Issues with pressure advance since RRF 3.4

-

@Argo I'd rather you keep input shaping off with Klipper (and with RRF) as that just simplifies things (as it does seem to have an impact on RRF).

-

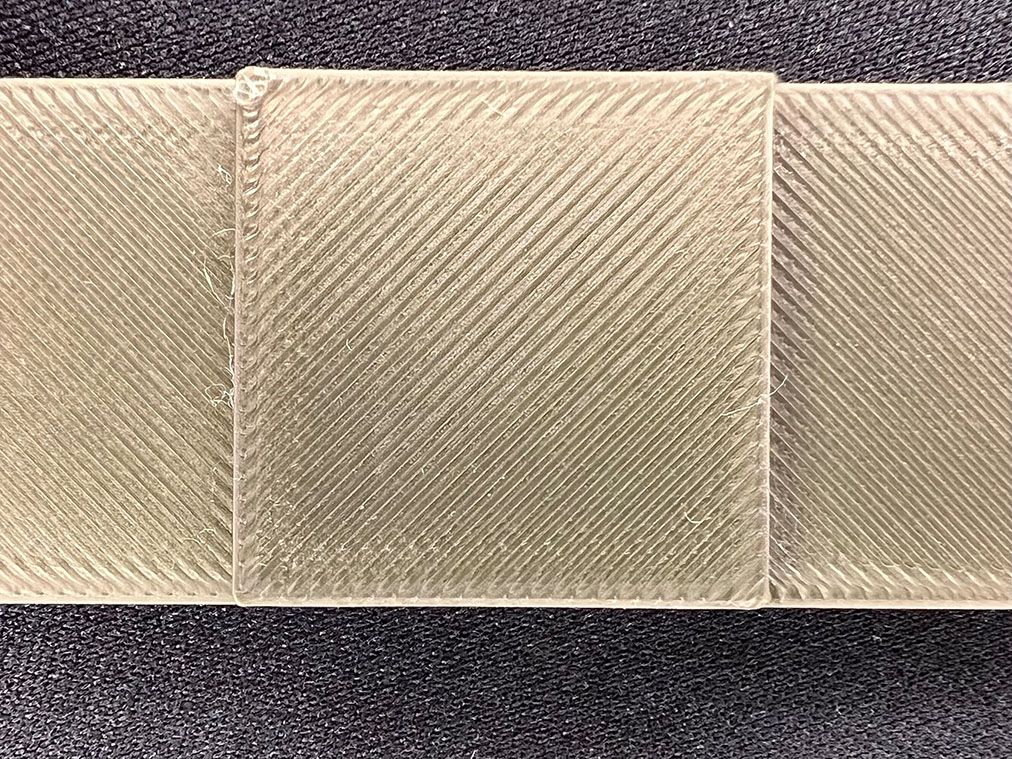

Bumped PA up from 0.05 to 0.052. I think maybe 0.054 could be the optimal value.

Decreased flow a tiny bit to improve top layer quality.

(Klipper)The result is quite comparable to what I get with RRF with "dynamic PA" (0.05 -> 0.08).

Sorry that I had to switch color. The bright green is empty after tons of testing. -

@Argo No problem, could you post your klipper and slicer settings (maybe post the gcode file you used with Klipper as that will have a lot of the details in it).

