Looks like I need a new printer!

-

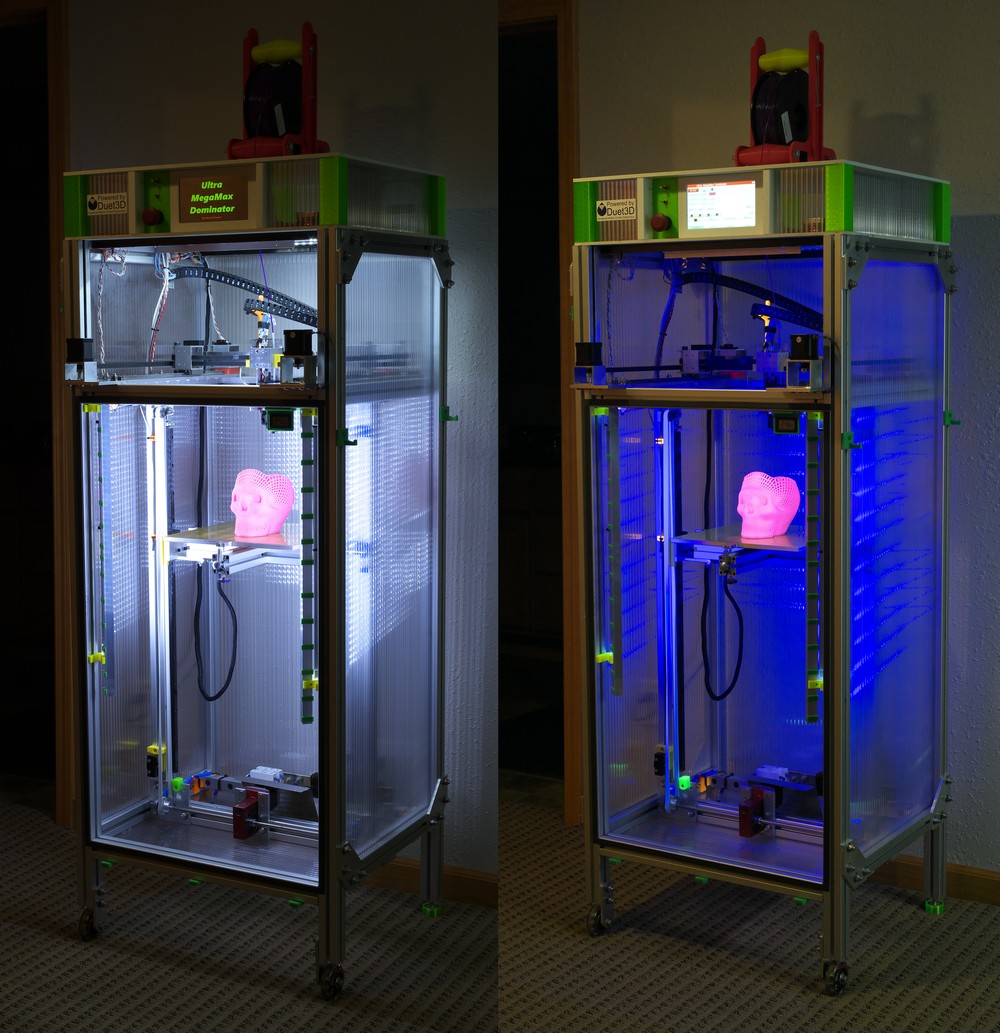

This corexy machine works pretty well for me.

But I suggest you design and build your own. It's more fun, you'll learn more, and since you are already familiar with the way printers work, you have a good base from which to start.

-

I must say i agree with @deckingman and @mrehorstdmd - if you have the time then making your own design will be really rewarding. I would spend quite a bit of time looking at existing designs and reading critiques of them though because there is a tendency in 3d printer designs to repeat errors that have been well documented before (for example over constraining axis).

On the other hand, if you want to build a really solid design but not have to work out all the details then the Railcore II would get my vote. I saw a large number of them, both self sourced and from ProjectR3D at MRRF and they were printing very impressively. @kraegar here is one of the developers.

None of that is to say that the RatRig or BLV mgn cube, or hypercube are bad, i just don't have experience with them.

