@christockos How do I mark this as 'Solved'?

Posts made by Christockos

-

RE: Voron 2.4 with Duet 3 Mini 5+ &1LC Toolboard Runs Slowposted in Duet Hardware and wiring

-

RE: Voron 2.4 with Duet 3 Mini 5+ &1LC Toolboard Runs Slowposted in Duet Hardware and wiring

@engikeneer said in Voron 2.4 with Duet 3 Mini 5+ &1LC Toolboard Runs Slow:

increase your E speed in your M203

Yup, that's it. I cranked my M203 setting to 2000mm/min and got this:

Mystery solved, thanks everyone!

-

RE: Voron 2.4 with Duet 3 Mini 5+ &1LC Toolboard Runs Slowposted in Duet Hardware and wiring

@christockos FWIW, here's the start of a Simplify 3D generated gcode file:

; G-Code generated by Simplify3D(R) Version 4.1.2

; Aug 23, 2022 at 4:43:35 PM

; Settings Summary

; processName,VoronPETG1.18.245.60.Vase

; applyToModels,Block4VaseMode092002

; profileName,Voron2.4.3x350 (modified)

; profileVersion,2022-08-08 14:20:07

; baseProfile,Default

; printMaterial,PETG

; printQuality,Medium

; printExtruders,

; extruderName,Extruder 1

; extruderToolheadNumber,0

; extruderDiameter,1.8

; extruderAutoWidth,0

; extruderWidth,2

; extrusionMultiplier,0.98

; extruderUseRetract,1

; extruderRetractionDistance,6.5

; extruderExtraRestartDistance,0

; extruderRetractionZLift,0.5

; extruderRetractionSpeed,2400

; extruderUseCoasting,0

; extruderCoastingDistance,0.2

; extruderUseWipe,0

; extruderWipeDistance,5

; primaryExtruder,0

; layerHeight,1

; topSolidLayers,0

; bottomSolidLayers,0

; perimeterOutlines,1

; printPerimetersInsideOut,0

; startPointOption,3

; startPointOriginX,0

; startPointOriginY,0

; sequentialIslands,0

; spiralVaseMode,1

; firstLayerHeightPercentage,100

; firstLayerWidthPercentage,100

; firstLayerUnderspeed,1

; useRaft,0

; raftExtruder,0

; raftTopLayers,3

; raftBaseLayers,2

; raftOffset,3

; raftSeparationDistance,0.14

; raftTopInfill,100

; aboveRaftSpeedMultiplier,0.3

; useSkirt,1

; skirtExtruder,0

; skirtLayers,1

; skirtOutlines,1

; skirtOffset,2

; usePrimePillar,0

; primePillarExtruder,999

; primePillarWidth,12

; primePillarLocation,7

; primePillarSpeedMultiplier,1

; useOozeShield,0

; oozeShieldExtruder,999

; oozeShieldOffset,2

; oozeShieldOutlines,1

; oozeShieldSidewallShape,1

; oozeShieldSidewallAngle,30

; oozeShieldSpeedMultiplier,1