-

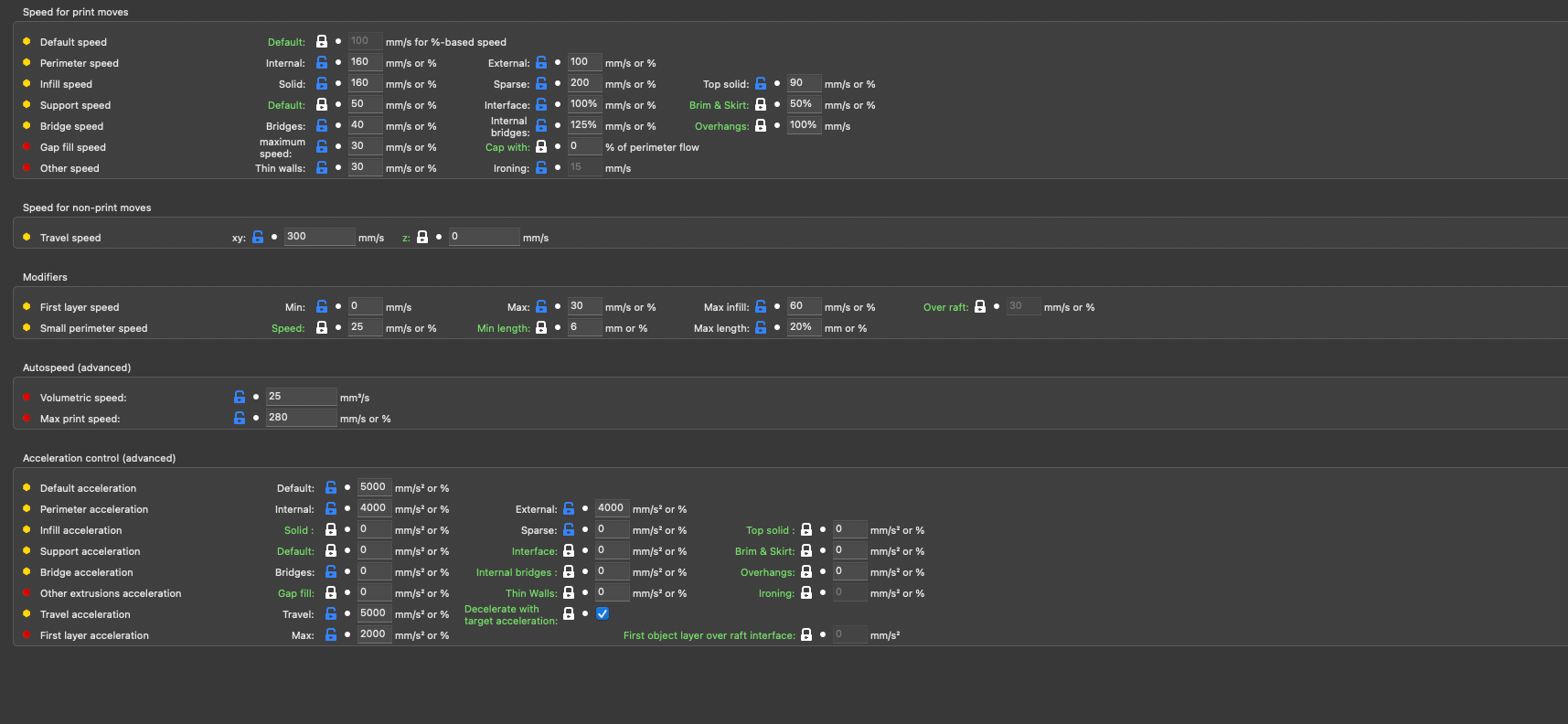

For Klipper itself nothing fancy.

square corner velocity = 5 mm/s

max feedrate = 350 mm/s

max acceleration = 5000 mm/sSlicer speed settings:

-

Been following this thread for a while now,

, and wondering if there's been any concrete, official update?

, and wondering if there's been any concrete, official update? -

Latest official statement is that the Duet team can't reproduce the issue so I assume there won't be a fix. That's why I'm glad I found a partial fix by using Super Slicer extrusion roles:

https://forum.duet3d.com/post/298231

At the moment I'm using 0.052 PA for every role except perimeter which use 0.075 PA (PLA filament). -

@Argo said in Issues with pressure advance since RRF 3.4:

Latest official statement is that the Duet team can't reproduce the issue so I assume there won't be a fix. That's why I'm glad I found a partial fix by using Super Slicer extrusion roles:

https://forum.duet3d.com/post/298231

At the moment I'm using 0.052 PA for every role except perimeter which use 0.075 PA (PLA filament).As you found, that isn't great though, since the change in PA causes the printer to dwell.

-

From my own testing a while ago I had noticed a difference in extruder jerk when I was getting some bulging corners. After retuning E jerk and PA it improved.

Has anyone noticed a difference in E jerk?

-

@Phaedrux possibly. It at least seems to be very sensitive to it. Right now, with even just a low poly curved surface, each segment is ~1.5mm long, I get a bulge at every direction change.

-

Yes, definitely.

If I increase or decrease the extruder pressure, I can influence whether there is more or less overshoot. But I can't get rid of it completely. -

Yes it’s far from optimal. But at least parts are usable again. Though I had Klipper flashed and it hasn’t the flaws I’m not really into using Klipper. Just a personal preference. But wouldn’t wonder if someone switches because of that.

