New heated enclosure printer

-

@phaedrux I think that activating pressure advance did not make an improvement to the main problem at hand, so in the interest of not trying to tweak too many variables at once, will turn it off and try a layer fan first. If the fan does not do it, both can be done and then will have a full data set for comparison.

-

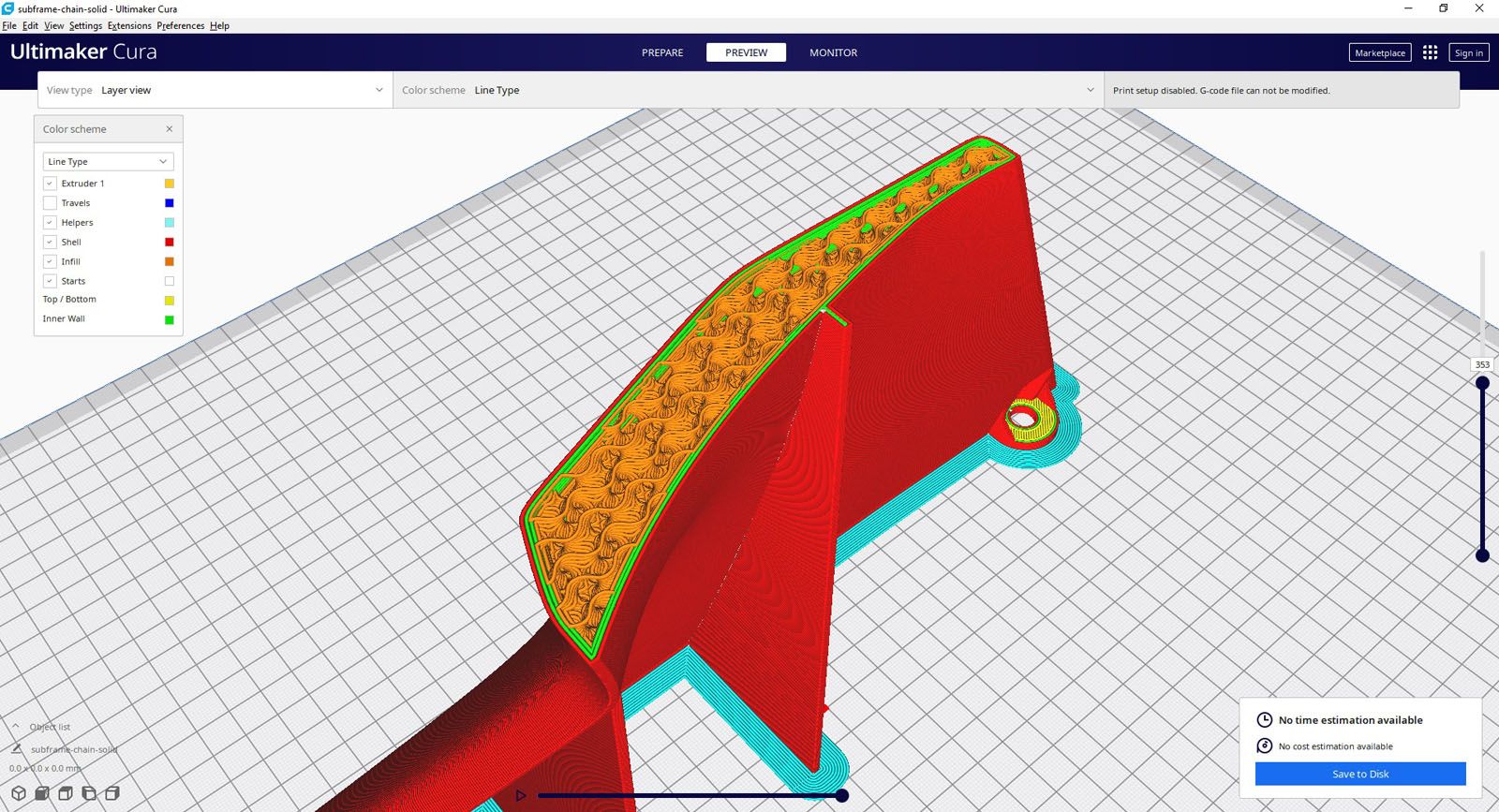

Last night I made some modifications to the part to see how much of the thin wall nature is the issue. I thickened the part to about 20mm and sliced it with a 0.8mm nozzle, 0.4mm layer, 20% gyroid infill and 2 walls. The result was the best yet, with a 5hr3min print time.

