@oliof As mentioned, it works really well, but I want the print to start after the variable for Mirror has been processed. And not continue with the subsequent gcode.

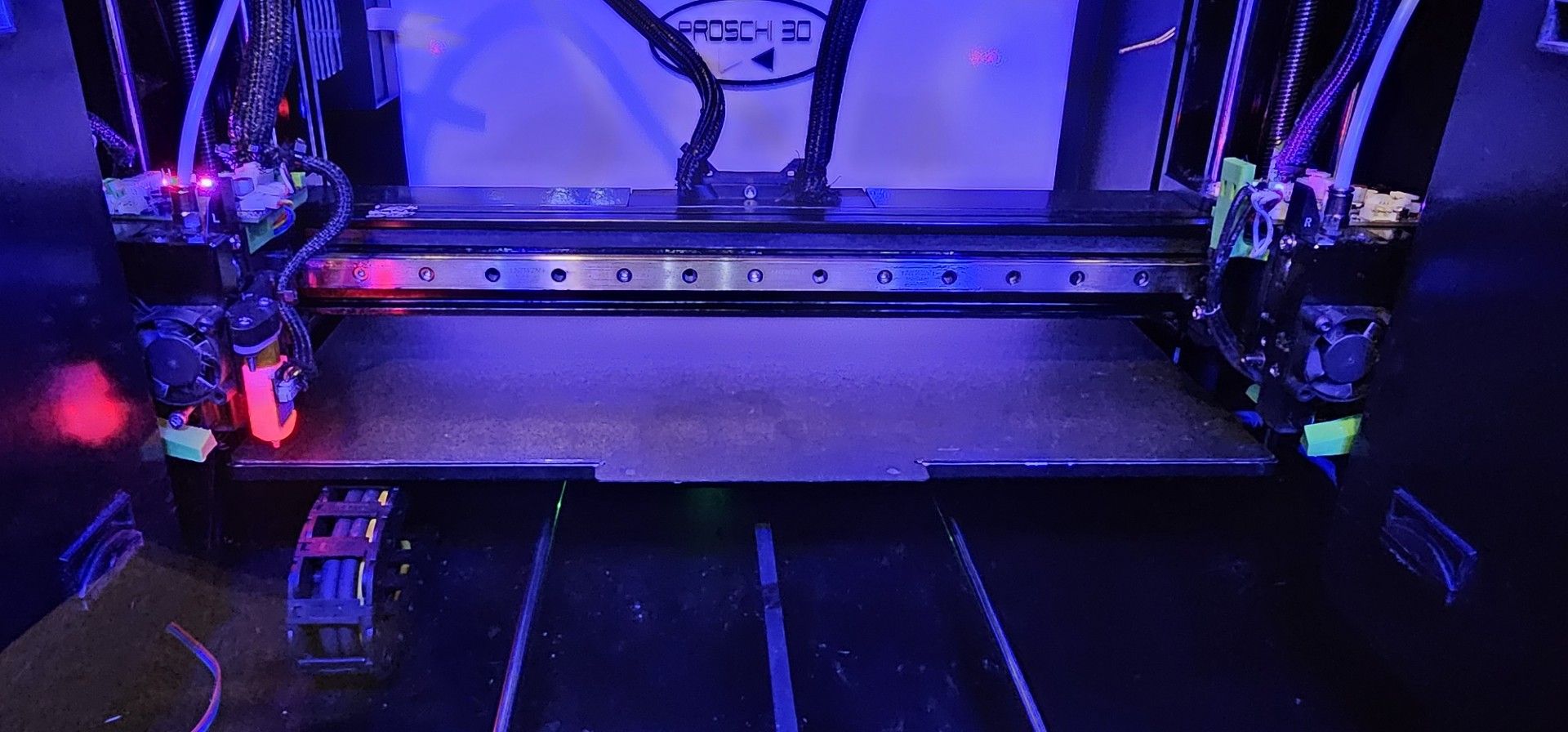

Posts made by Proschi3D

-

RE: Orca slicer start code Idexposted in Gcode meta commands

-

Orca slicer start code Idexposted in Gcode meta commands

Hello everyone.

I have created a start code for my IDEX printer for the Orca slicer. Everything works very well, except for the mirror mode. Here, I want it to perform a separate nozzle cleaning as specified in the code, and then start printing without executing the rest of the code. Does anyone have an idea?

