My DIY Maestro powered Bed-Slinger (many photos inside)

-

Shorting the coils of the motor will not stop the bed from dropping. There is no current in the coils unless the shaft turns, and the current is somewhat proportional to how fast the shaft turns. I tried it and found that it slowed the drop a little at first, and then the torque slips and the bed drops like a rock (my bed assembly weights 3.5 kg).

Someone at the makerspace used one of this type of motor/gearbox to drive a Z axis and it works well.

I used a Rino 30:1 worm gear reducer in my printer. The bed doesn't move at all when power is cut, so in theory, I can resume prints after a power failure.

You can buy motors with built in brakes, but they usually cost more than a motor with a gearbox.

You can work up a mechanical arrangement similar to the brake that stops a seat belt from moving in a car. -

Re shorting coils, think the Up! Mini 2 does this with a relay as it will hold the bed in position even if the power fails with the original electronics. When run of the duet the bed falls like a brick when steppers are disabled. But the bed is tiny and the needed holding torque is minimal on the Up! Mini 2, no idea how well it scales but you could try it, and look into disabling the stepper driver just before shorting out the coils if it gets you enough hold.

-

Hi Niklas,

I think your best bet is one of three:

- use a high inductance motor for the Z, they have a very high "turning resistance", I´d call it

- use a higher gear ratio so that your normal motor is OK

- Tension the belts a lot more

(4.) use a nema 23. That will have enough resistance when it is powered off.

Grüße,

Max -

There was a thread about shorting motor coils to ground with a relay a couple of months ago, but can't find it now! Anyone's else's searching-foo better than mine?

Ian

-

@sonderzug said in My DIY Maestro powered Bed-Slinger (many photos inside):

the obvious disadvantage is that the x-axis drops like a stone when the steppers have no power applied.

Counter balance it with some weight? Use a warm gear between the motor and the belt?

-

@bearer Shorting the coils does not stop the motor from turning. There is no current in the coils unless and until the motor turns. If the motor turns, the bed is by definition, dropping.

Without a counterweight, the gears/screws/nuts remain engaged at all times regardless of direction of motion so there's no possibility of backlash. If you unload the gears/screws/nuts by adding a counterweight, you introduce the possibility of backlash.

Here's a belt driven Z axis that does not move when power is cut:

-

I haven't studied the solution employed by tiertime, but it seems the 19v supply for the drivers is either feed to the drivers, or shorted to ground, resulting in the the bed not dropping if the motors are disabled and/or the power is lost; and if it moves a fraction of a 0.9 degree step and stays there then close enough. They do have a power fail resume function, but as it doesn't preheat the machine its of limited use. On the other hand power failure doesn't result in the bed dropping backriving the board with potential "high" voltage.

I'm pretty sure the lost microsteps + theoretical backlash in gears, axle torsion and belt strech is comparable to whatever motion is present on the Up Mini 2 when compared to the overall rigidity of the machine (which on the Up Mini 2 is a joke). Everything moves, not everything matters.

-

It was @smece in this thread https://forum.duet3d.com/topic/12341/e-_endstop-laser-and-rotary-filament-sensors-motor-enable, who was going to...

make small daugterpcb

... using ...

the ENABLE signal I need is the ENN net found on expansion port pin 28, so even easier to access

... to check the motor status and short the coils if turned off. Did he ever do it?!

@mrehorstdmd shorting the coils certainly makes the harder to turn, and has been used on a number of printers to hold the bed at power off. If the weight of the bed does cause the motor to turn still, there may at least be enough resistance to stop the bed "dropping like a stone" and causing damage. So may be an easier modification than redesigning the Z axis. Depends on what the objective is.

Ian

-

@droftarts said in My DIY Maestro powered Bed-Slinger (many photos inside):

... to check the motor status and short the coils if turned off. Did he ever do it?!

yes, works as expected

z motor is not very powerful so with original screw on ender5 it "kinda works" so with the glass off the bed it holds the bed, but barely, if there's a print on the bed it will sometimes slowly start to drop.. maybe glass is too heavy, there are also the big hands stiffening the bed, the precision piezo sensors.. but it holds it from "dropping like a stone" as it did before this mod. I'm now waiting for the new replacement screw (with 1 start compared to 4 starts on original one) and with backlash nut (not required for this use but backlash nut adds additional tension to the screw increasing friction) it will stay still even without this mod and with this mod I believe it will be rock solid. Unfortunately, we had a month of post on strike here so everything is now delayed

I doubt I'll get the new screw this year.. I will also replace original motor with the .9 degree one as I have few of them but they are high impedance so too slow for anything else so why not use it to increase precission even more :D, Z is slow anyhow

I doubt I'll get the new screw this year.. I will also replace original motor with the .9 degree one as I have few of them but they are high impedance so too slow for anything else so why not use it to increase precission even more :D, Z is slow anyhow

-

If all you're worried about is the bed somehow doing some damage when it drops, almost anything can be used including putting a couple springs at the bottom of the Z axis so the bed will make a soft landing.

