@Phaedrux thanks for the help, I added the home sequence and its working fine now Also I had the drives in the wrong order so the compensation was wrong at first, too.

Posts made by Steppenleguan

-

RE: Homing failed, computed corrections exceed limitposted in General Discussion

-

Homing failed, computed corrections exceed limitposted in General Discussion

Hey guys,

I recently swapped out my dual endstops on my bed for a BL Touch - goal is to achieve ABL and getting a mesh grid of my bed.

Homing XY is working just fine, but Z Axis (I am using dual leadscrews in the middle of the bed, left&right) is making trouble. After having finished the XY home sequence, the gantry is moving to the first probing point just fine and homing with BL Touch.

It´s then moving up the bed to home the 2nd point., where after the bed descends a whole lot and homing fails.2 problems:

- The bed is descending around 75-85 mm after the first probe point (I would like to reduce that, but I can´t seem to find how)

- Homing fails: Error: Some corrupted corrections exceed configured limit of 1.0mm: -75.040 -75.380

I have a feeling that, genereally that this is only a minor problem, as the limits are only 0.3 mm apart, so I´m hoping for an easy fix.

This is the bed.g:

; bed.g ; called to perform automatic bed compensation via G32 ; ; generated by RepRapFirmware Configuration Tool v3.2.3 on Sun Apr 04 2021 15:17:44 GMT+0200 (Mitteleuropäische Sommerzeit) ;G29 ; probe the bed and enable compensation G28 ; home M561 ; clear any bed transform ;M671 P5.0 X365.0:365.0 Y3-32:762 ; Z pivot points are at (340:-32) (340:712) 712 = 680+32 G30 P0 X365.0 Y100 Z-9999 ;PROBE NEAR A Front LEADSCREW ;G1 F60000 X20 Y235 Z10 G30 P1 X365.0 Y630 Z-9999 S2 ;PROBE NEAR A Back LEADSCREWconfig.g :

M569 P0 S1 ; Drive 0 X M569 P1 S1 ; Drive 1 Y ;M569 P2 S0 ; Left z-motor (original Z) ; NOT USED M569 P3 S1 ; Drive3 [Extruder 0] - new Extruder 0 [ENABLED] M569 P4 S1 ; Drive4 [Extruder 1] - new Extruder 1 [ENABLED] M569 P5 R1 T2.5:2.5:5:5 S0 ; BreakoutBoard_Driver5 - new Z Axis || Von Steuerkiste hinten M569 P6 R1 T2.5:2.5:5:5 S0 ; BreakoutBoard_Driver7 - new Z Axis || Von Steuerkiste vorne ; M569 P7 S1 ; Extruder2 - Physical Tool 2 ; M569 P8 S1 ; Extruder3 - Physical Tool 3 ; M569 P9 S1 ; Extruder4 - Physical Tool 4 M584 E3 E4 ; set drive mapping Driver Extruder 3, Extruder 4 M584 X0 Y1 Z5:6 P3 ; set drive mapping Driver 0 For X, 1 for Y, Z 5:7, with 4 Axis (exkl. Extruders) visible in UI ;M671 P5.0 X0:700 Y0:700 S2.5 ; leadscrews at left (connected to Z) and right (connected to E1) of X axis M671 P5.0 X365.0:365.0 Y-32:762 S1; Z pivot points ; Z-Probe M574 Z2 S2 P"bltouch" ; Z min active high endstop z-probe M950 S0 C"!exp.heater7" ; create servo pin 0 for BLTouch on Duet 2 Wifi + Expansion Board M558 P9 C"^zprobe.in" H5 F120 T6000 ; set Z probe type to bltouch and the dive height + speeds G31 P500 X43 Y-47.8 Z3.36 ; set Z probe trigger value, offset and trigger height ;M557 X20:710 Y20:710 S20 ; define mesh gridhomez.g:

G91 ; relative position G1 Z9 F6000 S2 ; lower z by 9 G90 ; absolute position G30 P0 X365 Y100 Z-9999 ; probe point 0 near a leadscrew G30 P1 X365 Y630 Z-9999 S2; probe point 1 near a leadscrew ;G1 Z-15 F5000 ; raise z to 15 G90 ; absolute positioningThanks for your help. I genereally understand the problem of the 2 axis not being able to compensate for 75 mm each, but in this case it doesn´t make any sense to me, as the bed is pretty level already.

-

RE: Independent dual z axis with endstops - z homing not workingposted in Using Duet Controllers

@knuxvomica no they don´t.