; Model: Proschi3d({nozzle_diameter[0]}/{nozzle_diameter[1]}) ; Printer : [printer_preset] ; Profile : [print_preset] ; Plate : [plate_name] ; --- initial_extruder: [initial_extruder] ; --- has_wipe_tower: [has_wipe_tower] ; --- total_toolchanges: [total_toolchanges] ; --- T0: {is_extruder_used[(initial_extruder % 2 == 0 ? min(initial_extruder + 0, 63) : max(initial_extruder - 1, 0))]} ; --- T1: {is_extruder_used[(initial_extruder % 2 == 0 ? min(initial_extruder + 1, 63) : max(initial_extruder - 0, 0))]} T[initial_extruder] {if plate_name =~/.*IDEXDupl.*/ || plate_name =~/.*IDEXCopy.*/ } T2 {elsif plate_name =~/.*IDEXMirr.*/} M140 S{first_layer_bed_temperature[initial_extruder]} M557 X{adaptive_bed_mesh_min[0]}:{adaptive_bed_mesh_max[0]} Y{adaptive_bed_mesh_min[1]}:{adaptive_bed_mesh_max[1]} P{bed_mesh_probe_count[0]}:{bed_mesh_probe_count[1]} ; Mesh-Bett-Nivellierung G28 X0 Y0 U0 T3 ; Eigener Düsenreinigungsprozess G0 Z10 F3000 ; Hebe die Düse an G0 X5 Y10 F6000 ; Bewege die Düse zur Reinigungsposition M109 S{max(230, min(290, nozzle_temperature_initial_layer[(initial_extruder % 2 == 0 ? min(initial_extruder + 0, 63) : max(initial_extruder - (1-0), 0))] + 15))} C2 W1 G0 Z1.6 G1 E10 Z5 F100 ; Extrudiere etwas Filament, um die Düse zu reinigen M104 S{nozzle_temperature_initial_layer[(initial_extruder % 2 == 0 ? min(initial_extruder + 0, 63) : max(initial_extruder - (1-0), 0))] + 5} G0 X15 Y10 F3000 G0 Z0.4 G0 E8 X70 Y10 G0 X70 Y20 Z10 G92 E0 ; Setze den Extruderzähler zurück ; Starte den Druckprozess M117 ; Starte den Druckprozess {else} M140 S{first_layer_bed_temperature[initial_extruder]} ; you can clean the nozzle {if is_extruder_used[(initial_extruder % 2 == 0 ? min(initial_extruder + 0, 63) : max(initial_extruder - (1-0), 0))]} M104 T{(initial_extruder % 2 == 0 ? min(initial_extruder + 0, 63) : max(initial_extruder - (1-0), 0))} S165 {endif} {if is_extruder_used[(initial_extruder % 2 == 0 ? min(initial_extruder + 1, 63) : max(initial_extruder - (1-1), 0))]} M104 T{(initial_extruder % 2 == 0 ? min(initial_extruder + 1, 63) : max(initial_extruder - (1-1), 0))} S165 {endif} G28 F5000 M557 X{adaptive_bed_mesh_min[0]}:{adaptive_bed_mesh_max[0]} Y{adaptive_bed_mesh_min[1]}:{adaptive_bed_mesh_max[1]} P{bed_mesh_probe_count[0]}:{bed_mesh_probe_count[1]} G29 S0 G28 X0 U0 F6000 G0 Z5 F6000 {if is_extruder_used[(initial_extruder % 2 == 0 ? min(initial_extruder + 0, 63) : max(initial_extruder - (1-0), 0))]} T{(initial_extruder % 2 == 0 ? min(initial_extruder + 0, 63) : max(initial_extruder - (1-0), 0))} G0 X{if 0 == 0}80{else}240{endif} Y0 F7000 {endif} {if is_extruder_used[(initial_extruder % 2 == 0 ? min(initial_extruder + 1, 63) : max(initial_extruder - (1-1), 0))]} T{(initial_extruder % 2 == 0 ? min(initial_extruder + 1, 63) : max(initial_extruder - (1-1), 0))} G0 X{if 1 == 0}80{else}240{endif} Y0 F7000 {endif} M190 R{first_layer_bed_temperature[initial_extruder]} G28 X Y f6000 M83 {if 1==1 && max(hot_plate_temp_initial_layer[initial_extruder], hot_plate_temp[initial_extruder]) >= 90} G0 Z0.06 G92 Z0 ;reset z {endif} {if is_extruder_used[(initial_extruder % 2 == 0 ? min(initial_extruder + 0, 63) : max(initial_extruder - (1-0), 0))]} ; preheat 0 M104 T{(initial_extruder % 2 == 0 ? min(initial_extruder + 0, 63) : max(initial_extruder - (1-0), 0))} S{max(230, min(290, nozzle_temperature_initial_layer[(initial_extruder % 2 == 0 ? min(initial_extruder + 0, 63) : max(initial_extruder - (1-0), 0))] + 15))} {endif} {if is_extruder_used[(initial_extruder % 2 == 0 ? min(initial_extruder + 1, 63) : max(initial_extruder - (1-1), 0))]} ; preheat 1 M104 T{(initial_extruder % 2 == 0 ? min(initial_extruder + 1, 63) : max(initial_extruder - (1-1), 0))} S{max(230, min(290, nozzle_temperature_initial_layer[(initial_extruder % 2 == 0 ? min(initial_extruder + 1, 63) : max(initial_extruder - (1-1), 0))] + 15))} {endif} {if is_extruder_used[(initial_extruder % 2 == 0 ? min(initial_extruder + 0, 63) : max(initial_extruder - (1-0), 0))] and (initial_extruder % 2) != 0} ; flush nozzle 0 T{(initial_extruder % 2 == 0 ? min(initial_extruder + 0, 63) : max(initial_extruder - (1-0), 0))} M104 S{max(230, min(290, nozzle_temperature_initial_layer[(initial_extruder % 2 == 0 ? min(initial_extruder + 0, 63) : max(initial_extruder - (1-0), 0))] + 15))}; common flush temp G0 Z1.6 F2000 G0 X{( 0 % 2 == 0 ? 