@oliof GRAZIE

Posts made by paolozampini1973

-

axis yxz internal print measurement errorsposted in General Discussion

Can anyone tell me why when I print any shape the internal part is narrower by about 8 tenths. I'll start by saying that the external part is perfect with an error of about 5 cents.

I wanted to point out that the prints are drawn at the pitch of the nozzle size -

RE: RFF3.42 display the extruder speedposted in Duet Web Control

@chrishamm said in RFF3.42 display the extruder speed:

DWC 3.5.1

DWC 3.5.1 works of love to upgrade because I know there are a few things to replace I have the version 3.4.2

I'm not aware of how many things you'll then have to reset -

RE: RFF3.42 display the extruder speedposted in Duet Web Control

@dc42 said in RFF3.42 display the extruder speed:

@paolozampini1973 RRF doesn't currently provide the instantaneous extrusion speed in the object model. I can look at adding that in RRF 3.5.

Currently the best you can do is to read move.extruders[n].position or move.extruders[n].rawPosition at intervals and calculate an average extrusion rate over the interval from the increase in value.

@dc42 Hi, do you remember I asked you two years ago to display the extrusion speed and you told me that you would insert it into the RF 3.5, did you do it then? Thanks

-

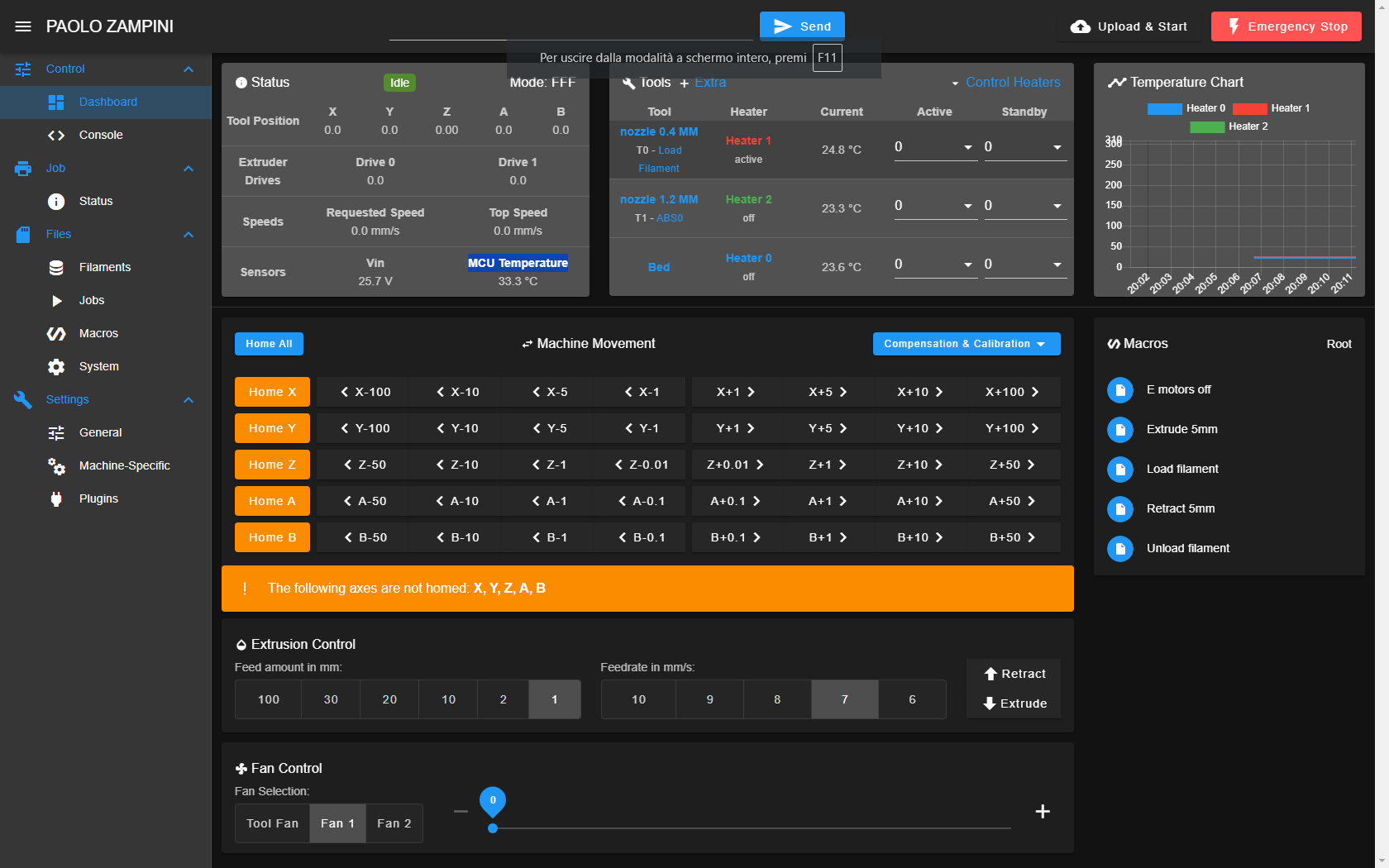

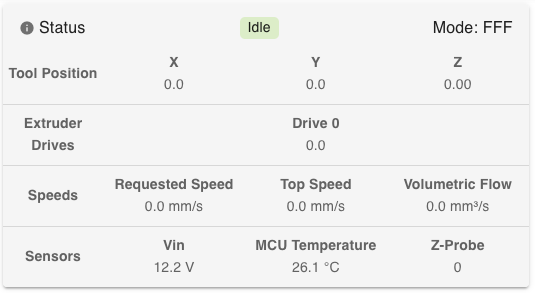