Current state: G28 homing failed , and nothing happens

Before with a homez.g: The axis lifts 5mm, moves down then passes! the endstops and hits my frame when I don´t emergency stop...As you can see I am using the M564 command to test the axis movements in advance (which works fine) but obviously I don´t have any homing , i.e. no printing possible

M564 H0 ;move without homing -

RE: Independent dual z axis with endstops - z homing not workingposted in Using Duet Controllers

Here is the full config.g:

; Configuration file for Duet WiFi (firmware version 3) ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v3.2.3 on Sun Apr 04 2021 15:17:44 GMT+0200 (Mitteleuropäische Sommerzeit) ;References ; -------------> https://docs.duet3d.com/en/User_manual/Reference/Gcodes <------------- M911 S21.0 R23.0 P"M913 X0 Y0 G91 M83 G1 Z5:6 E-3:4 F1000" ; Power Loss || Drives noch Anpassen ; sys/ressurect-prologue.g noch anlegen ; General preferences G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"Print Eastwood" ; set printer name M669 K1 ; select CoreXY mode ; Network M552 S1 ; enable network M586 P0 S1 ; enable HTTP M586 P1 S0 ; disable FTP M586 P2 S0 ; disable Telnet M564 H0 ;move without homing ; Define Drives M569 P0 S1 ; Drive 0 X M569 P1 S1 ; Drive 1 Y ;M569 P2 S0 ; Left z-motor (original Z) ; NOT USED M569 P3 S1 ; Drive3 [Extruder 0] - new Extruder 0 [ENABLED] M569 P4 S1 ; Drive4 [Extruder 1] - new Extruder 1 [ENABLED] M569 P5 R1 T2.5:2.5:5:5 S1 ; BreakoutBoard_Driver5 - new Z Axis Left M569 P7 R1 T2.5:2.5:5:5 S1 ; BreakoutBoard_Driver7 - new Z Axis Right M584 E3 E4 ; set drive mapping Driver Extruder 3, Extruder 4 M584 X0 Y1 Z5:7 P3 ; set drive mapping Driver 0 For X, 1 for Y, Z 5:7, with 4 Axis (exkl. Extruders) visible in UI M671 X-20:820 Y400:400 S2.5 ; leadscrews at left (connected to Z) and right (connected to E1) of X axis M350 X16 Y16 Z16:16 E16:16 I1 ; configure microstepping with interpolation - enable microstepping ich weiß gar nicht ob mehr als 16 überhaupt geht.... M92 X640 Y640 Z3200:3200 E3360:3440 ; set steps per mm M566 X500 Y500 Z20:20 E1500:1500 ; set maximum instantaneous speed changes (mm/min) [Jerk] M203 X30000 Y30000 Z420:420 E12000:12000 ; Set maximum speeds (mm/min) M201 X2500 Y2500 Z300:300 E2000:2000 ; Set accelerations (mm/s^2) M906 X2000 Y2000 E500:500 I30 ; set motor currents (mA) and motor idle factor in per cent M84 S60 ; Set idle timeout ; Axis Limits M208 X0 Y0 Z0 S1 ; set axis minima M208 X780 Y780 Z650 S0 ; set axis maxima ; Endstops M574 X1 S1 P"xstop" ; configure active-high endstop for low end on X via pin xstop M574 Y1 S1 P"ystop" ; configure active-high endstop for low end on Y via pin ystop M574 Z1 S1 P"e1stop+e0stop" ; configure active-low endstops for low end on Z via pins e1stop and e0stop ;M574 Z1 U1 S0 ; Set active low endstops DUAL Z ;M558 P0 X0 Y0 Z0 H2 F60 T6000 ; Set Z probe type to switch, the axes for which it is used and the dive height + speeds || P0 = keine Z-Probe verbaut ;G31 P600 X0 Y0 Z0 ; Set Z probe trigger value, offset and trigger height ;M557 X15:195 Y15:195 S20 ; Define mesh grid ; Temp Sensors M308 S0 P"spi.cs1" Y"rtd-max31865" ; create sensor number 0 as a PT100 sensor in the first position on the Duet 2 daughter board connector // BLAU GRAU // sets extruder 1 sensor type M308 S1 P"spi.cs2" Y"rtd-max31865" ; create sensor number 1 as a PT100 sensor in the second position on the Duet 2 daughter board connector // SCHWARZ ROSA // sets extruder 2 sensor type M308 S2 P"bed_temp" Y"thermistor" T100000 B4349 ;sets bed sensor type // UNUSED ; Heaters ; Main Nozzle M950 H0 T0 C"e0heat" ; make extruder #0 heater M950 H0 C"e0heat" T0 ; create nozzle heater output on e0heat and map it to sensor 0 M307 H0 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit M143 H0 S350 ; set temperature limit for heater 0 to 350C ; Secondary Nozzle M950 H1 T1 C"e1heat" ;make extruder #1 heater M950 H1 C"e1heat" T1 ; create nozzle heater output on e1heat and map it to sensor 1 M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit M143 H1 S350 ; set temperature limit for heater 1 to 350C ; M950 H2 T2 C"bedheat" ;make bed heater ; M307 H2 B2 S1.00 ;enable bang-bang mode for the bed heater and set PWM limit ; M143 H2 S100 ;set temperature limit for heater 0 to 120C ; M140 H2 ; AirPump M950 F0 C"bedheat" Q500 ; create fan 5 on pin bedheat and set its frequency (500Hz) M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off // BerdAir Q PWM 500Hz // Fan for Printing ; Hotend Fans M950 F1 C"fan0" Q500 ; create fan 1 on pin fan0 and set its frequency M106 P1 S255 H0 T45 ; set fan 1 value. Thermostatic control is turned on // Fan for Hotend 0 M950 F2 C"fan1" Q500 ; create fan 2 on pin fan1 and set its frequency M106 P2 S255 H1 T45 ; set fan 2 value. Thermostatic control is turned on // Fan for Hotend 1 ; Fans M950 F3 C"fan3" Q500 ; create fan 3 on pin fan3 and set its frequency M106 P3 S0 H-1 ; set fan 3 value. Thermostatic control is turned off M950 F4 C"fan4" Q500 ; create fan 4 on pin fan4 and set its frequency M106 P4 S0 H-1 ; set fan 4 value. Thermostatic control is turned on ;M950 F0 C"fan0" Q500 ; create fan 0 on pin fan0 and set its frequency ;M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off ; Tools M563 P0 D0 H0 S"Main" F1 ; define tool 0 // Hotend 0 // Fan1 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C M563 P1 D1 H1 S"Secondary" F2 ; define tool 1 // Hotend 1 // p toolnr // d drivenr // h heaternr // f fannr // Fan2 G10 P1 X0 Y0 Z0 ; set tool 1 axis offsets , noch setzen G10 P1 R0 S0 ; set initial tool 1 active and standby temperatures to 0C ; Custom settings are not defined ; Miscellaneous M575 P1 S1 B57600 ; enable support for PanelDue ; MCU Anpassung M912 P0 S82,5 -