-

@t3p3tony They can all be improved upon - but for me that's part of the fun. My printer is continuously evolving as readers of my blog will know. For me, there is a huge amount of satisfaction to be gained from making ones own design and tweaking it. But that may not be what the OP is looking for - only he can decide how much time and effort he wants to put in.

I just need to think of a name for mine. I was thinking along the lines of "Hyper Ballistic Vengeance Predator"

..............only joking - I'll just stick with "The tall coreXY" ..............

-

@deckingman you have bucked the trend. Normally one comes up with an awesome name and then builds a printer to fit!

-

Thank you all for your input, I REALLY appreciate it.

@deckingman - I would use Oozenest for my extrusions and have already been in touch with Ryan today asking if they can cut the rails if I gave them the dimensions.

They are about 1.5 hours away so I might take a run out there and go through whichever build I am going to do and save a delivery charge.

I have watched some of your videos and was amazed especially when you put the counter balance on.The RatRig, Yes I have to agree it would take a while for the parts to turn up and possible customs charges.

I started going through the Railcore BOM and started putting prices together.

Also I was looking on Openbuilds and other sites before I had all these superb responses.@mrehorstdmd That is a massive build and must say it does look impressive.

I honestly do not know what I would print with something that big!@T3P3Tony I am not clever in design, better at building things with a box of bits and would not know where to start designing my own. I am good at building computer networks and model helis and programming control systems to control houses.

Maybe after I have built one from scratch i would have a better idea.@zapta I think you are right, i will go for cut to order, makes sense, I do not think my multitool would be too good for accuracy!

At the moment I am learning towards the BLV as there are alot of metal parts I can source in the UK like the 90 degree metal brackets and I prefer metal to plastic, especially for the frame.

@Phaedrux - I think you are right Railcore might be a non starter as I would definately want the aluminium parts after reading the blog about the plastics giving up.

@dc42 A tool changer, lots of money! I think I will stick with a 2 colour head first!

More Duet boards and questions on the forum!

Do not hink I could justify the Diamond 5 colour head @deckingman has on his rig.I also prefer to use UK Suppliers, I would never buy a clone of anything, I have seen a £3k helicopter go down because the guy thought the £70 receiver was as good as the £275 receiver.

I think the other thing is the availability of the parts, I have mentioned Oozenest and E3D and of course Duet3D!

I am probably going to find others who I will need to supply me, like Simply Bearings, i use them a lot when I rebuild model Helicopter engines and things.Again, I thank you all for your input, it has blown me away.

Excel spreadsheets tomorrow!

Kind Regards,

Paul.

-

@paulhew said in Looks like I need a new printer!:

Excel spreadsheets tomorrow!

You know you've found the right hobby when you're excited to use Excel.

-

@PaulHew as long as UK is part of the European trade union, you won't be paying import tax on RatRig as they're based in Portugal.

That said, I had an order with them which I cancelled after five or so weeks -- they're seemingly victims of their own success and have met challenges scaling their operations. They're very friendly and helpful and there's a pretty welcoming community about RatRig on Facebook.

-

There are many places that sell the cut extrusions. Here is just one of them, so you may find somewhere a bit closer at equal or cheaper price. It's all the same stuff.

-

@jay_s_uk said in Looks like I need a new printer!:

There are many places that sell the cut extrusions. Here is just one of them, so you may find somewhere a bit closer at equal or cheaper price. It's all the same stuff.

Actually it isn't all the same stuff.

If you intend to use V-Wheels running on the slots then that stuff you linked just will not do the job properly you do need the Proper V Slot profile and not T-Slot like the Valuframe or even the motels or bosch-rexroth profiles for that matter.

Just my 2 pence (Cents) thoughts.

Doug

-

@paulhew You need also to think about how you are going to join the extrusion together. I favour the technique whereby you tap the ends of the extrusion, insert a button head screw, then drill a hole in the side of the other member that forms the corner. The side hole is clearance diameter for an Allen key. Like this

The "button head" of the screw slides into the slot in the mating extrusion. It's much neater, and cheaper, and arguably stronger than using those God awful brackets. The ends of the extrusion are already drilled to take the right size tap but many suppliers will tap the ends for you if you want. Drilling the holes in the sides is a little more tricky - I managed to do all mine with a hand held power drill but a bench drill or better still a small mill, would have made life easier.

