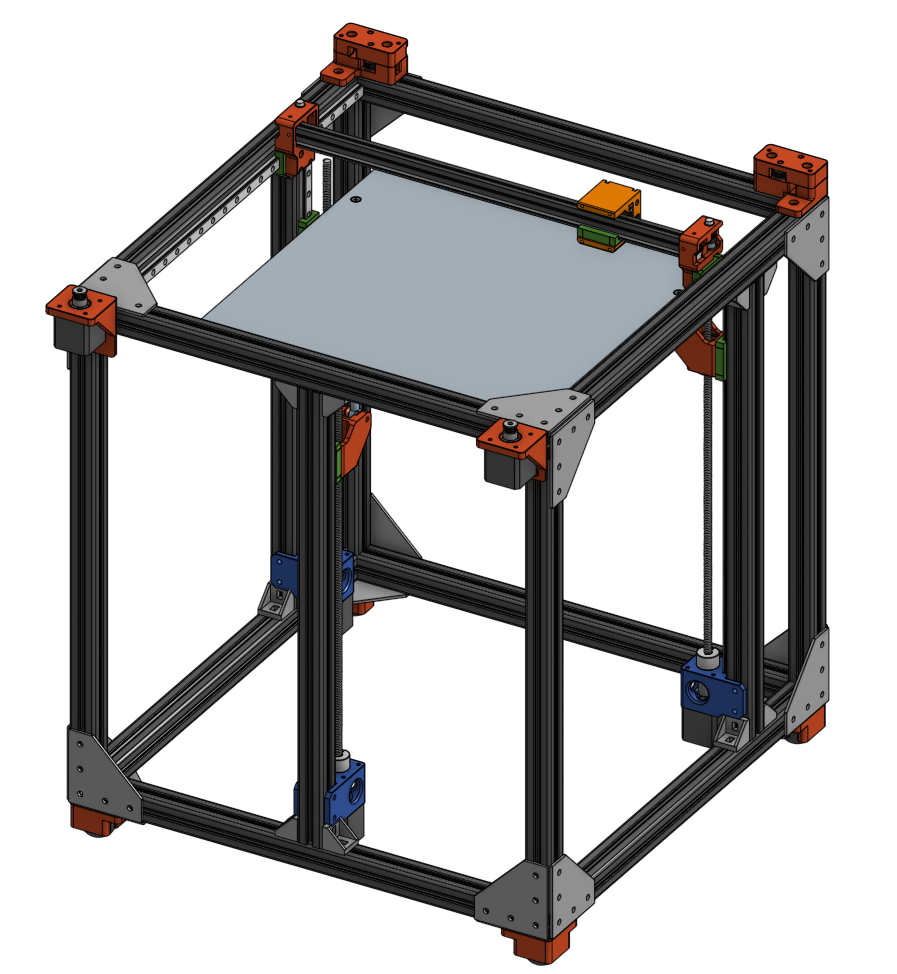

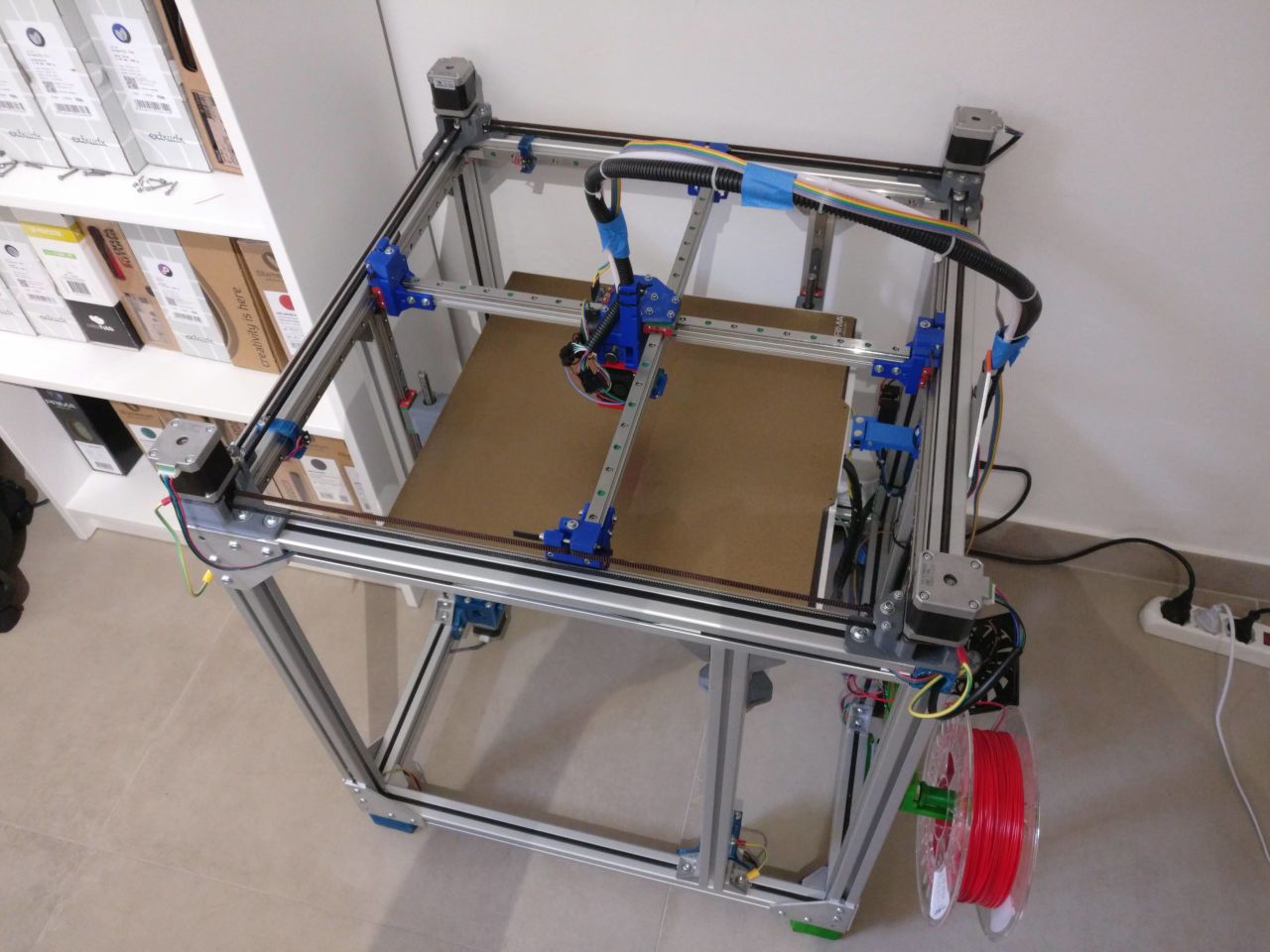

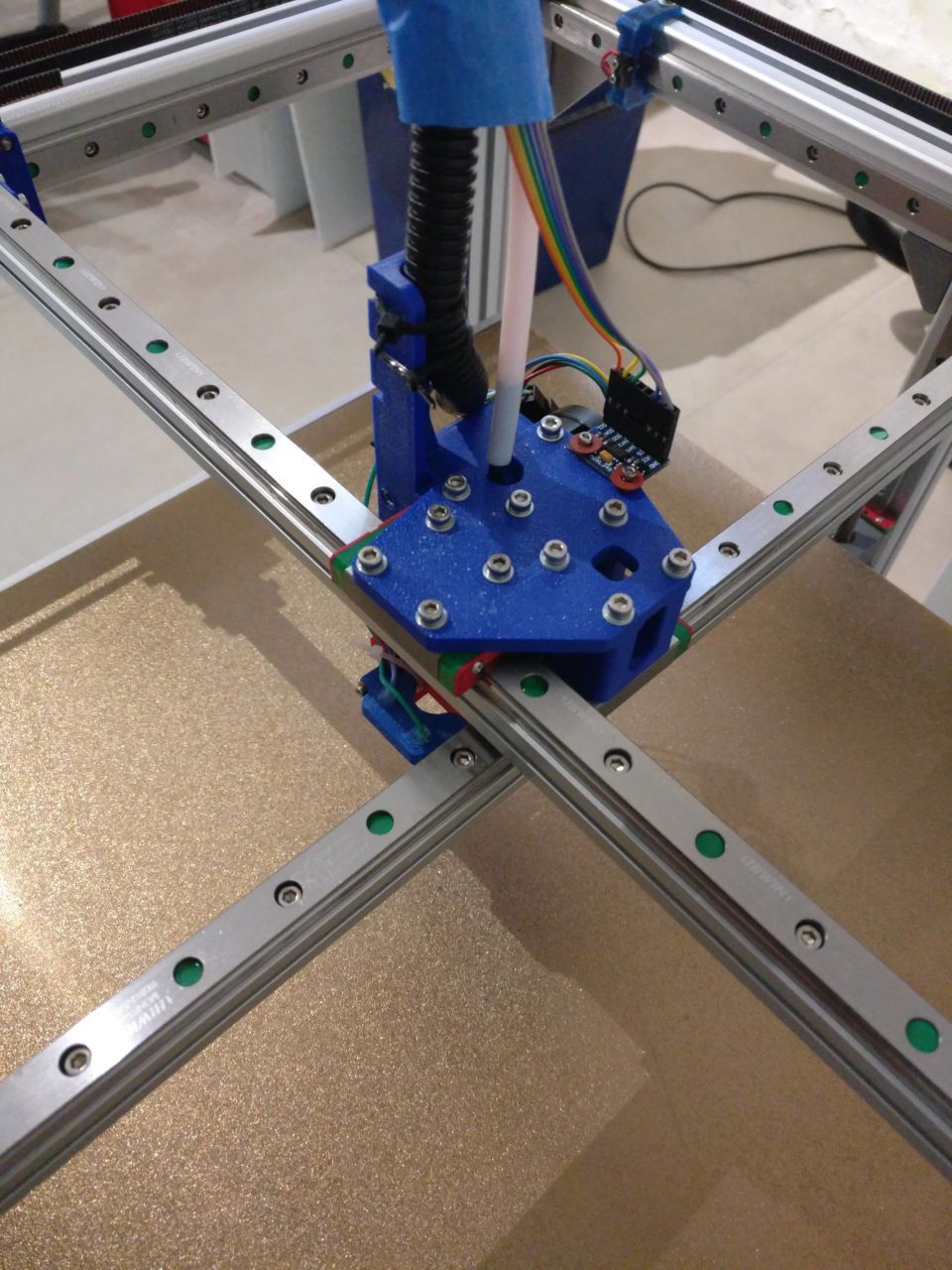

Its name is Agony, it took one year of my life but it's finally working as I'd hoped.

This is it, there are many like it, but this is mine.