; infillExtruder,0

; internalInfillPattern,Rectilinear

; externalInfillPattern,Concentric

; infillPercentage,0

; outlineOverlapPercentage,18

; infillExtrusionWidthPercentage,100

; minInfillLength,5

; infillLayerInterval,1

; internalInfillAngles,45,-45

; overlapInternalInfillAngles,0

; externalInfillAngles,45,-45

; generateSupport,0

; supportExtruder,0

; supportInfillPercentage,30

; supportExtraInflation,0

; supportBaseLayers,0

; denseSupportExtruder,0

; denseSupportLayers,0

; denseSupportInfillPercentage,70

; supportLayerInterval,1

; supportHorizontalPartOffset,0.3

; supportUpperSeparationLayers,1

; supportLowerSeparationLayers,1

; supportType,0

; supportGridSpacing,4

; maxOverhangAngle,45

; supportAngles,0

; temperatureName,Extruder 1,Heated Bed

; temperatureNumber,0,0

; temperatureSetpointCount,1,1

; temperatureSetpointLayers,1,1

; temperatureSetpointTemperatures,245,90

; temperatureStabilizeAtStartup,1,1

; temperatureHeatedBed,0,1

; fanLayers,1,2

; fanSpeeds,0,100

; blipFanToFullPower,0

; adjustSpeedForCooling,0

; minSpeedLayerTime,25

; minCoolingSpeedSlowdown,20

; increaseFanForCooling,0

; minFanLayerTime,45

; maxCoolingFanSpeed,100

; increaseFanForBridging,0

; bridgingFanSpeed,100

; use5D,1

; relativeEdistances,0

; allowEaxisZeroing,1

; independentExtruderAxes,0

; includeM10123,0

; stickySupport,1

; applyToolheadOffsets,0

; gcodeXoffset,0

; gcodeYoffset,0

; gcodeZoffset,0

; overrideMachineDefinition,1

; machineTypeOverride,0

; strokeXoverride,350

; strokeYoverride,350

; strokeZoverride,350

; originOffsetXoverride,0

; originOffsetYoverride,0

; originOffsetZoverride,0

; homeXdirOverride,-1

; homeYdirOverride,-1

; homeZdirOverride,-1

; flipXoverride,1

; flipYoverride,-1

; flipZoverride,1

; toolheadOffsets,0,0|0,0|0,0|0,0|0,0|0,0

; overrideFirmwareConfiguration,1

; firmwareTypeOverride,RepRap (Marlin/Repetier/Sprinter)

; GPXconfigOverride,r2

; baudRateOverride,115200

; overridePrinterModels,0

; printerModelsOverride

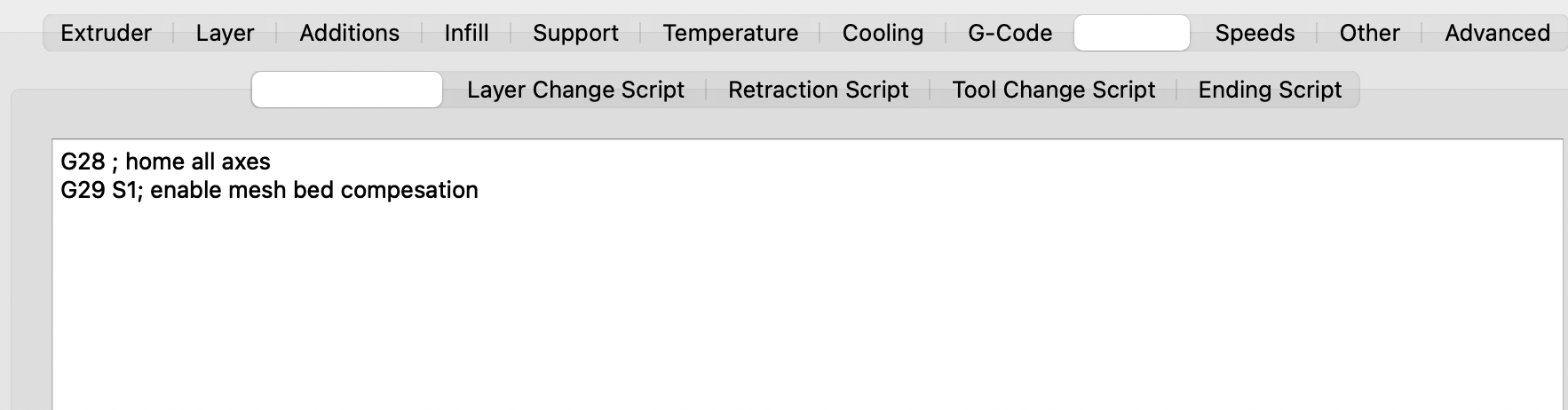

; startingGcode,G28 ; home all axes,G29 S1; enable mesh bed compesation

; layerChangeGcode,

; retractionGcode,

; toolChangeGcode,

; endingGcode,M104 S0 ; turn off extruder,M140 S0 ; turn off bed,G28 XY,M84 ; disable motors