-

Thanks @deckingman - I have a friend who has a bench drill / mill and he owes me a few favours!

There is a lot of 90 degree brackets on the BLV, still have not made my mind up.

I am like a kid in an ice cream shop!! -

To expand on @deckingman excellent advise, I use these from Motedis:

https://www.motedis.com/shop/Nutprofil-Zubehoer/Zubehoer-20-I-Typ-Nut-5/Verbinder-Winkel/Standardverbinder-20-I-Typ-Nut-5::570.html. It is the same principle as @deckingman uses but the plate will assure a straight connection between the 2 extrusions. Drilling holes in the extrusion is not hard to do with the right tools (and some cutting oil

)

) -

@whosrdaddy said in Looks like I need a new printer!:

To expand on @deckingman excellent advise, I use these from Motedis:

https://www.motedis.com/shop/Nutprofil-Zubehoer/Zubehoer-20-I-Typ-Nut-5/Verbinder-Winkel/Standardverbinder-20-I-Typ-Nut-5::570.html. It is the same principle as @deckingman uses but the plate will assure a straight connection between the 2 extrusions. Drilling holes in the extrusion is not hard to do with the right tools (and some cutting oil

)

)That's a good find - looks like they will give a bit more contact area than just the button head. I'll bear those in mind if I ever build another printer.

-

@t3p3tony said in Looks like I need a new printer!:

... there is a tendency in 3d printer designs to repeat errors that have been well documented before (for example over constraining axis).

@t3p3tony, can you explain over constraining? For example, in the larger version of hypercube evo, the Z bed it supported by four vertical rods and moved by two lead screws. What are the over constrains in this example?

Also, the bed is supported and leveled by 4 screws. Is it also an over constrain?

-

@zapta You would need one rod to fix the bed in X and Y, and another rod to keep the bed from rotating around the first rod. Anything more is technically over constrained. But in reality there are no perfectly rigid bodies and things do flex and sag, so adding more constraints can be used to overcome those problems, however it's not without its own problems, like binding when things aren't perfectly aligned. Or at least aligned to within tolerance.

For the bed leveling, 3 points define a plane, 4 points define a saddle parabola. If the bed is rigid enough to maintain a flat plane when supported at only 3 points leveling will be much easier. If the bed is too flexible to be adequately supported by 3 points, then 4 points can be used, and can still arrive at a flat plane, but it will take far more adjustment to take the twist out of the saddle.

If you're really interested in mechanical constraints in 3D printers I suggest this book: http://www.sublimepublications.com/store/p1/3D_Printer_Engineering_Volume_1%3A_Motion_Platform_Design.html

-

@zapta said in Looks like I need a new printer!:

@t3p3tony said in Looks like I need a new printer!:

... there is a tendency in 3d printer designs to repeat errors that have been well documented before (for example over constraining axis).

@t3p3tony, can you explain over constraining? For example, in the larger version of hypercube evo, the Z bed it supported by four vertical rods and moved by two lead screws. What are the over constrains in this example?

Also, the bed is supported and leveled by 4 screws. Is it also an over constrain?

IMO that's a classic case of being over constrained. The vertical rods should not support the bed - that's the job of the lead screws. The vertical rods should only prevent the bed from moving in the X or Y directions and two rods, one at each opposite corner is enough to do that. Trying to accurately align two rods so that they are perfectly parallel is difficult enough, three is even worse and four is asking for trouble. But then lifting a bed with only two screws is also asking for trouble...........

-

I do wish we could make getting a RailCore to the UK easier. Shipping and customs suck.

-

@phaedrux said in Looks like I need a new printer!:

If you're really interested in mechanical constraints in 3D printers I suggest this book: http://www.sublimepublications.com/store/p1/3D_Printer_Engineering_Volume_1%3A_Motion_Platform_Design.html

I will take a look, thanks.

-

@kraegar said in Looks like I need a new printer!:

I do wish we could make getting a RailCore to the UK easier. Shipping and customs suck.

Might be worth checking whether Ooznest stocks many of the parts already. If so then perhaps they could supply kits in this part of the world. They are already a Duet3D distributor.

-

@PaulHew How are you getting along? Any enlightening moments (so long as they weren't sod this!

) that you can share?

) that you can share?