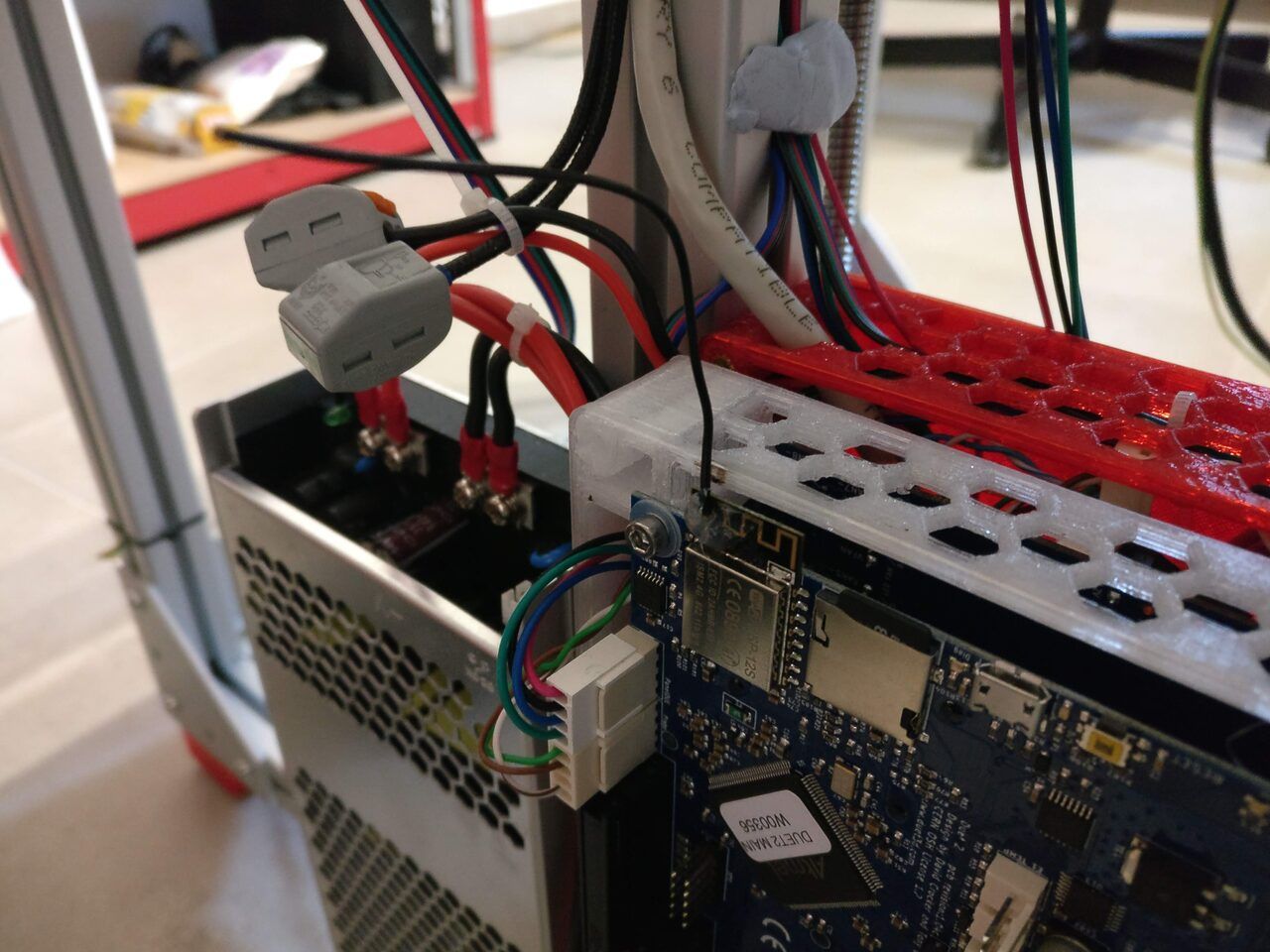

Still beta of course, need better cable management.

It's a relatively large printer. 610x610x610 frame. about 400x400 print area. That was the main challenge. I find that anything larger than about 300x300 becomes exponentially more difficult to build.

Anyway it can happily print at 200mm/s without too much distortion. The following are printed at 150mm/s external perimeter, with a 0.5mm nozzle (my new favorite nozzle size).

Why

It started because I couldn't find a printer with decent print area and reasonable speed. I also wanted to keep it super simple with few easy to print pieces and easy to source off-the-shelf hardware.