; exportFileFormat,gcode

; celebration,0

; celebrationSong,Random Song

; postProcessing,

; defaultSpeed,3600

; outlineUnderspeed,1

; solidInfillUnderspeed,1

; supportUnderspeed,1

; rapidXYspeed,36000

; rapidZspeed,7200

; minBridgingArea,50

; bridgingExtraInflation,0

; bridgingExtrusionMultiplier,1

; bridgingSpeedMultiplier,1

; useFixedBridgingAngle,0

; fixedBridgingAngle,0

; applyBridgingToPerimeters,0

; filamentDiameters,1.75|1.75|1.75|1.75|1.75|1.75

; filamentPricesPerKg,46|46|46|46|46|46

; filamentDensities,1.25|1.25|1.25|1.25|1.25|1.25

; useMinPrintHeight,0

; minPrintHeight,0

; useMaxPrintHeight,0

; maxPrintHeight,0

; useDiaphragm,0

; diaphragmLayerInterval,20

; robustSlicing,1

; mergeAllIntoSolid,0

; onlyRetractWhenCrossingOutline,1

; retractBetweenLayers,1

; useRetractionMinTravel,0

; retractionMinTravel,3

; retractWhileWiping,0

; onlyWipeOutlines,1

; avoidCrossingOutline,0

; maxMovementDetourFactor,3

; toolChangeRetractionDistance,12

; toolChangeExtraRestartDistance,-0.5

; toolChangeRetractionSpeed,600

; externalThinWallType,1

; internalThinWallType,2

; thinWallAllowedOverlapPercentage,10

; singleExtrusionMinLength,1

; singleExtrusionMinPrintingWidthPercentage,50

; singleExtrusionMaxPrintingWidthPercentage,200

; singleExtrusionEndpointExtension,0.2

; horizontalSizeCompensation,0

G90

M82

M106 S0

M140 S90

M190 S90

M104 S245 T0

M109 S245 T0

G28 ; home all axes

G29 S1; enable mesh bed compesation

; process VoronPETG1.18.245.60.Vase

; layer 1, Z = 1.000

T0

G92 E0.0000

G1 E-6.5000 F2400

; feature skirt

; tool H1.000 W2.000

G1 Z1.000 F7200

G1 X161.678 Y154.050 F36000 -

RE: Voron 2.4 with Duet 3 Mini 5+ &1LC Toolboard Runs Slowposted in Duet Hardware and wiring

