Hello everyone.

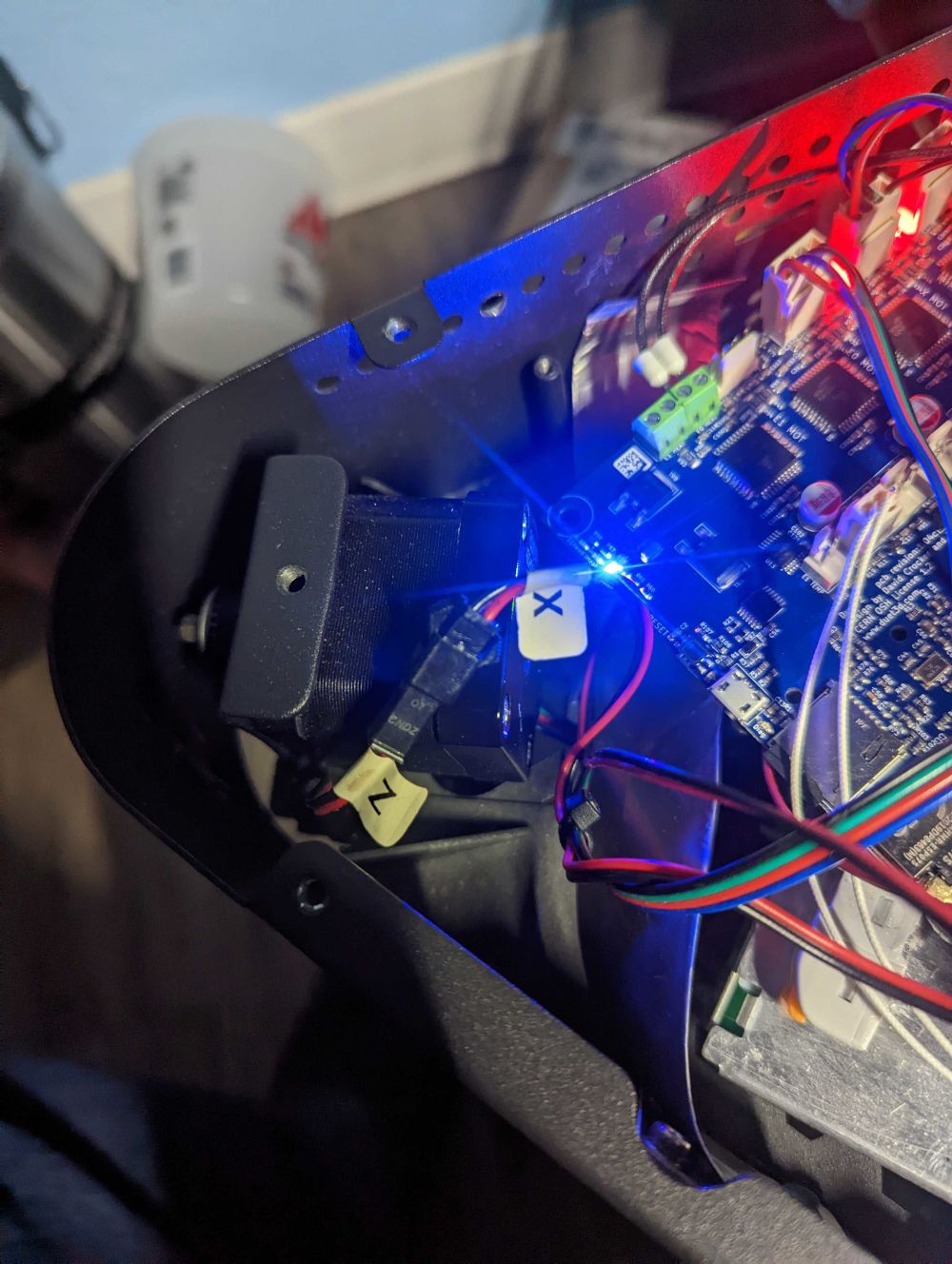

I've been having some issues with the endstops on an FLSUN Q5 delta printer.

I've replaced the old board with the Duet 2 wifi. Firmware version 3.4.4

M115

FIRMWARE_NAME: RepRapFirmware for Duet 2 WiFi/Ethernet FIRMWARE_VERSION: 3.4.4 ELECTRONICS: Duet WiFi 1.02 or later FIRMWARE_DATE: 2022-10-20 16:17:41

I have everything wired in correctly and it's mostly working.

I am however having an issue with the endstops. When I home the printer, the movement crashes against the endstops and wants to keep going. Then DWC shows an M121 error with insufficient axes homed.