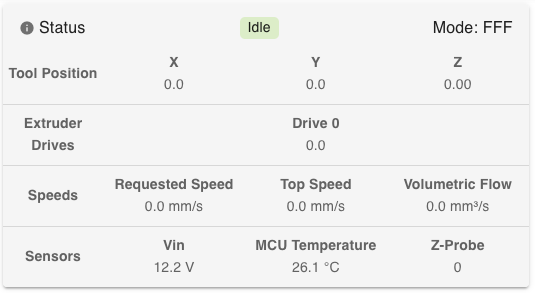

MCU Temperature duet wifiposted in Duet Web Control

@dc42

MCU Temperatura Volevo sapere come accendere la ventola quando MCU Temperatura supera i 40° perche adesso e sempre accesa

18/05/2024, 19:57:43 m122

=== Diagnostics ===

RepRapFirmware for Duet 2 WiFi/Ethernet version 3.4.2 (2022-09-13 15:11:16) running on Duet WiFi 1.02 or later + DueX2v0.11

Board ID: 0JD2M-9F8TA-GJ4TD-6J9F2-3S06P-KQNA7

Used output buffers: 1 of 26 (24 max)

=== RTOS ===

Static ram: 23860

Dynamic ram: 77028 of which 0 recycled

Never used RAM 11192, free system stack 170 words

Tasks: NETWORK(notifyWait,26.2%,242) HEAT(notifyWait,0.0%,333) Move(notifyWait,0.0%,363) DUEX(notifyWait,0.0%,24) MAIN(running,73.6%,410) IDLE(ready,0.2%,30), total 100.0%

Owned mutexes: WiFi(NETWORK)

=== Platform ===

Last reset 00:07:53 ago, cause: software

Last software reset at 2024-05-18 19:49, reason: User, GCodes spinning, available RAM 11192, slot 2

Software reset code 0x0003 HFSR 0x00000000 CFSR 0x00000000 ICSR 0x0041f000 BFAR 0xe000ed38 SP 0x00000000 Task MAIN Freestk 0 n/a

Error status: 0x00

Aux0 errors 0,0,0

Step timer max interval 0

MCU temperature: min 32.4, current 33.7, max 34.0

Supply voltage: min 25.5, current 25.7, max 26.1, under voltage events: 0, over voltage events: 0, power good: yes

Heap OK, handles allocated/used 0/0, heap memory allocated/used/recyclable 0/0/0, gc cycles 0

