The nozzle scratches the part

-

@deckingman Thank you for your answer; I will try it (again) at home. I have already done it at the beginning of the commissioning and as I remember it was ok. I have 200 steps/rev; 2mm/rev; and micro stepping 1/16. I have:

M350…Z16

M92 … Z1600

I think it’s correct -

@redax27 That looks fine, providing your lead screws really are 2mm lead.

-

@redax27 A few things to try:

- Try homing your Z, then moving it 100mm - double-check with a ruler that it actually has moved 100mm. Your maths for the z-steps seems right but if it only moves 50mm, you'll prove you've got something wrong somewhere.

- Have you calibrated your e-steps? If the Z is moving the right amount, then the other obvious thing is that you are pushing out too much plastic

- Have you got your slicer settings wrong (e.g. wrong filament diameter? using volumetric extrusion? etc)

I also notice that your hotend thermistors are still using the default value (B4318). It's probably worth trying to find out what the correct values are for the thermistor you are using just in case that means you are significantly out on temperature.

-

@deckingman Hi, I try this morning to move the Z 50mm and the bed moves exactly 50mm. I have no time enough to check separately each screw, I measured in front of the right screw, I will try this evening the left screw; maybe I have a problem on the second motor…

-

@engikeneer Hi, I will check each proposition.

-

It doesn’t seem to be the Z calibration (second motor to be checked to remove a problem on one of both motors.

-

I have already calibrated the extrusion by measuring the effective length processed

-

The thermistors settings could be also checked again. As I remember, I followed a procedure to set each thermistor PID, I could do it again.

-

I will check on my slicer the extruding type. I don’t remember to change something…

Anyway, thank you for your suggestions !

-

-

@engikeneer Sorry for this newbie question… do you know where to change volumetric settings in Cura? Regards

-

@redax27 I'm not sure about volumetric settings in Cura, but it could be that the filament diameter is set incorrectly. If you use 1.75mm filament, but Cura is set to 3mm filament, you will get massive over-extrusion.

Ian

-

@droftarts said in The nozzle scratches the part:

If you use 1.75mm filament, but Cura is set to 3mm filament, you will get massive over-extrusion.

I think it will be the other way around... in this case, you will have massive under-extrusion.

-

@cosmowave Yes, you're right, thanks!

Ian

-

@redax27 Can you post a picture of your first print? That might help us see if the problem is over-extrusion. If you can also post the gcode file, it may show if the gcode is sending commands it shouldn't.

Ian

-

@droftarts First of all, thank you to participate to solve my problem!