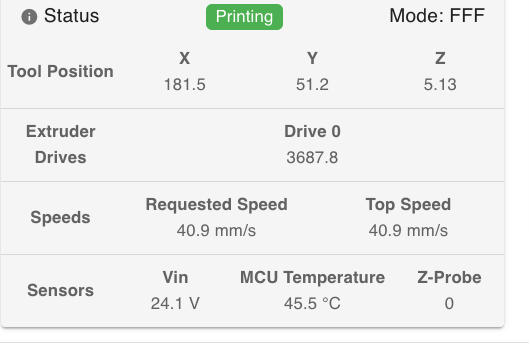

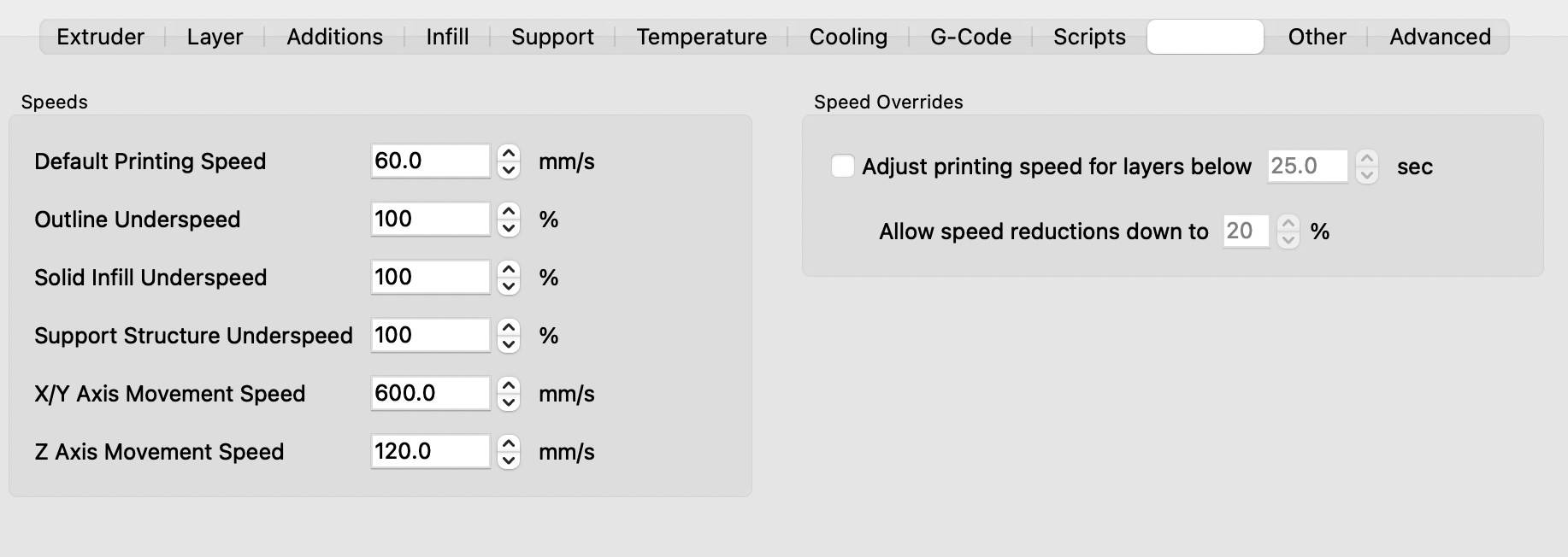

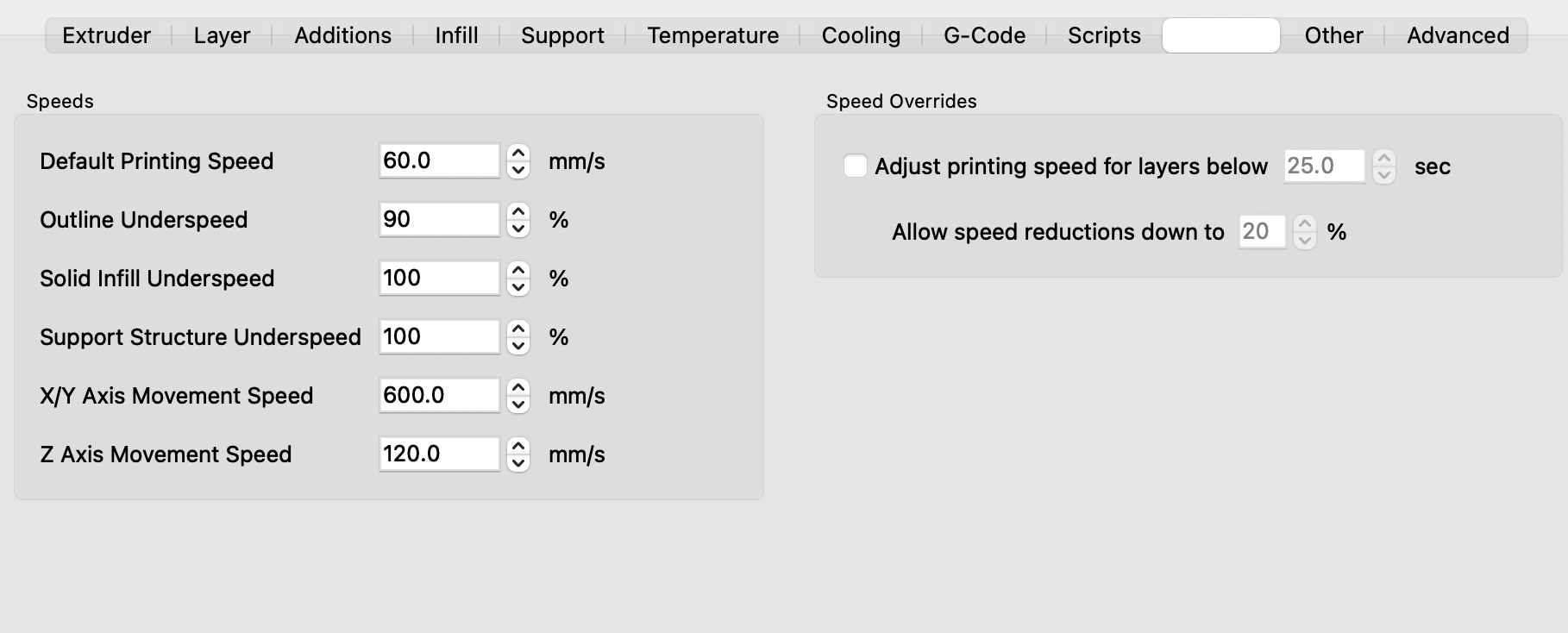

@dc42 Okay, I've done some troubleshooting (after updating to 3.4.2-rc2) and even though I have my speed in Simplify 3d set to 60mm/s:

and my first layer speed at 100%, my printer's 'requested speed' and 'top speed' both max out at 24.5mm/s.

I don't see anything else in Simplify3D where I would be slowing my print down to less than 50%.

It seems that "If the move is slow but those figures are equal then the issue is with the slicer settings" is the case, but I can't seem to find where the issue lies.

Confounding.

Thanks for any thoughts,

Chris -

RE: Voron 2.4 with Duet 3 Mini 5+ &1LC Toolboard Runs Slowposted in Duet Hardware and wiring

@jay_s_uk I do not have a start.g (at least when I look in the system, where the config.g file lives).

-

RE: Voron 2.4 with Duet 3 Mini 5+ &1LC Toolboard Runs Slowposted in Duet Hardware and wiring

Yeah, nothing suspicious as far as I can tell.

-

RE: Voron 2.4 with Duet 3 Mini 5+ &1LC Toolboard Runs Slowposted in Duet Hardware and wiring

@jay_s_uk I run Simplify 3D and they way I understand it, Minimum Layer Time isn't an option, rather they use the "adjust printing speed for layers below BLANK seconds".

-

RE: Voron 2.4 with Duet 3 Mini 5+ &1LC Toolboard Runs Slowposted in Duet Hardware and wiring

@jay_s_uk I run Simplify 3D and the only speed settings I can see that might affect it is the "adjust printing speed for layers below BLANK" and that doesn't seem to be the culprit. I have all of my speeds adjusted as such:

I don't see anywhere in the gcode where my prints are being slowed. Here's an example of the beginning code of one of my gcode files:

G90

M82

M106 S0

M140 S90

M190 S90

M104 S245 T0

M109 S245 T0

G28 ; home all axes

G29 S1; enable mesh bed compesation

; process VoronPETG1.18.245.60.Vase

; layer 1, Z = 1.000

T0

G92 E0.0000

G1 E-6.5000 F2400

; feature skirt

; tool H1.000 W2.000

G1 Z1.000 F7200

G1 X161.678 Y154.050 F36000

G1 E0.0000 F2400

G92 E0.0000

G1 X161.825 Y153.921 E0.1600 F673

G1 X162.449 Y153.442 E0.8009

G1 X162.612 Y153.333 E0.9609I wonder if my microstepping coupled with MeshBed compensation has anything to do with it?

(see my config)

Thanks so much,

Chris -

RE: Voron 2.4 with Duet 3 Mini 5+ &1LC Toolboard Runs Slowposted in Duet Hardware and wiring

Also, any Noob mistakes noticed would be much appreciated. Thanks. Love this forum and the top notch folks helping us all.

-

Voron 2.4 with Duet 3 Mini 5+ &1LC Toolboard Runs Slowposted in Duet Hardware and wiring

Hello,

Forgive me if I've missed something. I knew when I jumped into this project it would be a lot to chew, but I wanted to learn. I've put Duets in all of my machines and have always lusted after a Voron. After I saw Thomas Salanderer's live builds I decided to jump in.

This printer is super-fast and I love it, but I think I'm screwing up somewhere since it does not seem to print faster than 24.5 mm/s. (usually when I have an issue with my Duets I can figure out where I've gone wrong by reviewing others' posts, but here I am at a loss).

I wonder if my Toolboard is the culprit. Or maybe how much plastic I'm moving.