Events: 0 queued, 0 completed

Driver 0: standstill, SG min n/a

Driver 1: standstill, SG min n/a

Driver 2: standstill, SG min n/a

Driver 3: standstill, SG min n/a

Driver 4: standstill, SG min n/a

Driver 5: standstill, SG min n/a

Driver 6: standstill, SG min n/a

Driver 7:

Driver 8:

Driver 9:

Driver 10:

Driver 11:

Date/time: 2024-05-18 19:57:40

Cache data hit count 4294967295

Slowest loop: 21.07ms; fastest: 0.19ms

I2C nak errors 0, send timeouts 0, receive timeouts 0, finishTimeouts 0, resets 0

=== Storage ===

Free file entries: 10

SD card 0 detected, interface speed: 20.0MBytes/sec

SD card longest read time 7.7ms, write time 0.0ms, max retries 0

=== Move ===

DMs created 83, segments created 0, maxWait 0ms, bed compensation in use: none, comp offset 0.000

=== MainDDARing ===

Scheduled moves 0, completed 0, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1

=== AuxDDARing ===

Scheduled moves 0, completed 0, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1

=== Heat ===

Bed heaters 0 -1 -1 -1, chamber heaters -1 -1 -1 -1, ordering errs 0

Heater 1 is on, I-accum = 0.0

=== GCodes ===

Segments left: 0

Movement lock held by null

HTTP is idle in state(s) 0

Telnet is idle in state(s) 0

File is idle in state(s) 0

USB is idle in state(s) 0

Aux is idle in state(s) 0

Trigger is idle in state(s) 0