If you want to absolutely stop bed motion when power is lost so that you can resume a print after a power interruption, you need either a brake, a worm gear drive, or some other solution that locks the bed in position. A high ratio conventional gearbox (or a series of pulleys and belts) may work if the detent torque of the motor multiplied by the gear ratio is greater than the torque created by the potentially falling mass.

If the bed drops and you want to resume a print, you have to have an accurately calibrated Z ordinate for the bottom of the Z axis. Then you can just move the bed back to the previous Z ordinate and resume printing. It might be useful to use a switch at the bottom of the Z axis.

-

@smece said in My DIY Maestro powered Bed-Slinger (many photos inside):

backlash nut adds additional tension to the screw increasing friction

I think you'll likely notice the 1 start lead screw is more than enough to stop any automatic downward movement. The backlash nut would likely add enough extra friction in that case to allow for easy binding. At least that's what I found with my 1mm pitch single start lead screws. My bed assembly is very heavy and during a power loss there is no movement whatsoever, even when loaded up with several kilograms of filament on the bed. When I first tested the anti backlash nuts the z axis would bind and stall at the start of long travel moves. I had to reduce the acceleration dramatically to overcome that. I gave up on the anti backlash nuts after that.

-

@Phaedrux said in My DIY Maestro powered Bed-Slinger (many photos inside):

The backlash nut would likely add

I'll do the test when the darn thing finally arrives... with a month of strike the amount of backlog our post office now has and the half of January in holidays I'm lucky if I get it during winter

My first experience with Z screws and anti-backlash nuts was some ~10 years ago on RapMan by bitsfrombytes (the duet team surely knows them, they were from uk too, one of the pioneers) and they used plexy + two M8 screws with a spring to create anti-backlash contraption. The first mod for rapman was to remove that spring as a bed that heavy had no need for those springs

and that simple mod made the Z work great (and mind they used nema23 motors, quite power ones) ... so yes I also believe that nut will lose the anti-backlash part ... but .. will know when it arrive

and that simple mod made the Z work great (and mind they used nema23 motors, quite power ones) ... so yes I also believe that nut will lose the anti-backlash part ... but .. will know when it arrive

-

@mrehorstdmd said in My DIY Maestro powered Bed-Slinger (many photos inside):

If all you're worried about is the bed somehow doing some damage when it drops, almost anything can be used including putting a couple springs at the bottom of the Z axis so the bed will make a soft landing.

It can still generate quite the voltage spike even if the mechanical fall is cushioned; and again - print resume with shorted coils work just fine for the tolerances applicable in consumer 3d printer as proven by Tiertimes design in the Up Mini 2. I can find a flat earther leaflet for you if you wanna keep arguing pointless stuff:P

-

Hey all,

thanks for the discussion around keeping the bed, or x-axis beam in my case, steady without enabled steppers. Let's postpone this discussion though, as it seems to get a little pointless without test results from my side.

... I hope to make some progress this weekend.

-

@mrehorstdmd said in My DIY Maestro powered Bed-Slinger (many photos inside):

I've broken taps in plates before.

You can use Alum to dissolve a broken drill or steel tap in aluminum.

-

First off I have to say that is quite the beautiful build. Do you have it modeled and etc in Fusion 360 or some similar program? Also would you mind sharing your source for black pei? I've been looking for a pei that isn't clear. Is it actually pei or more like buildtak?

-

@sonderzug said in My DIY Maestro powered Bed-Slinger (many photos inside):

the obvious disadvantage is that the x-axis drops like a stone when the steppers have no power applied

A geared motor like this one could keep it in place when power goes off.

https://forum.duet3d.com/topic/12942/get3d-free-give-away-free-extruder/17?_=1577063841912

-

Hi all,

"next weekend" turned into a few weeks, but with the holidays and everything I only had limited time to work on this project. However, the remodeling is more or less completed.