All extrusions are 550mm, all rails are 500mm, you don't need special tools to cut/drill/tap, everything can be easily sourced.

If I had to start over today I would probably build an Annex K2... but it is what it is and learned a lot in the process.

A bumpy road

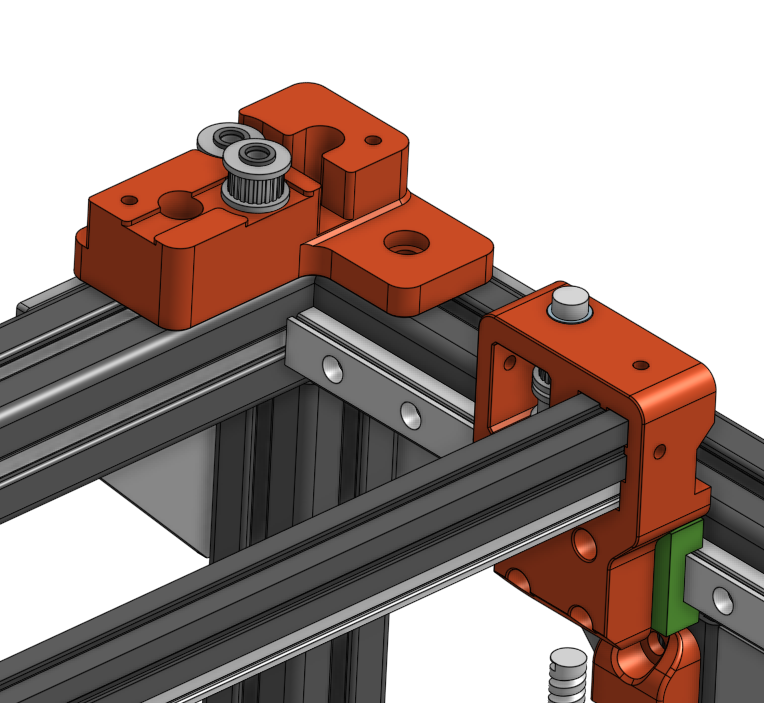

Agony was originally a CoreXY (named Corezilla), but I couldn't solve some resonance issues I had and that generated heavy vibrations at certain speeds. So I converted to a cross-rail cartesian. I then found out that the resonance was due to the belt tensioner design, but it was too late but I'm happy I moved to a cartesian system anyway.

