Coming soon: Accelerometer Support

-

@dc42 one other question, for the direct connection method, where you say to connect it to the SPI daughterboard, via MISO and MOSI. I noticed that the temp daughterboard connector also has SPI0_MISO and SPI0_MOSI connections - does that mean those could be used, AND also still connect a SBC, which has SPI1_MISO and SPI1_MOSI?

-

@nuramori said in Coming soon: Accelerometer Support:

I understand that the one side of the toolboard is terminated with the r120, so would that be removed and the sammyc21 put in the chain, with a termination after that?

Yes; or alternatively, connect the SAMMYC21 between the main board and the tool board, so that the termination resistor is still at the end of the chain. Or, if the SAMMYC21 is on the tool head so the wires between it and the tool board are short, just connect the SAMMYC21 CAN pins in parallel with the tool board CAN pins.

-

@nuramori said in Coming soon: Accelerometer Support:

@dc42 one other question, for the direct connection method, where you say to connect it to the SPI daughterboard, via MISO and MOSI. I noticed that the temp daughterboard connector also has SPI0_MISO and SPI0_MOSI connections - does that mean those could be used, AND also still connect a SBC, which has SPI1_MISO and SPI1_MOSI?

Yes, use the temp daughterboard connector to connect an accelerometer directly. The SBC uses a separate SPI bus. However, currently accelerometer data can only be saved to file when running in standalone mode.

-

@dc42 can the sbc still function,, as in, can I use the plugin to see the data, even if it’s not being saved?

-

@nuramori unless DSF has been updated to include accelerometer support, no

-

@jay_s_uk rats.

I'm designing the mount for the accelerometer, and now I'm trying to understand the "Inn" orientation parameter for M955. It's not quite clear how to determine the correct value. I have a core xy (BLV cube) and I'm looking to orient the board 90 degrees from what the board symbol shows, which would otherwise align with the printer x/y axis. So if the "default" is 21, I'm not sure what it would be if I rotated the board clockwise 90 degrees.

-

@nuramori, the documentation was wrong. The default (which corresponds to the chip axes lining up with the machine axes) is 20, not 21.

When you rotate the chip, if chip +Z is still up then the first digit 2 doesn't change. The second digit will be 1 if the chip +X direction faces the machine +Y direction, or 5 if it faces machine -Y.

-

@dc42 aaaah, I get it now, thanks! The silkscreen arrow on the adafruit board helps put that together.

-

@nuramori said in Coming soon: Accelerometer Support:

I'm designing the mount for the accelerometer..

Is the accelerometer supposed to be mounted permanently or just used one time to measure the reassurance frequency(s) of the system?

-

@zapta My understanding it's providing real time or near real time feedback that's taken into account for all movement. So in short, a permanent part of the system.

-

@nuramori on klipper its a run once and remove from the system thing until you change something.

not sure if it will be used in the same way here or not -

@jay_s_uk said in Coming soon: Accelerometer Support:

@nuramori on klipper its a run once and remove from the system thing until you change something.

not sure if it will be used in the same way here or notMy understanding is also that it's a run once to characterise the resonance of the printer.

Input shaping is an open loop approach as far as I understand.

However, the accelerometer needs to be rigidly secured to the print head to accurately measure the printers characteristics so a dedicated mount IMO is a good idea.

That's not to say we won't find other uses for an accelerometer in the the future of course!!

-

-

@nuramori said in Coming soon: Accelerometer Support:

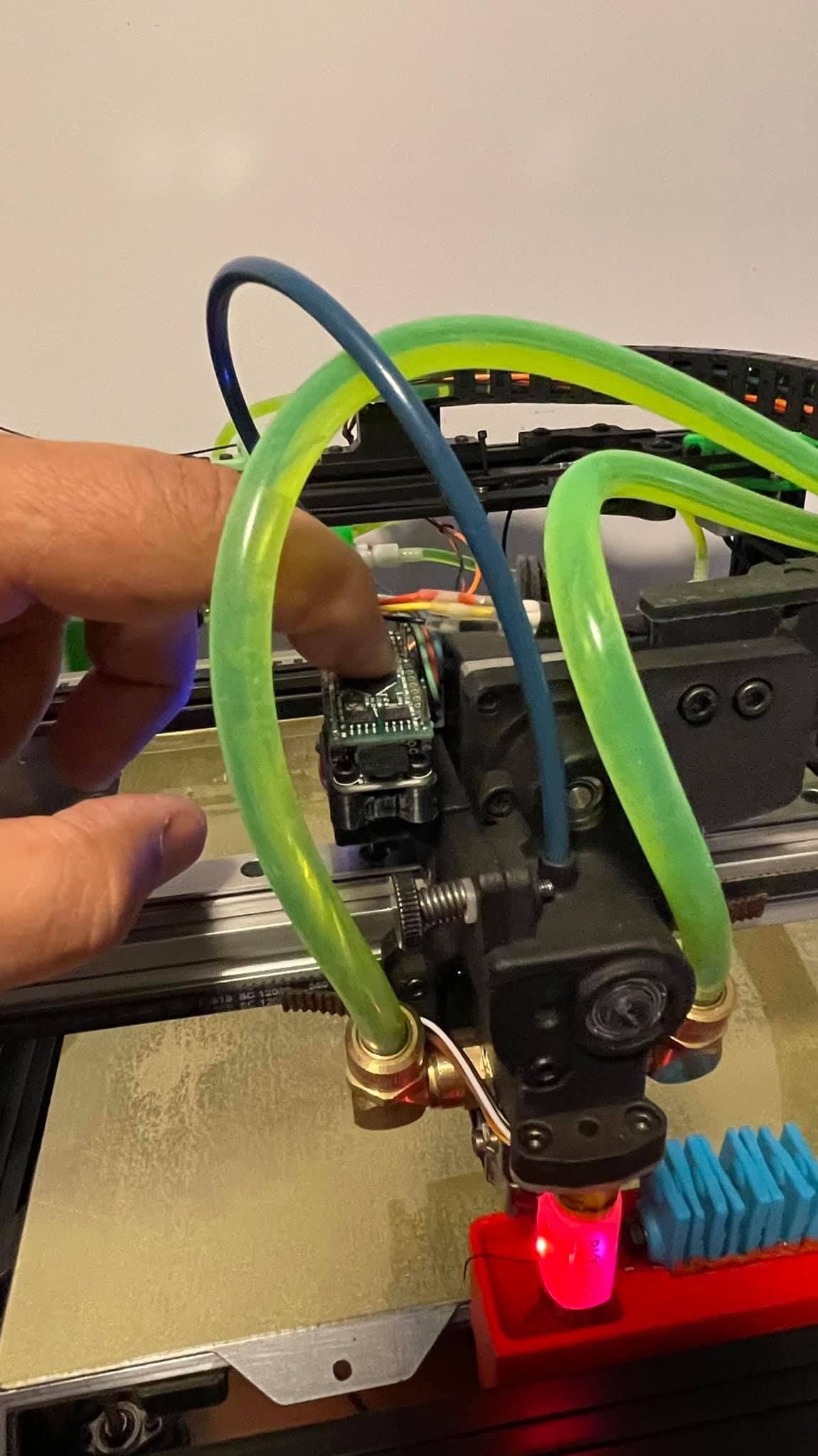

My soon to be installed Sammy/LIS3DH combo.

That's nice, I've got an order in for a couple of duet Sammy boards from Germany. Looking forward to having a play with my Duet 3 mini.

-

So would the accelerometer be mounted to the frame or motor? Does its position matter for it to read any ringing frequency.

This article is interesting:

https://www.omega.com/en-us/resources/accelerometershttps://www.pcb.com/resources/technical-information/mounting

-

@aprz said in Coming soon: Accelerometer Support:

So would the accelerometer be mounted to the frame or motor?

It would be mounted on the print head. For a bed slinger, you would also need to take measurements with it mounted on the bed.

-

@aprz This is how/where I'm mounting mine...

-

@nuramori

I like your silicone-sock wiper

-

@dc42 said in Coming soon: Accelerometer Support:

@aprz said in Coming soon: Accelerometer Support:

So would the accelerometer be mounted to the frame or motor?

It would be mounted on the print head. For a bed slinger, you would also need to take measurements with it mounted on the bed.

@dc42 Given the bed on a bed slinger increases in mass during a print would it be beneficial to alter the ringing frequency during the print to account for the print mass?

If so I guess we could embed input shaping gcode in the print file or something like that.

Perhaps enter the total print mass at the start of a print and profile the shaping based on % complete and a survey of frequencies across a print mass range.

Interesting

stuff...

stuff... -

@cncmodeller the amount of filament used is known already so it wouldn't be too difficult to track that to mass being added