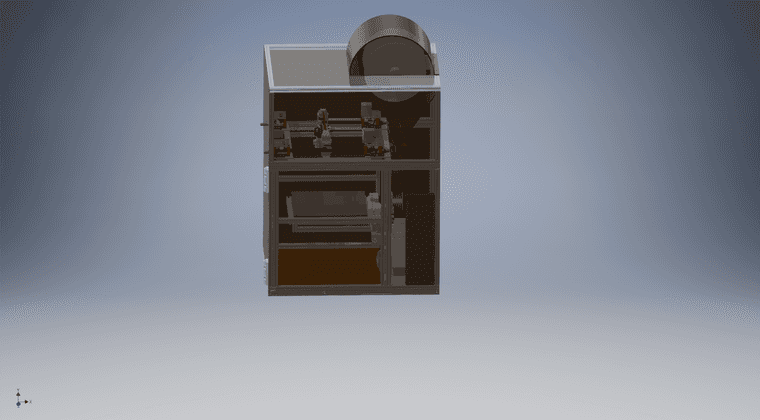

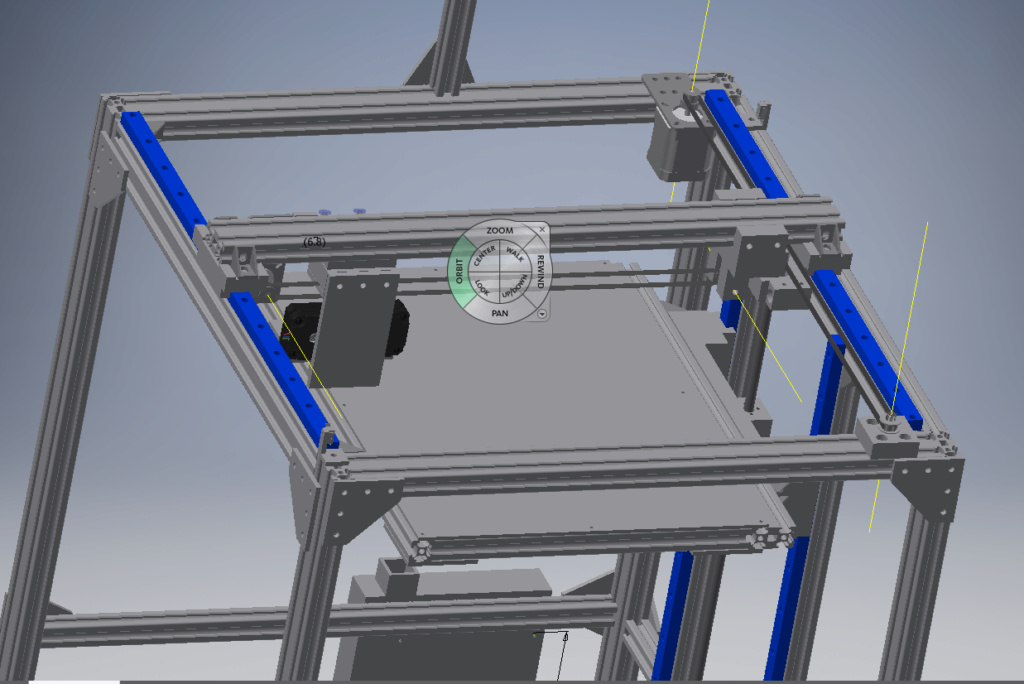

Here my machine , it has a duet 3 running in stand alone , i had a rostock max v2 before but i always been unhappy with some of the feature or quality of the piece it would print , i started looking at other printer i wanted dual extrusion capability but couldn't find one that had a decent build size , so i started toying around the idea of designing my own , i Used autodesk inventor a lots for drawing parts in the past so i went to work.

