Thank you for both your comments, I have very little experience with cantilevers and after all the time I've spent trying to work it out in a cost effective way I thought it best to just ask.

@sonderzug said in Cantilever bed advice:

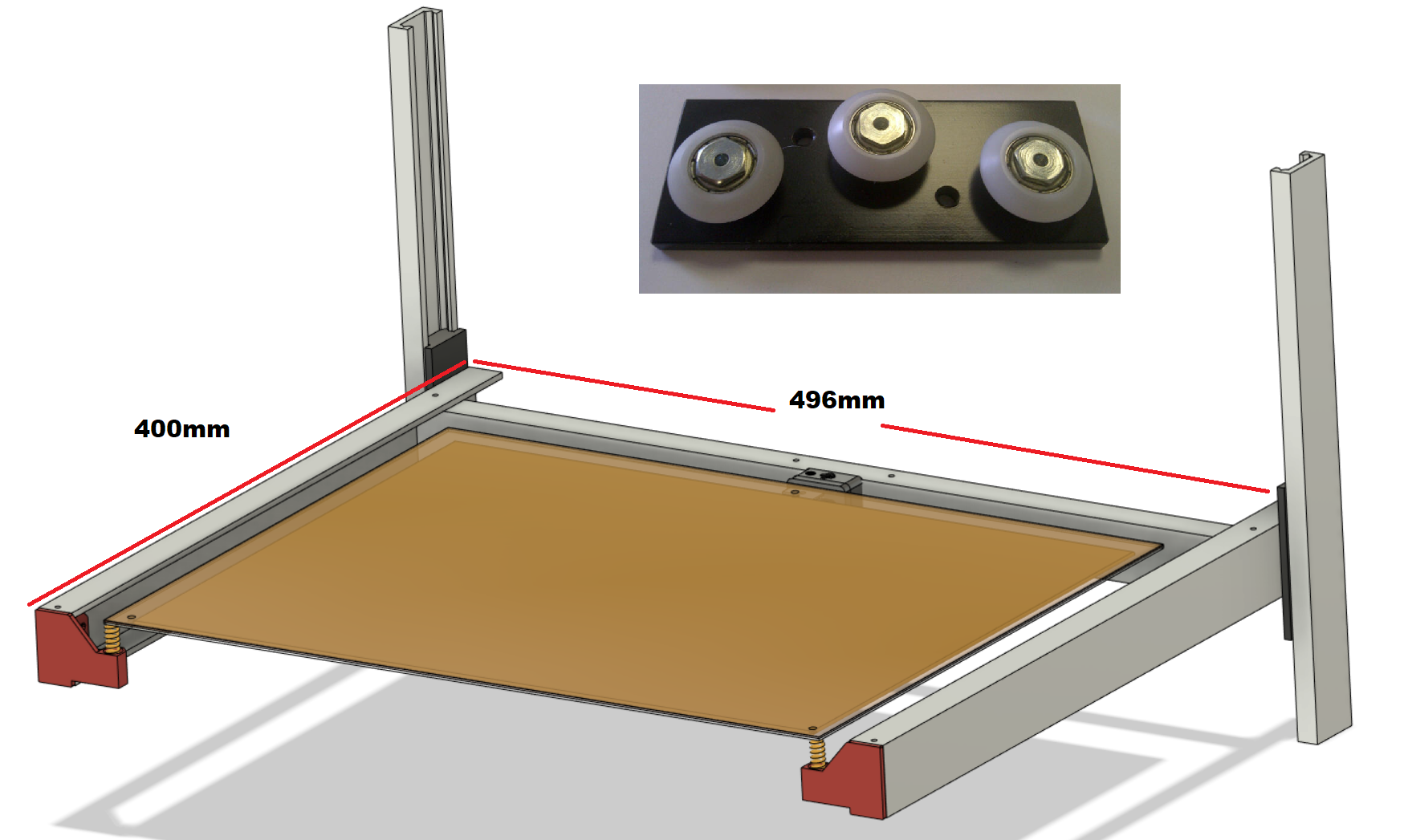

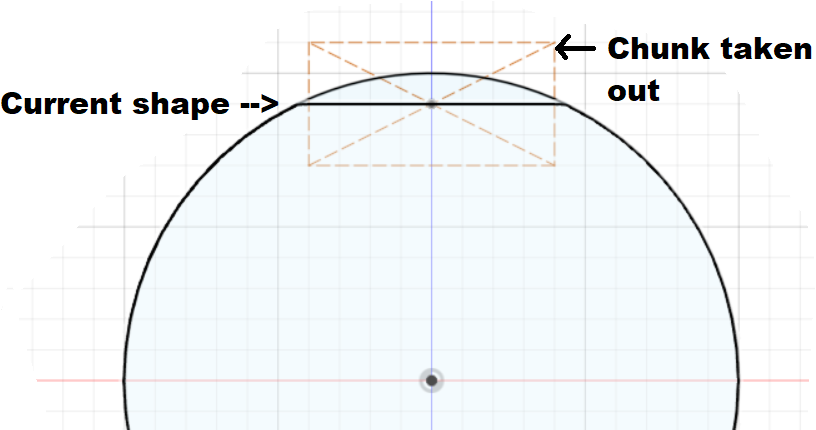

To eliminate the torque on the bearing block, either move the linear rail to the center of the bed's side (which would have been the sensible thing to do in the first place), or add another bearing block per rail that is spaced to the original one at least half of the distance between rail and the bed's center of gravity.

I thought about that last night, and it seems like what I will have to do. It complicates other parts of the frame so I had been reluctant to try it as I had been trying to keep costs down. To test it from the sides, I should be able to modify the side panels, though it will take some fresh aluminium to span the gap. My contact at a certain company had not commented that the cantilever design would not work when I shared it.

@mrehorstdmd said in Cantilever bed advice:

Cantilevers really only work if the guides are very rigid and the bearings have no play. Even at that, there will be a low frequency resonance that will have the bed bouncing like a diving board simply because of the movement of the XY mechanism. You can avoid that by operating the XY mechanism slowly - i.e. print slowly - but who wants to do that?

I have/had a Cubex Duo printer with a cantilevered bed that printed very nicely as long as print speed was kept <40 mm/sec. Ugh! That probably explains why I haven't done anything with it in a few years.

If you must cantilever, I think it would be better to use two screws, located as closely as possible to the guides. It would be better still to add a third screw to support the free end of the bed- then it won't bounce.

Printing slowly is really something I don't want to do. The gantry is capable of printing at 200mm/s. Cantilevering seemed like a sensible choice with strong enough supports as I wanted to keep to a single leadscrew. I don't really want to go to two leadscrews as when I had a Prusa clone years ago it was a huge pain, though that was in part to how poor quality it was. I'll post the results of moving it to the sides when I've found the time.