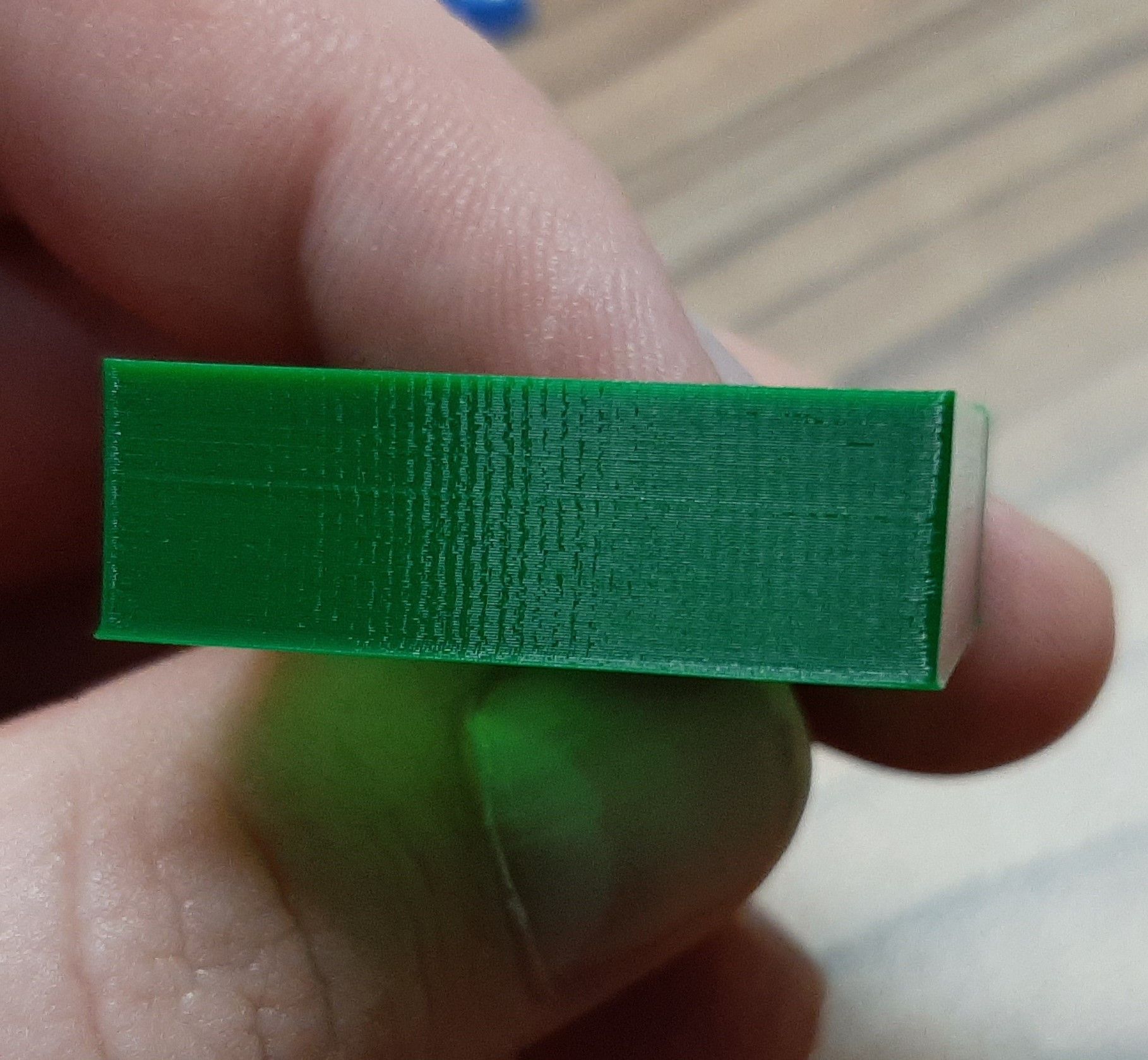

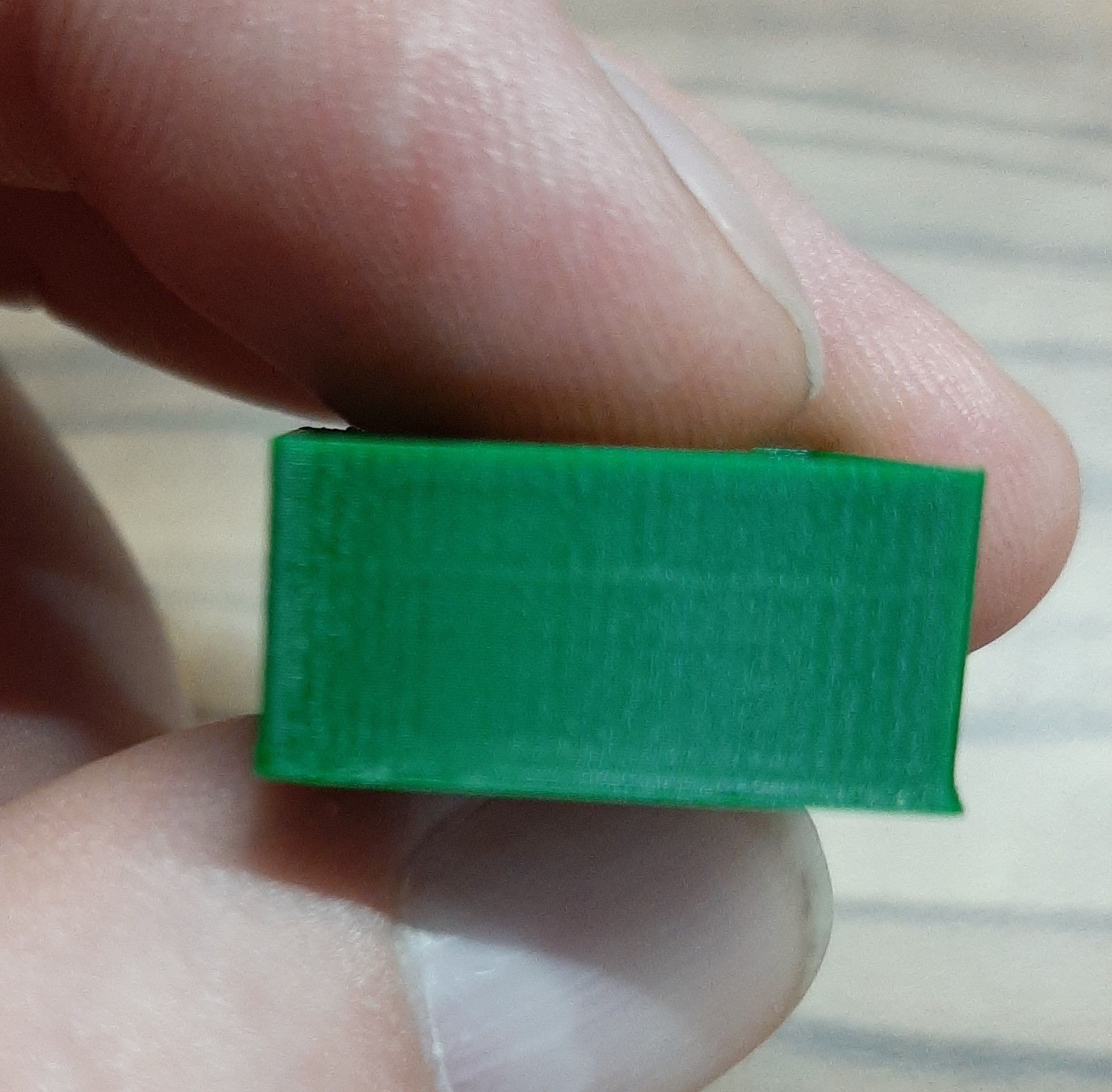

Problems with "wave pattern" in printing on the HEVO

-

Good evening,

Am currently on a problem where I do not know.

In my Hevo had now replaced the stepper, the pulleys on which of Gates with 16 teeth, the idler exchanged for flanges.

Have already tried with various settings, only the waves do not go away in print.Currently I drive with a jerk of 5. I always printed with 60mm / s outline with 50%.