167.0 : 197.0 )} F7000 G0 Y0 F7000 M109 S{max(230, min(290, nozzle_temperature_initial_layer[(initial_extruder % 2 == 0 ? min(initial_extruder + 0, 63) : max(initial_extruder - (1-0), 0))] + 15))} C2 W1 G1 E20 F80.0 G92 E0 M106 S{min(255, (fan_max_speed[(initial_extruder % 2 == 0 ? min(initial_extruder + 0, 63) : max(initial_extruder - (1-0), 0))] + 10) * 2.55)} M104 S{nozzle_temperature_initial_layer[(initial_extruder % 2 == 0 ? min(initial_extruder + 0, 63) : max(initial_extruder - (1-0), 0))] + 5} G1 E12.0 F200 G92 E0 G1 E8.0 Z4.6 F200 G92 E0 G0 Z5.6 F200 M107 G0 X{( 0 % 2 == 0 ? 137.0 : 187.0 )} F7000 G0 Z0.3 F240.0 M109 S{nozzle_temperature_initial_layer[(initial_extruder % 2 == 0 ? min(initial_extruder + 0, 63) : max(initial_extruder - (1-0), 0))]} C3 W1 G1 E3 F200 G92 E0 G1 X{( 0 % 2 == 0 ? 0 : 324 )} E8.5437 F7000 G92 E0 G1 E-{retract_length_toolchange[0]} F200 G92 E0 G0 Y20 F7000 M104 S{temperature_vitrification[(initial_extruder % 2 == 0 ? min(initial_extruder + 0, 63) : max(initial_extruder - (1-0), 0))]} {endif} {if is_extruder_used[(initial_extruder % 2 == 0 ? min(initial_extruder + 1, 63) : max(initial_extruder - (1-1), 0))] and (initial_extruder % 2) != 1} ; flush nozzle 1 T{(initial_extruder % 2 == 0 ? min(initial_extruder + 1, 63) : max(initial_extruder - (1-1), 0))} M104 S{max(230, min(290, nozzle_temperature_initial_layer[(initial_extruder % 2 == 0 ? min(initial_extruder + 1, 63) : max(initial_extruder - (1-1), 0))] + 15))}; common flush temp G0 Z1.6 F240.0 G0 X{( 1 % 2 == 0 ? 167.0 : 197.0 )} F7000 G0 Y0 F7000 M109 S{max(230, min(290, nozzle_temperature_initial_layer[(initial_extruder % 2 == 0 ? min(initial_extruder + 1, 63) : max(initial_extruder - (1-1), 0))] + 15))} C2 W1 G1 E20 F80.0 G92 E0 M106 S{min(255, (fan_max_speed[(initial_extruder % 2 == 0 ? min(initial_extruder + 1, 63) : max(initial_extruder - (1-1), 0))] + 10) * 2.55)} M104 S{nozzle_temperature_initial_layer[(initial_extruder % 2 == 0 ? min(initial_extruder + 1, 63) : max(initial_extruder - (1-1), 0))] + 5} G1 E12.0 F200 G92 E0 G1 E8.0 Z4.6 F200 G92 E0 G0 Z5.6 F200 M107 G0 X{( 1 % 2 == 0 ? 157.0 : 207.0 )} F6840.0 G0 Z0.3 F240.0 M109 S{nozzle_temperature_initial_layer[(initial_extruder % 2 == 0 ? min(initial_extruder + 1, 63) : max(initial_extruder - (1-1), 0))]} C3 W1 G1 E3 F200 G92 E0 G1 X{( 1 % 2 == 0 ? 0 : 324 )} E8.5437 F7000 G92 E0 G1 E-{retract_length_toolchange[1]} F200 G92 E0 G0 Y20 F6840.0 M104 S{temperature_vitrification[(initial_extruder % 2 == 0 ? min(initial_extruder + 1, 63) : max(initial_extruder - (1-1), 0))]} {endif} ; flush initial nozzle T[initial_extruder] M104 S{max(230, min(290, nozzle_temperature_initial_layer[(initial_extruder % 2 == 0 ? min(initial_extruder + initial_extruder, 63) : max(initial_extruder - (1-initial_extruder), 0))] + 15))}; common flush temp G0 Z1.6 F240.0 G0 X{( initial_extruder % 2 == 0 ? 167.0 : 197.0 )} F7000 G0 Y0 F7000 M109 S{max(230, min(290, nozzle_temperature_initial_layer[(initial_extruder % 2 == 0 ? min(initial_extruder + initial_extruder, 63) : max(initial_extruder - (1-initial_extruder), 0))] + 15))} C2 W1 G1 E20 F80.0 G92 E0 M106 S{min(255, (fan_max_speed[(initial_extruder % 2 == 0 ? min(initial_extruder + initial_extruder, 63) : max(initial_extruder - (1-initial_extruder), 0))] + 10) * 2.55)} M104 S{nozzle_temperature_initial_layer[(initial_extruder % 2 == 0 ? min(initial_extruder + initial_extruder, 63) : max(initial_extruder - (1-initial_extruder), 0))] + 5} G1 E12.0 F200 G92 E0 G1 E8.0 Z4.6 F200 G92 E0 G0 Z5.6 F200 M107 G0 X{( initial_extruder % 2 == 0 ? 157.0 : 207.0 )} F6840.0 G0 Z0.3 F240.0 M109 S{nozzle_temperature_initial_layer[(initial_extruder % 2 == 0 ? min(initial_extruder + initial_extruder, 63) : max(initial_extruder - (1-initial_extruder), 0))]} C3 W1 G1 E3 F200 G92 E0 G1 X{( initial_extruder % 2 == 0 ? 0 : 324 )} E8.5437 F6840.0 G92 E0 G1 E-{retraction_length[initial_extruder]} F200 G92 E0 G0 Y20 F7000 ; ready [plate_name] -