I'm printing with a Misquito Magnum 1.8mm nozzle, 2.0mm Extrusion width, 1mm layer height. I know, I'm pushing it, but that's what I'm shooting for. Previously I had printed with a 1.2mm nozzle (1.44 Extrusion width) on a Mamorubot SX4 outfitted with a Duet 2 Maestro Ethernet.

Stuff like this makes me feel like the eternal Noob, but I'm hoping someone can point out where I'm screwing up. I may have bitten off more than I can chew, but I'm determined to figure out where I'm choking. Thanks so much in advance,

ChrisHere's my config:

;; Helpful Toolboards commands

;M115 B121 ; Show board 121

;M997 B121 ; Update tool 121

;M122 B121 ; Detailed status of toolboard

G4 S1 ; wait 1s for expansion boards to start; General preferences

G90 ; send absolute coordinates...

M83 ; ...but relative extruder movesM550 P"VoronHoward" ; set printer name

; Network

M552 S1 ; enable network

M586 P0 S1 ; enable HTTP

M586 P1 S0 ; disable FTP

M586 P2 S0 ; disable Telnet; Printer geometry

M669 K1 ; Select CoreXY mode

M208 X10:355 Y10:370 Z-0.2:320 ; Axis Limits

M564 H0 ; allow unhomed movement;------- drives from top---------------------------------------------------

; B -------+------ A

; | P.02 | P.03 |

; -------+------- Z-Drives

; | P0.1 | P0.4 |

; -------+-------

; Front; Drive Mappings

M569 P121.0 S0 D2 ; Drive 121.0: E Axis

M569 P0.1 S1 D2 ; Drive 1: Z-LeftFront Axis

M569 P0.2 S0 D2 ; Drive 2: Z-LeftRear Axis

M569 P0.3 S1 D2 ; Drive 3: Z-RightRear Axis

M569 P0.4 S0 D2 ; Drive 4: Z-RightFront Axis

M569 P0.5 S1 D2 ; Drive 5: Expansion: A motor (Y-axis)

M569 P0.6 S1 D2 ; Drive 6: Expansion: B motor (X-axis); Motor remapping for dual Z and axis Limits

M584 X6 Y5 Z1:2:3:4 E121.0 ; Motor mapping

M671 X-60:-60:400:400 Y-6:410:410:-6 S20 ; Z leadscrews positions Left Front - Let Rear - Right Rear - Right Front; Microstepping and Speed

M350 X32 Y32 E16 Z32 I1 ; MODIFIED, XY&E were 32. Configure microstepping with interpolation

M92 X160.00 Y160.00 Z800.00 E417.00 ; Set steps per mm 1.8 motors; Speeds, Acceleration and Jerk

M566 X900.00 Y900.00 Z60.00 E120.00 ; set maximum instantaneous speed changes (mm/min)

M203 X60000.00 Y60000.00 Z18000.00 E1200.00 ; set maximum speeds (mm/min)

M201 X6000.00 Y6000.00 Z4000.00 E250.00 ; set accelerations (mm/s^2); Motor currents

M906 X1400.00 Y1400.00 Z1200.00 E700.00 I55 ; Set motor currents (mA) and motor idle factor in percent

M84 S30 ; Set idle timeout; Axis Limits

M208 X0 Y0 Z0 S1 ; set axis minima

M208 X345 Y345 Z300 S0 ; set axis maxima; Endstops for each Axis

M574 Z1 S1 P"io4.in" ; Z endstop switch

M574 X2 S1 P"^io5.in" ; configure switch-type (e.g. microswitch) endstop for high end on X via pin ^io5.in

M574 Y2 S1 P"^io6.in" ; configure switch-type (e.g. microswitch) endstop for high end on Y via pin ^io6.in; Z-Probe

M558 P8 C"121.io0.in" H8 F3000 T6000 R0.2 ;wired to ToolBoard; set Z probe

G31 P500 X0 Y25 Z1.4 ; set Z probe trigger value, offset and trigger height

M557 X10:340 Y10:340 S40 ; define mesh grid; Bed Heaters and Thermistor

M308 S0 P"temp0" A"Bed" Y"thermistor" T100000 B3950 ;B4725 C7.060000e-8 ; Heatbed Thermistor Sensor 1