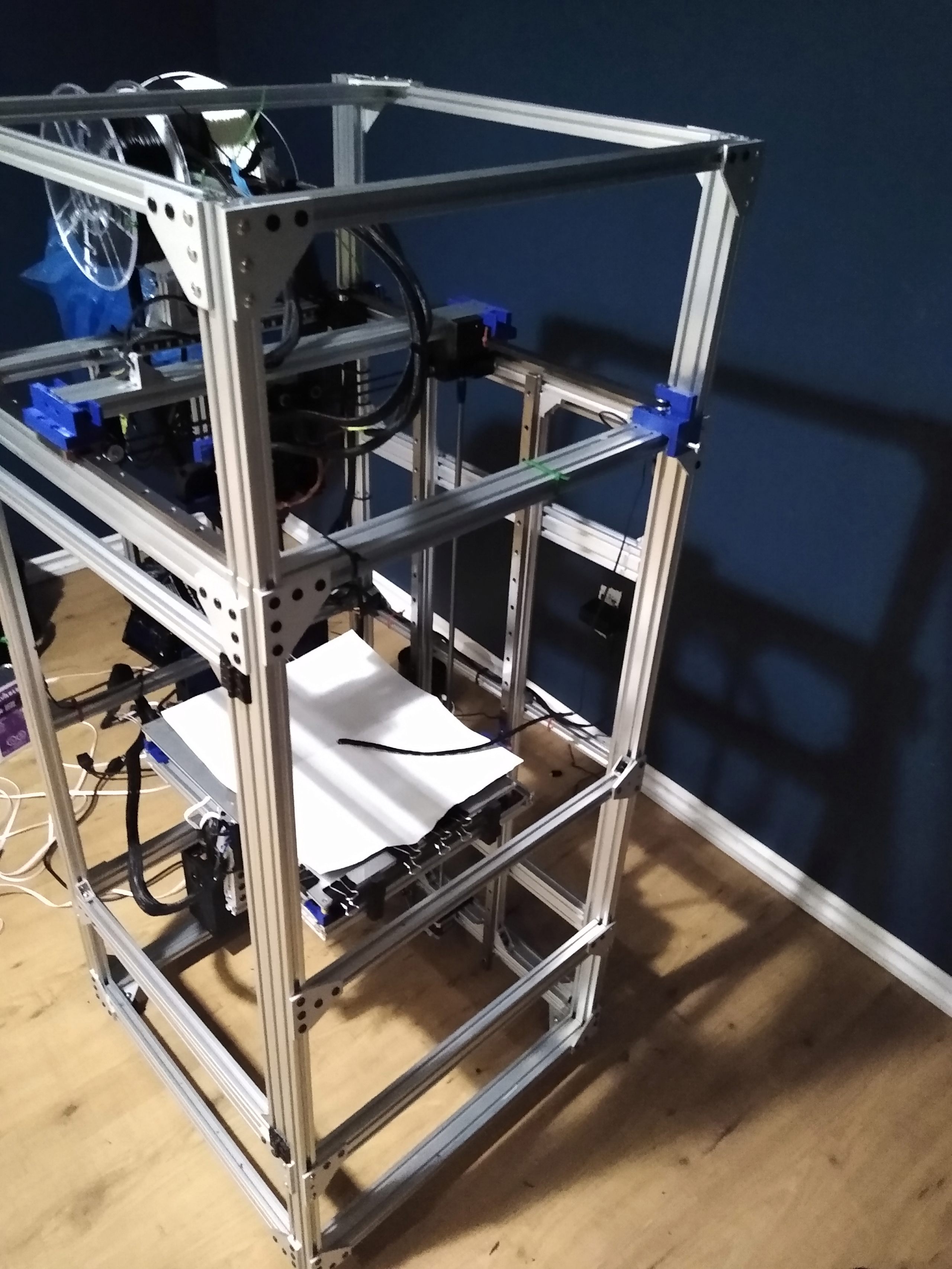

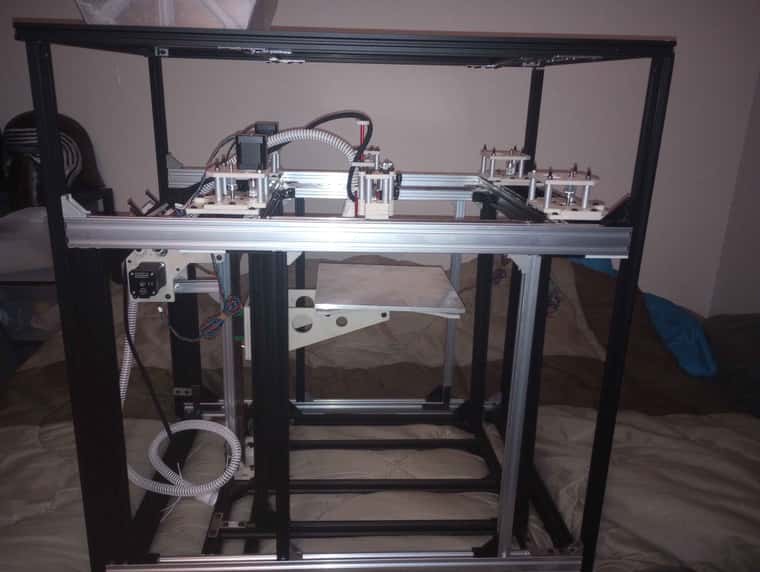

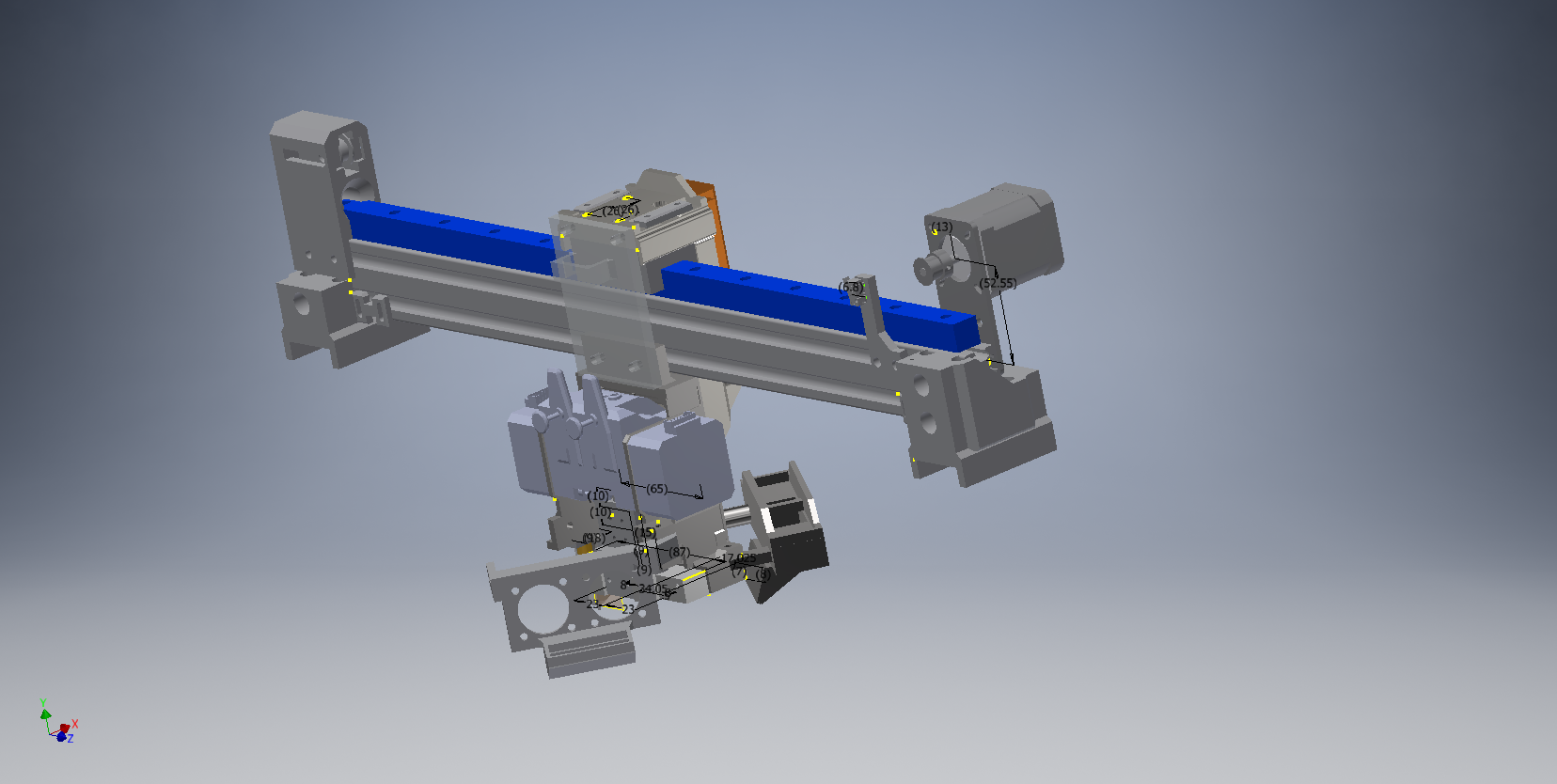

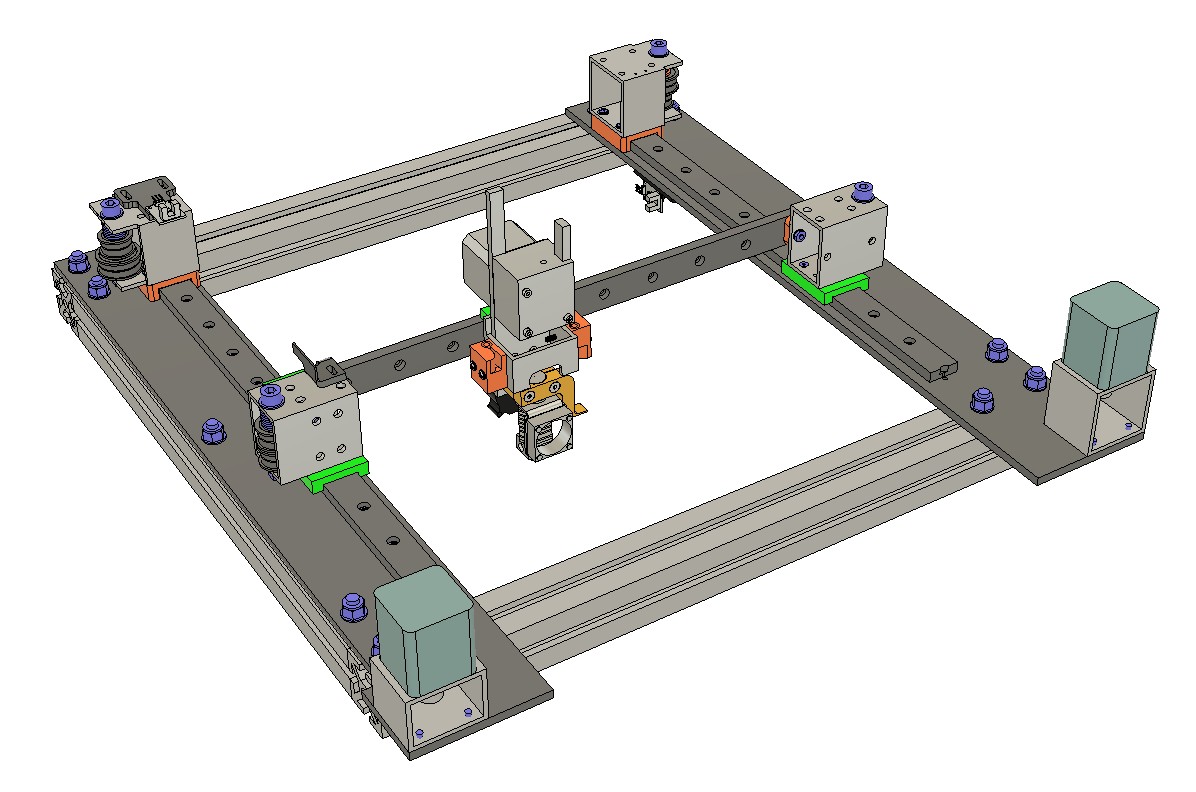

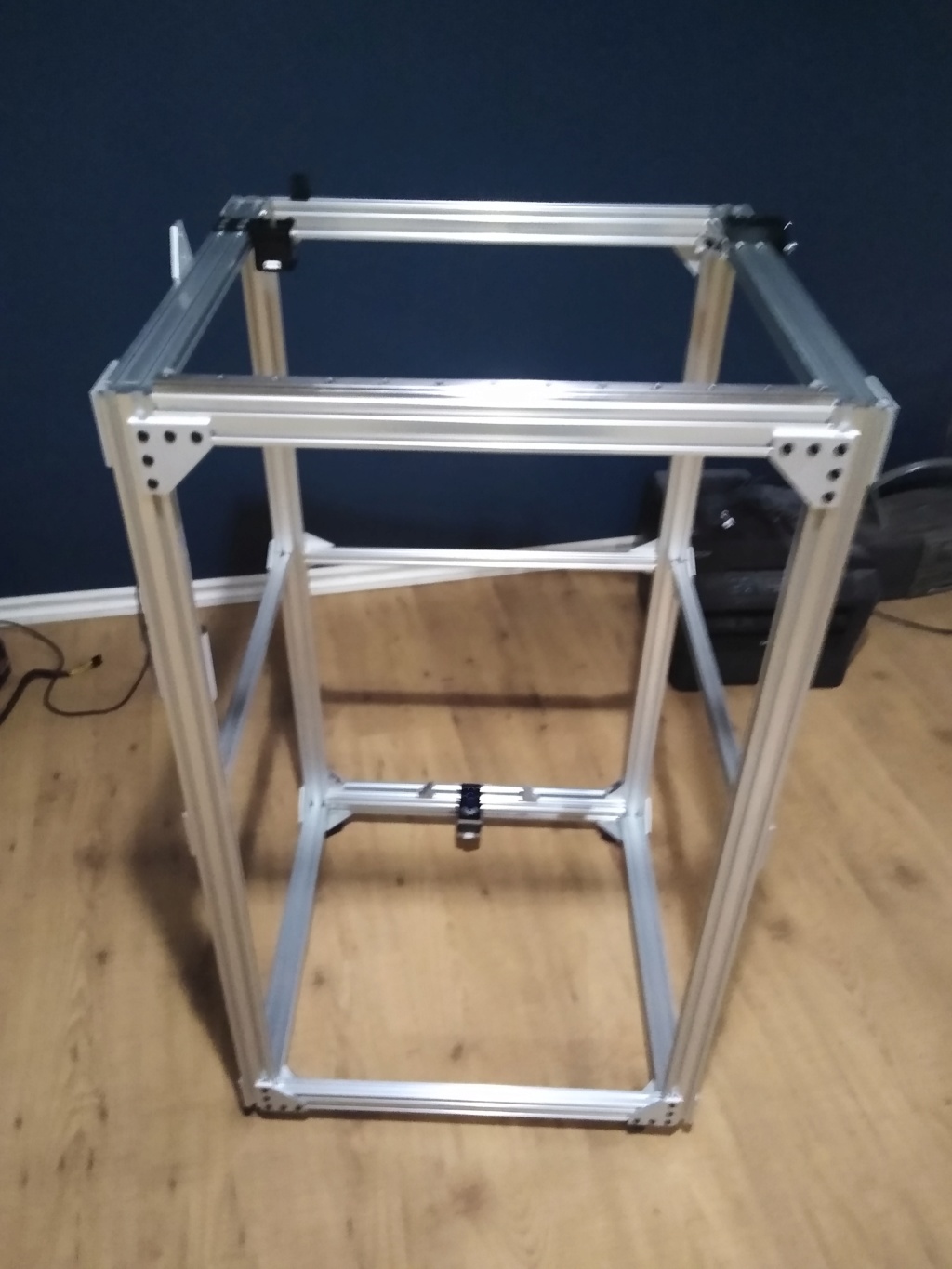

I looked at a few design and when for a more cube design since they seemed more robust than many other design around , main frame is made of 2040 aluminum extrusion bolted together with corner plate with a few reinforcement in the middle of the section the back one as more since it support the vertical rail. it sit on top of 4 big compression spring that act as leg so vibration is not spread back in the frame

