Hi all!

I'd like to present my latest Delta design to you all.

The aim of this design was to create a scalable platform which uses what I consider to be the best available components. My requirements are:

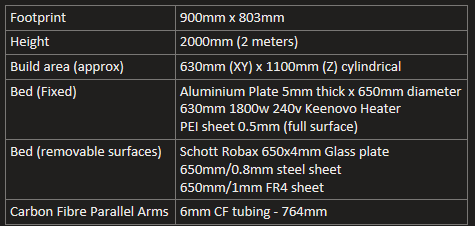

- Scalable from large (XXL 400+ XY, 300+Z) size to monstrous (XXXL 650+XY, 1100+Z)

- Be 'enclosable'

- Have a choice of removable bed surfaces

- Quick change tooling

- Have a simple assembly, manageable by one person alone

- Be capable of creating very large, accurately sized, high strength parts in reasonable times

- Be able to print common materials such as PLA, PETG, ASA, ABS

- Have a low count of overall parts

- Use 'best of breed' parts where possible

- Design printed parts so that they can be produced on a 'normal' sized 3D printer

- Be as 'open source' as possible

I think for the most part I've managed to achieve the above, and have created a design which stands up to heavy use without breaking a sweat. Between the two machines I've created with this design, I've performed around 2000 hours printing so far.

The design is heavily influenced by such machines as Johann's excellent Mini Kossel and the T3DP3D version of that machine which I used for several years. During that time I was able to spot some of the weaknesses and wear failure points after a long period of heavy use which didn't quite work for my use case, and make changes accordingly in my version.

The generic specification for my design is:

- 4040 V-Slot aluminium frame

- Meanwell 24v 400W PSU for electronics

- Duet3d Duet Wifi /PT100 daughterboard

- Duet3d Smart Effector

- Duet3d PanelDue 5i/7i

- Duet3d Magnetic Filament Monitor

- E3D Supervolcano / 0.8mm nozzle (standard)

- E3D Super Whopper 1.8 degree motors or E3D High Torque 0.9 degree motors

- E3D Hermera Bowden Extruder

- Capricorn Bowden Tubing

- Mains driven 1.8kw Keenovo bed heater with Celduc SSR

- 5mm thick aluminium bed base plate with mounting for removable PEI coated steel sheets, Schott Robax Glass plate etc

- 6mm/8mm Carbon Fibre parallel arms (depending on tool weight) with Haydn's Delrin sleeves for magnetic coupling

- Gates Powergrip 2GT 9mm belts

- Solid V Xtreme carriage wheels

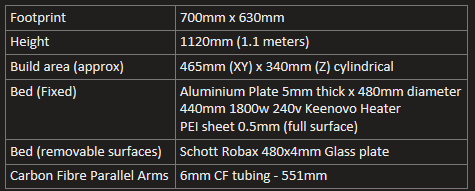

Obviously, some of the components would need to be sized or customised depending on the size of the machine being built. The main differences when scaling the machine would be the length of 4040 extrusion required, along with the bed components, belt lengths and the carbon fibre toolhead arms.

The two example machines I've assembled have the following specifications:

BigBoy - The size of this machine was constrained by the space I had available to house and develop it, otherwise it likely would have been even bigger! It uses the generic specification with the following differences:

LittleSis - The baby of the pair was to see how small I could build a machine with the same design. It's turned out to be extremely rigid, and takes up almost exactly half of a dining room table, which means your better half will surely approve of it in the dining room.

The LittleSis machine also benefits from an enclosure which has greatly aided with printing larger models in materials such as ABS. The current enclosure design is basic to say the least and is more of a very efficient draft blocker than a proper enclosure, however this is down to me using only 2mm thick Correx sheets in order to prove the design. Now that I know it will work, I will likely replace the panels with a thicker aluminium faced sheets, add proper insulation and actively heat the enclosure as required for the job at hand. Even as it stands though with passive heating, I've noted the chamber temperature getting up to around 55c just being passively heated by a 110c bed!

In terms of print speeds, I've found that the design easily out performs my other consumer machines with stock profiles - on average with the prints being produced in slightly less than half the time when compared with a normal bed slinger printing at 0.3mm with a 0.4mm nozzle. This is of course largely down to the Supervolcano and a 0.8mm nozzle and Hermera extruder combination and is highly dependent on the slicing profile being used, and whether or not Pressure Advance etc is being applied. Profiles definition and tuning is a huge part of getting an machine to perform well, and for me at least seems to be a never ending cycle of testing and experimentation. I have managed to produce several 'stock' profiles for different print requirements such as 0.2mm Detail, 0.4mm Normal and 0.6mm Draft, however these are more starting points in my view and I'm constantly tweaking them depending on the print job. I have to say, it's very satisfying to be able to produce a print which is not only double the size and height of my other machines capabilities, but also have it complete in hours, rather than days!