I can see all the motors and axes working correctly.

Testing the switches with the M119 command shows the switches working correctly.

M119: Endstops - X: not stopped, Y: not stopped, Z: not stopped, Z probe: not stopped ; nothing triggered

M119: Endstops - X: not stopped, Y: not stopped, Z: not stopped, Z probe: at min stop ; Z probe active

M119: Endstops - X: at max stop, Y: not stopped, Z: not stopped, Z probe: not stopped ; X stop active

M119: Endstops - X: not stopped, Y: at max stop, Z: not stopped, Z probe: not stopped ; Y stop active

M119: Endstops - X: not stopped, Y: not stopped, Z: at max stop, Z probe: not stopped ; Z stop active

This is my config.g.

; Configuration file for Duet WiFi (firmware version 3.3)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool v3.3.14 on Wed Nov 09 2022 00:32:21 GMT-0700 (Mountain Standard Time)

; General preferences

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

M550 P"FLSUN Q5" ; set printer name

M665 R104 L215 B104 H160 ; Set delta radius, diagonal rod length, printable radius and homed height

M666 X0 Y0 Z0 ; put your endstop adjustments here, or let auto calibration find them

; Network

M552 S1 ; enable network

M586 P0 S1 ; enable HTTP

M586 P1 S0 ; disable FTP

M586 P2 S0 ; disable Telnet

; Drives

M569 P0 S1 ; physical drive 0 goes forwards

M569 P1 S1 ; physical drive 1 goes forwards

M569 P2 S1 ; physical drive 2 goes forwards

M569 P3 S1 ; physical drive 3 goes forwards

M584 X0 Y1 Z2 E3 ; set drive mapping

M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation

M92 X80.00 Y80 Z80.00 E13.00 ; set steps per mm

M566 X1200.00 Y1200.00 Z1200.00 E1200.00 ; set maximum instantaneous speed changes (mm/min)

M203 X12000.00 Y12000.00 Z12000.00 E12000.00 ; set maximum speeds (mm/min)

M201 X1000.00 Y1000.00 Z1000.00 E1000.00 ; set accelerations (mm/s^2)

M906 X800 Y800 Z800 E800 I30 ; set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout

; Axis Limits

M208 Z0 S1 ; set minimum Z

; Endstops

M574 X2 S1 P"xstop" ; configure switch-type (e.g. microswitch) endstop for high end on X via pin xstop

M574 Y2 S1 P"ystop" ; configure switch-type (e.g. microswitch) endstop for high end on Y via pin ystop

M574 Z2 S1 P"zstop" ; configure switch-type (e.g. microswitch) endstop for high end on Z via pin zstop

; Z-Probe

M558 P5 C"!^zprobe.in" H5 F120 T6000 ; set Z probe type to switch and the dive height + speeds

G31 P500 X0 Y0 Z20.34 ; set Z probe trigger value, offset and trigger height

M557 R85 S20 ; define mesh grid

; Heaters

M308 S0 P"bedtemp" Y"thermistor" T100000 B4092 ; configure sensor 0 as thermistor on pin bedtemp -Slice Engineering 300Deg Thermistor

M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0

M307 H0 B1 S1.00 ; enable bang-bang mode for the bed heater and set PWM limit

M140 H0 ; map heated bed to heater 0

M143 H0 S120 ; set temperature limit for heater 0 to 120C

M308 S1 P"e0temp" Y"thermistor" T100000 B4680 C6.455513e-8 ; configure sensor 1 as thermistor on pin e0temp -Slice Engineering values

M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1

M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit

M143 H1 S290 ; set temperature limit for heater 1 to 290C -Slice Engineering Mosquito

; Fans

M950 F0 C"fan0" Q500 ; create fan 0 on pin fan0 and set its frequency

M106 P0 C"Part Cooling" S0 H-1 ; set fan 0 name and value. Thermostatic control is turned off

M950 F1 C"fan1" Q500 ; create fan 1 on pin fan1 and set its frequency

M106 P1 C"Mosquito" S0 H-1 ; set fan 1 name and value. Thermostatic control is turned off

; Tools

M563 P0 S"HotEnd" D0 H1 F0 ; define tool 0

G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets

G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C

; Custom settings are not defined

; Miscellaneous

M501 ; load saved parameters from non-volatile memory

T0 ; select first tool

I'm starting to think the switches are going bad but, they get used so little compared to the other equipment, it doesn't make much sense.

These are the switches - https://www.ebay.com/itm/334506838039

I can't even find this kind anymore! Perhaps I need updated ones.

Any help is appreciated.

Thanks.