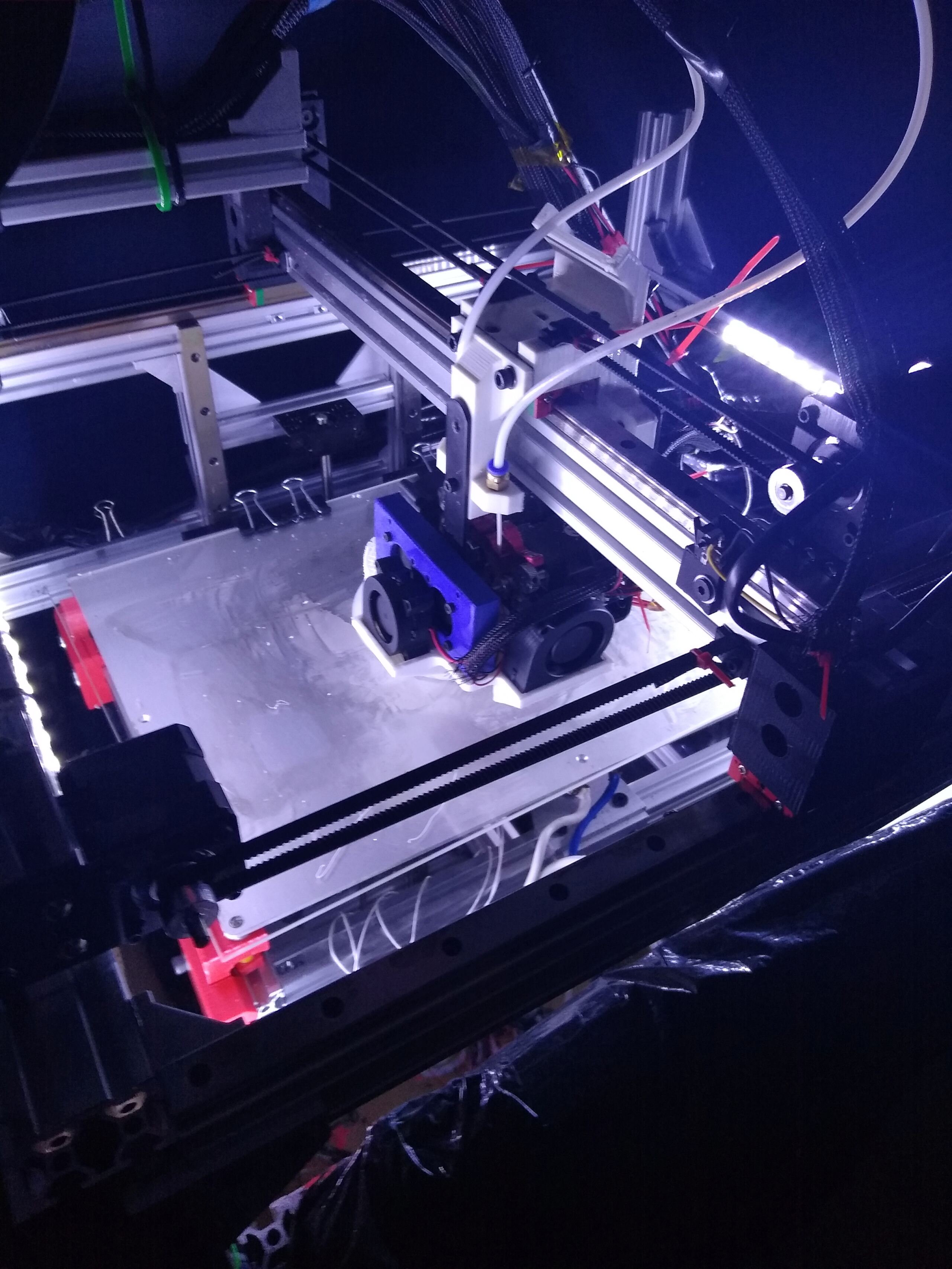

I wasnt ready for the challenge this build was going to bring me , my plan was to use the power supply i was using for my rostock a 850 watt 12 volt pc power supply , the heat bed it on the bigger side 300x400mm caused me many problem , i had to get a mosfet for the bed , still caused wire to melt , ended up having to buy a better mosfet and a dedicated 24volt power supply for the heatbed , it solve all my wire problem now they stay cool , the rest of the machine is still powered by the 12volt unit ,