M950 H0 C"out0" T0 Q10

M307 H0 R0.803 K0.436:0.000 D3.64 E1.35 S1.00 B0

M140 H0 ; Bed uses Heater 0

M143 H0 S116 ; Set temperature limit for heater 0 to 115C Bed; HotEnd Heater and Thermistor

M308 S1 P"121.temp0" A"HotEnd" Y"thermistor" T100000 B3950 ;T100000 B4725 C7.06e-8 ; define E0 temperature sensor

M950 H1 C"121.out0" T1 Q100 ; Create HotEnd Heater

;M307 H1 R4.568 K0.683:0.000 D4.04 E1.35 S1.00 B0 V24.4 ; PID as heater

M307 H1 R3.018 K0.407:0.013 D8.83 E1.35 S1.00 B0 ;Auto tuning heater 1 completed after 3 idle and 10 tuning cycles in 676 seconds.

M143 H1 S285 ; Set temperature limit for heater 1 to 285C HotEnd

;M302 S15 R15 ; min extrusion (cold extrusion) temp

M572 D0 S0.06 ; set extruder 0 pressure advance to 0.06 seconds;Case Fan

M950 F3 C"out5" Q500 ; create fan 3 on pin out3 and set its frequency

M106 P3 S255 H-1 ; set fan 3 value. Thermostatic control is turned off

M950 F4 C"out6" Q500 ; create fan 3 on pin out3 and set its frequency

M106 P4 S255 H-1 ; set fan 3 value. Thermostatic control is turned off; Fan Hotend

M950 F1 C"121.out1" Q100 ; Creates HOTEND Fan

M106 P1 S255 T45 H1 ;Thermostatic fan for sensors 1. 70% above 45°. Sensor 1.; Fan Part Cooling

M950 F0 C"121.out2" Q80 ; Creates PARTS COOLING FAN

M106 P0 S0 H-1 ; Set fan 0 value, PWM signal inversion and frequency. Thermostatic control is turned off PARTS COOLING FAN; Tools

M563 P0 S"MisquitoMagnum" D0 H1 ; define tool 0

G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets

G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C; Filament Sensor

M591 D0 P2 C"121.io1.in" S1 ; simple sensor (high signal when filament present) connected to 121.io1 for drive D121.0, enabledM955 P121.0 I05 ; specify orientation of accelerometer on Toolboard 1LC with CAN address 121

M593 P"zvdd" F46 ; use input shaper with zvdd profile

M911 S21.0 R23.0 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ;auto save on loss of power -

RE: New Large Format IDEX Printer Projectposted in My Duet controlled machine

Hey!

I started an inquiry to you about you're impressive machine, but instead, threw the question out to everybody in a new, more recent post. I mentioned you and this post in the new thread, but I'll ask you directly here:How's your machine running? How fast can it print, as fast as a Voron 2.4? Most importantly, could it be modified to print two prints (250mm x 250mm) side by side?

Okay, that's it. Thanks for sharing your design. You rule!

Onward,

Chris -

Help with custom IDEX machine.posted in My Duet controlled machine

I originally started this post as an inquiry to @sebkritikel who has DIY’d an impressive IDEX machine:

https://forum.duet3d.com/topic/13696/new-large-format-idex-printer-project

I had come across his IDEX machine while seeing if anyone had made something like an IDEX Voron 2.4 (which doesn’t seem to exist, yet).The more I wrote my post, the more I thought I’d ask everybody, so here goes:

BTW, the reason I’m hardcore Duet is because of the wealth of knowledge, and all the smart folks sharing their knowledge and skills on this board. ahem

I'm planning a Printer Farm of 10–20 IDEX machines not only to produce small runs of my product (Kickstarter in the Fall), but also prototype future products that will eventually be produced in much larger runs (Injection Molded). TMI, I know, but I’m looking for advice.

What I think I need:

Duet controlled IDEX printer with a bed size large enough to print two 250mmx250mm(X, Y) prints side by side. Z isn’t as important so 250mm or greater.