Queue is idle in state(s) 0

LCD is idle in state(s) 0

Daemon is idle in state(s) 0

Autopause is idle in state(s) 0

Code queue is empty

=== Filament sensors ===

Extruder 0 sensor: ok

Extruder 1 sensor: ok

=== DueX ===

Read count 1, 0.13 reads/min

=== Network ===

Slowest loop: 30.57ms; fastest: 0.00ms

Responder states: HTTP(0) HTTP(0) HTTP(0) HTTP(0) FTP(0) Telnet(0), 0 sessions

HTTP sessions: 1 of 8

= WiFi =

Network state is active

WiFi module is connected to access point

Failed messages: pending 0, notready 0, noresp 0

WiFi firmware version 1.27

WiFi MAC address e8:68:e7:7f:6d:82

WiFi Vcc 3.46, reset reason Power up

WiFi flash size 2097152, free heap 24760

WiFi IP address 192.168.1.15

WiFi signal strength -60dBm, mode 802.11n, reconnections 0, sleep mode modem

Clock register 00002002

Socket states: 0 0 0 0 0 0 0 0 -

RE: plugin DuetRff ultimaker curaposted in Duet Web Control

@oliof Thanks everyone for the information

-

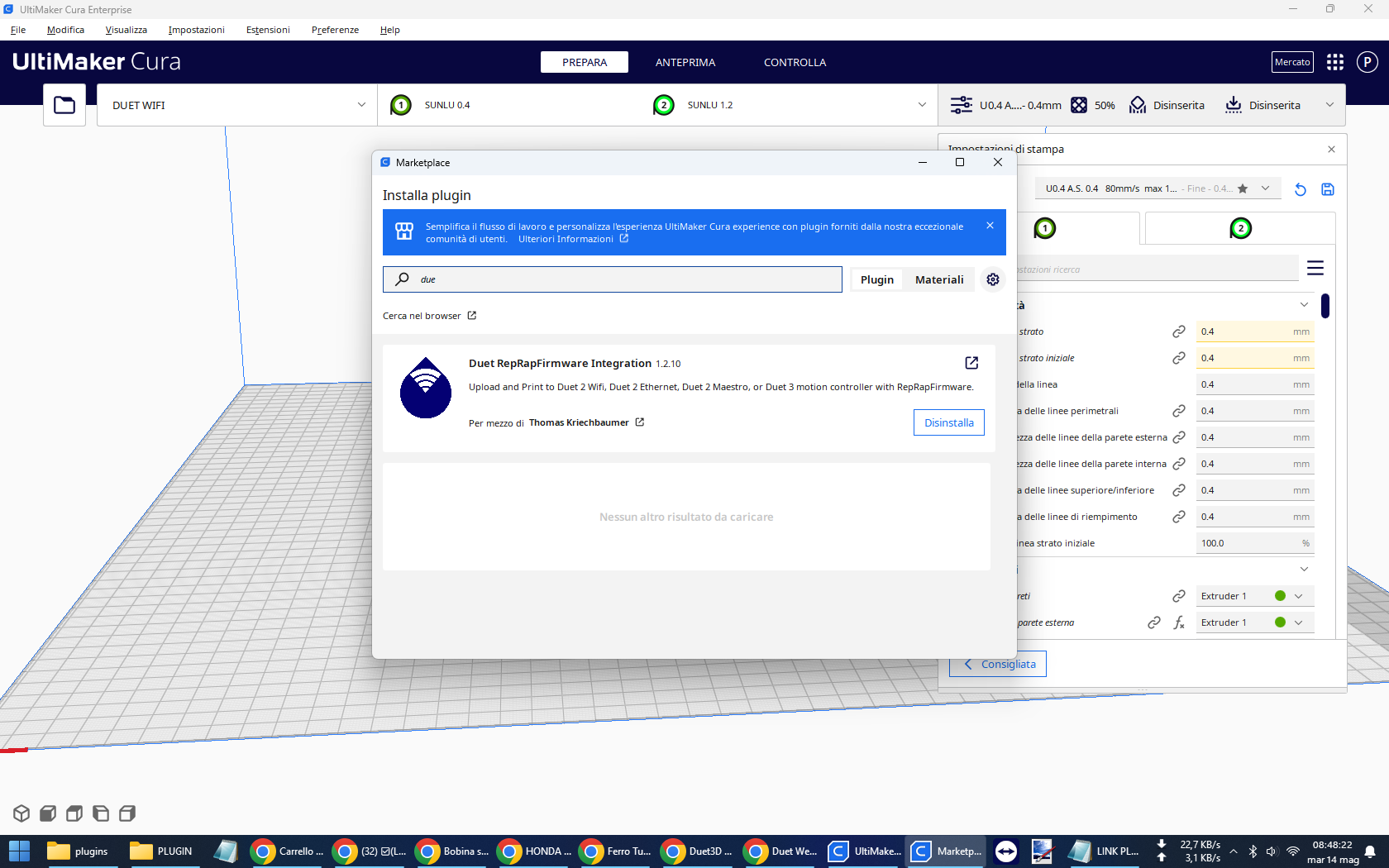

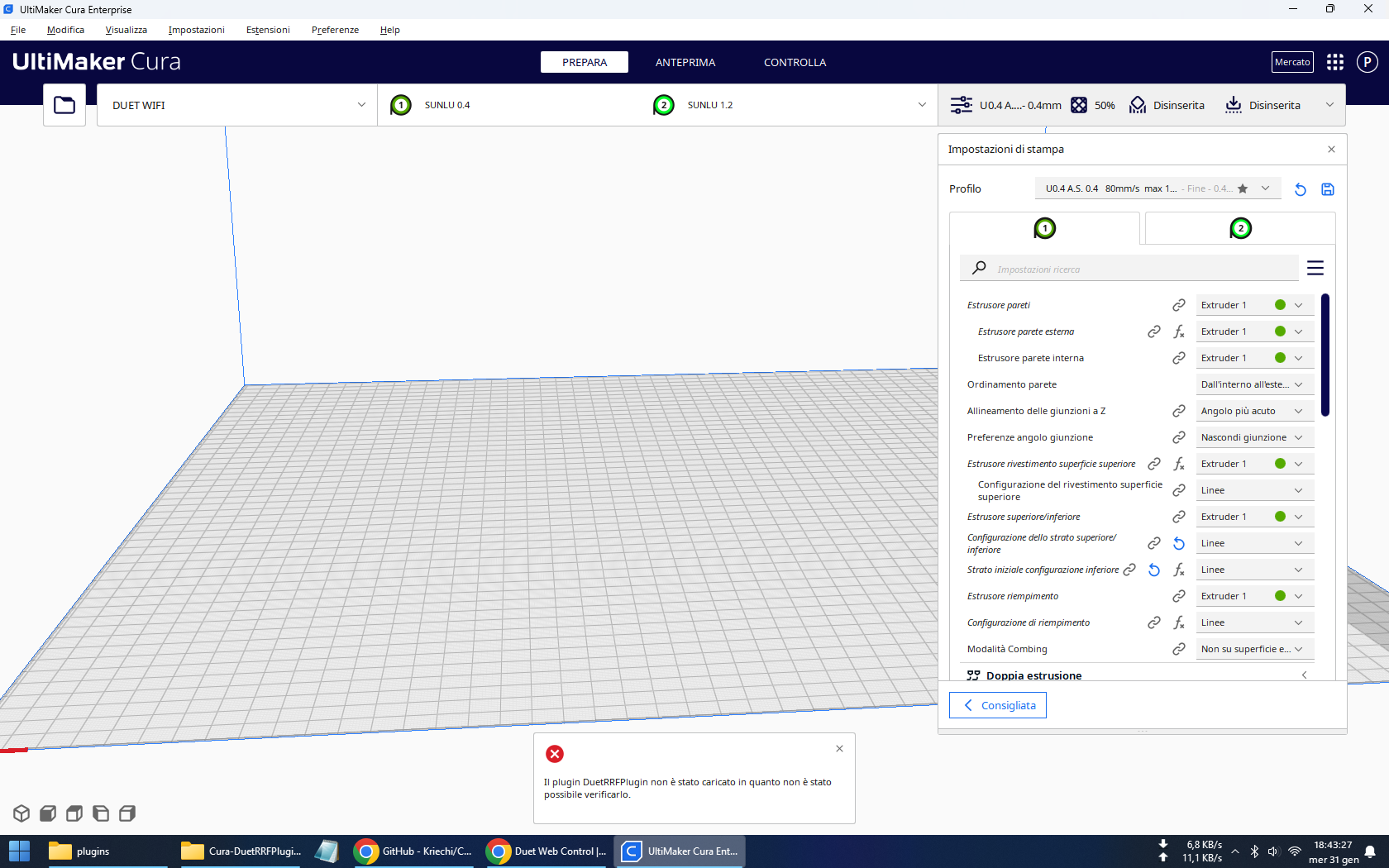

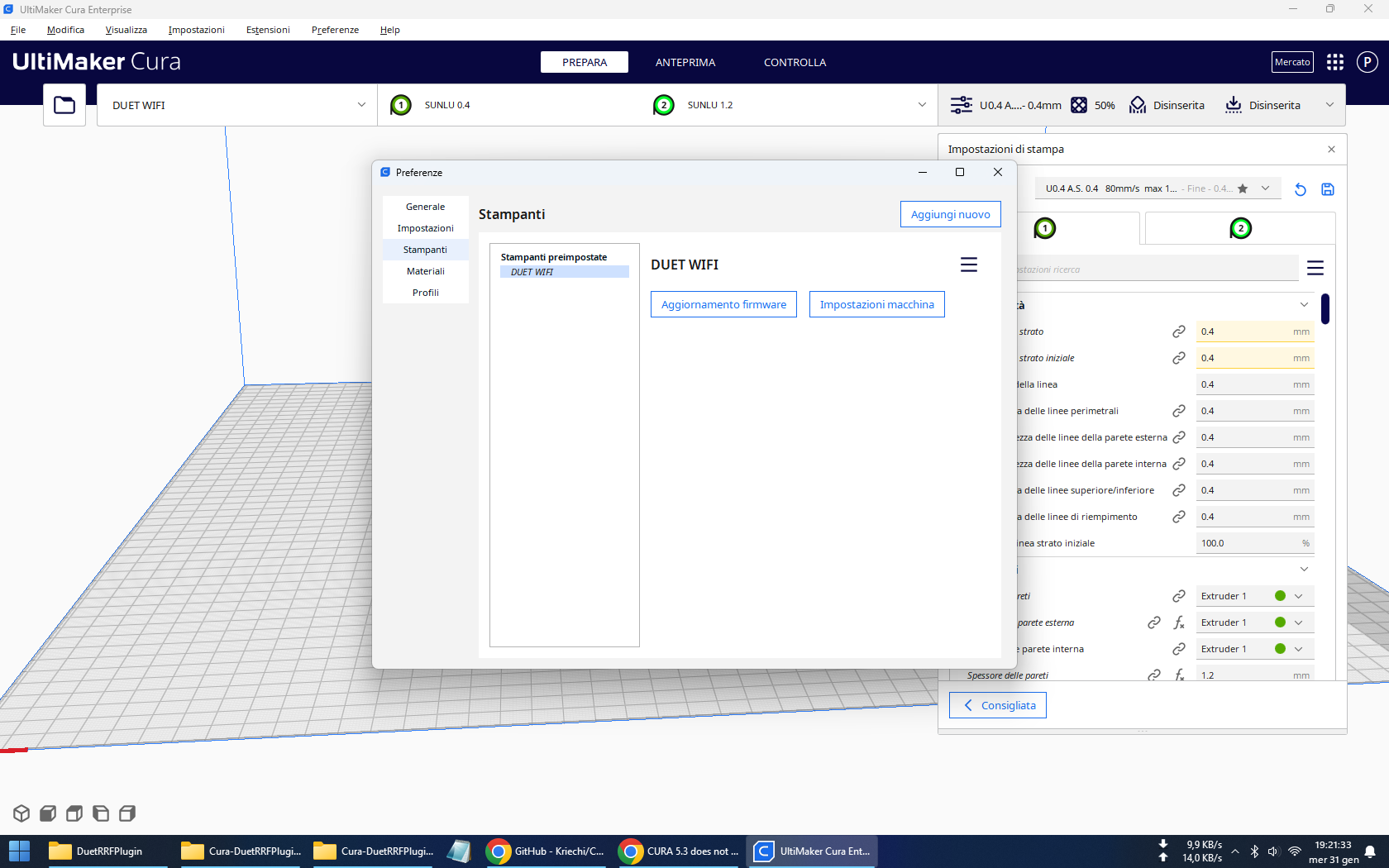

RE: plugin DuetRff ultimaker curaposted in Duet Web Control

@droftarts I also tried the other older plugins but the problem persists, the version I have, if you noticed, is the interprise; from the Street shot However, I repeat even with older versions of plugins and the problem remains