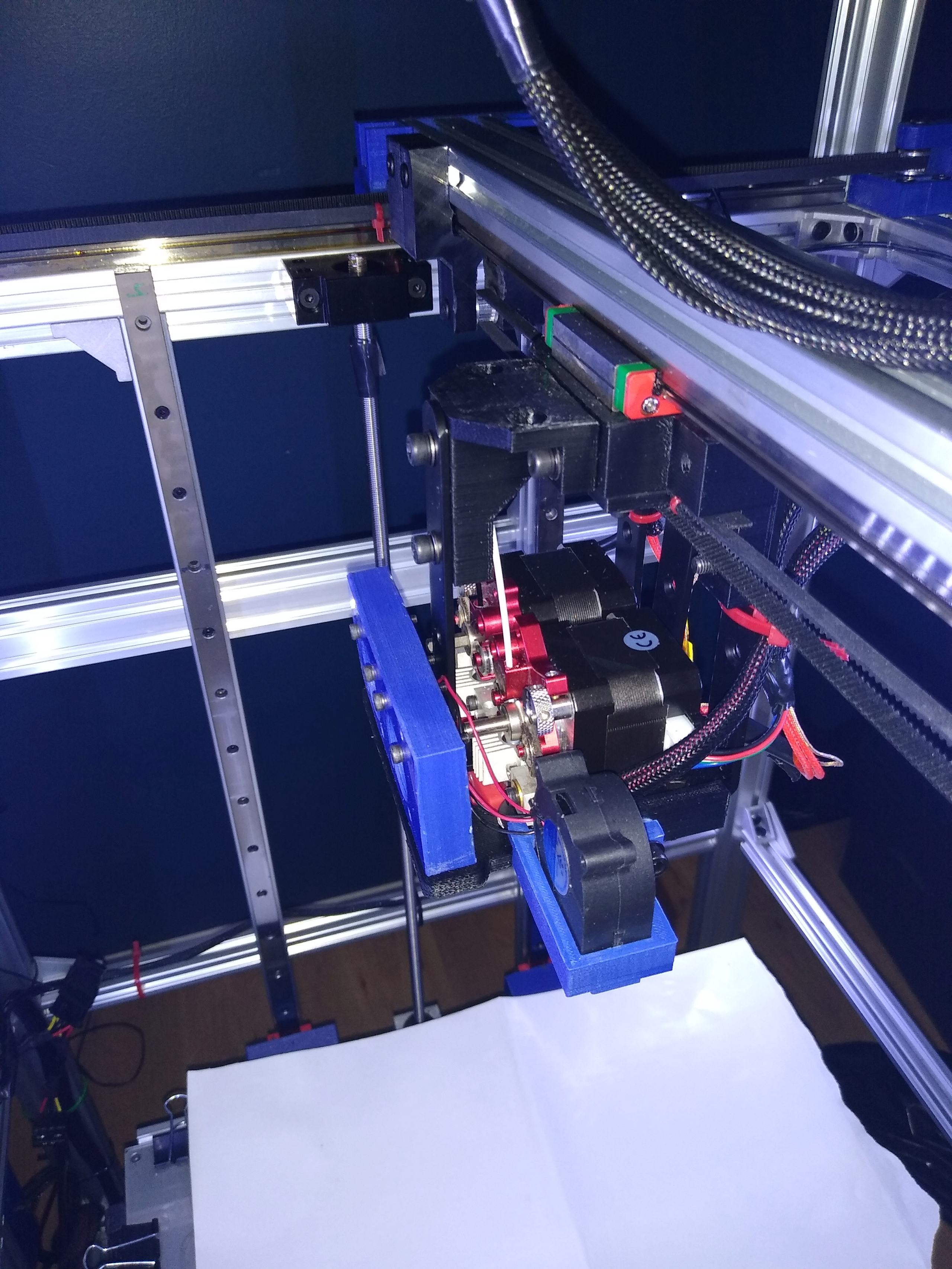

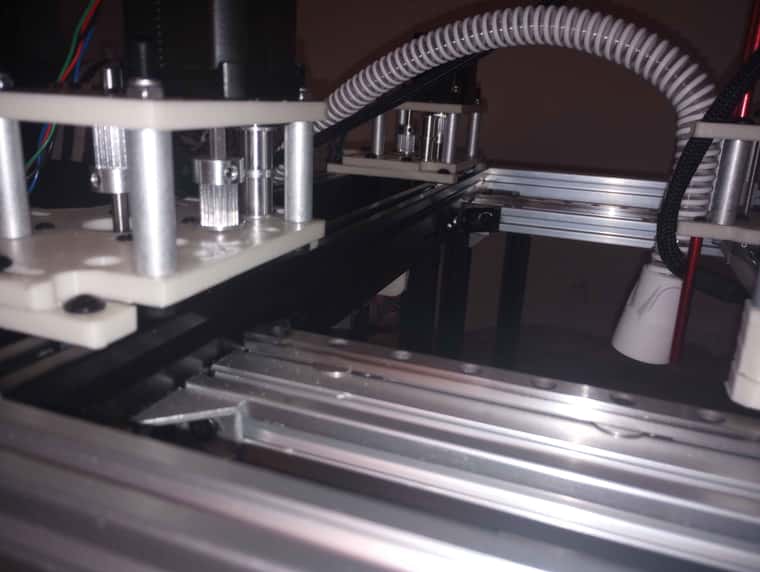

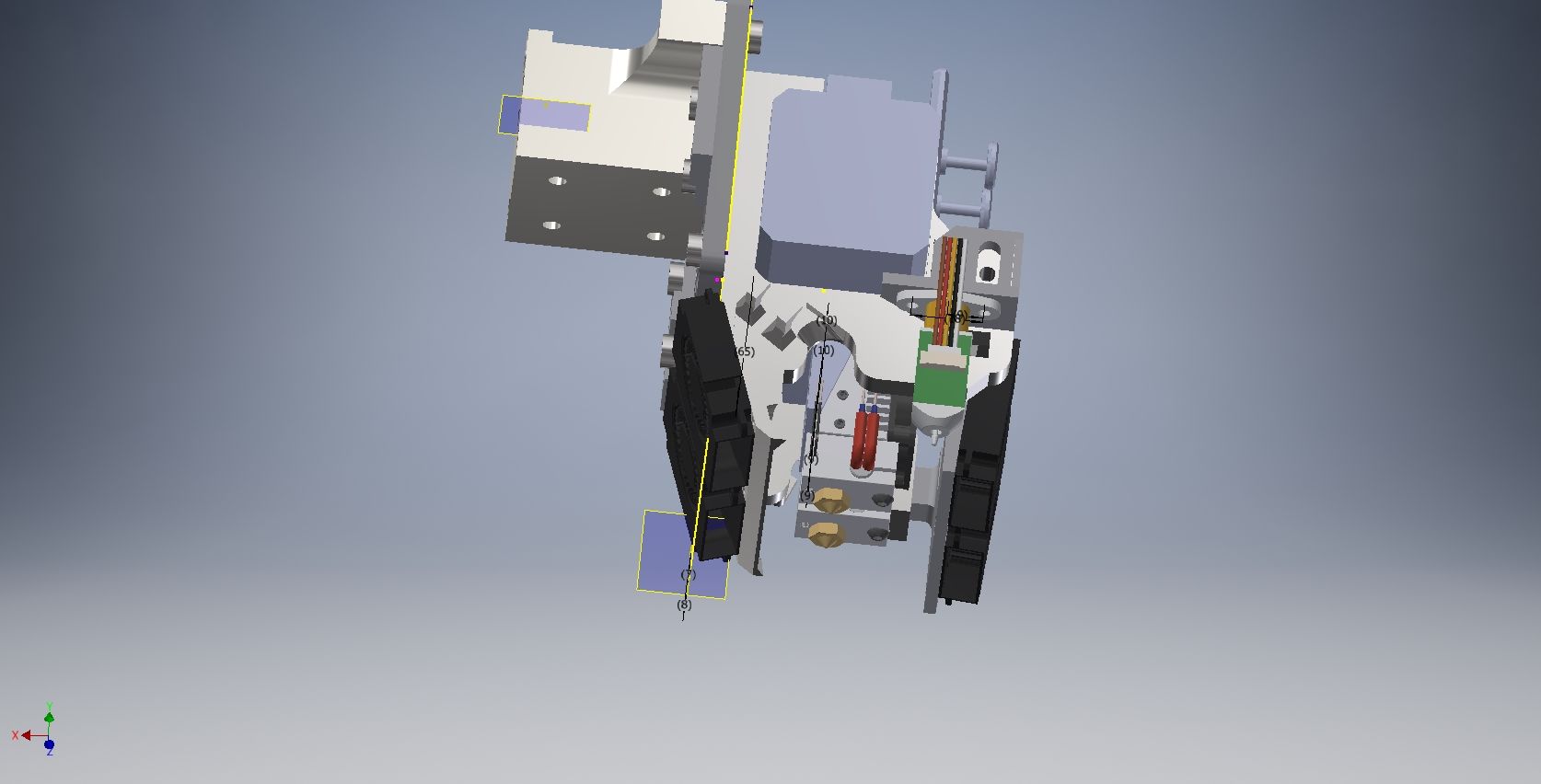

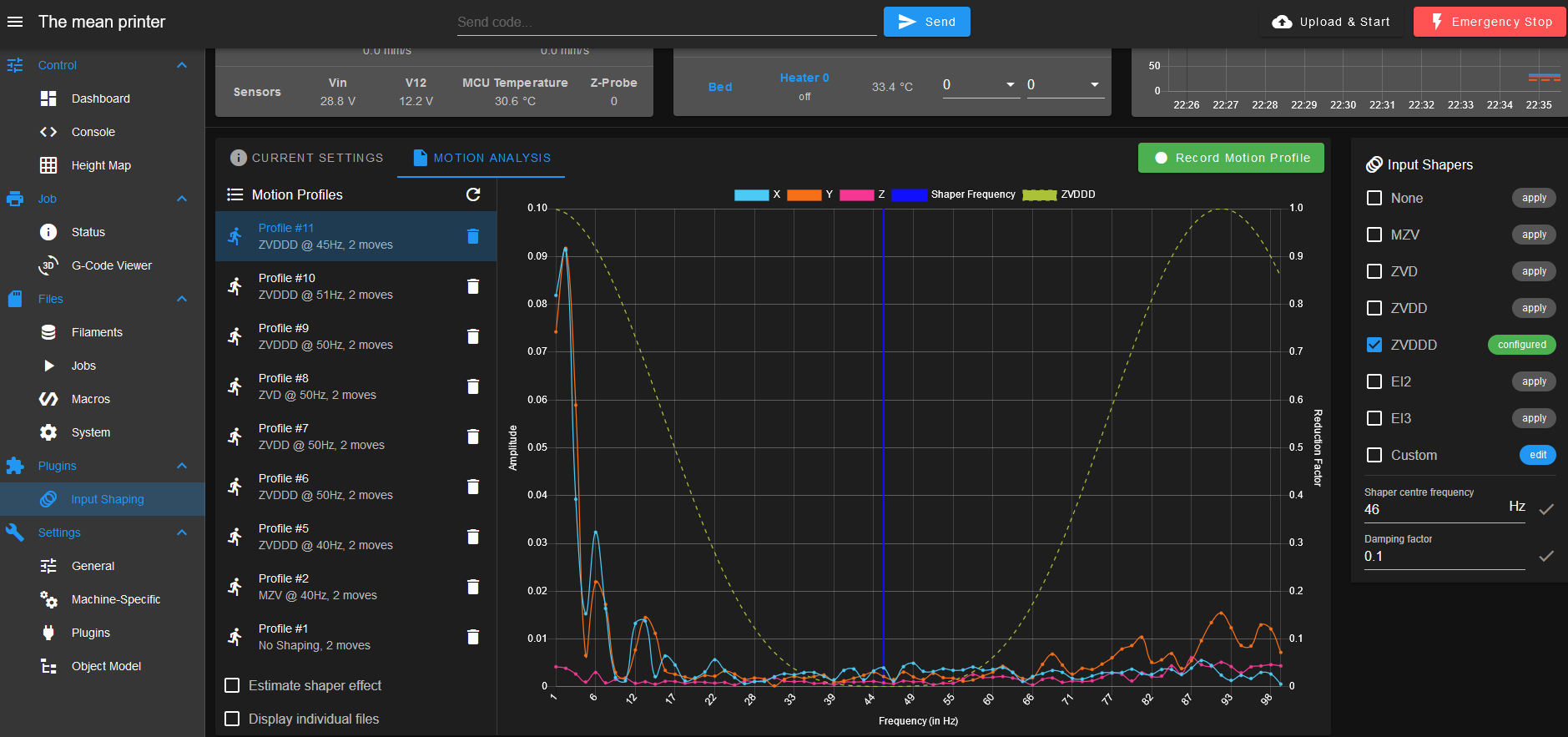

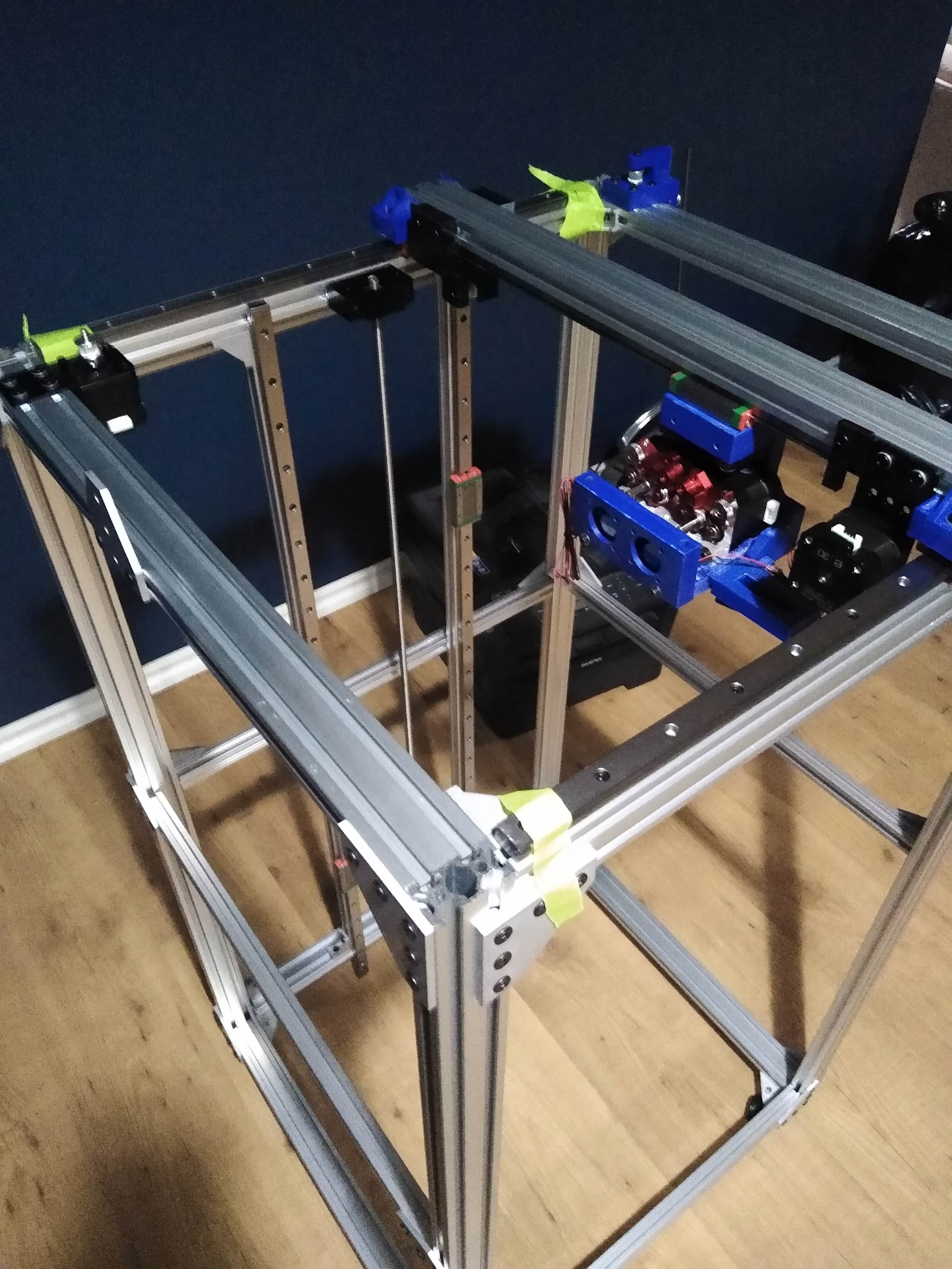

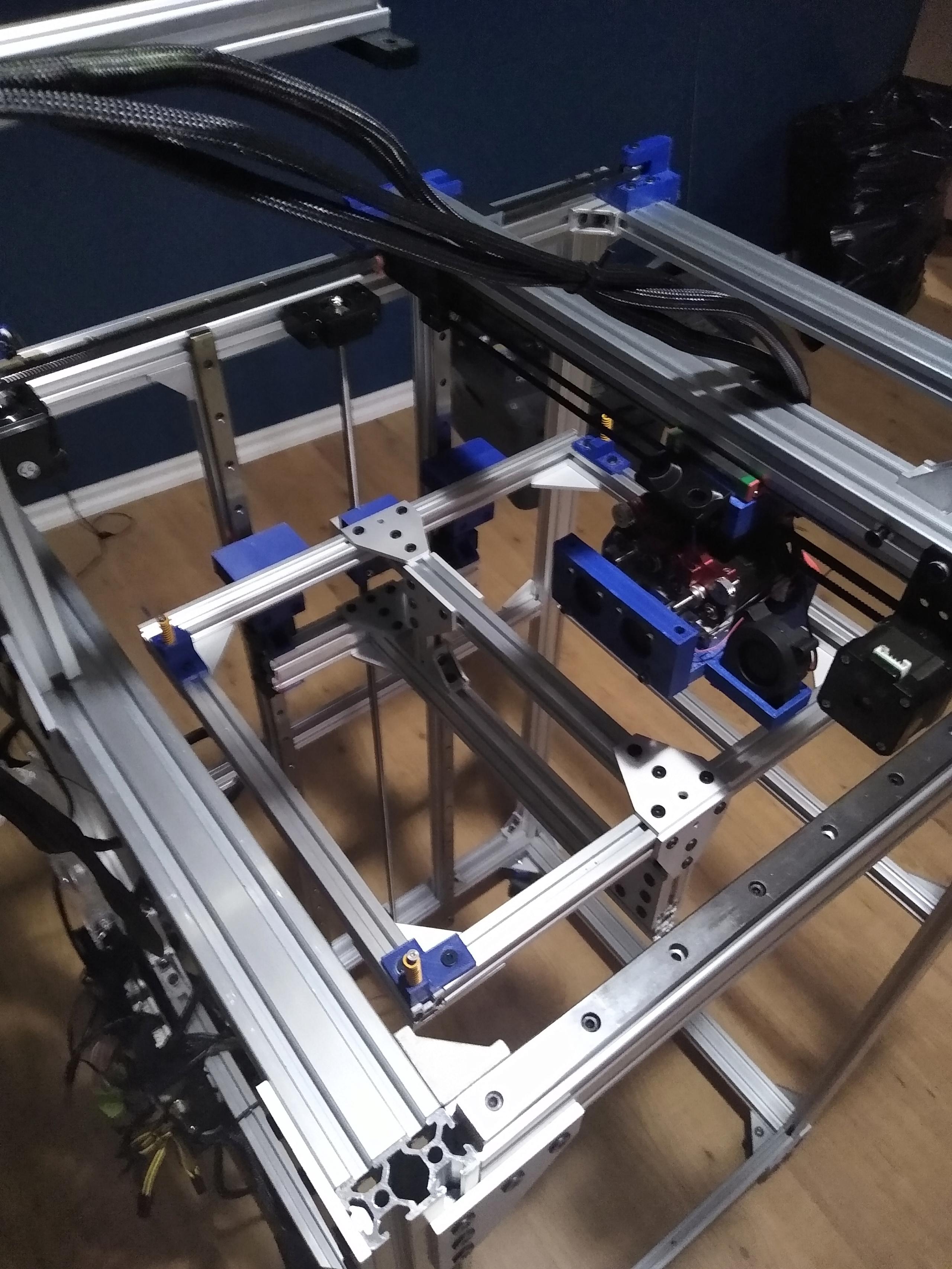

The Y gantry went throw a few change throw the project. each change solved an issue , each axis was supposed to be powered by only one .9 degree stepper motor but due to the weight and inertia of the gantry i had to add another one for the X axis , this solved many vibration problem , then came the Y axis , my original idea wasnt great to tension the belt and then found that the cheap linear rail on the Y axis had play in it since i had it in a reverse position , (should have bought the real hiwin) , ended up changing a few thing gain some MM in the Y axis , fixed most vibration now ,

