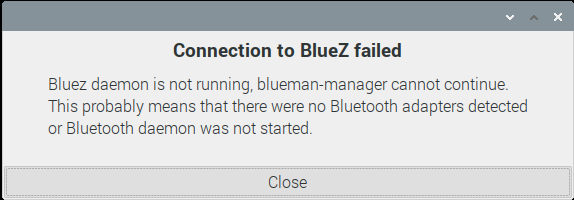

S3D has a feature where you can send the file and start printing after you slice it but I'm having issues getting it connected.

This is the instructions on the page:

Most network-enabled 3D printers support auto-discovery, meaning that the software can automatically detect the printer on the network and determine the appropriate connection details. To test this process, go to Tools > Machine Control Panel within Simplify3D and click “Add New” to launch the New Connection Wizard. Select the “Network Connection” protocol, choose the “Search for Connections” option, and then click “Search for Devices” to begin the auto-discovery process. Note that this process will only work if your firewall and network rules allow UDP traffic back between the printer and your computer. In many cases, you will need to add a firewall exception to allow Simplify3D to detect the 3D printer.

If the software cannot find your 3D printer, you can still enter the connection details manually. Select the “Manual Connection Details” option and then enter the IP address for your 3D printer. This information can typically be found using the LCD screen on the 3D printer to browse to the info or network status page. The software can typically select the correct port automatically based on your printer profile, but you can also enter the port number manually if needed. Common port values used by different manufacturers are listed below:

FlashForge: port 8899

Ultimaker: port 80

MakerBot: port 9999

Dremel: port 80

Qidi Technology: port 3000

XYZprinting: port 9100

Once you have entered the correct details, you can click Next and press “Begin Connection Test” to establish a connection with the printer. If the software fails to connect, it typically means that the firewall or network settings are still blocking the connection. Make sure a firewall exception has been properly configured and consult your network IT manager to make sure traffic between the printer and your computer is permitted. Once a connection is successfully established, Simplify3D will automatically save the correct settings for the future, so you only need to perform this setup process once.

While trying to connect I enter my printers IP and for port number I select automatic but it fails.