-

I will only use it as an emergency backup. Sure if RRF fits again I'll switch back, I think. I'm already a fan of Duet.

But to test whether my hardware fits, I'll try Klippers. The last parts will arrive in the days for the test with me. -

I don't know if this helps but I decided to run some tests. Two printers were used to compare the output. One is a CR10-S5 and one is a Jubilee printer. The CR10 is running a Duet2wifi and a Duex5 expansion card, the Jubilee is running a Duet3-6HC with the extruder being run off a tool board.

In both cases the extruder is a direct drive extruder. Both use firmware 3.4.0.

I used a pressure advance python script that I plugged the correct data into in order for it to generate a gcode file. The file prints a single line with fast and slow segments. Slow segment was 5 mm/sec, fast segment was 100 mm/sec.

The same filament (same roll) was used in both cases.

It probably has been well over a year since I last ran this pressure advance test but it used to show very clearly what the pressure advance should be set to.

I can report that the result was absolutely useless - there was no discernible difference in the layer lines. I ran pressure advance from 0.000 to 1.000 just to cover my bases but did more in-detail testing in the 0.000 to 0.080 range which is the expected range for a direct drive extruder.

There was an occasional abnormality here and there but it was not consistent and certainly was not repeatable.

I have set config.g on both printers to 0.01 as a wild guess. I could have chosen pretty much any figure between 0.00 to 0.08 as the test print showed no difference in the output.

When I was getting close to 1.0, I was seeing some issues but again, there was no clear 'this is good' and 'this is bad'.

I am left with two possible alternative explanations: 1) I don't know what I am doing or 2) PA is completely and utterly borked.

Since these tests have been a good indicator for PA before, I am leaning towards #2.

In all fairness, it did take me some time to tweak the python script to work with a multi extruder printer which initially also caused no change in the printed output. That was caused by me printing with extruder 1 but setting the pressure advance for extruder 0 ... doooohhhh ..... but I did correct that and feel that I have valid gcode files and pressure advance is simply not working. I have run M572 on the active extruder and as far as I can tell, the printer thinks it is set to the right pressure advance. -

@jens55 What was the version of firmware you were using when this test worked? Has anything else changed in your printer setup (hardware or configuration) since then?

If you think this is a problem with 3.4 that did not exist on an earlier version please switch back to that earlier version and publish the results from both. So far I do not think we have any examples that show this is a change between versions of the firmware (when using the same settings and hardware for both new and old versions). If you are using any 3.4 features (like input shaping), you may want to try disabling them and re-run the 3.4 test again before switching back to the older version.

-

@gloomyandy, I do not use input shaping. It's been likely a year or more since I last ran these tests. I can not reasonably claim that nothing else has changed. Heck, I wouldn't even know where to start the recreating of old config.g files. I am not in a position to start reverting to old versions. I have neither the time nor the energy to go through that process in a thorough manner. I will likely continue my experimenting for a while but it isn't an exhaustive investigation (and is not meant as such). I am simply throwing my observations into the mix of things.

-

@jens55 If you are not using any 3.4 features, I don't think switching to 3.3 would be a big problem, your 3.4 configuration should work I think.

-

@jens55 i've ran a 3.4 config with 3.2 quite happily

-

Did you already have the time to print a comparison between RRF and Klipper on your setup?

-

@jens55 I was stimulated by your post to try again a gcode script I use to calibrate PA, adapted from a previous post. For me, this seems to work as expected:

It does 4 lines at 20mm/sec, then 4 lines speeding up from 20mm/sec to 100mm/sec and back for each PA setting - I have pictured to speeding up section, where you can clearly see the effect of PA, and confirming the .04 I usually use.

My system is pretty basic - duet2wifi with no SBC running 3.4.4, with mzv IS, single nozzle, direct drive orbiter 2.

-

@Adrian52 should add that the script is adapted from that posted by DonStauffer (https://forum.duet3d.com/user/donstauffer) here

https://forum.duet3d.com/post/250961

I found it quicker without a raft, so made an anchor piece to start the test strips . Apologies to DonStauffer for mangling your script.

