This project sounds similar. Measuring the surface of a coin using a duet-controlled machine:

Posts made by HebigT

-

RE: Automatic Three-Coordinate Measuring Instrumentposted in General Discussion

-

RE: Optimizing Multi-Extruder 3D Printing by Preheatingposted in Gcode meta commands

If you use PrusaSlicer this might be an option for you.

https://github.com/mkudzia84/toolchanger-pspp

It’s an older project, and may not work out of the box, or at all, but could be worth a try.

Beyond that, I wonder if Prusa has already implemented something like this for the Prusa XL?

-

RE: Cleaning Brushposted in Tuning and tweaking

You can put those purge and brush macros into your TPost_.g and run them as sub-programs using the M98 command.

TPost_.g occurs AFTER the tool is picked up.

-

RE: waterjet cutter and duetposted in General Discussion

@Aurimas said in waterjet cutter and duet:

Just thinking aloud - I don't it is much different from CNC and/or laser. M3 and M5 will turn the flow and off

rest of it is per normal.

what is needed is the postprocessor definition for the Fusion360 or alike.I imagine you’ve done some research since you originally posted this topic-

In principle, yes you could use those M codes to open and close a valve. You should probably start with M453 (CNC more) and figure out what I/O to define.

For a post processor, I recommend you search the duet forum via Google search. “Duet3d cnc fusion360 post processor”

There should be one or two options to test. I’ve used one successfully in the past but can’t remember which. Without a doubt, you’ll need to either modify the post processor or at least review the generated gcode to remove or add codes that are needed for your specific application.

Also look into the ooznest cnc to see if anyone has a post process for rep rap firmware

@o_lampe ‘s comment about motors is relevant. If you haven’t already, you’ll need to decide on the platform and how the motion will work. Will it use steppers or servos? If steppers, what size? Will they have encoders for feedback? Etc.

But sure, as far as motion control the duet can do it. You’ll just need to define the system details and work out the integration.

Do you have any specific components you’re trying to use in the build?

-

RE: How do I change to a new sd card?posted in General Discussion

This should be a good resource for you in the process:

https://docs.duet3d.com/User_manual/RepRapFirmware/SD_card

The specific file structure is necessary. Also make sure to backup any critical files before you do this. Config.g, gcode for prints, etc.

-

RE: Printing directly onto aluminum plateposted in General Discussion

You can also consider a 3-4mm thick PEI (Ultem 1000) plate. If high temp is needed find a plate without adhesive backing then use binder clips or Swiss clips to secure it to your heater - attaching rigidly with fasteners will lead to stress cracks in the Ultem, eventually.

With Ultem you may not need to use adhesive or as high of build plate temperature. Hopefully you could flex the parts off the surface and not have to use a spatula because it’s a polymer and even softer than aluminum!

-

Duet 3 DC motor control & Tacho Feedback?posted in CNC

Hello,

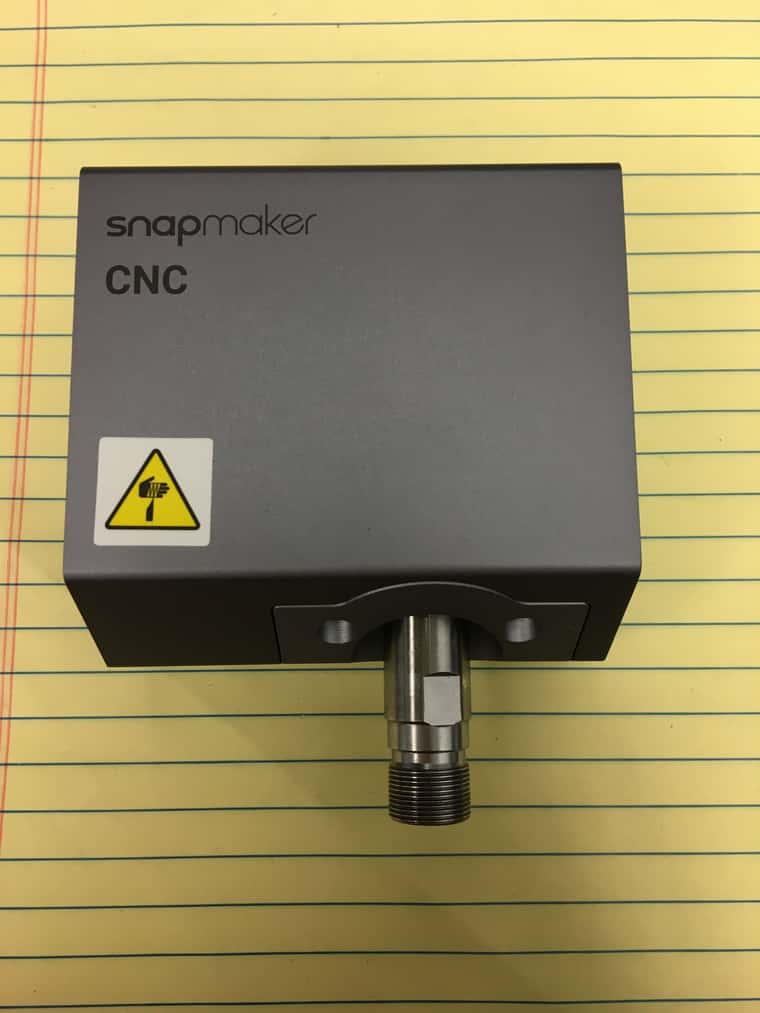

I found this snapmaker CNC tool 2nd hand and I want to use it on a small CNC mill.