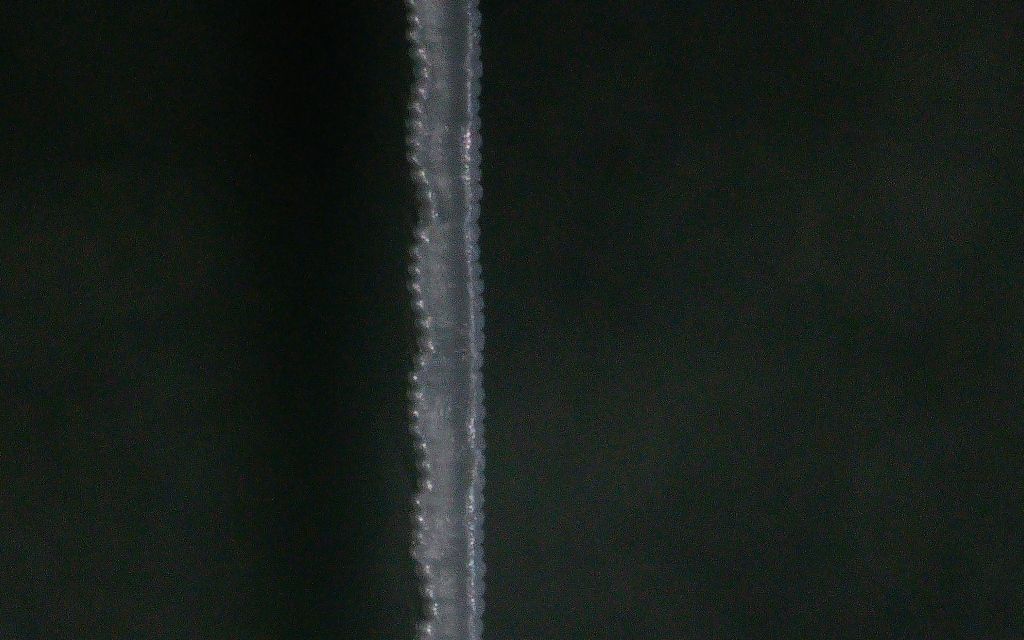

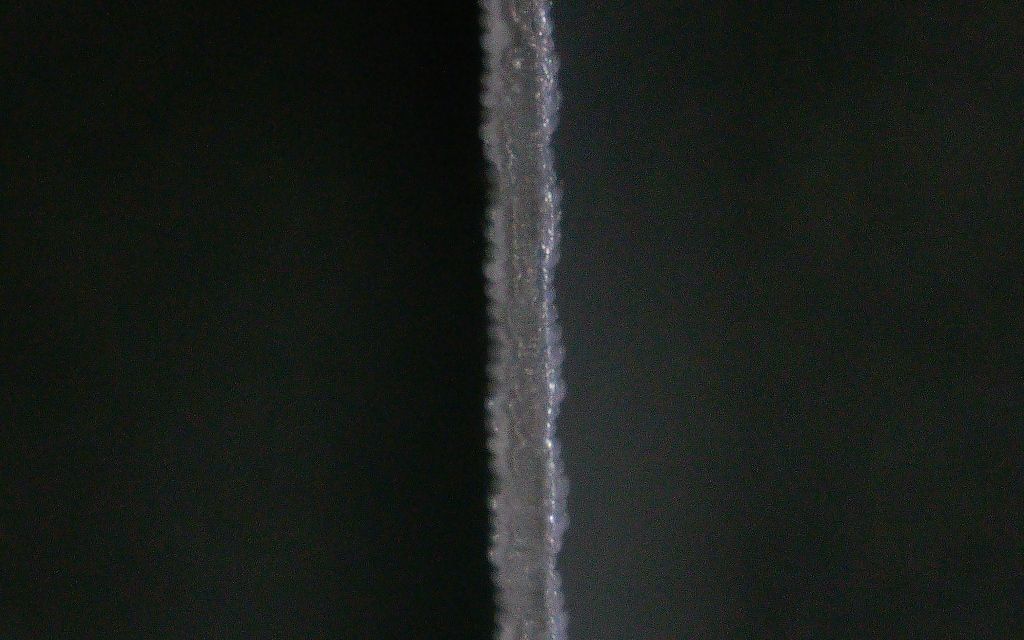

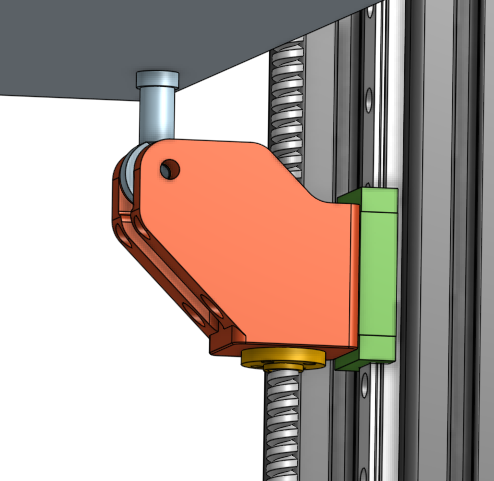

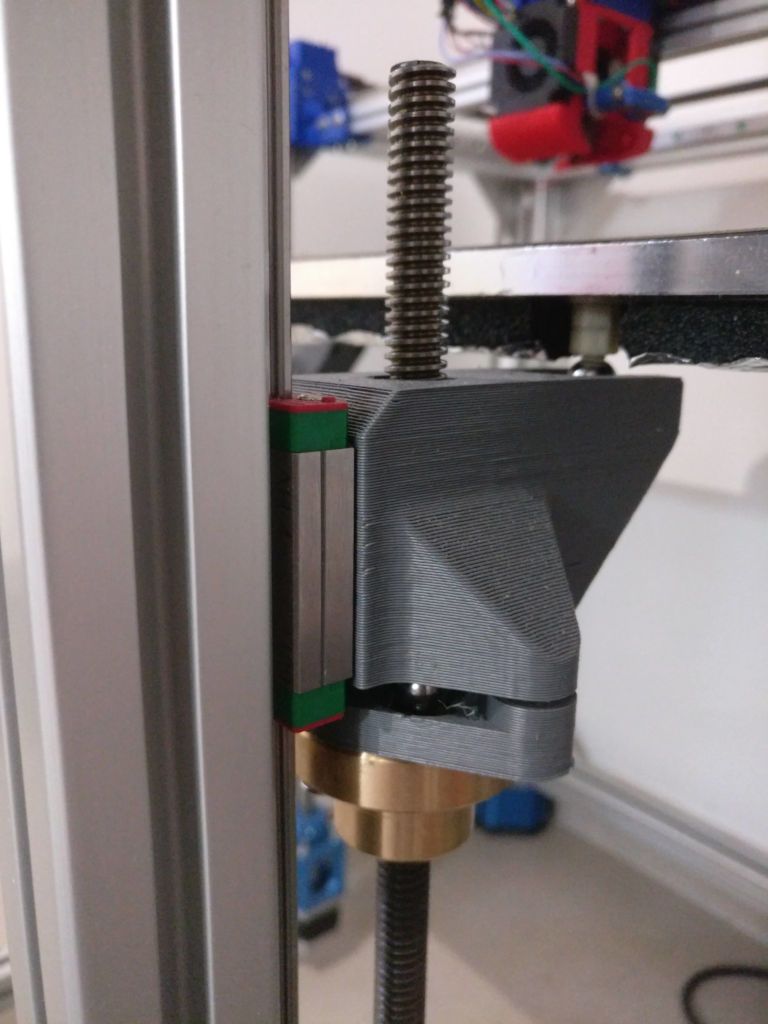

Another issue I had was with z-banding. Apparently it's impossible to get decent leadscrews (or ballscrews) and anyway it's incredibly hard to align 3 of them. The revelation arrived when I saw somewhere a sort of magnetic cushion to be placed on the Z-carriages.

Basically the leadscrew wobbliness is not transmitted to the carriage and now the Z is just perfect.

Finding the right motors was another adventure. Long story short: 0.9° on the XY and 1.8° on the Z. I tried quite a few motors from steppersonline and LDO but ultimately the best I've found are the Moons MS17HA6P4200.