; set variables var StartX = -70 var StartY = -25 var LinesPerTest = 4 var LinesBetweenTests = 4 var AnchorLines = 10 var TempBed = 60 var TempTool = 195 var ToolNum = 0 var Ext1 = 0 var Ext2 = 1 var Width = 0.55 var Height = 0.2 var ExFactor = 1.0 var Retract = 1.0 var Prime = 0 ; Before Raft var PALow = 0.0 var PAHigh = 0.07 var PAIncrement = 0.01 var SpeedRaft = 400 var SpeedSlow = 1200 var SpeedFast = 6000 var SpeedTravelXY = 9000 var SpeedTravelZ = 1200 var SpeedRetract = 7200 ; Calculated and Utility Variables var TestCount = 1 + floor((var.PAHigh - var.PALow) / var.PAIncrement + 0.5) var FilFactor = var.ExFactor * var.Width * var.Height / (pi * 1.75 * 1.75 / 4) var PA = var.PALow - var.PAIncrement var Dist = 0 ; PREPARE T{var.ToolNum} M82 ; Extruder Absolute Mode ; Heat Bed and set Hot Ends to Standby M400 M117 "Heat" M140 S{var.TempBed} ; set Bed Temp M568 P{var.ToolNum} S{var.TempTool} A2 ; set Tool Temp M116 H{var.ToolNum + 1} S1 ; Wait for temp G4 S12 ; Delay to Allow for Overshoot M116 H{var.ToolNum + 1} S1 ; Wait for Recovery M116 H0 S1 ; Wait for Bed M400 M117 "Home" G1 Z30 F3000 G30 M400 ;M117 "Anchor" ; Go to StartX - Width *5, StartY G90 ; Absolute G92 E0 G0 E{-var.Retract} F{var.SpeedRetract} G1 X{var.StartX - var.Width * (var.AnchorLines-4) } Y{var.StartY} F{var.SpeedTravelXY} G1 Z{var.Height} F{var.SpeedTravelZ} G91 ; Relative set var.Dist = (2 * var.TestCount * var.LinesPerTest + var.LinesBetweenTests * (var.TestCount - 1)) * var.Width M221 S110 ;set extrusion factor to 110% for anchor while iterations < var.AnchorLines ; Draw anchor Line G0 Y{var.Dist} E{abs(var.Dist) * var.FilFactor} F{var.SpeedRaft} G92 E0 ; Break here if last time if iterations + 1 >= var.AnchorLines break ; Move Over G0 X{var.Width} E{var.Width * var.FilFactor} F{var.SpeedRaft} G92 E0 set var.Dist = -var.Dist G0 E{-var.Retract} F{var.SpeedRetract} ; Retract ; BEGIN TEST PATTERN M400 M117 "Test Pattern" ; Go to StartX, StartY G90 ; Absolute G1 Z{var.Height} F{var.SpeedTravelZ} G1 X{var.StartX} Y{var.StartY} F{var.SpeedTravelXY} G91 ; Relative while iterations < var.TestCount ; set PA set var.PA = var.PA + var.PAIncrement M572 D{var.Ext1} S{var.PA} M572 D{var.Ext2} S{var.PA} echo "PA=",{var.PA} ; Draw Reference Lines while iterations < var.LinesPerTest G0 E0 F{var.SpeedRetract} ; Unretract G0 X140 F{var.SpeedSlow} E{140 * var.FilFactor} G92 E0 G0 E{-var.Retract} F{var.SpeedRetract} ; Retract G1 Y{var.Width} F{var.SpeedTravelXY} G1 X-140 F{var.SpeedTravelXY} ; Draw Test Lines while iterations < var.LinesPerTest G0 E0 F{var.SpeedRetract} ; Unretract G0 X35 F{var.SpeedSlow} E{35 * var.FilFactor} G0 X70 F{var.SpeedFast} E{105 * var.FilFactor} G0 X35 F{var.SpeedSlow} E{140 * var.FilFactor} G92 E0 G0 E{-var.Retract} F{var.SpeedRetract} ; Retract G1 Y{var.Width} F{var.SpeedTravelXY} G1 X-140 F{var.SpeedTravelXY} ; Move to start of next comparison G1 Y{var.LinesBetweenTests * var.Width} F{var.SpeedTravelXY} ; Finish up M400 M117 "Done" G10 P0 S0 ; turn off temperature M140 S0 ;turn off bed heater G28 ; home