Independent dual z axis with endstops - z homing not workingposted in Using Duet Controllers

Hi guys, I was trying to follow the documentation on the dual independent z-axis for my printer.

My problem is, that it is not mentioned how the homez.g should look like:

this is where you can find the documentationI am using RRF3.x Firmware and I cannot home my z-axis at the moment.

This is what I am currently using in my config.g:M569 P5 R1 T2.5:2.5:5:5 S1 ; BreakoutBoard_Driver5 - new Z Axis Left M569 P7 R1 T2.5:2.5:5:5 S1 ; BreakoutBoard_Driver7 - new Z Axis Right M584 X0 Y1 Z5:7 P3 ; set drive mapping Driver 0 For X, 1 for Y, Z 5:7 M671 X-20:820 Y400:400 S2.5 ; leadscrews at left (connected to Z) and right (connected to E1) of X axis M574 Z1 S1 P"e1stop+e0stop" ; configure active-low endstops for low end on Z via pins e1stop and e0stopI am using the Duet Breakout Board and have my 2 external stepper drivers connected to the pins 5 and 7 - the corresponding endstops are wired to "e1stop&e0stop". The wiring is correct, the motors are moving and the LED is flashing, when the endstops are pressed.

This is the bed.g:

G28 ; home M401 ; deploy Z probe (omit if using bltouch) G30 P0 X20 Y400 Z-99999 ; probe near a leadscrew, half way along Y axis || P = Probe Number G30 P1 X780 Y400 Z-99999 S2 ; probe near a leadscrew and calibrate 2 motors M402 ; retract probe (omit if using bltouch)I have no clue what my homez.g should look like rn. I have had several errors and completely leaving it out won´t work either ^^ .

homeall.g:

G91 ; relative positioning G1 H1 X-805 Y-805 F3000 ; move quickly to X or Y endstop and stop there (first pass) coarse home X or Y G1 H1 X-805 ; home X axis coarse G1 H1 Y-805 ; home Y axis coarse G1 X5 Y5 F500 ; go back a few mm G1 H1 X-10 ; move slowly to X axis endstop once more (second pass) G1 H1 Y.10 ; then move slowly to Y axis endstop G90 ; absolute positioning X/Yhomez.g: [probably the main issue, also the fact, that there are like 300 different possibilities for z probing is super confusing - at least for me]

;G91 ; relative positioning ;G1 H2 Z5 F6000 ; lift Z relative to current position ;G90 ; absolute positioning ;G1 X5 Y85 F6000 ; go to first probe point ;G30 ; home Z by probing the bedThanks a lot in advance. I wouln´t write this if I hadn´t tried fixing it by myself for the last 5 hours...

I might be using a BL Touch in the future but this is a different story. -

RE: Stepper motor turns only in one directionposted in Duet Web Control

@alankilian I might have found the problem.

I checked the resistances of the 5V signal wires

from the breakout board to the stepper drivers again and I found one cable that has infinite resistance.

It seems like it is one of the dir+- cables. So that would explain why the motor is running but cannot change its director.At first I was expecting it to be the crimps or the connectors, but it appears that even with new crimps the cable is corrupted.

I'm checking in again in the evening and take a new cable, measure the resistances and hope that this solves to problem.

-

Stepper motor turns only in one directionposted in Duet Web Control

Hey folks, I am having a super weird problem with my setup rn.

I am using a Duet 2 Wifi Board with Expansion Breakout Board. My 2 Z-Axis motors (Nema 23 4.2A) are connected to a external driver (DM542T) with an external PSU. The 4 signal connectors come from the Breakout board (and the ENABLE is not connected).

As soon as I start the motion via the UI, the weirdness happens:

If I press up : both z-motors turn forward and up

If I press down: one motor turns backwards (as expected) - the other one turns in the opposite direction.I have tried the different motors on the different driver; they are wired correctly. I have tried exchanging the signal cables + reasigning different ports , and nothing changed.