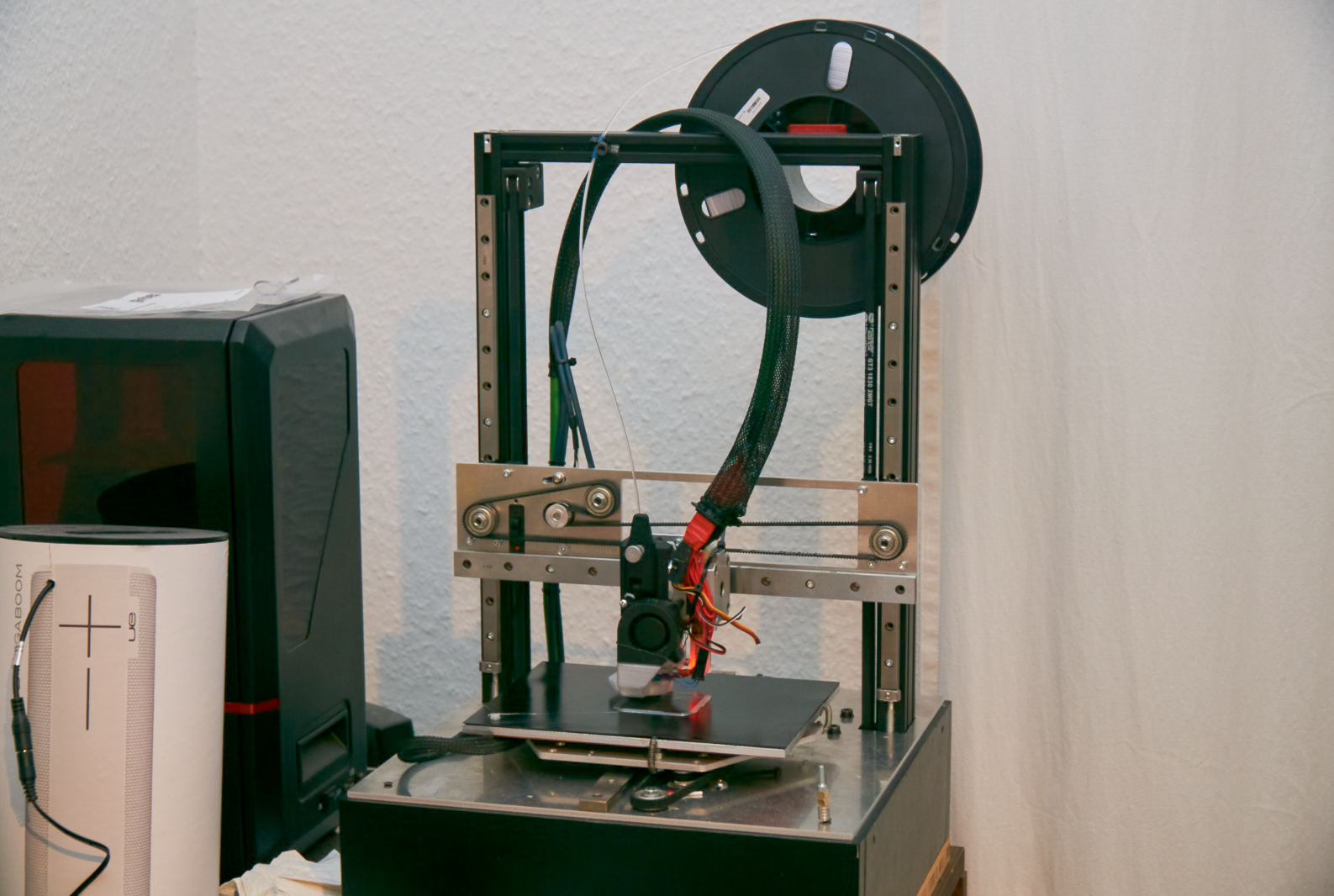

I announced that I would be ditching the igus linear rails. I did so in favor of used/new old stock THK linear rails that I obtained from ebay. In particular, I bought RSR12 (ZMUU) and RSR9 (WVM - double wide rail) rails, which will help this build achieve a much higher mechanical quality but will also be carried over to future builds (the lenghts allow for a bigger build volume than this has).

The problem with the igus rails was, as mentioned, that I chose the square profile rails which are not tensionable. The round profile drylin W rail has options for setting the tension of the gilder with a screw.For the new rails, I obviously had to account for the missing structural components of the drylin rails. The easiest and most precise thing for me was to have aluminium sheets lasercut for my purpose. So this is what I did.

I further wanted to eliminate the cheap chinese belt idlers, which I replaced with 608zz bearings on which the backsides of the belt run. Obviously there are no flanges to guide the belt, which is a bigger problem than I anticipated, so I will have to replace some of those with flanged bearings.

I opted for genuine Gates GT3 belt, to eliminate further influence from cheap components. So far the print results are way better than before, regarding the quality aspects that can be traced to the mechanics of the printer.

Pictures:

the x-axis plate has mounting options for the rail, idler, motor and optical endstop. The stepper motor is mounted in a seperate printed part that allows it to be pivoted around the lower mounting hole, allowing to tension the belt.

This arrangement is copied for the y-axis. The heatbed will be mounted like before.

assembled and running:

right now the printer is printing some parts for itself, namely the cooling ducts for hotend and part.