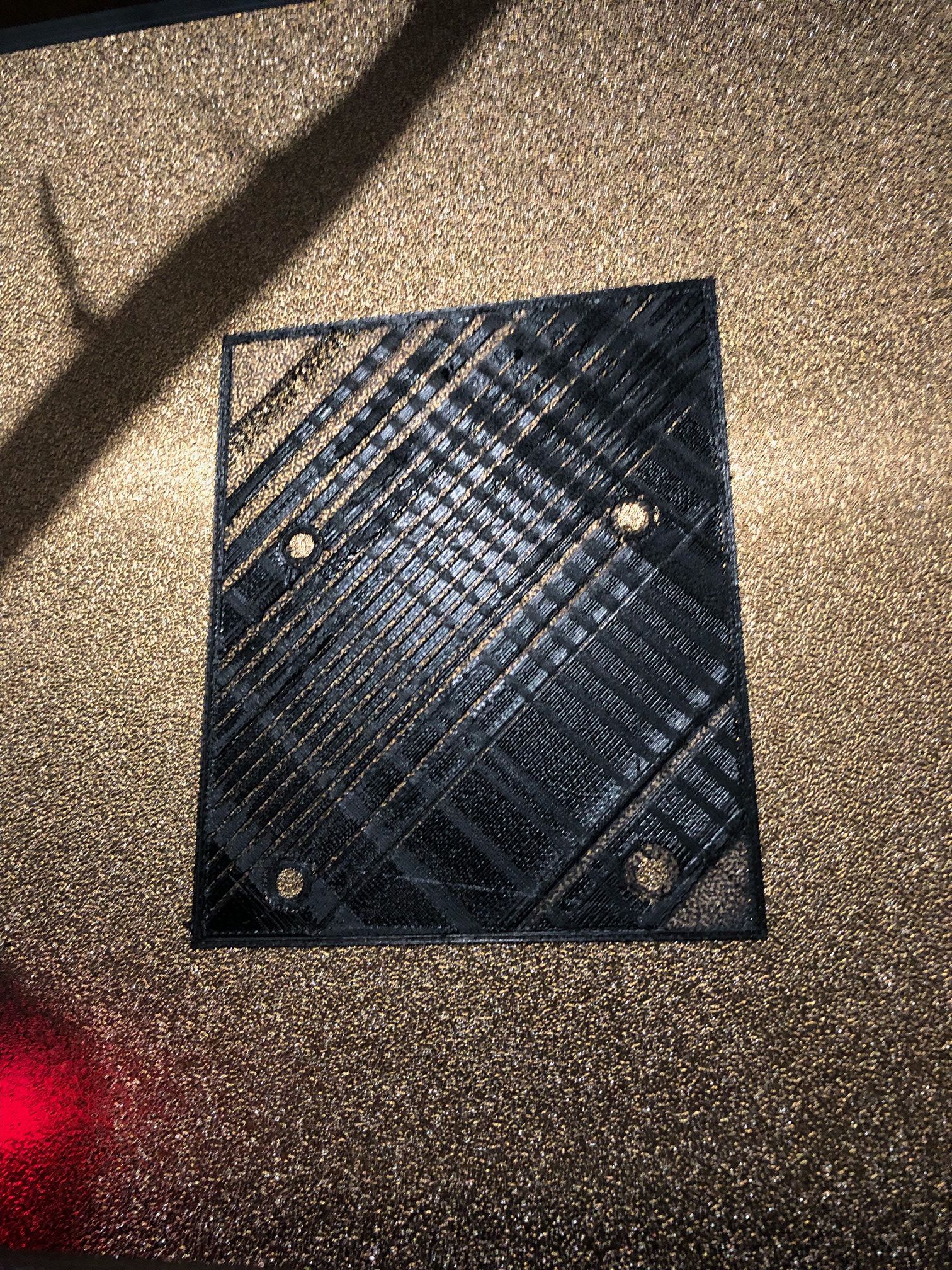

See below a picture of a part aborted; We can see strange traces like that from the first layer. I attach also the G-code but it is too big; I post only the beginning of the file.

I note also frequently strange over-speeds...

-

@droftarts:

Hi,

Did you have a little moment to see my file?

This evening, I try another print coming from another version of Cura on another computer.

It's worse and stops earlier after the first layer

-

@redax27 Nothing obvious sticks out to me with your print file.

When you start a print, do you start the file with the build plate cold? In your print file it appears as if you home the printer first, and then preheat your bed. I recommend changing your Cura profile to either preheat the bed and nozzle before homing, or re-home after the build plate and nozzle temperatures are reached.

I ask because of this area (same as bottom right):

It looks as if the nozzle and build plate are coming closer together (or even the bed is not level/bent). This COULD happen if your bed, nozzle, frame, etc, are expanding as they increase in temperature. Although, 60°C isn't TOO hot. Could also be that your bed is not flat.

-

@sebkritikel Hi,

Thank you for your answer; the reason why I do it like that is an accuracy measurement problem.

As I let the bed heat during the bl-touch measurement causes a big error (more than 0.5/0.6mm).

If I have no heating and no fans, in this case I have a good measurement and always the same.

I can maybe begin to heat and stop the heating only during the short measurement.

Do you think it's a good idea? The best way is to solve the measurement mistake, but I have no idea how to solve that.

Regards -

@redax27 The accuracy problem - do you mean you see a big difference in the height map when the bed is cool vs. when the bed is hot (for example, you measure when cold, then later measure when hot)? Or do you mean that the BL touch homing may vary/error by .5 / .6mm?

Do you do a height map? If so, can you upload one?

-

@sebkritikel As you say, I think it's an interference when heating. If I do G30-S-1 alone or G30 S-1 with the heating, I have a big measurement difference (around 0,5/0,6). I will add B term as proposed to M558 . For information, see enclosed my map. I have done it by heating the bed @60°C and cut it during the process. It's not perfect because the bed cools down but better than nothing.

heightmap.csv -

@sebkritikel Hi, after some week-end tests, I go ahead but not completely cancelled my problem.

Adding B1 to M558 during measurement cycle is appropriate and cut the heating during measures.

After applying this new feature, G29 seems correct and the printing of the first layer is better. But after several layers the extruder forces again and stops the material feeding.

I begin to be really disappointed because it’s difficult to print something simple.

Below my last test. Could it be the atmosphere moisture?

-

Below my last test.

Don’t know much about your printer, the filament you use and the parameters you apply to a print, but your "cabriolet" benchy reminds me of what I get from a (partially) clogged nozzle.

The potential reasons are manyfold and difficult to spot, maybe you can give us some hints:

- filament type (I assume: PLA?)

- wattage of the heater

- heater temperature

- nozzle diameter

- print speed

- retraction settings

- setup of your customised print head

The last item from my list is aimed at a possible heat-creep which may block the filament flow over time. That depends largely on the cooling of your hotend (fan1) and the retraction settings.

-

@infiniteloop, Hi, thank you for your interest.

My last post follows the beginning of the post; at a moment, the nozzle finishes by scratching the part and blocks the material feeding. Below some additional requested information :- filament type: PLA+

- wattage of the heater: 40W

- heater temperature: 210 °C

- nozzle diameter: 0,4

- print speed: 100mm/s

- retraction settings 3mm - no Z hop - no combing mode - 40mm/s

- setup of the customised print head: Bowden head designated to be twice. Running at the moment with a single head (as it’s difficult to make it run, I prefer to begin with a single head). The fan 0 pipe is a weak point, I know it and I have to print a new part. It could be an explanation but I have also the same problem with long time layers (on other parts) where the cooling is less important. But, not 100% sure that it’s not the reason of the problem…

-

@redax27 Thx for the data points. Most of them are quite plausible and unsuspicious to cause nozzle clogging due to heat creeping up to the cold part of the hotend. So, everything looks fine, but …

I don’t wanna adress the part cooling fan (that’s fan 0?) at this stage, although stringing deserves a second thought. To avoid said heat-creep, it is essential to effectively cool the upper part of your hotend - in my understanding of your config.g, that’s the task of fan 1?

Well, whatever fan takes this task - try to verify its operation. In your config, the F parameter in all of your

M106GCodes puzzles me: it should no longer be valid with RRF 3.x. Better to remove that.A second thing to try: halve print speed. I don’t want to doubt the capabilities of your printer, it’s just better to start low.

Then, print a benchy. If you still encounter the same problem, reduce retracts to <0.8 mm: if that works, you have a strong indicator of insufficient hotend cooling. Else, I’m on the wrong path.