Settings on the external drivers (i.e. microstepping, currents are identical)First thought: Driver must be having a problem , exchanged it - same problem again.

What could be the problem here?

I can only see some potential errors in the software but I am not aware of anything like this even being possible.

The 2 Z drives are currently connected to the drivers 5 & 7 on the Breakout Board.Config.g:

M569 P0 S1 ; Drive 0 X M569 P1 S1 ; Drive 1 Y M569 P2 S0 ; Left z-motor (original Z) ; NOT USED M569 P3 S1 ; Drive3 [Extruder 0] - new Extruder 0 [ENABLED] M569 P4 S1 ; Drive4 [Extruder 1] - new Extruder 1 [ENABLED] M569 P5 R1 T2.5:2.5:5:5 S1 ; BreakoutBoard_Driver5 - new Z Axis Left M569 P7 R1 T2.5:2.5:5:5 S1 ; BreakoutBoard_Driver7 - new Z Axis Right ; M569 P7 S1 ; Extruder2 - Physical Tool 2 ; M569 P8 S1 ; Extruder3 - Physical Tool 3 ; M569 P9 S1 ; Extruder4 - Physical Tool 4 M584 E3 E4 ; set drive mapping Driver Extruder 3, Extruder 4 M584 X0 Y1 Z5:7 P4 ; set drive mapping Driver 0 For X, 1 for Y, Z 5:7, with 4 Axis (exkl. Extruders) visible in UI M350 X16 Y16 Z16:16 E16:16 I1 ; configure microstepping with interpolation - enable microstepping ich weiß gar nicht ob mehr als 16 überhaupt geht.... M92 X640.00 Y640.00 Z3200:3200 E3360:3440 ; set steps per mm M566 X500.00 Y500.00 Z20.00:20.00 E1500:1500 ; set maximum instantaneous speed changes (mm/min) [Jerk] M203 X18000 Y18000 Z420::420 E12000:12000 ; Set maximum speeds (mm/min) M201 X1200 Y1200 Z100:100 E2000:2000 ; Set accelerations (mm/s^2) M906 X2000 Y2000 E500:500 I30 ; set motor currents (mA) and motor idle factor in per cent M84 S60 ; Set idle timeoutI appreciate your help! Also I don´t really know a fitting Category for this...

-

RE: Where is the MCU locatedposted in Duet Hardware and wiring

@engikeneer as I said, I calibrated it this morning. The Temp showed neg. 59 Deg. so I had to change the value by 80,5 but thats too much I assume!

-

RE: Where is the MCU locatedposted in Duet Hardware and wiring

@luke-slaboratory yes the whole electronics are placed in a box. But it has the PCU fan AND 2 80mm EWM Pabst fans that are permanently running.

-

RE: Where is the MCU locatedposted in Duet Hardware and wiring

@bot ah , so the ATMEL ARM XYZ Chip. Thx! So thats truely a calibration problem. The measured temp is 27 C. I was wondering alreadz as there is neither a print nor eny steppers running.

-

Where is the MCU locatedposted in Duet Hardware and wiring

I assume MCU is short for motor control unit?

I think i have a problem with the calibration, but the Temperature showed 108 C on the Web Interface. I saw a post online saying, that the limit was 85 C so I halted the system. I have a thermostate on hand so I can check the real temperature of the components. But i need to find out where the MCU is located on the DUET 2 WIFI. Thx -

RE: V_Fan does not match V_Inposted in Duet Hardware and wiring

@fulg do you know what the problem might be when it comes to the 5v? I mean it's working there obvs. Also I could just use the FAN_IN to supply the 24V there but I don't want to take the risk of lighting up the house.

Also the board is a clone. Maybe it's due to poor product quality.

Do you have any more tips of how I can measure everything just to be safe?

I found something about a "fan fuse 1A". I hardly think it's the reason, but might be that fuse one of the problems?Sadly I cannot really go without the fans or power them otherwise because I am planning on using an air pump cooling system which needs the pwm etc.

-

RE: V_Fan does not match V_Inposted in Duet Hardware and wiring

@fulg thanks for the answer. So fan 3 and 4 are of course not needed, I didn't know that, but as I said, I was just testing because I couldn't get the results I wanted.

The wiring is definitely correct. I have used the bucks multiple times on other printers and they have not yet let me down.