RE: RepRapFirmware 3.6.0-alpha.2 for Duet main boards availableposted in Beta Firmware

I have also tested the firmware and am very satisfied with the improved quality. I haven’t been able to make any fine adjustments yet, but I have increased the speed by 50mm/s as well.

-

RE: SFS V2.0 to Duet 3 Miniposted in General Discussion

@SonnyD1 With version 3.5.2, it works perfectly. I mean my filament sensors on the Duet3 Mini and use two tool boards. Before version 3.5.2, I also got an error message unknown pin name.

-

RE: Neopixel not working after install komponentsposted in Duet Hardware and wiring

@droftarts Thanks first of all. I will try it this way, with an external power supply.

-

RE: Neopixel not working after install komponentsposted in Duet Hardware and wiring

@Phaedrux

I have now connected a new neopixel, without success. I cannot explain why it no longer works. Neither on one duet mini nor on the other.Perhaps someone here who operates the neopixel on the duet3 mini with firmware 5.1.2 rc1 can post the config.g and the M150 commands?

-

RE: Neopixel not working after install komponentsposted in Duet Hardware and wiring

@Phaedrux I’ve ordered some new ones again that I will test. But actually, I can’t imagine that all of them have broken down together. We will see.

-

RE: Neopixel not working after install komponentsposted in Duet Hardware and wiring

@Phaedrux

I connected them to the Neopixel output on the Duet Mini, and it worked until I connected the other hardware. I connected the first Duet to the tool distribution board, then the two tool boards, and on the tool distribution board’s CAN out, a second Duet Mini. They also don’t work on the second Duet, I’ve already tried that.M950 E1 C"led" T1 U16 -

RE: Neopixel not working after install komponentsposted in Duet Hardware and wiring

I just tried it with the firmware that was installed before, unfortunately without success, the LED does not turn on.

-

RE: Neopixel not working after install komponentsposted in Duet Hardware and wiring

@Phaedrux Yes, I will go back to 3.5.0 tomorrow to test it. I will report back then.

-

RE: Neopixel not working after install komponentsposted in Duet Hardware and wiring

@Phaedrux Yes, it worked flawlessly before. However, I did the update to 3.5.2 on all components at the same time right after the hardware installation.

For example, when I send M150 E1 B255 S16, the command goes through without error, but the neopixel remains off. I have also connected a second neopixel for testing, but without success.

-

RE: IDEX HOMING ISSUESposted in Firmware installation

@Proschi78 said in IDEX HOMING ISSUES:

@Rollux

try this as homeallCan you take over the code with copy paste for homeall that I posted here?

M561 G91 G1 H2 Z5 F6000 ; raise head 4mm to keep it clear of the bed G1 H1 X-450 Y-450 U0 F3000 ; coarse home X, Y and U G1 X5 Y5 U-5 F3000 ; move 4mm away from the homing switches G1 H1 X-400 Y-430 U0 F600 ; fine home X, Y and U G90 ; absolute positioning ; Now home Z using the Z probe G1 X243 Y200 F3000 ; move to bed centre for probing G30 ; probe the bed and set Z height G1 x-450 y-430 U0 F3000 G29 S1 -

RE: IDEX HOMING ISSUESposted in Firmware installation

It looks to me like the mesh bed compensation is going on a total roller coaster ride. Can you disable it before homing

-

Neopixel not working after install komponentsposted in Duet Hardware and wiring

Does anyone have an idea why my neopixel LED is not working anymore? I have only installed a tool distribution board and two tool boards in my Idex printer which runs with a duet mini. Everything works perfectly except for the LED. I have the current firmware 3.5.2 release candidate 1.