One suggestion, if you need a big print area but you don't need a lot of height, just make the printer as short as possible. That helps a lot with stability. If I had to redo it, I'd probably limit it to like 250 on the Z.

Lastly the gantries.

I tried with the bare rail and with a 15x15 backer. While the bare-rail solution is better in many ways, at the end I had to use supports for the rails. That was a game changer in terms of stability. I was using the rails vertically and at high speed they tend to "flap" at sudden moves change. So I put them on 15x15 extrusions and placed them flat.

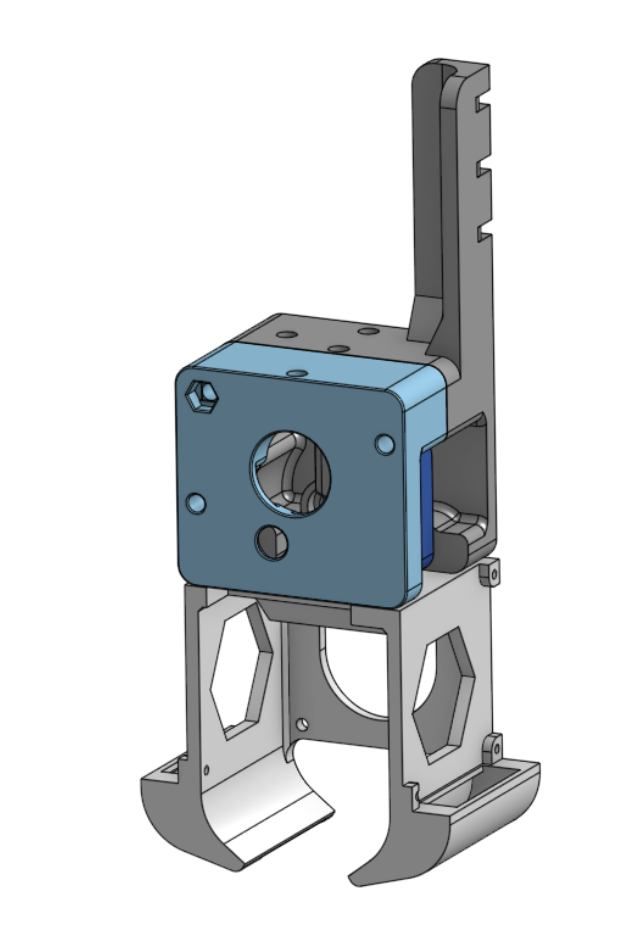

Hotend + Extruder

It's basically a custom extruder based on the now famous small LDO NEMA14 and the guts of a bondtech extruder. The hotend is an original Mosquito (the standard one) and from my initial tests everything's fine up to 200mm/s, over that I start getting extrusion problems on acceleration... but haven't tested it carefully yet.

Despite being so small the 45mm Delta blowers push a lot of air, so at the moment I'm happy with them but I might switch to bigger fans if speed requires it.

Duet & RRF

Now the hard part.

I wanted to use a Duet3 mainly because of the toolboard. I jumped in a little too early unfortunately and the experience was really painful. I was able to fix most of the issues but at the end I hit my head on a firmware bug that produced inconsistent extrusion. I understand that bug is now fixed (and a new toolboard is out), but it was the last straw so to speak so I removed everything and redesigned the printer for the Duet2+Duex5 (that I already had on another printer) but this time I wiped RRF and put Klipper on it.

Now. I owe 90% of what I know about 3d printing to this forum and the help of the generous community and I do love the "everything is gcode" RRF philosophy... but Klipper really made my printer fly.

It was painful at the beginning and the community is much less supportive, you are mostly on your own, but the documentation is good. It's in a constant beta(alpha?)-stage but at the end it worked wonderfully and I feel that any problem I have is now caused 100% by me.

The Duet is a wonderful piece of hardware, something that most of the chinese boards can only dream of BUT my suggestion is: if you need a quick replacement for your printer totally get a duet2/3 with RRF; if you want something complex and custom... in my experience a fysetc board and Klipper is a better option. I hope you'll forgive my candor. I'll still be using the Duet boards I have for other projects but I guess to each its own.

Want more?

I would never ever suggest anyone to build Agony, but if you want to look around, head to onshape and search "Agony" in the public projects. You'll find it, it's the only one... but be warned it's a very messy project.

Thanks, sorry for the long post.

Thanks!

Thanks!