Hi all,

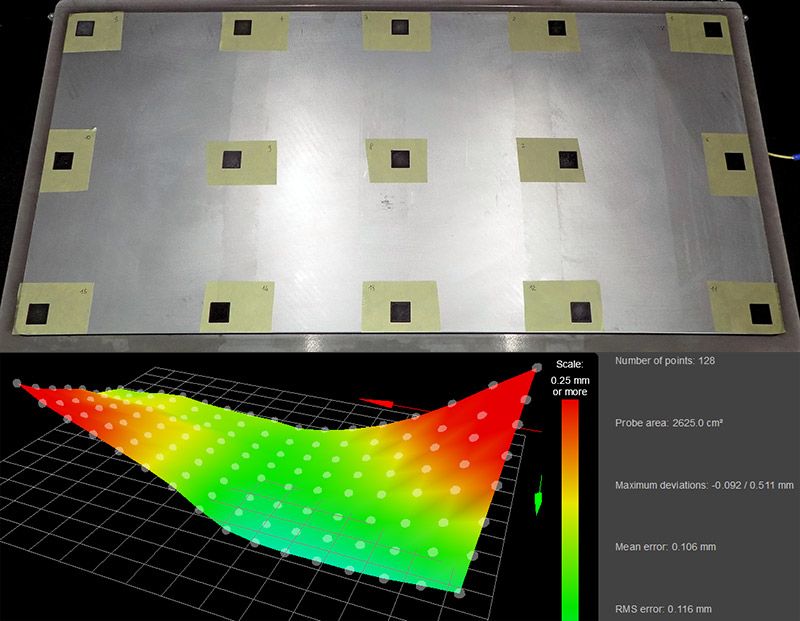

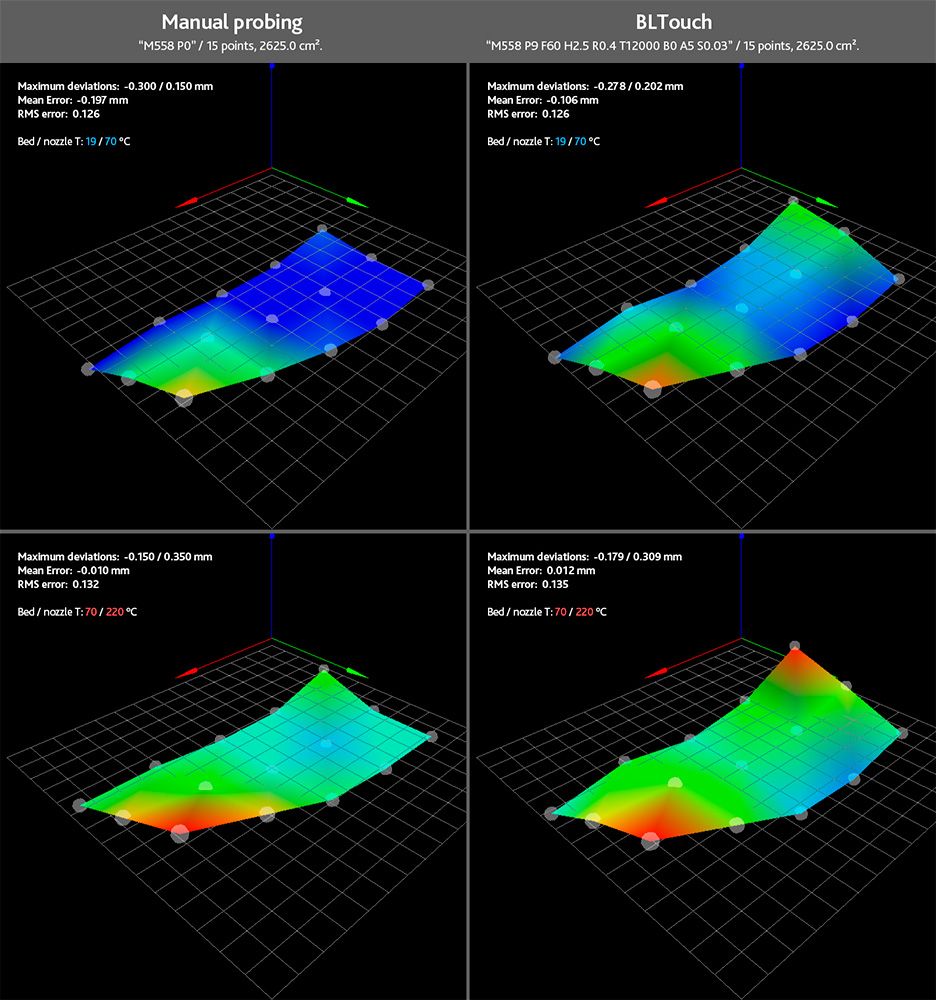

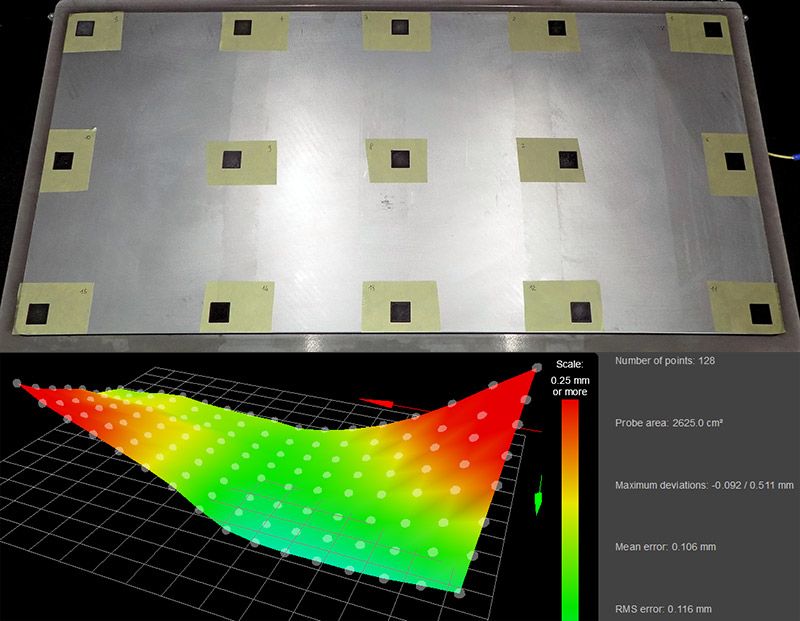

the attached image show single layer (0,2 mm) 20x20 mm rectangles printed on the the 800x400mm bed (at 50 °C) of my custom printer, with the heightmap created using a BLtouch and these M558 settings:

M558 P9 F100 H3 R0.3 T10000 B0 A5 S0.03

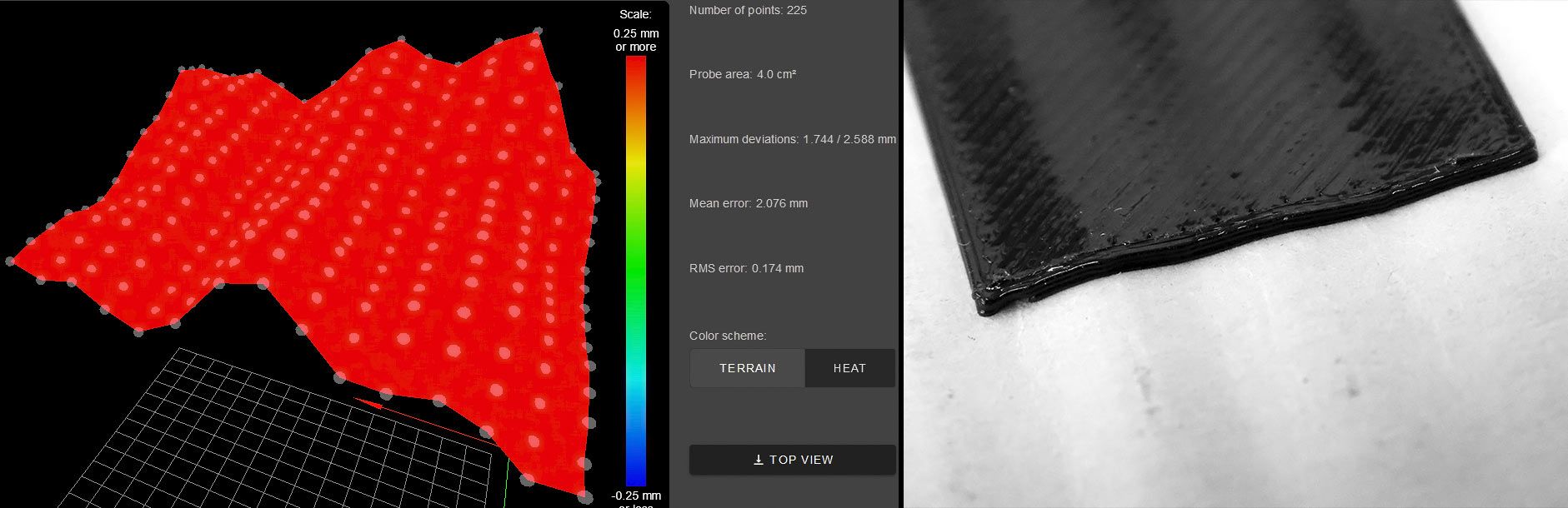

The bed show a non-negligible deviation from flatness and I noticed that:

-

Printing each rectangle one at a time, using a simple 2x2 probing grid for each of them, I'm able to obtain a perfect first layer for each of them.

-

Printing all the rectangles in the same session, also using a 400+ points grid on the entire plane, the rectangles situated in the areas that most deviate from flatness are printed very bad (ex. 0,35 mm thickness instead of the nominal 0,2 mm.)

So, I wonder about the true capabilities of the Mesh Bed Compensation function.

What am I missing? Am I asking too much from G29?

Obviously when printing on a full large bed surface, despite using 400+ probe points, you will never able to abtain the same points density of probing with a 3x3 grid an 20x20 mm area, but… the deviation of flatness of a 20x20mm area are not so significant (imho, for a rectified aluminium plate) to disallow a good print also with a single probe point at the center of each 20x20mm area.

So I'm just wondering that the Mesh Bed Compensation function is not truly suited for very large print surface, maybe due to the math used in order to process the probe points information, but I will glad to listen to your opinions and experiences!

Thank you!

P.S. I'm using RepRapFirmware for Duet 2 WiFi/Ethernet 2.05 (2019-12-13b1) on Duet Ethernet 1.02 or later + DueX2