; Configuration file for Duet 3 Mini 5+ (firmware version 3.3) ; General preferences_____________________________________________________________________________________________ M575 P1 S1 B57600 ; enable support for PanelDue G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"Proschi 3D E2" ; set printer name M552 S1 ; enable network M586 P0 S1 ; enable HTTP M586 P1 S1 ; disable FTP M586 P2 S0 ; enable Telnet G4 S5 ; Drives___________________________________________________________________________________________________________ M569 P0.4 S0 D3 H50 V30 ; physical drive 0.0 goes forwards M915 P0.4 T50 M569 P0.1 S1 D3 H45 V35 ; Y Achse physical drive 0.1 goes forwards M915 P0.1 T50 M569 P0.2 S0 D3 H50 V30 ; physical drive 0.2 goes forwards M915 P0.2 T50 M569 P10.0 S0 ; physical drive 0.3 goes forwards M569 P0.0 S0 D3 H50 V30 ; physical drive 0.4 goes forwards M915 P0.0 T50 M569 P11.0 S1 ; physical drive 0.5 goes forwards ;M569 P25.0 S0 D3 H50 V30 ; physical drive 0.5 goes forwards M584 X0.4 Y0.1 Z0.2 E10.0:11.0 U0 ; set drive mapping M350 X16 Y16 U16 Z16 E16:16 I1 ; configure microstepping without interpolation M92 X80 Y160 U80 Z800 E286.216 :286.216 ; set steps per mm M566 X480 Y480 U480 Z30 E300:300 ; set maximum instantaneous speed changes (mm/min) M203 X9000 U9000 U9000 Y7200 Z650 E3000:3000 ; set maximum speeds (mm/min) M201 X1000 U1000 Y1000 Z120 0 E3000:3000 ; set accelerations (mm/s^2) M906 X1200 U1200 Y1400 Z900 E800:800 I30 ; set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout ; Axis Limits_________________________________________________________________________________________________________________ M208 X10 Y-3 Z-0.3 U35 S1 ; set axis minima M208 X335 Y255 Z240 U355 S0 ; set axis maxima ; Endstops____________________________________________________________________________________________________________________ M574 Y1 S1 P"io1.in" M574 X1 S1 P"io2.in" M574 U2 S1 P"Io4.in" ;M574 Z1 S1 P"!Io6.in" ; Auto Z offset ;M915 X S-63 H10 R1 ; Set very sensitive stall detect ;M574 X1 S3 ; configure endstop for stall detection ;M915 X S20 H140 R0 ; Set very sensitive stall detect ;M915 X S-63 H10 R1 ; Set very sensitive stall detect ; Filament Sensoren___________________________________________________________________________________________________________ ;M591 D1 P1 C"io5.in" S1 ;M591 D0 P1 C"spi.cs2" S1 M950 J3 C"spi.cs2" M581 P1:2 S1 T3 R0 ; T5 only while processing gcode M581 P1:2 S0 T4 R0 M950 J2 C"io5.in" M581 P1:2 S1 T1 R0 ; T5 only while processing gcode M581 P1:2 S0 T2 R0 ; Z-Probe_____________________________________________________________________________________________________________________ M558 K0 P8 C"io3.in" H5 S0.008 F200 T6000 ; set Z probe type to unmodulated and the dive height + speeds G31 K0 P500 X10 Y30 ;0.55 Simplify set Z probe trigger value, offset and trigger height ;BL Touch________________________________________________________________________________________________________________________ M950 K1 S0 C"10.io0.out" M558 K1 C"10.io0.in" P9 H5 F200 T18000 B0 A4 S0.005 R0.4 ; disable Z probe but set dive height, probe speed and travel speed G31 K1 P500 X15 Y-5.50 Z2.381 ;M557 X30:330 Y50:200 P14 ; define mesh grid ;G31 P500 X10 Y30 ; BLTouch X and Y offset M557 X{move.axes[0].min + sensors.probes[0].offsets[0] + 1, move.axes[0].max + sensors.probes[0].offsets[0] - 1} Y{move.axes[1].min + sensors.probes[0].offsets[1] + 0, move.axes[1].max + sensors.probes[0].offsets[1] - 75} P15:10 ; The M557 is used to define the mesh grid area. It uses the P parameter to set the amount of probing points. P10:10 would be a 10x10 grid. Supports up to a 21x21 grid. M98 P"config_probe.g" ; Load the Z-offset from the config_probe.g file ; The Z_offset value is now set in config_probe.g, not in config.g ; Adjust the values there, do not adjust anything here. ; Heaters_______________________________________________________________________________________________________________________ M308 S0 P"Temp0" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin temp0 M950 H0 C"out0" T0 ; create bed heater output on out0 and map it to sensor 0 M307 H0 B1 S1.00 ; enable bang-bang mode for the bed heater and set PWM limit M140 H0 ; map heated bed to heater 0 M143 H0 S120 ; set temperature limit for heater 0 to 120C M308 S1 P"11.Temp0" Y"thermistor" T100000 B4725 C7.06e-8 ; configure sensor 1 as thermistor on pin temp1 M950 H1 C"10.out0" T2 ; create nozzle heater output on out1 and map it to sensor 1 M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit M143 H1 S340 ; set temperature limit for heater 1 to 340C M308 S2 P"10.Temp0" Y"thermistor" T100000 B4725 C7.06e-8 ; configure sensor 2 as thermistor on pin temp2 M950 H2 C"11.out0" T1 ; create nozzle heater output on out2 and map it to sensor 2 M307 H2 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit M143 H2 S340 ; set temperature limit for heater 2 to 340C M308 S3 P"25.temp0" Y"thermistor" A"Gehäuse" T100000 B4138 ; configure sensor 1 as thermistor on pin temp1 ; Temp Sensoren_________________________________________________________________________________________________________________________ M308 S10 Y"mcu-temp" A"MCU" ; defines sensor 10 as MCU temperature sensor ;M308 S11 Y"drivers" A"Duet stepper drivers" ; defines sensor 11 as stepper driver temperature sensor M308 S8 Y"mcu-temp" P"25.dummy" A"Can MCU" ;M308 S9 Y"drivers" P"25.dummy" A"Can Stepper" ; Fans___________________________________________________________________________________________________________________________________ M950 F1 C"10.out1" Q500 ; create fan 0 on pin out4 and set its frequency M106 P1 C"Links" S0 H-1 M950 F0 C"11.out1" Q500 ; create fan 0 on pin out4 and set its frequency M106 P0 C"Rechts" S0 H-1 M950 F7 C"11.out2" Q500 ; create fan 0 on pin