I'm really happy with the surface finish and if this last issue can be resolved will consider the printer a complete success.

Though the same problem happened along one of the inner edges.

The narrow ribs with no triangular ends (done to try to make the problem happen) printed great, through they did show signs that pressure advance could be beneficial. Most of the wall was 2.8mm thick, but it fattened up to a teardrop shaped 3.5mm bulge at the end.

Now to install the layer fan and duct and run the same file again, modified to turn the fan on after 100 layers.

-

@coseng said in New heated enclosure printer:

Could you upload the gcode for this print? Would like to take a peek and see whats going on there.

-

@sebkritikel Here's a screenshot of the area. The problem area is the sharp vertex in the forground. The gcode is 28MB, where would I upload it to here?

-

@coseng That duct looks pretty restrictive for an axial fan.

-

@phaedrux Well rev1 did not fit because I did the bellows mounting on the fly and was not in the CAD model! So I'll make rev2 bigger.

-

Do you have a radial blower fan for more static pressure?

-

@phaedrux I was thinking it would not need significant amounts of air, but I good point, why underestimate? Let me see what I have in the back with some more oomph.

-

@sebkritikel said in New heated enclosure printer:

Could you upload the gcode for this print? Would like to take a peek and see whats going on there.

https://drive.google.com/file/d/1bjFQm2guAu9zjHL3NyoJ2kZlp8FMA5ES/view?usp=sharing

Here it is zipped.

-

@coseng Thank you!

I was trying to see if any of Cura's coasting settings were configured, but nope, the gcode looks pretty good. You're printing ABS right? In the specific image I quoted, I think a small amount of part cooling could be beneficial - taking into account the slight overhang you're printing combined with the corner segments and movement speed. I'd guess the material is peeling back during those segments.

I've found ABS doesn't need as extreme of cooling as PLA does at similar feed rates. Really, ABS does quite well without cooling, but a small amount has helped me solidify my overhangs+corner sections.

Your general surface finish is much improved - I try to print my inner walls first, followed by my outer walls, and then my infill segments- helps me avoid any infill bleed-through (I do allow for some infill overlap with my inner walls in Cura).