What I could do:

A. Buy large (600x600) mass-produced IDEX printers and replace their boards to DUETs, Hotends, etc. Doable, since I’ve done it with all four of my current printers, but wasteful pulling all the boards, parts, heated bed from the stock model to make it something I want (need).B. Build my own machine. IDEX, Duet, Volcano, tool plate Kenovo bed, 700(?) x 260(?). Direct Drive, easy-to-enclose, reliable, fast, built like a tank and somewhat easy-to-maintain.

Questions:

- Am I out of my mind? Am I better off buying a bunch of $4K machines? So far, I haven’t found what I need. Something about producing our-own custom machines, and tweaking them for what we need in the future seems more proactive in the long run. I foresee adding/modifying/growing the Printer Farm, and having smarter guys than I am working with me, hot-rodding the Farm for years to come.

- Is there a rock solid design out there I’m missing, something I should check out? I only just came across the Voron 2.4 (I wish it were IDEX). I don’t really need/want 600x600 bed size since I will be mostly doing the same print side by side (no more than 250mm x 250mm). The extra Y of a square bed seems to be a waste.

- I love @sebkritikel’s large format IDEX printer, but I came across it while looking for an IDEX Voron. The thing I love about the Voron is how fast it prints (https://youtu.be/P11L0uK5a2M). Can a CoreXY machine w/o the stationary bed (Z moves down, unlike a Voron) be able print as fast and well? What makes the Voron so fast?

- I want an IDEX machine as fast as a Voron 2.4, with a 600x250 bed and Duet. Any recommendations?

Forgive the forever-noobiness of this post, but you all are the smartest guys I know (3DP, anyway, heh).

Onward!

Chris

-

RE: HELP! New Cast Alum. Bed doesn't seem to AutoMeshLevelposted in General Discussion

So, turns out I had a faulty cooling fan (amongst a bunch of other things I went over, disassembling my hot end/extruder and cleaning, checking alignment, etc.). Turns out my bed is just fine and mesh leveling works as it should. Lots of other little adjustments, fixes and the aforementioned cooling fan and I'm back in business.

Thanks so much everybody! I love my machines with Duets running them. The great community of knowledgeable and generous geniuses make my love of the Duet even stronger and more enduring.

Rock on!

Chris -

RE: HELP! New Cast Alum. Bed doesn't seem to AutoMeshLevelposted in General Discussion

@mendenmh Thanks for sharing. I've tried 90C and even 100C. Both work swimmingly.

-

RE: HELP! New Cast Alum. Bed doesn't seem to AutoMeshLevelposted in General Discussion

@o_lampe It's fine. Thanks for asking. You rule!

-

RE: HELP! New Cast Alum. Bed doesn't seem to AutoMeshLevelposted in General Discussion

@theruttmeister Well, I'd become so accustomed to 24V DC heating my bed (88°C max, even in a heated enclosure) that cranking it for PETG had never occurred to me. Well, making my PETG prints stick is no longer a problem, thanks to the 110V AC silicone heater. Amazing! Thanks Ruttmeister and everyone else.

-

RE: HELP! New Cast Alum. Bed doesn't seem to AutoMeshLevelposted in General Discussion

@Veti said in HELP! New Cast Alum. Bed doesn't seem to AutoMeshLevel:

M305 P1 T100000 B4725 R2200 C7.06e-8

Much Thanks!

-

RE: HELP! New Cast Alum. Bed doesn't seem to AutoMeshLevelposted in General Discussion

@Veti I'm using a Semitec104gt-2. I have a Volcano Hot End.

-

RE: HELP! New Cast Alum. Bed doesn't seem to AutoMeshLevelposted in General Discussion

@Phaedrux Hey Phaedrux!

This is what I get after a M122

Bed compensation in use: mesh, comp offset 0.000That's the only Mesh related thing in the report, via typing M122 in console. I assume that's the only way to do it.

So it says it's working. hmmm

Such weird symptoms, I'm baffled.

Thanks,

Chris -

RE: HELP! New Cast Alum. Bed doesn't seem to AutoMeshLevelposted in General Discussion

@percar No, I'm printing on a spring steel sheet/magnet combo, like a WamBam, but TinyMachines version.