[solved] strong vibration with pressure advance

-

@phaedrux

You are right ... I'm sleeping

-

@phaedrux

I tried to rise the retraction speed till 35mm/s (after changing the E in M203) . But this doesn't changed much.

With PA at 0.8 there are still no differences in blobs and the vibration is still really strong during the performing of PA.

Still before at 20mm/s the retraction was good. With the extra prime amount at restart I'm able to reduce the pressure at the start.

What seems I can't avoid is the very small blob at the end.

Is normal that the retraction is so fast and produce this vibration? Probably is the part too small ? 3cm X 3cm (wall 3mm thick) So the retraction must happen really fast ... The only solution for avoid this to happen is to slow down really much the print speed , right? But 35mm/s is already slow.

Now I try again with the coasting option and without the PA. That retraction produce a too noise sound and I cant leave the printer on during night. or stay in the same room during the day either.

Other advice are welcome !

I saved in the bookmark the macro post tnx

tnx -

You're running into a downside of bowden extruder setups.

-

@phaedrux

Ok, I have to finish this printer and then I'll start to mount the CoreXY full metal . Now it is in pieces in boxes.

If I found solutions I'll update this post. Thx as always for your time !

-

@giostark said in strong vibration with pressure advance:

If I found solutions I'll update this post.

Hours of rigorous testing and tuning with those macros. Maybe changing to more exotic capricorn tubing. Maybe a different extruder motor. Mounting a flying extruder to reduce distance to the print head.

-

@phaedrux

The tube is already an original capricorn , the 0.9 motor should be fine (german provenience) . In origin I had the fly system but I changed it for the enclosure system , for light the head and avoid to leave the extruder inside the hot chamber. The direct drive on the Smart effector seems not an option right? I'm already spending so much time back this damn trap but seems that I have to put still some effort on it.

but seems that I have to put still some effort on it.

I'm proceeding with other test... -

@giostark said in strong vibration with pressure advance:

The direct drive on the Smart effector seems not an option right?

With the right motivation anything is possible.

-

@phaedrux

Eh , I posted there ... this should be an interesting solution to adapt: -

I have one other thought. Measure your filament diameter and ensure there is not interference with the Capricorn tubing. I ended up getting rid of the Capricorn on all of my setups because it caused too much drag on the filament and I was unable to retract without losing steps in the extruder. Or that you are not changing the shape of the filament too much by squeezing it so hard with the BMG.

-

@giostark

There were guys adapting the Orbiter to a SmartEffector, needs a bit more work, though. -

Hi all the mate that try to help me !

News... As suggested by Phaedrux I reverted to a fly system the extruder , I had no choice. In origin I wanted to put it out the chamber for avoid the heat. But seems that a long tube can affect the pressure quite a lot.

I suspended the extruder and used a near 10cm of Capricorn.

The earlier horrible rumor was because the stiffness of the structure . Too rigid , the quick and strong extruder reversing generate a reverberation long the aluminium bars of the structure increasing the final rumor.

Now , the plastic belt with spring that suspend the extruder work as dampeners and also because inside the double plexiglass chamber all the rumors are gone !!!

I tried the pressure advance again at 0.2 disabling "extra prime amount" and leaving a 5mm retraction (70mm/s) + a 0.2 of coasting. (0.3mmlayer height)

