For a while I have been having issues with first layer when printing models that have a large surface area on the first layer.

The bed is pretty flat and the print starts out well and as the first layer progresses the bottom infill does not stick well.

I went through the normal debugging with Z Probe, bed leveling etc. Things I have tried that did not make a difference.

- Rebuilt the Z-axis to make sure nothing is loose.

- Switched between BL-Tocuh and SuperPinda

- Printed with Mesh Bed Leveling ON and OFF

- Switched between using TWO Z Motors and ONE

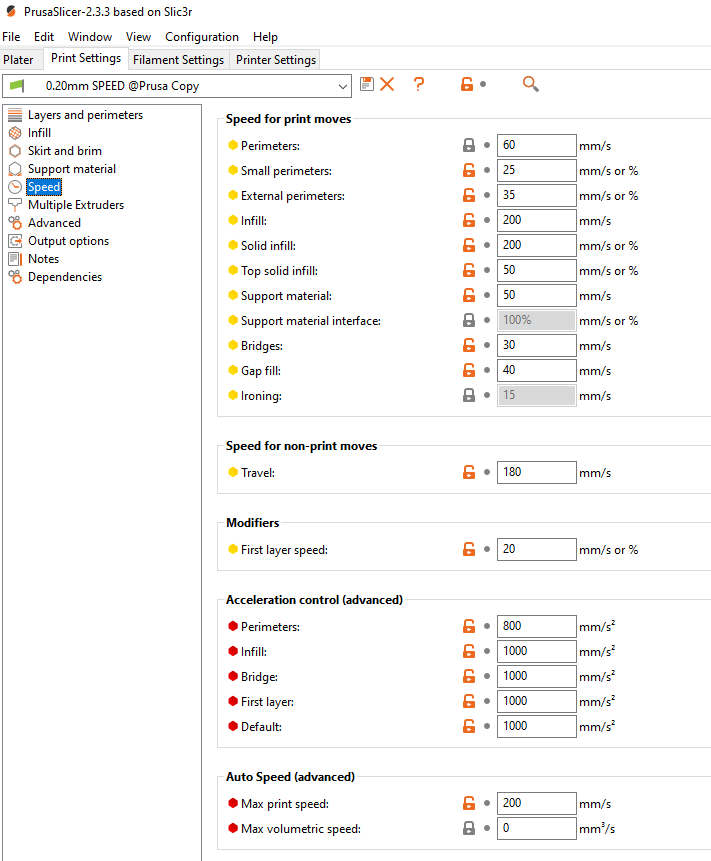

- Tried PrusaSlicer and Simplify3D

- Tried with Pressure Advance ON and OFF