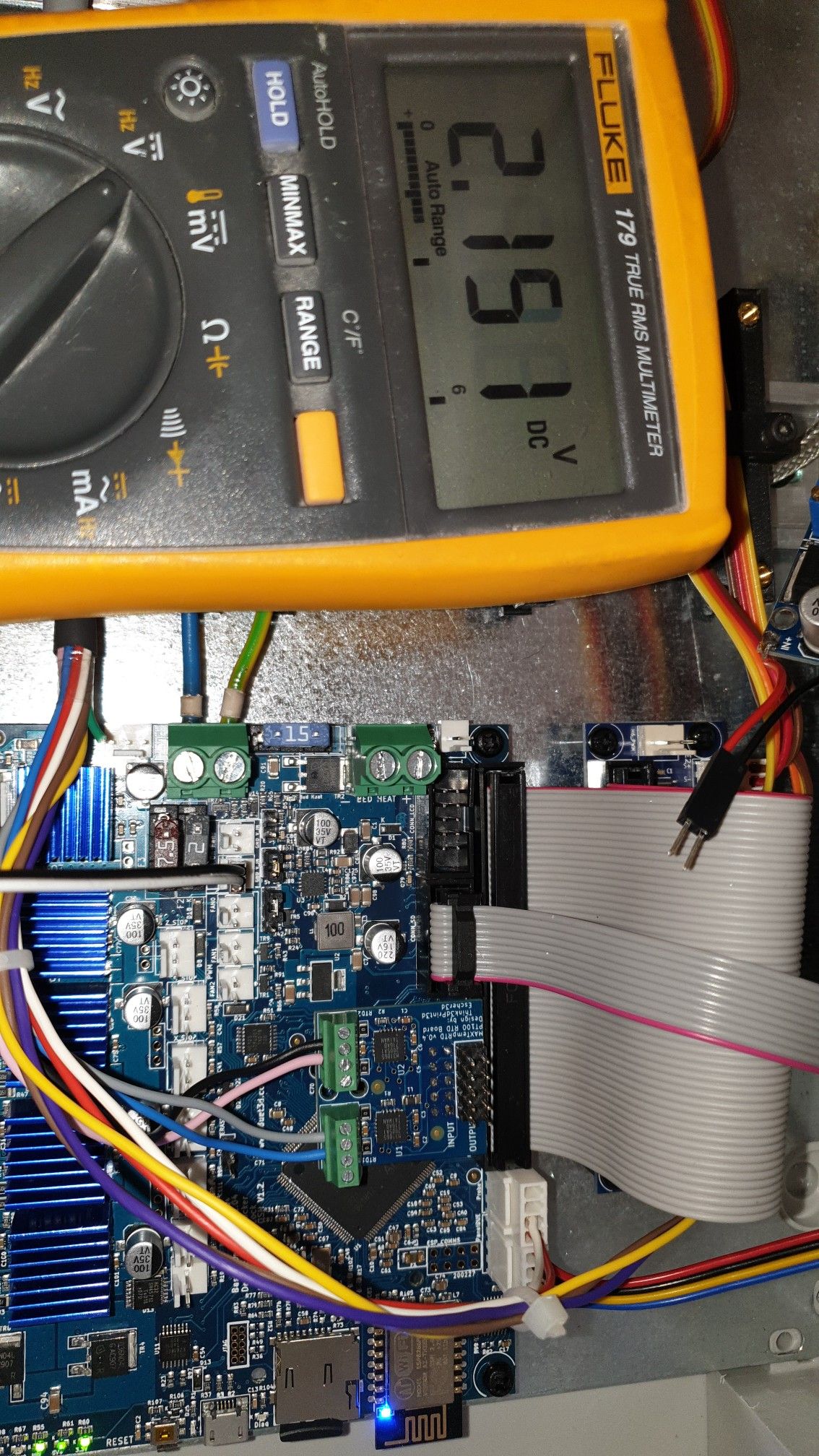

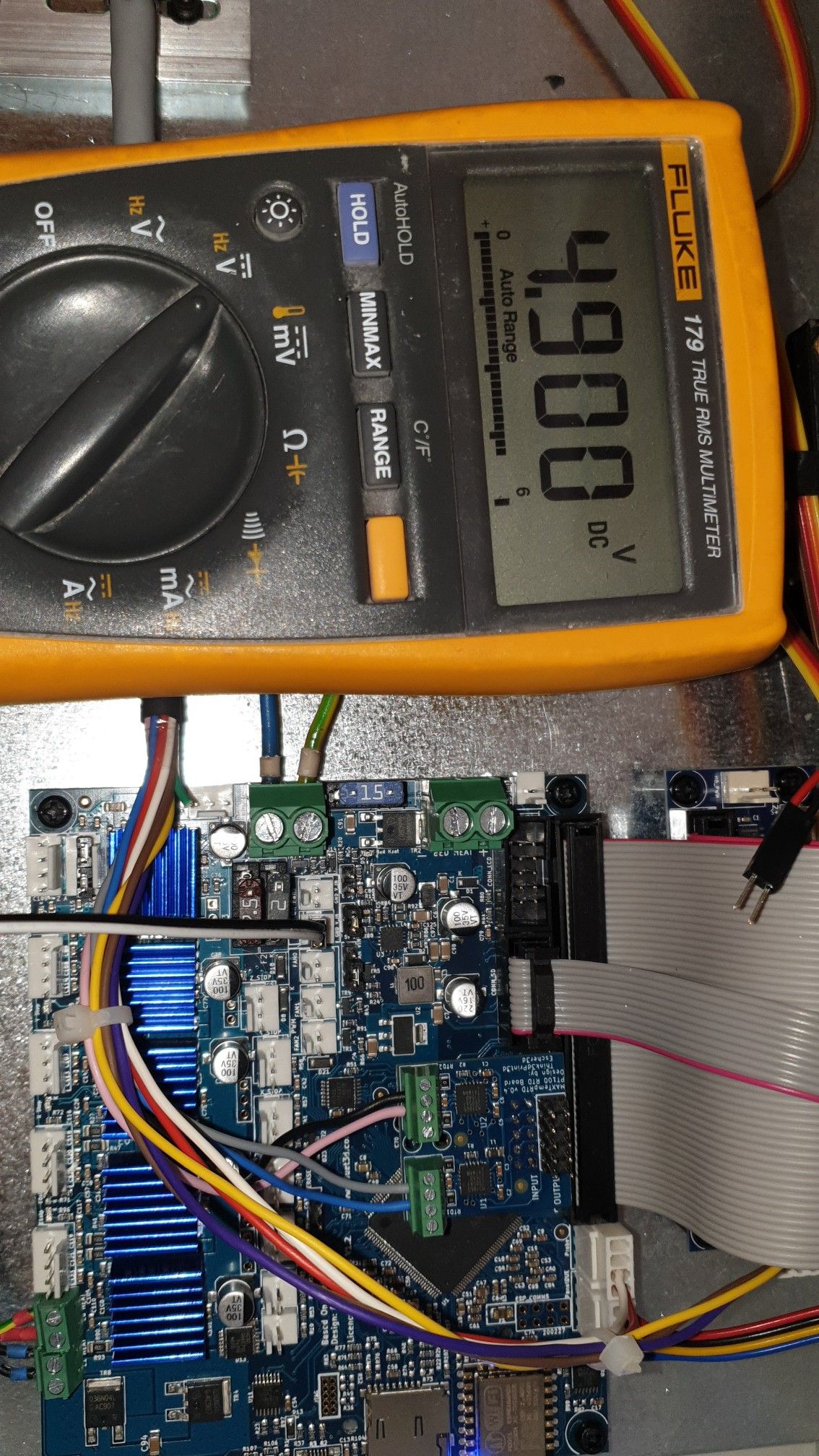

I took 2 photos with the different positions for the jumper so you can see what I am talking about. V_IN from the main supply is 24.1V, so no problem there (btw no difference between the always on fans or the temp fans when it comes to voltage)!

-

V_Fan does not match V_Inposted in Duet Hardware and wiring

So I´m currently trying to add some fans to my hotend and the power case.

I have some 12V EBM Pabst fans with a DC Buck that i am using (as always on fans) and some 24V 30mm fans for the hotend.

I have been measuring the voltage of the V_FAN and it appears i am stuck to having 2,1 -2,2 V, which is super weird as i was expecting to have permanent 24V (at the always on pins).

As soon as i switch the jumpers i am getting some clean 4,9V output.I´m not entirely sure how an impelmentation in the software should look like, but i used the standard code as a reference and came up with this:

; Fans M950 F0 C"fan0" Q500 ; create fan 0 on pin fan0 and set its frequency M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off M950 F1 C"fan1" Q500 ; create fan 1 on pin fan1 and set its frequency M106 P1 S1 H1 T45 ; set fan 1 