I'll be using a Duet 3.

The motor itself is supposedly 50W at 24v, and I cannot find any more details online, so far.

There's a daughter board nearby with the power and other connections (possibly CAN-based?):

- PWM (guessing speed control)

- DIR (not sure how this would be handled by duet..)

- FG (Frequency Generation - possibly a hall sensor?)

- NC (I'm assuming "no connection" on this one)

In principle, do you think I can control this motor directly from the board (power, speed control and feedback?)

I see some docs which recommend using a flyback diode.

Some also recommend a not sharing ground connection between duet and the motor.

Any advice is appreciated!

-

Rubedo - PA calibration via line laserposted in General Discussion

https://github.com/furrysalamander/rubedo

Not my project, just wanted to share.

-

ChatGPT & duetposted in General Discussion

Question for all interested:

How do you plan to integrate AI into your 3DP workflow/development? -

RE: Surfacing Macroposted in CNC

With 3.3 you should still be able to pass a parameter in the macro call. You’ll just have to modify the macro (hopefully only once!) to assign that parameter to the DOC variable (e.g. var DepthOfCut= {param.y} )

It’ll still be a manual process of entering the parameter each time you start the macro, but it should save you the trouble of having to change the DOC variable within the macro each time.See the macro parameter section at this link:

https://docs.duet3d.com/User_manual/Reference/Gcode_meta_commands

-

RE: Surfacing Macroposted in CNC

I know you can pass parameters to a macro in the macro call itself (e.g. depth of pass)

Manually choosing this value on each run of the macro may be possible now using M291 on 3.5 beta firmware.

-

RE: Updating to a new 3D printerposted in Firmware installation

@mperdue Here are a couple of useful links:

https://duet3d.dozuki.com/Wiki/Installing_and_Updating_Firmware#Section_Updating_from_RRF_2_x_to_3_x

https://docs.duet3d.com/en/User_manual/RepRapFirmware/Migration_RRF2_to_RRF3

Otherwise, I would say save your old config.g for reference and use the RRF config tool to create new system files.

https://configtool.reprapfirmware.org/Start

Doing that should get you most of the way there on your new printer.

-

RE: Help understanding M26 and M27posted in Firmware developers

@dc42 Thank you for the detailed explanation!

-

Help understanding M26 and M27posted in Firmware developers

I have an application where I'll need to store the SD position and then reference that position later on (for instance, at each layer-change)

Is M27 and M26 the correct way to do this?

The GCode dictionary entry for M26 mentions that the SD position is referenced by the number of bytes in the print file.

Does referencing the number of bytes ensure that the position is always at the start of a line?

-

RE: Real-time gcode stream (window) for current job?posted in CNC

@Sindarius @chrishamm Thank you for the feedback on this!

-

Real-time gcode stream (window) for current job?posted in CNC

Many commercial CNC software have a dedicated window that shows a real-time stream of gcode commands.

I'd like to create a plugin to do the same - but have no idea how realistic it is or where to start.

I think Sandarius's gcode viewer offers some similar functionality in that it loads the current job and gives a visual preview of commands to come.

Would it be sufficient to simulate the active job in parallel, provided that they both start (and remain) synchronized?

Any thoughts are appreciated!

-

RE: Repetition of movements with E3D toolchanger toolsposted in General Discussion

@fj3d Hi,

Does this mean that two layers will be printed at the same height?

It sounds like simplify doesn't like the models at the same position? I don't have that software, so i can't say for sure whether it's possible.

You can write your own code to do this, but keep in mind it is difficult to recreate the complexity of what a slicer does (infill patterns, dynamic extrusion, etc.)

You could try using a slicer to do the hard work of generating the gcode commands for a cube. Then, use a text editor to copy a section of the code (for instance, gcode for printing just one layer) and put that code inside a while loop (make a custom macro). Inside and outside your while loop you can add commands to switch between tools and do whatever other things you need for your process.

This would require a bit of testing, but this is a good place to start for meta commands (loops, variables in RRF)

https://docs.duet3d.com/en/User_manual/Reference/Gcode_meta_commands

https://forum.duet3d.com/assets/uploads/files/1589979002114-conditional-g-code-best-practice.pdf

-

RE: Setting up a pressure sensor with Duet3posted in Duet Hardware and wiring

@t3p3tony Thank you for the tip! This is what I ordered, although I can't say for sure whether it scales the input like you described.