out3 and set its frequency M106 P7 C"Hotend Fan rechts" S1 H1 T45 ; set fan 0 name and value. Thermostatic control turned on for Hotend M950 F8 C"10.out2" Q500 ; create fan 0 on pin out3 and set its frequency M106 P8 C"Hotend Fan links" S1 H2 T45 ;M950 F5 C"out6" Q500 ;M106 P5 C"Board" S0 H-1 M950 F2 C"out3" Q500 ; create fan 0 on pin out4 and set its frequency M106 P2 C"Filter Lüfter" S0 H-1 Q25000 ; set fan 0 value. Thermostatic control is turned off M950 F3 C"out5" Q500 ; create fan 2 on pin vfd and set its frequency M106 P3 C"LED" S150 H-1 ; set fan 2 value. Thermostatic control is turned off M950 F4 C"out4+out4.tach" Q25000 M106 P4 C"Aktiv Kühlung" S0 H-1 M950 F5 C"25.out5" Q100 M106 P5 C"Board Kühler" ;Die Lüftersteuerung ist in Deamon.g festgelegt ; Create a tool that uses the low end (X) carriage M950 F6 C"25.out4+out4.tach" Q100 M106 P6 C"CanBoard" ;Acclerometer M955 P11.0 I24 ; configure accelerometer on toolboard with CAN address 121 and specify orientation M593 F37.1 S0.2 P"ZVDDD" M955 P10.0 I24 ; configure accelerometer on toolboard with CAN address 121 and specify orientation ;Switch_______________________________________________________________________________________________________________________________ M950 J1 C"25.io6.in" M581 P1 S0 T5 R0 ; T5 only while processing gcode M581 P1 S1 T6 R0 ;Tools________________________________________________________________________________________________________________________________ M563 P0 D0 H1 F1 S"linker Extruder" ; tool 0 uses extruder 0, heater 1 and fan 0 G10 P0 X0 Y0 Z-0.1 S0 R0 ; set tool 0 offsets and temperatures ; Create a tool that uses the high end (U) carriage M563 P1 D1 H2 X3 F0 S"rechter Extruder" ; tool 1 uses extruder 1, heater 2, fan 2, and maps X to U G10 P1 Y-0.2 U27,3 Z-0.1 R0 ; set tool 1 offsets and temperatures ; Create a tool that prints 2 copies of the object using both carriages M563 P2 D0:1 H1:2 X0:3 F0:0 S"Duplicate"; tool 2 uses both extruders, hot end heaters and fans, and maps X to both X and U G10 P2 X-25 Y0 U-176.3 Z0.0 S0 R0 ; set tool offsets and temperatures G10 P2 R0 S0 M567 P2 E1:1 ; set mix ratio 100% on both extruders ;Create a tool that Prints in Mirrior Mode M563 P3 S"Mirror" H1:2 D0:1 X0:3 F0:0 G10 P3 X165 Y0 U-165 Z0 S0 R0 G10 P3 R0 S-2 ; Custom settings are not defined ;Temperatur anpassung MCU M912 P0 S2 ; Miscellaneous_________________________________________________________________________________________________________________________________ M501 ; load saved parameters from non-volatile memory ;M911 S10 R11 P"M913 X0 U0 Y0 G91 M83 G1 Z3 E-5 F1000" ; set voltage thresholds and actions to run on power loss ;Global Variables_______________________________________________________________________________________________________________________________ M98 P"GlobaleBuildplate.g" ;LED Neopixel___________________________________________________________________________________________________________________________________ M950 E1 C"led" T1 U16=== Diagnostics === RepRapFirmware for Duet 3 Mini 5+ version 3.5.2-rc.1 (2024-05-28 11:53:48) running on Duet 3 Mini5plus WiFi (standalone mode) Board ID: L0Z2A-S096U-D65J0-40KMU-MY03Z-RMV8H Used output buffers: 31 of 40 (35 max) === RTOS === Static ram: 103368 Dynamic ram: 123808 of which 0 recycled Never used RAM 11384, free system stack 192 words Tasks: NETWORK(2,nWait 7,31.7%,211) HEAT(3,nWait 6,0.0%,331) Move(4,nWait 6,0.0%,341) CanReceiv(6,nWait 1,0.1%,796) CanSender(5,nWait 7,0.0%,336) CanClock(7,delaying,0.0%,348) TMC(4,nWait 6,0.8%,101) MAIN(1,running,66.0%,665) IDLE(0,ready,0.4%,29) AIN(4,delaying,0.9%,259), total 100.0% Owned mutexes: WiFi(NETWORK) === Platform === Last reset 00:01:55 ago, cause: power up Last software reset at 2024-06-02 10:31, reason: User, Gcodes spinning, available RAM 11296, slot 0 Software reset code 0x0003 HFSR 0x00000000 CFSR 0x00000000 ICSR 0x00000000 BFAR 0xe000ed38 SP 0x00000000 Task MAIN Freestk 0 n/a Error status: 0x00 Aux0 errors 0,0,0 MCU revision 3, ADC conversions started 115268, completed 115266, timed out 0, errs 0 MCU temperature: min 12.2, current 22.6, max 22.6 Supply voltage: min 23.7, current 23.8, max 23.9, under voltage events: 0, over voltage events: 0, power good: yes Heap OK, handles allocated/used 99/1, heap memory allocated/used/recyclable 2048/20/0, gc cycles 0 Events: 0 queued, 0 completed Driver 0: standstill, SG min 0, read errors 0, write errors 0, ifcnt 15, reads 6032, writes 15, timeouts 0, DMA errors 0, CC errors 0 Driver 1: standstill, SG min 0, read errors 0, write errors 0, ifcnt 15, reads 6032, writes 15, timeouts 0, DMA errors 0, CC errors 0 Driver 2: standstill, SG min 0, read errors 0, write errors 0, ifcnt 15, reads 6031, writes 15, timeouts 0, DMA errors 0, CC errors 0 Driver 3: standstill, SG min 0, read errors 0, write errors 0, ifcnt 10, reads 6036, writes 10, timeouts 0, DMA errors 0, CC errors 0 Driver 4: standstill, SG min 0, read errors 0, write errors 0, ifcnt 15, reads 6032, writes 15, timeouts 0, DMA errors 0, CC errors 0 Driver 5: not present Driver 6: not present Date/time: 2024-06-04 10:01:18 Cache data hit count 199703773 Slowest loop: 36.14ms; fastest: 0.12ms === Storage === Free file entries: 19 SD card 0 detected, interface speed: 22.5MBytes/sec SD card longest read time 6.3ms, write time 0.0ms, max retries 0 === Move === DMs created 83, segments created 0, maxWait 0ms, bed compensation in use: none, height map offset 0.000, max steps late 0, min interval 0, bad calcs 0, ebfmin 0.00, ebfmax 0.00 no step interrupt scheduled Moves shaped first try 0, on retry 0, too short 0, wrong shape 0, maybepossible 0 === DDARing 0 === Scheduled moves 0, completed 0, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1 === DDARing 1 === Scheduled moves 0, completed 0, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1 === Heat === Bed heaters 0 -1 -1 -1, chamber heaters -1 -1 -1 -1, ordering errs 0 === GCodes === Movement locks held by null, null HTTP is idle in state(s) 0 Telnet is idle in state(s) 0 File is idle in state(s) 0 USB is idle in state(s) 0 Aux is idle in state(s) 0 Trigger is idle in state(s) 0 Queue is idle in state(s) 0 LCD is idle in state(s) 0 SBC is idle in state(s) 0 Daemon is idle in state(s) 0 Aux2 is idle in state(s) 0 Autopause is idle in state(s) 0 File2 is idle in state(s) 0 Queue2 is idle in state(s) 0 Q0 segments left 0, axes/extruders owned 0x0000000 Code queue 0 is empty Q1 segments left 0, axes/extruders owned 0x0000000 Code queue 1 is empty === CAN === Messages queued 1083, received 6337, lost 0, errs 0, boc 0 Longest wait 2ms for reply type 6053, peak Tx sync delay 53, free buffers 26 (min 25), ts 576/575/0 Tx timeouts 0,0,0,0,0,0 === Network === Slowest loop: 146.02ms; fastest: 0.00ms Responder states: MQTT(0) HTTP(2) HTTP(2) HTTP(0) HTTP(0) FTP(0) Telnet(0) HTTP sessions: 2 of 8 === WiFi === Interface state: active Module is connected to access point Failed messages: pending 0, notrdy 0, noresp 1 Firmware version 2.1.0 MAC address f0:08:d1:03:80:5e Module reset reason: Power up, Vcc 3.39, flash size 2097152, free heap 23280 WiFi IP address 192.168.178.91 Signal strength -34dBm, channel 6, mode 802.11n, reconnections 0 Clock register 00002001 Socket states: 0 3 0 0 0 0 0 04.6.2024, 10:01:20M122 === Diagnostics === RepRapFirmware for Duet 3 Mini 5+ version 3.5.2-rc.1 (2024-05-28 11:53:48) running on Duet 3 Mini5plus WiFi (standalone mode) Board ID: L0Z2A-S096U-D65J0-40KMU-MY03Z-RMV8H Used output buffers: 31 of 40 (35 max) === RTOS === Static ram: 103368 Dynamic ram: 123808 of which 0 recycled Never used RAM 11384, free system stack 192 words Tasks: NETWORK(2,nWait 7,31.7%,211) HEAT(3,nWait 6,0.0%,331) Move(4,nWait 6,0.0%,341) CanReceiv(6,nWait 1,0.1%,796) CanSender(5,nWait 7,0.0%,336) CanClock(7,delaying,0.0%,348) TMC(4,nWait 6,0.8%,101) MAIN(1,running,66.0%,665) IDLE(0,ready,0.4%,29) AIN(4,delaying,0.9%,259), total 100.0% Owned mutexes: WiFi(NETWORK) === Platform === Last reset 00:01:55 ago, cause: power up Last software reset at 2024-06-02 10:31, reason: User, Gcodes spinning, available RAM 11296, slot 0 Software reset code 0x0003 HFSR 0x00000000 CFSR 0x00000000 ICSR 0x00000000 BFAR 0xe000ed38 SP 0x00000000 Task MAIN Freestk 0 n/a Error status: 0x00 Aux0 errors 0,0,0 MCU revision 3, ADC conversions started 115268, completed 115266, timed out 0, errs 0 MCU temperature: min 12.2, current 22.6, max 22.6 Supply voltage: min 23.7, current 23.8, max 23.9, under voltage events: 0, over voltage events: 0, power good: yes Heap OK, handles allocated/used 99/1, heap memory allocated/used/recyclable 2048/20/0, gc cycles 0 Events: 0 queued, 0 completed Driver 0: standstill, SG min 0, read errors 0, write errors 0, ifcnt 15, reads 6032, writes 15, timeouts 0, DMA errors 0, CC errors 0 Driver 1: standstill, SG min 0, read errors 0, write errors 0, ifcnt 15, reads 6032, writes 15, timeouts 0, DMA errors 0, CC errors 0 Driver 2: standstill, SG min 0, read errors 0, write errors 0, ifcnt 15, reads 6031, writes 15, timeouts 0, DMA errors 0, CC errors 0 Driver 3: standstill, SG min 0, read errors 0, write errors 0, ifcnt 10, reads 6036, writes 10, timeouts 0, DMA errors 0, CC errors 0 Driver 4: standstill, SG min 0, read errors 0, write errors 0, ifcnt 15, reads 6032, writes 15, timeouts 0, DMA errors 0, CC errors 0 Driver 5: not present Driver 6: not present Date/time: 2024-06-04 10:01:18 Cache data hit count 199703773 Slowest loop: 36.14ms; fastest: 0.12ms === Storage === Free file entries: 19 SD card 0 detected, interface speed: 22.5MBytes/sec SD card longest read time 6.3ms, write time 0.0ms, max retries 0 === Move === DMs created 83, segments created 0, maxWait 0ms, bed compensation in use: none, height map offset 0.000, max steps late 0, min interval 0, bad calcs 0, ebfmin 0.00, ebfmax 0.00 no step interrupt scheduled Moves shaped first try 0, on retry 0, too short 0, wrong shape 0, maybepossible 0 === DDARing 0 === Scheduled moves 0, completed 0, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1 === DDARing 1 === Scheduled moves 0, completed 0, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1 === Heat === Bed heaters 0 -1 -1 -1, chamber heaters -1 -1 -1 -1, ordering errs 0 === GCodes === Movement locks held by null, null HTTP is idle in state(s) 0 Telnet is idle in state(s) 0 File is idle in state(s) 0 USB is idle in state(s) 0 Aux is idle in state(s) 0 Trigger is idle in state(s) 0 Queue is idle in state(s) 0 LCD is idle in state(s) 0 SBC is idle in state(s) 0 Daemon is idle in state(s) 0 Aux2 is idle in state(s) 0 Autopause is idle in state(s) 0 File2 is idle in state(s) 0 Queue2 is idle in state(s) 0 Q0 segments left 0, axes/extruders owned 0x0000000 Code queue 0 is empty Q1 segments left 0, axes/extruders owned 0x0000000 Code queue 1 is empty === CAN === Messages queued 1083, received 6337, lost 0, errs 0, boc 0 Longest wait 2ms for reply type 6053, peak Tx sync delay 53, free buffers 26 (min 25), ts 576/575/0 Tx timeouts 0,0,0,0,0,0 === Network === Slowest loop: 146.02ms; fastest: 0.00ms Responder states: MQTT(0) HTTP(2) HTTP(2) HTTP(0) HTTP(0) FTP(0) Telnet(0) HTTP sessions: 2 of 8 === WiFi === Interface state: active Module is connected to access point Failed messages: pending 0, notrdy 0, noresp 1 Firmware version 2.1.0 MAC address f0:08:d1:03:80:5e Module reset reason: Power up, Vcc 3.39, flash size 2097152, free heap 23280 WiFi IP address 192.168.178.91 Signal strength -34dBm, channel 6, mode 802.11n, reconnections 0 Clock register 00002001 Socket states: 0 3 0 0 0 0 0 04.6.2024, 10:01:07Verbindung zu 192.168.178.91 hergestellt -