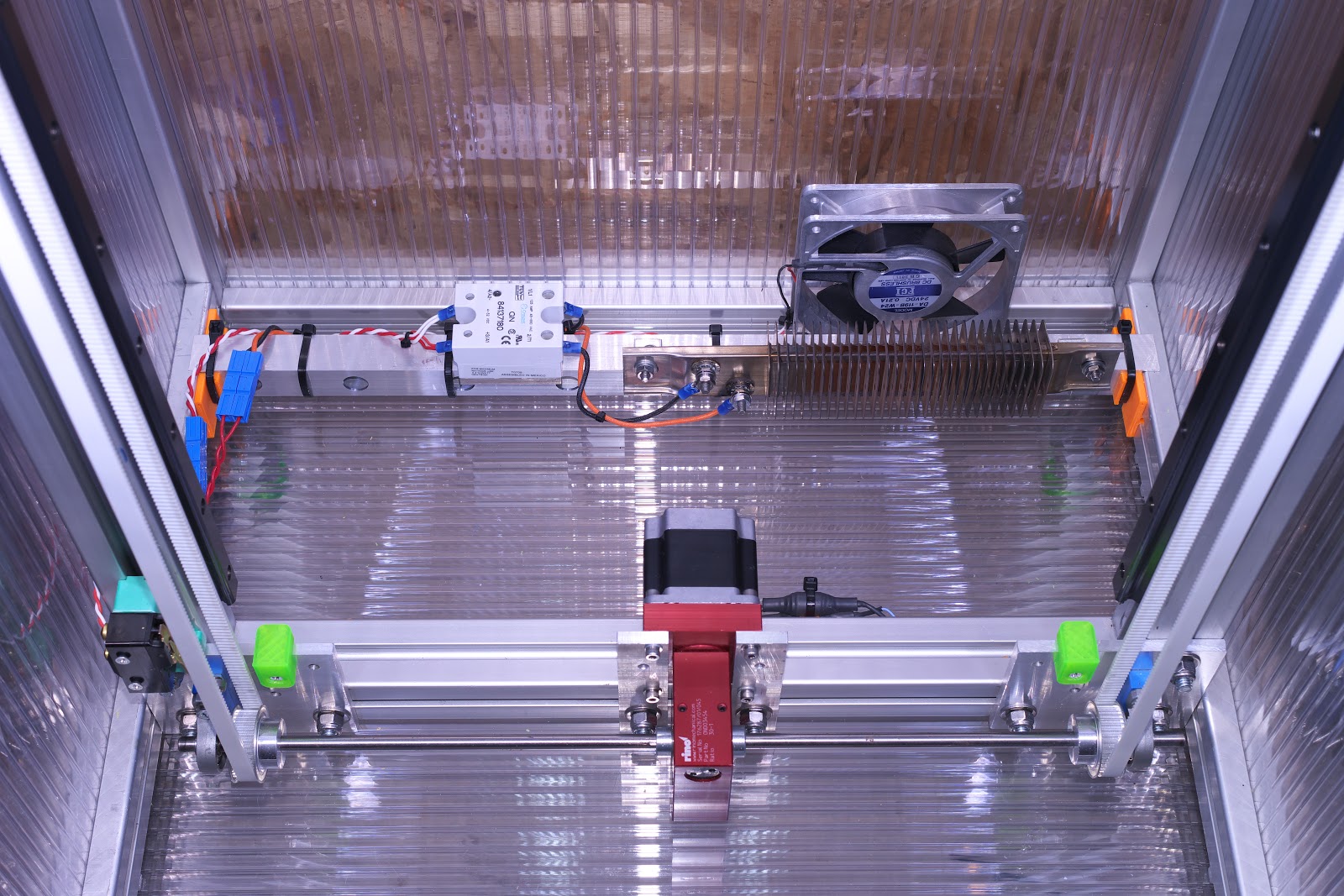

A short glimpse under the hood:

Why the board hasn't been mounted with it's edge facing outward to easily connect the ethernet cord, I can't tell

I didn't deem it too important at the time, unfortunately.

I didn't deem it too important at the time, unfortunately.I still have to tidy up the cabling of the hotend as well; the cables are connected with two 8-pin connectors for which I want to design plug housings and strain reliefs as well.

On the topic of the x-axis falling down when the power is taken off the steppers.... yes it will of course, and unfortunately also when the stepper's coils are shorted. I will design a little lever that the x-axis can run over at the z-max end, which will snap into place to keep the x-axis up after power-off; I have a RC servo lying around which I will use to release it automatically.

I'm overall happy with the rebuild and hope I'll be able to use the printer for railway modelling etc. in the future.

Best regards, Niklas