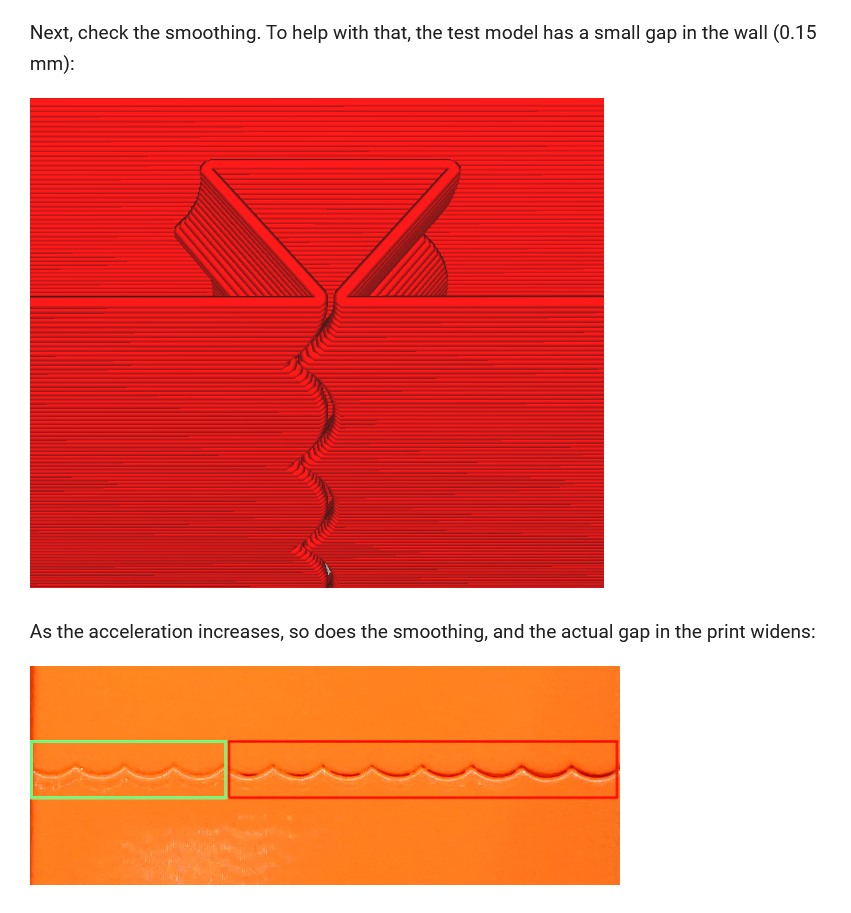

For pressure advance, there are a few good calibration macros (that allow you to set your PA range, line segment lengths+speeds), but I find the best values there are a hair conservative. Try printing the Klipper ringing tower (maybe a few bottom layers, but otherwise inner and outer walls only - no infill or top surface layers), sweeping across PA values (starting with 0, ending with a fairly high value). A good area to look at is this section:

While that doc is detailing input shaping, you'll see (and feel) the PA impacts on the areas indicated by green and red. -

@sebkritikel OK, thanks for the info. This part just ran overnight, 5hr35min, and I think came out quite good. It is definitely better than the thin wall version and not much heavier and a lot stiffer. The problem is this technique is not applicable to all of the parts. I will do it when possible, but will dedicate today to running some of these calibration processes in the hope of getting both types of parts running well.

Instead of the ribs of the previous runs, this is modeled as solid with some cutouts for the mounting holes.

There are a few printing artifacts and hopefully today's activities will help to address them, but I'm very happy with these very usable parts.

-

Made and ran a PA test part with geometry similar to my problem areas. This part's toolpaths are one continuous pass per layer, no infill, retractions, etc. 0.8mm nozzle, 0.5mm layer height. 135mm/sec actual print speed.

It printed mostly great, with the exception of one area:

The location of this problem points strongly to thermal issues of the extrusion bead cooling, so next on deck is the layer fan.

The PA test changes were subtle and easier felt with your fingertips and not a camera. Best value seems to be 0.03 where there was the least amount of bulging at the rib ends but no other weirdness at corners and transitions.

Progress!

-

@dc42 I'm having a little trouble in paradise this evening. I was about to install the layer fan and had modified the system.cfg file to add the two lines for fan definition, and noticed the DWC with the wired internet connection was acting sluggishly. I made an error with the config.sys file in not changing the numbers from 3 to 4 to add the fan. I updated the file by changing those two lines, and I clicked reboot mainboard for the updated config.sys file and presto, the web browser could not reconnect with the printer.

I did the 'ol printer reboot, and then the paneldue partially booted but had 'connecting' in the upper right corner and the bed temps and other displays were not present and I still had no ethernet connectivity. I did another reboot and the paneldue now did not display anything, just blank with the backlight on.

Windows says that nothing is plugged in to the internet port and none of the ethernet plug lights are on on either end.

Before I started messing around and doing something stupid, I was hoping for a little guidance.

-

@coseng said in New heated enclosure printer:

Before I started messing around and doing something stupid, I was hoping for a little guidance.

Take a look through this guide and see how far you can get.

https://docs.duet3d.com/en/User_manual/Troubleshooting/Duet_wont_respond

-

@phaedrux Thanks. I see a USB port in devmgr but it is listed as 'USB Serial Device (COM3)' , not any of the options listed in the guide.

-

Are you able to reach it through a USB serial terminal like YAT?

-

@phaedrux YAT says access to COM3 is denied. The last time I used YAT was to set the 6HC up so the setting should be the same.

-

What LEDs are lit when power is applied, either through VIN or USB?

-

@phaedrux The proper LEDs from the recover guide are lit. I reinstalled the windows drivers and now have 'Duet3 Motion control Electronics (COM3)' listed in devmgr and can connect in YAT. A M115 gives me this response:

'FIRMWARE_NAME: RepRapFirmware for Duet 3 MB6HC FIRMWARE_VERSION: 3.4.0 ELECTRONICS: Duet 3 MB6HC v1.01 or later FIRMWARE_DATE: 2022-03-15 18:57:26

ok' -

@phaedrux OK, I was able to use the 'fallback procedure #1' from the recovery guide, copied the 3.4.1 files to the sd card, performed the update with yat, then did a M115 and received the confirmation with the updated firmware version. Still get nothing from the ethernet connection and DWC. No lights on the ethernet port and Windows says the cable is unplugged. Paneldue is still blank. One slow blinking LED between SD card and reset switch, then the group of 4 leds, green, red, orange, blue, are all solid lit.