-

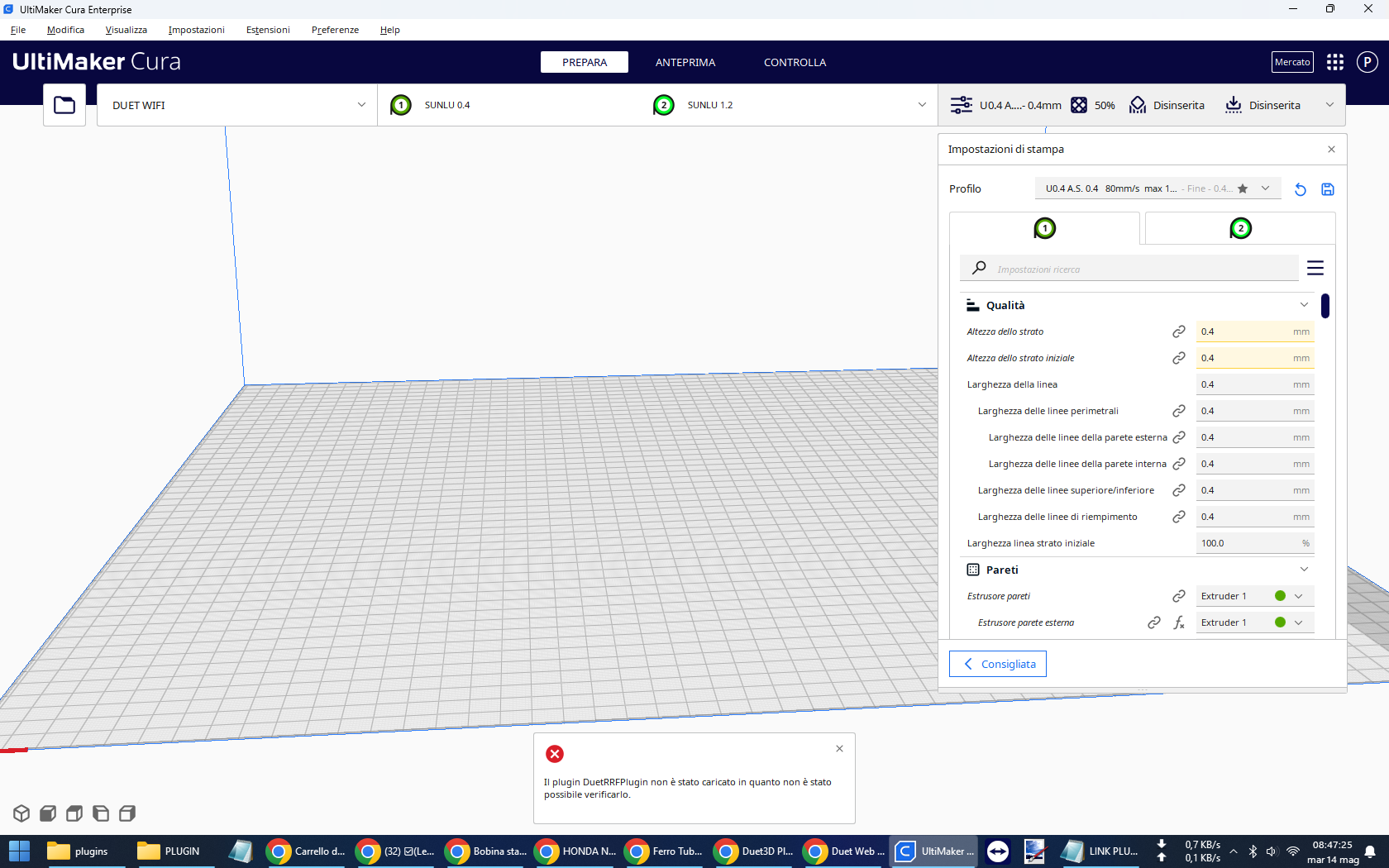

plugin DuetRff ultimaker curaposted in Duet Web Control

@dc42

I tried all the plugins but none of them work with version 5.3. How can you solve the problem, thanks

-

RE: CURA 5.3 does not load the pluginposted in Third-party software

@Phaedrux I also changed the cure versions but nothing to do. Thanks

-

CURA 5.3 does not load the pluginposted in Third-party software

@Phaedrux Can anyone help me I installed cura 5.3 and I installed the 1.2.10 plugin but it tells me that it could not be loaded because it is not possible to configure it and I also tried 1.2.9 and I tried many older versions up to 1.2.4

-

RE: instant extruder speedposted in Duet Web Control

@T3P3Tony said in instant extruder speed:

@paolozampini1973 unfortunately not, this display relies on information from the newer firmware.

OK

-

RE: instant extruder speedposted in Duet Web Control

@droftarts said in instant extruder speed:

@paolozampini1973 It has been added to RRF, I think it is this: https://github.com/Duet3D/RepRapFirmware/wiki/Changelog-RRF-3.x-Beta#reprapfirmware-350beta1

Added floating point field move.currentMove.extrusionRate (returns the current total extrusion rate in mm/sec)

We are testing internally a version of DWC 3.5b1 that shows volumetric flow:

But you should be able to see it through the Object Model.

Ian

it is possible to have only the upgrade of the instantaneous volumetric part of the extruder and without upgrading all the firmware because I don't want to have problems and by the way everything works fine now

-

RE: instant extruder speedposted in Duet Web Control

@droftarts said in instant extruder speed:

@paolozampini1973 It has been added to RRF, I think it is this: https://github.com/Duet3D/RepRapFirmware/wiki/Changelog-RRF-3.x-Beta#reprapfirmware-350beta1

Added floating point field move.currentMove.extrusionRate (returns the current total extrusion rate in mm/sec)

We are testing internally a version of DWC 3.5b1 that shows volumetric flow:

But you should be able to see it through the Object Model.