RE: IDEX HOMING ISSUESposted in Firmware installation

@Rollux

try this as homeallM561 G91 G1 H2 Z5 F6000 ; raise head 4mm to keep it clear of the bed G1 H1 X-450 Y-450 U0 F3000 ; coarse home X, Y and U G1 X5 Y5 U-5 F3000 ; move 4mm away from the homing switches G1 H1 X-400 Y-430 U0 F600 ; fine home X, Y and U G90 ; absolute positioning ; Now home Z using the Z probe G1 X243 Y200 F3000 ; move to bed centre for probing G30 ; probe the bed and set Z height G1 x-450 y-430 U0 F3000 G29 S1 -

RE: IDEX HOMING ISSUESposted in Firmware installation

@Rollux

increase the x value to x-450; called to home all axes ; ; generated by RepRapFirmware Configuration Tool v3.4.1 on Sun May 26 2024 18:23:03 GMT+0800 (Australian Western Standard Time) G91 ; relative positioning G1 H2 Z5 F6000 ; lift Z relative to current position G1 H1 X-450 Y-430 U0 F1800 ; move quickly to X Y and U axis endstops and stop there (first pass) G1 H2 X5 Y5 U-5 F6000 ; go back a few mm G1 H1 X-450 Y-4300 U0 F360 ; move slowly to X Y and U axis endstops once more (second pass) G90 G1 F6000 X243 Y200 G30 ; absolute positioning G29 S1 ; this loads the contents of /sys/heightmap.csv -

RE: IDEX HOMING ISSUESposted in Firmware installation

@Rollux Are your end stops working properly? Are the motors running in the right direction?

-

RE: IDEX HOMING ISSUESposted in Firmware installation

@Rollux Thats my Home U

; generated by RepRapFirmware Configuration Tool v3.3.14 on Wed Nov 16 2022 15:37:19 GMT+0100 (Mitteleuropäische Normalzeit) G91 ; relative positioning G1 H2 Z5 F6000 ; lift Z relative to current position G1 H1 U430 F3000; move quickly to U axis endstop and stop there (first pass) M400 G1 H2 U-5 F6000 ; go back a few mm G1 H1 U430 F360 ; move slowly to U axis endstop once more (second pass) G1 H2 Z-5 F6000 ; lower Z again G90 ; absolute positioningthe only thing that strikes me is that your G30 for G90 is in homeall.g

-

RE: IDEX HOMING ISSUESposted in Firmware installation

@Rollux my homall.g

M561 G91 G1 H2 Z5 F6000 ; raise head 4mm to keep it clear of the bed G1 H1 X-35 Y-245 U355 F3000 ; coarse home X, Y and U G1 X4 Y4 U-4 F3000 ; move 4mm away from the homing switches G1 H1 X-400 Y-245 U400 F600 ; fine home X, Y and U G90 ; absolute positioning ; Now home Z using the Z probe G1 X170 Y110 F3000 ; move to bed centre for probing G30 ; probe the bed and set Z height G1 x-35 y-245 U365 F3000 G29 S1

!

!