Terrible print

-

What printer is it? It looks like maybe an ender 3. Have you seen this guide series? It goes through setup and calibration, etc. https://duet3d.dozuki.com/Guide/Ender+3+Pro+and+Duet+Maestro+Guide+Part+1:+Wiring/37

We'd need to see your config.g and print settings to have a more educated guess.

-

If nothings blocked or the extruder gear isn't skipping, you are at best under extruding massively.

I'd try calibrating the extruder esteps at 205degC for that material with a fresh nozzle fitted, any listen for any clicking or bad behavior from the extruder while doing it.

-

@apex2011 Post your config.g, also send M115 and post response. A little information about your machine may be helpful too. Is the print a test cube? Could be that you have the Z steps per mm set wrong.

Ian

-

do the auto pid tuning

-

Is it set to the correct filament diameter on the slicer?

-

Sorry for the late replies. I have attached my config.g

Printer is an Ender 3. the print is a test cube

slicer settings are:

Nozzle Diameter 0.40

Extrusion multiplier 0.90

retraction 4mm

retraction speed 2400mm/min

extruder temp 230

bed temp 60

Fan Speed 0 first layer 80 for the restM115 response FIRMWARE_NAME: RepRapFirmware for Duet 2 Maestro FIRMWARE_VERSION: 2.03 ELECTRONICS: Duet Maestro 1.0 FIRMWARE_DATE: 2019-06-13b2

-

@CaiJonas I have done auto pid tuning but will try it again

-

Extrusion multiplier should be around 1.0

from config.g:

I am not familiar with an ender 3 but the following thoughts are based on a Creality CR10

M92 should have an E value of around 100 unless you have a reduction gear extruder in which case it should be around 400.

Motor current seems a bit low but should work.

Edit:

I suspect that you re way too high on your steps per mm and the extruder is grinding your filament like there is no tomorrow. Every once in a while it catches and moves the filament forward a bit. -

@jens55 said in Terrible print:

I suspect that you re way too high on your steps per mm and the extruder

He's got x128 microstepping set for E, so 769 / 8 and you get 96. Also mentioned here: https://duet3d.dozuki.com/Guide/Ender+3+Pro+and+Duet+Maestro+Guide+Part+2:+Configuration/38#s128

@apex2011 The way your print looks thinner as it goes up just makes me think the Z is moving too far. Can you shut me up by moving Z to 0, then move it up 10mm, and measuring how far it has moved up?!

Ian

-

@droftarts please correct me if I misunderstood but I homed my Z axis and then moved up 10mm. I measured approx 9.98mm from Z home location

. -

@apex2011 said in Terrible print:

@droftarts please correct me if I misunderstood but I homed my Z axis and then moved up 10mm. I measured approx 9.98mm from Z home location

.Thanks for checking! That seems correct. Would seem to be extrusion related, then.

Ian

-

- How fast are you trying to print that cube?

- Tangled filament path?

- Clogged nozzle?

- Loose pinch idler on the extruder?

Those would be my guesses.

-

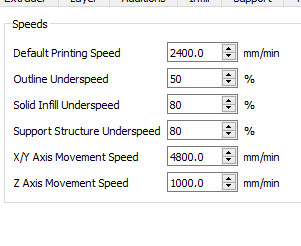

@Phaedrux here are the print speeds

-

So definitely not too fast.

If you tell the hotend to extrude into free air, does it come out smoothly?

-

@Phaedrux yes, it looks like it comes out nice and smooth, no skipping on the gear either.

I had a VERY small step in the right direction by going through the entire setup process again. The print is still terrible....just a little less terrible lol

-

@apex2011 Can you post the gcode file you're trying to print?

Ian

-

Do you happen to have the slicer configured to expect 3mm filament? This sometimes happens with Cura defaulting to 2.85mm filament after an update when you're actually using 1.75mm filament leading to huge under extrusion similar to what you're seeing.

Your screen shot of the speed settings looks like... Simplify3D? What filament diameter do you have configured?

Also, what nozzle size are you using and what size is configured in the slicer? Using a larger nozzle than you think could lead to under extrusion like that as well.

-

@droftarts sure, here is the gcode from the last print. I slowed it down a lot just to rule out print speed.

[0_1583623423559_800 Test_Cube.gcode](Uploading 100%)

-

@Phaedrux I am using Simplify 3d. I confirmed that it is set to 1.75mm filament. the nozzle is 0.4mm. just before my last print I cleaned out the block and changed the nozzle to a fresh, new one.

-

And you've gone through the extruder calibration from that Ender 3 guide?