value. Thermostatic control is turned on M950 F2 C"fan2" Q500 ; create fan 2 on pin fan2 and set its frequency M106 P2 S1 H1 T45 ; set fan 2 value. Thermostatic control is turned on M950 F3 C"fan3" Q500 ; create fan 3 on pin fan3 and set its frequency M106 P3 S0 H-1 ; set fan 3 value. Thermostatic control is turned off M950 F4 C"fan4" Q500 ; create fan 4 on pin fan4 and set its frequency M106 P4 S0 H-1 ; set fan 4 value. Thermostatic control is turned onI am not sure about the frequency etc, but as this is only a test, I thought I´d simply use the standard value.

Please let me know if you see any big mistakes.

[The firmware comes more or less straight out of the config file, as it needed to be reset due to a corrupted wifi setup]M115 FIRMWARE_NAME: RepRapFirmware for Duet 2 WiFi/Ethernet FIRMWARE_VERSION: 3.2.2 ELECTRONICS: Duet WiFi 1.02 or later FIRMWARE_DATE: 2021-02-11 -

RE: Duet2 + Breakout Board with external stepper driverposted in Duet Hardware and wiring

@droftarts Sorry, here, the M122. The system is moving by now. I just left out the resistor on the PUL+ and it worked. The speed is a bit lackluster and the homing doesn´t yet work, but ill find out tomorrow. Up until now, thanks a lot for your help!