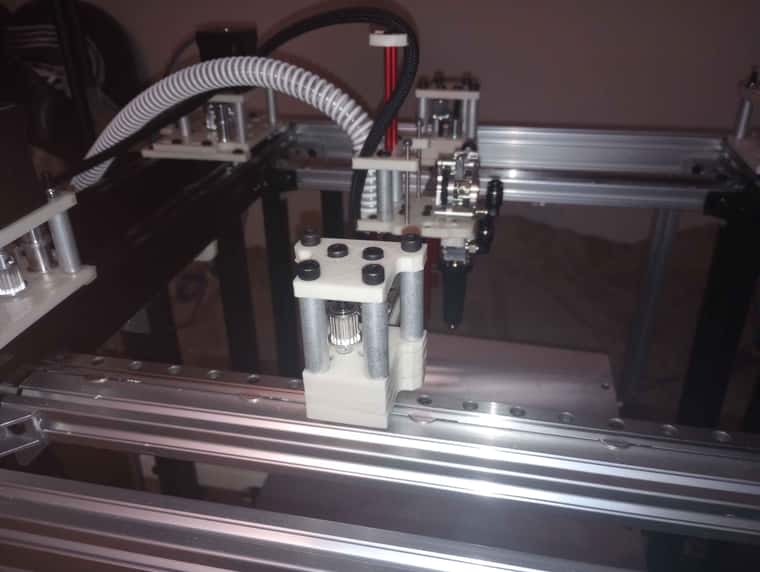

Printable area so far seem to be around 300x350x600mm .i am using a Flexion HT kit for the extruder. print head has 3 blower to cool the print , 1x40mm and 2 x50mm. All stepper motor are .9 degree. The lead screws is m8 x1 one lead only , it take a while to home and get up but give good resolution on the Z plus the 40mm stepper is sufficient even when power is off to keep the Z up

I still have a few tweak to do here and there but overall it is really close of what i had imagined , i did break my budget a little as well , eventually i will have the whole printer encloses in some Acrylic sheets or similar material, i have 4 set of LED band in the printer as well, all running from the sata connector on the modular power supply ,

There is still a few things i will likely change and upgrade to my liking just to fix the last few issue and then the rest will be to figure out the best CURA setting for the material i use.

Here a few picture from the start to the end , it doesnt show everything otherwise there would be too many picture

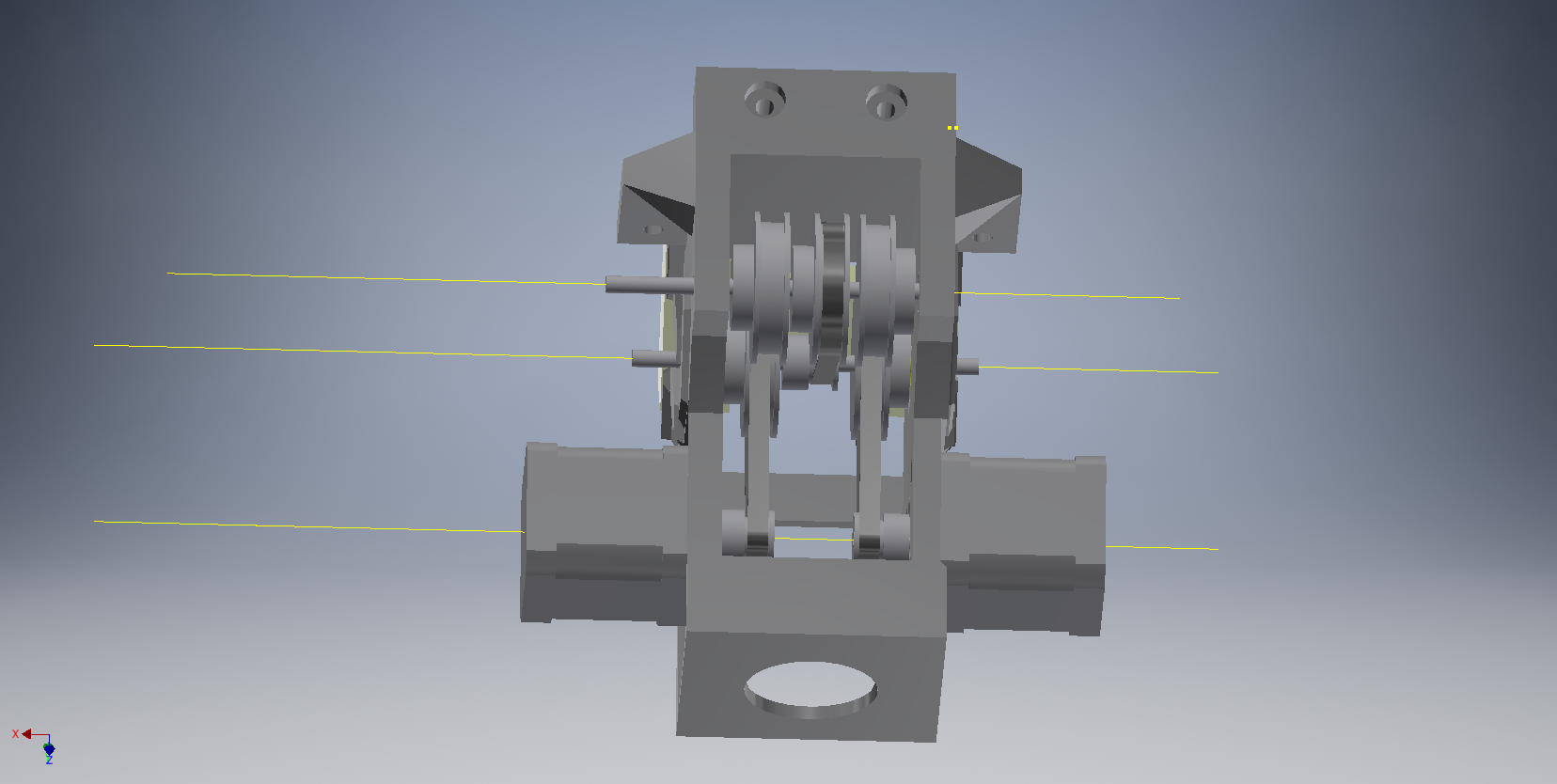

The way the bed is attached to the rail this is now one big piece