Duet 3 Scanning Z probe

-

@edsped 4mm should be fine. We are doing more testing to establish maximums, including with different temperatures

-

@T3P3Tony Perfect thank you for answering.

-

Lowering the max working distance of the probe, may allow to reduce the probe size, to simplify the integration.

Regarding the temperature affect, is it dominated by hotend or bed temperature?

-

@T3P3Tony I would love to follow the progress on this because TAMV is good and works really well when it works but sometimes it's really bad, the nozzle has to be pristine and with the coil sensing the metal only would be great, it would just need a macro similar to prusa pinda measuring the magnets in the bed to find their center

-

@zapta said in Duet 3 Scanning Z probe:

Regarding the temperature affect, is it dominated by hotend or bed temperature?

We are doing research to determine whether the predominant effect is the temperature of the coil (which is affected by the temperature of the hot end) or the temperature of the bed plate. We have sensors for both. If it proves necessary, we will extend RRF to provide compensation for both.

-

@dc42, I was thinking about the Z probe and meshing issue.

Since you control also the Z while scanning in X,Y, instead deducing height in mm from the probe, you can just pick a certain probe measurement value and then, while scanning in X,Y, dynamically adjust the Z to maintain that level.

This will equal-height surface that is well calibrated to mm by the accuracy of the Z steps, and will still be must faster than the stop-and-probe approach of BL Touch.

BTW, the same approach can possibly also be used with your IR sensor, assuming that its differential mechanism can give you a on-target/above/below indication.

Does this make sense?

-

@zapta can you explain a bit more why this would be beneficial vs the current approach for scanning?

-

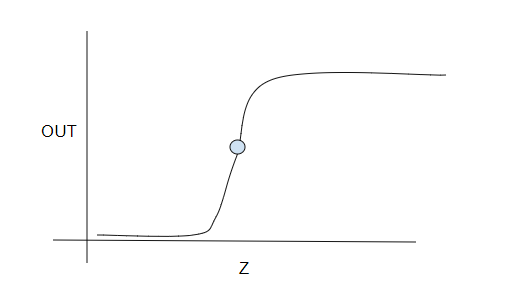

@T3P3Tony, with the current approach, you rely of the scale calibration of the sensor, or the K1 in the linear approximation below:

L[mm] = K0 + K1*SensorTicks

With this approach you are K1 agonistic since the Z measurement is inherently calibrated by the Z steps which is also what the printing process uses. In other words, you relax the requirements from the sensor, and at the same time, can still mesh faster than the traditional stop-and-probe.

Does this make sense?

EDIT: it's same concept as using a null meter instead of a volt meter.

-

@zapta I see what you mean. It would be slower than the scanning mesh on many machines (depending on Z speed) but would give the Z positions where the sensor reads the same all over the bed. I still don't think it will necessarily be any more accurate though.

-

@T3P3Tony, I see.

I am trying to find a way to speed up touch sensors such as BL Touch but this approach should apply also to other sensors types. My hypothesis is that if instead of a binary state they provide a small hysteresis-free continuous region around a known point, the meshing can be speed up significantly since it requires only minor Z adjustments during the scan to tack that point. Not much different from the mesh compensation during the actual printing.

Will see how it goes.

-

I want to setup a Scanning Tool for our printers but can not find a wiring schematic in the documentation

Can you tell me how to connect pls?

Thank you in advance

-

@CR3D the PCB silkscreen points out what the pins are, I can see GND to the left, and C_L (CAN low) and C_H (CAN high) to the right. Second from the left is VCC then, this tracks with the connection description on the documentation page https://docs.duet3d.com/en/Duet3D_hardware/Duet_3_family/Duet_3_Scanning_Z_Probe#description-of-connections

The source for 5V depends on the board you use, on the Duet 3 mini 5+ I would choose 5V and GND from IO 4 due to proximity to the CAN header.

-

-

-

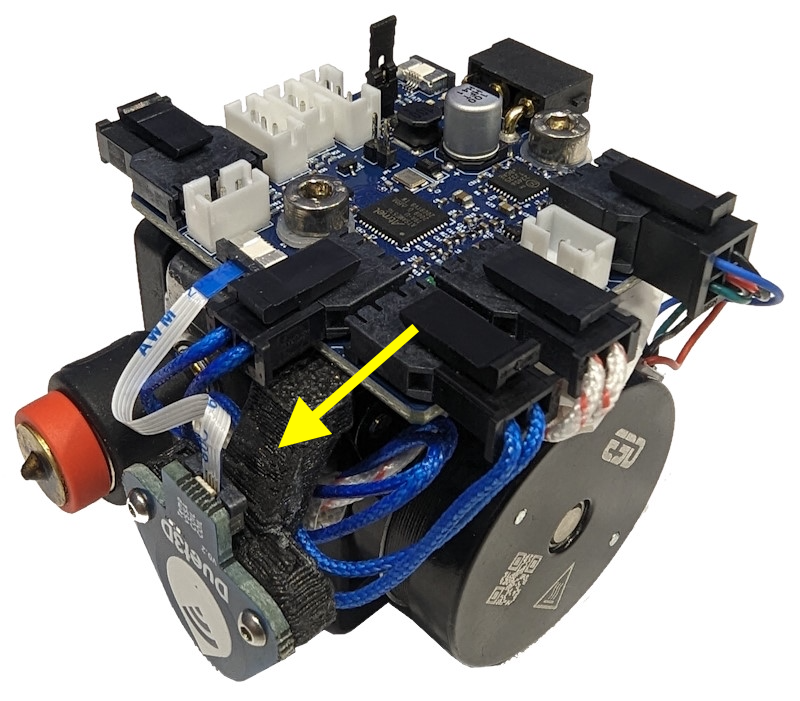

@droftarts

Thank you for the correction. I grabbed the pic from the current doc. -

@bricor I know, I was going to do the same thing until I noticed it was different! So I took a picture of the one I had on my desk that I received earlier this week. @T3P3Tony will put up a proper wiring diagram soon, hopefully.

Edit: I've updated the documentation with the above picture: https://docs.duet3d.com/en/Duet3D_hardware/Duet_3_family/Duet_3_Scanning_Z_Probe#physical-connections

Ian

-

Thanks to all!

-

@ofliduet said in Duet 3 Scanning Z probe:

Is the STL / STEP for the probe holder availalbe that I see in the picture of the Revo toolboard?

Any updates on the availability of this specific mount?

It seems like it's a modified version of the PCB spacer

I would really like to integrate it into my E3D ToolChanger setup