You will also find homeall.g and homez.gM122 === Diagnostics === RepRapFirmware for Duet 2 WiFi/Ethernet version 3.2.2 running on Duet WiFi 1.02 or later Board ID: 08DJM-9178L-L2MS8-6J9DJ-3S46S-TVHUN Used output buffers: 3 of 24 (20 max) === RTOS === Static ram: 23460 Dynamic ram: 73604 of which 24 recycled Never used RAM 14992, free system stack 191 words Tasks: NETWORK(ready,217) HEAT(blocked,322) MAIN(running,449) IDLE(ready,20) Owned mutexes: WiFi(NETWORK) === Platform === Last reset 00:01:06 ago, cause: power up Last software reset at 2021-03-04 15:53, reason: User, GCodes spinning, available RAM 14992, slot 1 Software reset code 0x0003 HFSR 0x00000000 CFSR 0x00000000 ICSR 0x00400000 BFAR 0xe000ed38 SP 0x00000000 Task MAIN Freestk 0 n/a Error status: 0x00 Aux0 errors 8,8,8 MCU temperature: min 29.0, current 31.4, max 31.8 Supply voltage: min 23.9, current 24.0, max 24.1, under voltage events: 0, over voltage events: 0, power good: yes Driver 0: position 0, standstill, SG min/max not available Driver 1: position 0, standstill, SG min/max not available Driver 2: position 0, standstill, SG min/max not available Driver 3: position 0, standstill, SG min/max not available Driver 4: position 0, standstill, SG min/max not available Driver 5: position 0 Driver 6: position 0 Driver 7: position 0 Driver 8: position 0 Driver 9: position 0 Driver 10: position 0 Driver 11: position 0 Date/time: 2021-03-04 19:58:05 Cache data hit count 79494073 Slowest loop: 7.99ms; fastest: 0.21ms I2C nak errors 0, send timeouts 0, receive timeouts 0, finishTimeouts 0, resets 0 === Storage === Free file entries: 10 SD card 0 detected, interface speed: 20.0MBytes/sec SD card longest read time 10.2ms, write time 0.0ms, max retries 0 === Move === DMs created 83, maxWait 0ms, bed compensation in use: none, comp offset 0.000 === MainDDARing === Scheduled moves 0, completed moves 0, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1 === AuxDDARing === Scheduled moves 0, completed moves 0, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1 === Heat === Bed heaters = 0 -1 -1 -1, chamberHeaters = -1 -1 -1 -1 === GCodes === Segments left: 0 Movement lock held by null HTTP is idle in state(s) 0 Telnet is idle in state(s) 0 File is idle in state(s) 0 USB is idle in state(s) 0 Aux is assembling a command in state(s) 0 Trigger is idle in state(s) 0 Queue is idle in state(s) 0 LCD is idle in state(s) 0 Daemon is idle in state(s) 0 Autopause is idle in state(s) 0 Code queue is empty. === Network === Slowest loop: 30.24ms; fastest: 0.00ms Responder states: HTTP(0) HTTP(0) HTTP(0) HTTP(0) FTP(0) Telnet(0), 0 sessions HTTP sessions: 1 of 8 - WiFi - Network state is active WiFi module is connected to access point Failed messages: pending 0, notready 0, noresp 0 WiFi firmware version 1.25 WiFi MAC address 98:f4:ab:d1:e4:90 WiFi Vcc 3.40, reset reason Turned on by main processor WiFi flash size 4194304, free heap 25784 WiFi IP address 192.168.2.125 WiFi signal strength -59dBm, mode 802.11n, reconnections 0, sleep mode modem Clock register 00002002 Socket states: 0 0 0 0 0 0 0 0Homeall

; homeall.g ; called to home all axes ; ; generated by RepRapFirmware Configuration Tool v3.2.3 on Sun Feb 28 2021 15:17:04 GMT+0100 (Mitteleuropäische Normalzeit) G91 ; relative positioning M584 Z2 ; Split Z into 2 (Z+U) G1 Z250 U250 F2000 H1 ; Move up to 250mm in the +Z direction. S1 to stop if endstop is triggered G1 H1 X-805 Y-805 F3600 ; move quickly to X or Y endstop and stop there (first pass) G1 H1 X-805 ; home X axis G1 H1 Y-805 ; home Y axis G1 X5 Y5 F6000 ; go back a few mm G1 H1 X-805 F360 ; move slowly to X axis endstop once more (second pass) G1 H1 Y-805 ; then move slowly to Y axis endstop ; G90 ; absolute positioning G1 Z-2 U-2 F600 H2 ; Move 2mm in the -Z direction - (I'm not sure what S2 is for?) G1 Z+3 U+3 F100 H1 ; Move slowly 3mm in the +Z direction, stopping at the homing switch M584 Z5:6 ; Join U to Z again (pay attention to drive numbers used) G1 Z-5 F3000 ; Move back again 5mm in the -Z direction G90 ; Back to absolute mode ; Uncomment the following lines to lift Z after probing ;G91 ; relative positioning ;G1 Z5 F100 ; lift Z relative to current position ;G90 ; absolute positioningHomez

; homez.g ; called to home the Z axis ; ; generated by RepRapFirmware Configuration Tool v3.2.3 on Sun Feb 28 2021 15:17:04 GMT+0100 (Mitteleuropäische Normalzeit) G91 ; Relative mode M584 Z2 ; Split Z into 2 (Z+U) G1 Z250 U250 F2000 H1 ; Move up to 250mm in the +Z direction. S1 to stop if endstop is triggered G1 Z-2 U-2 F600 H2 ; Move 2mm in the -Z direction - (I'm not sure what S2 is for?) G1 Z3 U3 F100 H1 ; Move slowly 3mm in the +Z direction, stopping at the homing switch M584 Z5:6 ; Join U to Z again (pay attention to drive numbers used) G1 Z-5 F3000 ; Move back again 5mm in the -Z direction G90 ; Back to absolute modeIt also says it couldn´t find 0:/filaments , does this mean i should add a folder on the SD card with that name?