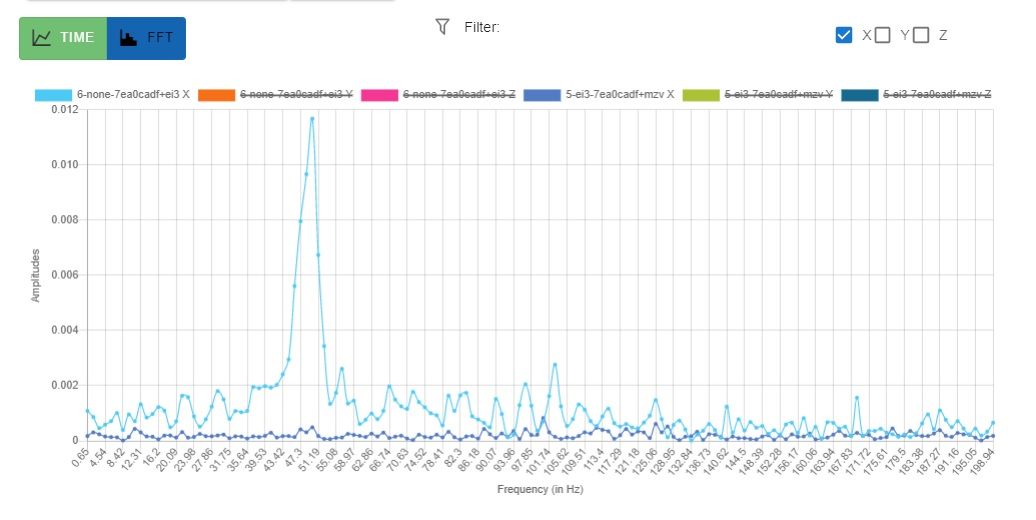

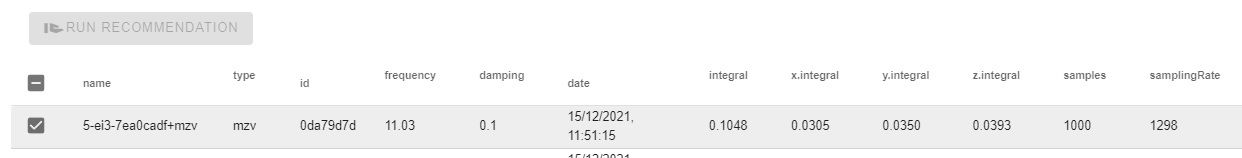

The machine specification technically allows for far greater than 350mm/s movement speeds in all axis, and frame is rigid enough to support this. Since moving to a magnetically coupled tool head though, I've restricted movement speed to 180mm/s in travel moves, as I didn't fancy finding a toolhead embedded in the wall opposite the machine if the magnets failed. To be fair this was me being what I consider sensible, rather than any bad experiences driving this decision! Indeed on one toolhead, which used ball joints and M4 hardware to secure it, I was able to run the larger machine at 300mm/s during print moves without any issues other than intolerable ringing in the resulting printed model. This could be something I return to later once I nail the intricacies of Input Shaping on Duet machines. For now though, having the clear print time reductions with the extruder and hot end choices have made this a lower priority other than curiosity.

During my design and assembly processes I've used several different sized nozzles with the SuperVolcano, including 0.6, 0.8, 1.0,1.2 & 1.4mm. I've landed on the 0.8mm as being the best balance between speed and quality, so this is my default on this specification.

In terms of cost per machine…I can say that the two I've built are considerably more expensive than what the next person could expect, as I've gone through a lot of product testing - meaning I bought & discarded components as I made my final decisions. However, one of my considerations was that these machines should be affordable and accessible to those with the inclination to build one, so I haven't gone too crazy. If one was printing all the parts themselves, and sourcing all the parts from the usual suspects online, I'd expect an average build for a smaller machine to be around £1200 GBP, which for machines of this size and capability I'd say is pretty reasonable. Of course, the cost mentioned doesn't include filament to print the parts (you'd need around 6kg of PETG, and 1kg of ABS), fasteners, wiring, switches or interconnects. Depending on your choices there, it could add between £150-£500 GBP to the overall cost.

Additionally, aside of the basic machine, there are companion designs for custom electronics mounting, lighting, machine enclosures, filament spool holders, magnetic tool hangers etc.

If there is any interest in the design, I will include a full BOM for both of my example machines on an upcoming website, along with a library of printed parts, design files and assembly instructions. This would also cover all of the safety features I've included such as thermal cut-outs, emergency stop switches and safety settings to be made in the firmware, along with nice-to-have's like Bowden Pop-Out monitoring.

Again, if there is interest in the design from the community I might be willing to put together kits of pre-printed parts and/or other 'stock' components for the build - let me know if you're interested!