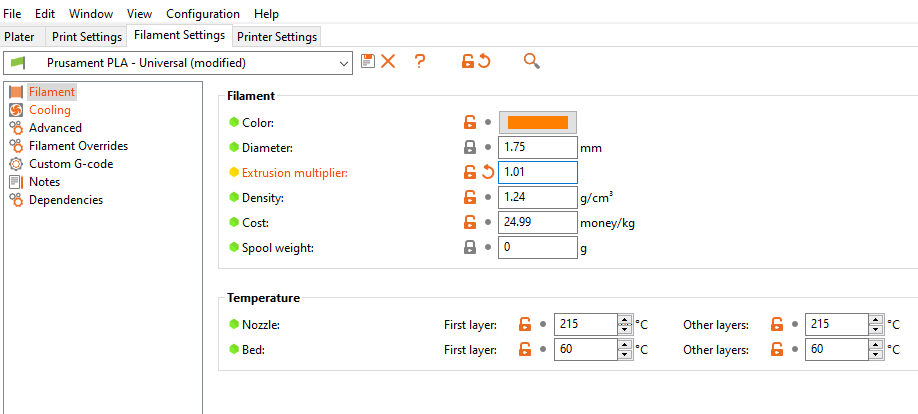

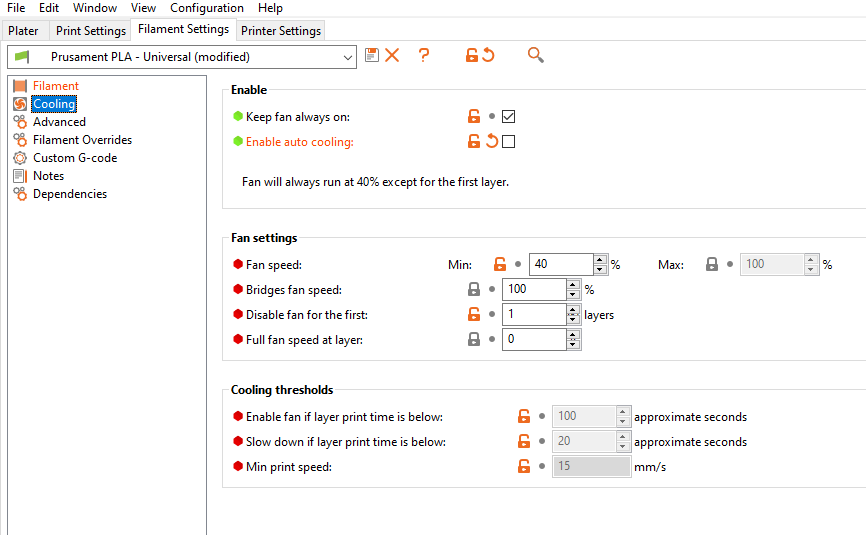

- Tried a few different filaments

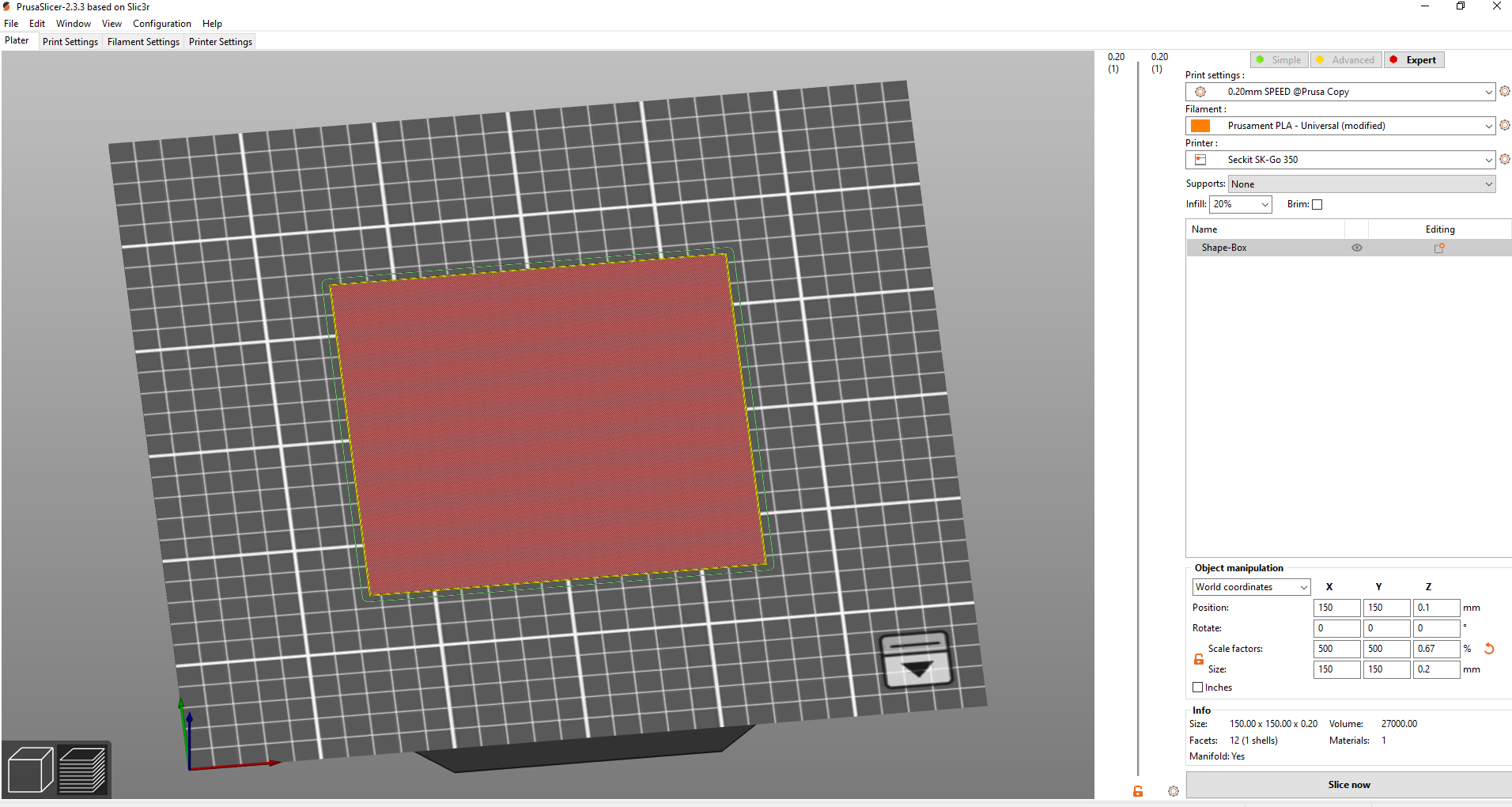

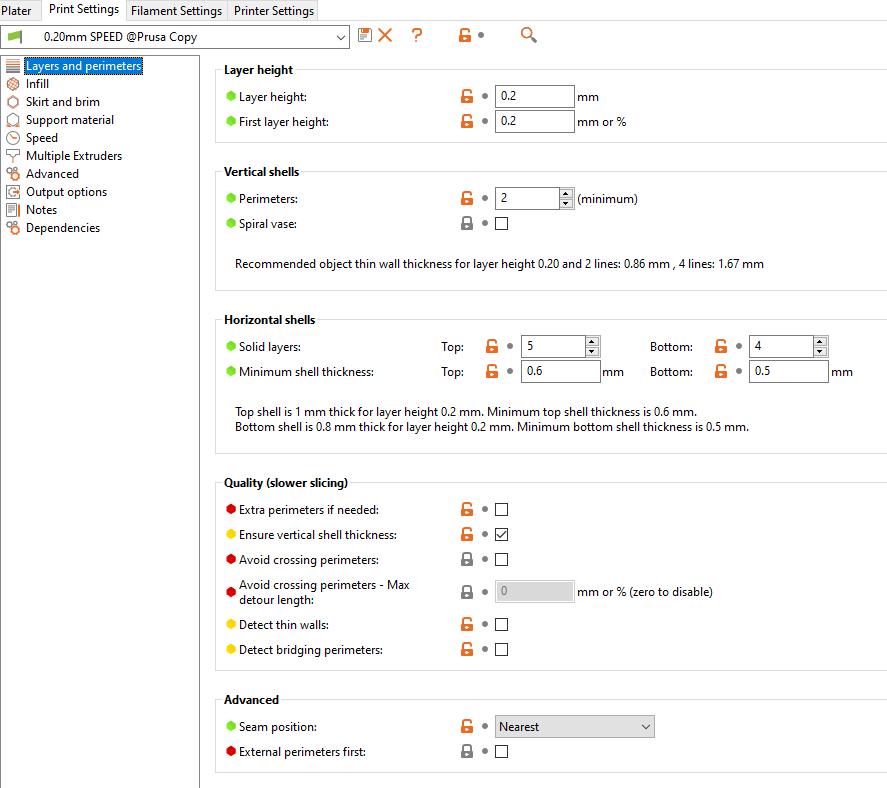

When nothing seemed to solve it I tried a few different infill patterns that go in different directions, this was to make sure the issue is not with bed leveling. The model is just a rectangle with 0.2mm height and printed with PLA

I tried

- Monotonic infill (goes from Right to Left)

- Concentric (outside to inside)

- Hilbert curve (starts out bottom left and moves through the layer and end bottom right)

With these infill patterns the issue seemed to be with extrusion "slowing down" as the first layer progresses, since the gaps in infill increase by the end of first layer.

So I replaced the extruder stepper motor and made sure the Bondtech Extruder is setup correctly.

Still the issue persists. So I am kind of lost on what the next steps are to debug this issue.

I have attached a photo with two printouts of the first layer (Monotonic and Hilbert infill style)

With the Hilbert curve style the layer sticks well all through, and there are no bumps to touch, but at the end of the layer the gap between the fractals ends has increased a lot.

config.g

bed.g

diag.txt

Is there something else I can monitor during the print to check on extrusion.