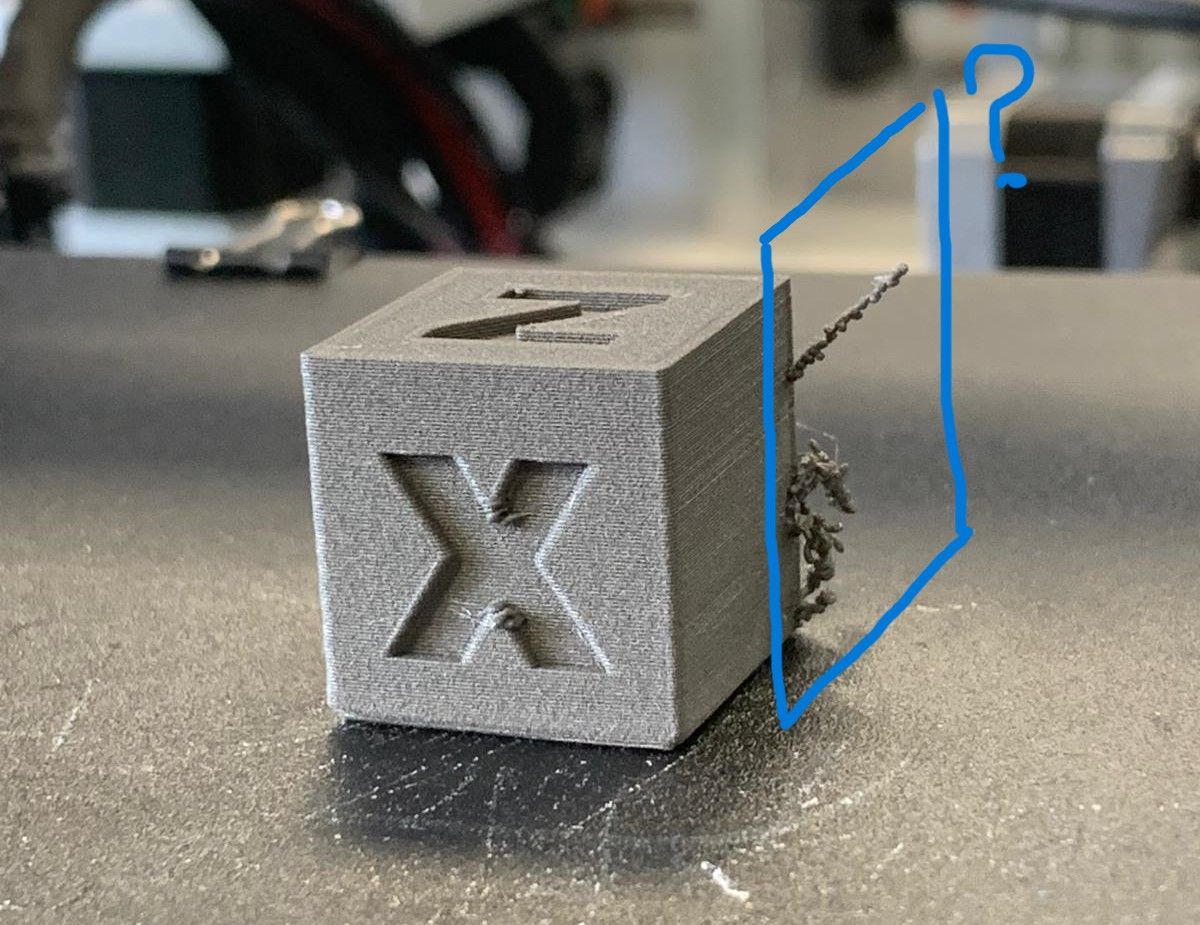

I forgot for a second that the E1 heater output doesn't match the coil requirements for this relay, which operates at 5V. Are there any suitable pins on the board that I could use instead? If not, I'll need to consider using a different relay.

Thanks for the note as well.

. This solved the issue perfectly.

. This solved the issue perfectly.