Ian

GRAZIE

-

RE: instant extruder speedposted in Duet Web Control

@Phaedrux said in instant extruder speed:

@paolozampini1973 It is available now.

https://github.com/Duet3D/RepRapFirmware/releases/tag/3.5.0beta1

Thanks for the information. Here I understand that the instantaneous extruder velocity function has not been added as @dc42 said

-

RE: instant extruder speedposted in Duet Web Control

@dc42 said in instant extruder speed:

@paolozampini1973 I hope to release 3.5beta1 next week. It's currently in the testing and bug fixing phase.

Good morning when will firmware version firmware 3.5beta1 be available ?

-

RE: Spindle nema 34 duet 2 wifiposted in CNC

@oliof said in Spindle nema 34 duet 2 wifi:

@paolozampini1973 Duet2Wifi will not be able to fit new features due to space constraints.

thanks for the answer can it be clearer please Thanks

-

RE: UPDATE VFD TO NEMAposted in General Discussion

@jay_s_uk said in UPDATE VFD TO NEMA:

@paolozampini1973 what @Falcounet said. And the firmware doesn't support continuous rotational axis. And you can't move an axis that isn't in sync with others

Thanks for your answer

-

RE: Spindle nema 34 duet 2 wifiposted in CNC

@dc42 said in Spindle nema 34 duet 2 wifi:

@paolozampini1973 @CNCModeller if there is enough interest then I can look at providing the option to run a stepper motor as a spindle in a future version of RRF. However, it's likely to be a Duet 3 feature only because of lack of flash memory on Duet 2.

reading on the forum I saw that there are people particularly interested in the DUET 2 WiFi As for removing plastics with a cutter, I have a lot of experience and also with turning, over time I have understood that high speed has many disadvantages It is better to work at low speed with some strategies you can achieve excellent results without lengthening the times excessively

-

RE: Spindle nema 34 duet 2 wifiposted in CNC

@dc42 said in Spindle nema 34 duet 2 wifi:

Will a stepper motor provide sufficient speed and torque? Stepper motors are limited to a few revs/second due to back emf.

the stepper motor provides high torque at low revs which the vfd motor does not and this brings many advantages for my experience that I have done some technical tests

-

RE: Spindle nema 34 duet 2 wifiposted in CNC

@dc42 @CNCModeller @jay_s_uk

a stepper motor can reach 3200 RPM WITHOUT step loss tests done by me personally (nema 17 , 23 , 34 ) and as we know the advantage is the maximum torque at under 500 - 800 rpm and working on the export of materials at low speed leads only advantages because:- the metal heats up little

- vibrations are very low

- high precision

- for most of the processes it requires very little lubrication and for other processes there is no need to lubricate

- working plastic parts at 200 RPM they work very well having a high torque

VFD motors WORK from 0-22000 RPM i ne or 2 types example: a 3kw at 50 Newton +or- and a 1,5kw disadvantages: - high current draw

- below 1000 rpm very low torque and does not allow to do some machining especially at 200 RPM

- it takes a lot of lubrication I'LL STOP HERE BECAUSE THERE'S SO MUCH MORE TO SAY ABOUT THE DISADVANTAGES

I CLOSE BY SAYING THAT THE LOW SPEED IS THE BEST IN THE END EVEN IF THE PROCESSING TIMES LONGER

OR I READ THAT THERE ARE NUMEROUS PEOPLE INTERESTED

I ASK TO ADD TO @DC42 THE FOLLOWING FUNCTIONSIN DUET 2 WIFI, IN ME THE MOST SUITABLE:

MILL :- AXIS FOR CONTINUOUS USE MILLING (ROTATIVE) WHICH HAS THE SAME FUNCTION AS THE VFD

LATHE: - A OR B OR C AXIS FOR THREADING AND TURNING

I'M SORRY IF I WAS LITTLE SYNTHETIC IN THE EXPLANATIONS AND THANK YOU EVERYONE FOR PARTICIPATING

@DC42 I WOULD LIKE TO HELP