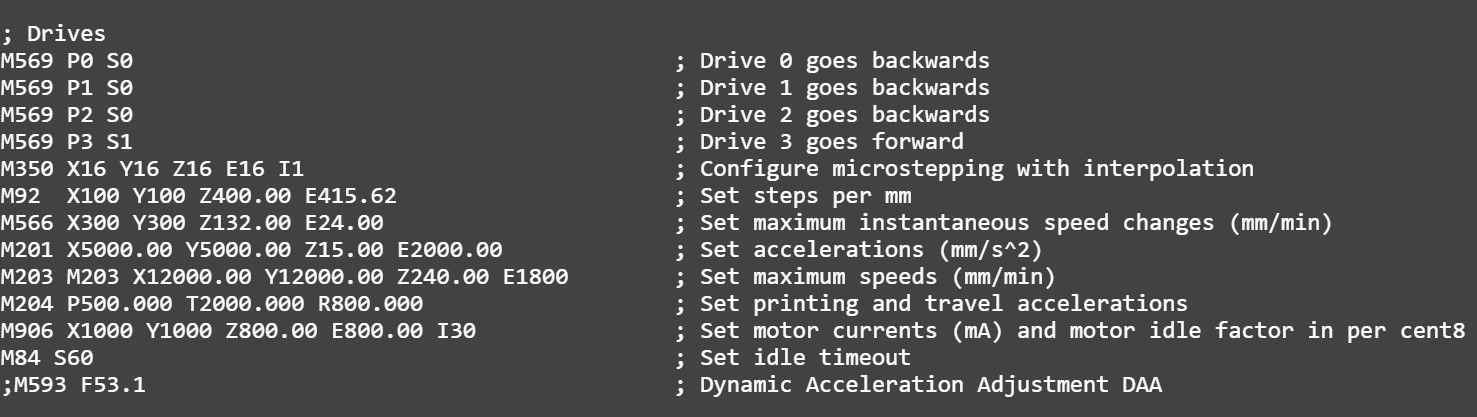

Material petg from extrudr with 220 ° C hotend and 75 ° C heating bed.Here are the values from the config.

M566 X300 Y300 Z132.00 E24.00

M201 X5000.00 Y5000.00 Z15.00 E2000.00

M203 X12000.00 Y12000.00 Z240.00 E1800

M204 P500,000 T2000,000 R800,000

M906 X1000 Y1000 Z800 E800 I30

-

What steppers did you choose?

Looks like VFA (vertical fine artefacts) to me. -

Maybe M204 is wrong, with P 500000 etc. (I expect you wanted to use dot instead of comma)

-

I use this stepper for X and Y "Nema 17 45Ncm 2A"

and for Z I use "Nema 17 59Ncm 2A"

I wrote the P500000 with a dot. Is it correct that way?

-

@Patrick_487 With dots it's ok then.

Maybe https://forum.duet3d.com/topic/5319/strange-ringing-artifacts-on-corexy helps you, if Hevo means Hypercube Evolution. Looks similar.

-

@Patrick_487 A while back I saw someone with a similar issue whom increased his stepper currents and that seemed to help a considerable amount.

He started at 800, and went to 1600 for reference.

-Tim -

This is a wild guess but could resolution of the extruder cause a little hump when it extrudes and a little valley while it is waiting for the next step of the extruder ?

-

@jens55 said in Problems with "wave pattern" in printing on the HEVO:

This is a wild guess but could resolution of the extruder cause a little hump when it extrudes and a little valley while it is waiting for the next step of the extruder ?

This can be determined by printing with a different layer height and observing if the pattern pitch changed.

I would also try to print it rotated by 45deg to see if it's an interaction between the two x/y motors (with diagonal lines, only of of the motor is turning).

-

see my post about the same issue.

https://forum.duet3d.com/topic/9438/artefacts-on-wallsswitching to 0.9 degree steppers made it acceptable for me.

-

I have now tested 1400mA for X and Y, but with no visible changes. The upper part has been printed at 1400 mA, the lower one is printed at 1000 mA.

-

Possibly similar issue on my modded HEVO: https://forum.duet3d.com/topic/8213/ringing-at-20-70mm-s-mostly-during-acceleration-deceleration

I didn't update the original post, but what I've found is this:

- Since two motors work in tandem, they probably tend to vibrate (reach resonance) more often than other printer geometries.

- The resonance might appear like ghosting due to high jerk, but it's suspiciously consistent, usually at around one full step in amplitude (e.g. 0.2mm - amplitude not distance peak to peak - for HEVO 1.8 deg ).

- Loose or bad components on the axes may increase the vibration.

- 0.9 steppers help but not eliminate it.

- Normal to slow speeds are worst, 60mm/s being worst and above 90mm/s being better and 120mm/s or more being best.

It would be interesting to see if any of this applies to your HEVO...