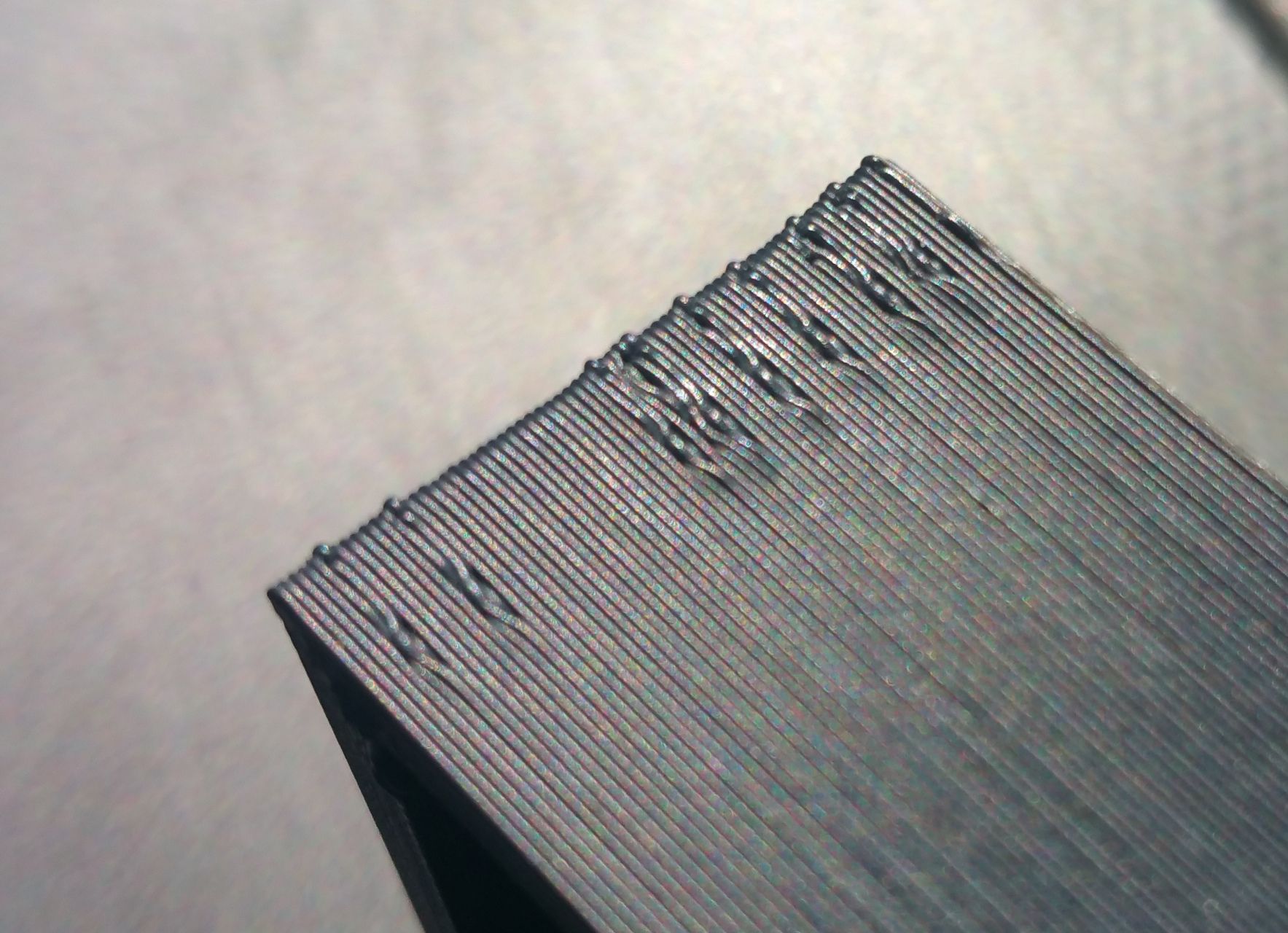

This is the result , I need MORE testing but for today I'm fine , is late and I'm exhausted. Also cables and roll need new arrangement.

Attached the video with no rumors anymore and a part now printed... I noticed that on the left a small vibration is because some extruder settings. If I disable pressure advance and some Cura option the wave go away but start the blobs . On the right corner the prominent edges correspond to the old blob that now are more flat.

So , no more rumors and room for get a better printed part...good to go!

The direct driver is really intriguing. Is not excluded a future upgrade...

no-rumors.mp4

-

@giostark

Looks good, but the errors on the left and right edge seem to have a regular distance, like you have Z-banding or wobble? -

@o_lampe

At first I suspected it but reverting to neutral setting in Cura and disabling the pressure advance they were gone. Seems different amount of material.

This wave artifact appear ONLY after that the nozzle turn the corner. (in this case the printer nozzle go form left to right).

On the right the small white sign are excess of material (the light reflected them resulting in small white).

An other strange behavior of the coasting (with the long tube and a big value of it) was that when the printer stop to extruder before applying the coasting , it leave a small blob (seems a hole but from the top view is an excess of material). This let me thing that is difficult to control the pressure so I shortened the tube.

Now I have to play between "pressure advance", "coasting", "wall inserting" , "retraction" .

Any your consideration is welcome!

-

@giostark How about the belt tension ? It seems the head goes too much due to the belt loosness.

-

@hiroaki

I can try to pull them , I'll report it in the evening... now is time for prepare the climbing afternoon

tnx all of you ! -

Generally when using pressure advance it's recommended to turn off any coasting or pre-load features of the slicer as they will fight each other.

Also it might help to set your seam position to a fixed point to get a better idea of what the end of line is looking like. And when possible set to inside > outside perimeters to hide the atrocities that can't be tuned out.

-

@phaedrux

Other testing here. The ringing was not for the tension of the belt , at least it should not be for that, but for the speed. The belt sound as "dong". I'm not sure if are pulled enough and at the same time I don't wanna pull them to much. 30mm/s for 90degree after every corner generate that wave. 20mm/s reduce the effect a lot. Pressure advance disabled and not option enabled for the seam in Cura.

-Top left seam at 20mm/s.

-Top right seam at 30/mms.

-Bottom left corner at 20mm/s (with one vertical line after every corner).

-Bottom right corner at 30mm/s (with 6 vertical lines after every corner).

Could be this because the head of the printer now is more heavy that in origin?

I already have the Hayden bars , the effector seems rigid enough. The belt are chinese (the ones come with the printer). The belt with metal core were not good, them create some bad movement resulting in horrible digging on the glass. Those rubber belt can reproduce a calibration between 0.02 and 0.03 all the times but maybe are too elastic?

I lowered the Jerk to M566 X800 Y800 Z800 E1200 and the acceleration to M201 X1000 Y1000 Z1000 E3000 , but the only thing that make a change was the final speed decreasing from 30 to 20 mm/s.

Suggestions?

-

o_lampe was right , it have a wobbing issue. I noticed this only now that I'm trying to speed up the machine. Are arriving new belts (hope Original Gates or at least good enough).

I read about removing the ringing in several guide.

Can someone suggest a good pancake nema 17 for the extruder? Maybe that didn't suffer of heat at ambient temp of 50 degree.

I should light a little the head. A direct and light drive system should be better. -

Maybe an orbiter?

-

@phaedrux

David was intrigued by the V2 ... maybe is worth waiting for this solution.

I'm trying at 20mm/s , the result seems pretty good , even without pressure advance. But it is so slooooow...