-

RE: Duet2 + Breakout Board with external stepper driverposted in Duet Hardware and wiring

Do you mean this one? https://betrue3d.dk/duet-wifieth-use-m584-to-autolevel-or-sync-z-axis-using-2-or-more-motors/

I can see quite a lot of issues and errors with that guide. If you have your Z motors connected to different stepper motor drivers, then use our guide: https://duet3d.dozuki.com/Wiki/Bed_levelling_using_multiple_independent_Z_motorsYes, i was using this guide. At least his guide was understandable for a non gcode and native english speaker

I know i have a lot of finetuning to do, but you can find the config.g for this project here:; Configuration file for Duet WiFi (firmware version 3) ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v3.2.3 on Sun Feb 28 2021 15:17:04 GMT+0100 (Mitteleuropäische Normalzeit) ; General preferences G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"R2-3D2" ; set printer name M669 K1 ; select CoreXY mode ; Network M552 S1 ; enable network M586 P0 S1 ; enable HTTP M586 P1 S0 ; disable FTP M586 P2 S0 ; disable Telnet ; Define Drives ; Physical Drive connection M569 P0 S1 ; Drive 0 X M569 P1 S1 ; Drive 1 Y ; M569 P2 S0 ; Left z-motor (original Z) M569 P3 S0 ; Drive3 [Extruder 1] - new Extruder 1 [ENABLED] M569 P4 S0 ; Drive4 [Extruder 2] - new Extruder 2 [ENABLED] M569 P5 R1 T2:2:10:10 S0 ; Extruder0 - BreakoutBoard_Driver5 - new Z Axis Left M569 P6 R1 T2:2:10:10 S0 ; Extruder1 - BreakoutBoard_Driver6 - new Z Axis Right ;Pnnn Motor driver number ;Snnn Direction of movement of the motor(s) attached to this driver: 0 = backwards, 1 = forwards (default 1) ;Rnnn Driver enable polarity: 0 = active low, 1 = active high, -1 = driver is always disabled and is not monitored (default 0) ;Tnnn (firmware 1.14 and later) Minimum driver step pulse width and interval in microseconds ;Taa:bb:cc:dd (firmware 1.21 and later) Minimum driver step pulse width, step pulse interval, direction setup time and direction hold time, in microseconds ;Dnn (firmware 2.0 and later, only applies to TMC2660, TMC22xx, TMC2160, TMC5160 and TMC5161 stepper drivers) Driver mode: 0=constant off time, 1=random off time, 2=spread cycle, 3=stealthChop or stealthChop2 ;mode 3 for TMC22xx/TMC2160/TMC516x only). The default is spreadCycle for TMC2660, TMC2160 and TMC516x drivers, and stealthChop2 for TMC22xx. ;In stealthChop mode the drivers will switch over to spreadCycle automatically at high speeds, see the V parameter. ;Fnn (firmware 2.02 and later) Off-time in the chopper control register, 1 to 15 ;Cnnnn (firmware 2.0 and later, only applies to TMC2660, TMC22xx, TMC2160 and TMC516x stepper drivers) Lowest 17 bits of the chopper control register value. ;Bnn (firmware 2.02 and later) Blanking time (tbl) in the chopper control register, 0 to 3. See the TMC driver datasheet. ;Hnn (firmware 2.02 and later) thigh parameter for those stepper driver chips that support it, e.g. TMC5160 and TMC2160. Send M569 P# (where # is the driver number) with no additional parameters to see how this ,translates into mm/sec. See also the V parameter. ;Yaa:bb or Yaa:bb:cc (firmware 2.02 and later) Hysteresis start, end and decrement values in the chopper control register. See the TMC driver datasheet for the meaning. ;Vnnn (firmware 2.02 and later) tpwmthrs parameter for those stepper driver chips that support it. This is the interval in clock cycles between 1/256 microsteps below which the drivers will switch from stealthChop ;to to spreadCycle mode. Only applies when the driver is configured in stealthChop mode. Typical value are from 100 (high speed) to 4000 (low speed). Send M569 P# (where # is the driver number) with no additional ;parameters to see how this translates into mm/sec. ; M569 P7 S1 ; Extruder2 - Physical Tool 2 ; M569 P8 S1 ; Extruder3 - Physical Tool 3 ; M569 P9 S1 ; Extruder4 - Physical Tool 4 M584 X0 Y1 Z5:6 E3:4 P3 ; set drive mapping Driver 0 For X, 1 for Y, Z=5:6, Extruder 3:4 ; M671 X-20:220 Y0:0 S0.5 ; leadscrews at left (connected to Z) and right (connected to E1) of X axis ; copied from guide M350 X16 Y16 E16:16 I1 ; configure microstepping with interpolation M92 X80.00 Y80.00 M92 Z800:800 ; set steps per mm E92 E400:400 M566 X6000.00 Y6000.00 Z60.00:60.00 U60.00 E120.00:120.00 ; set maximum instantaneous speed changes (mm/min) M203 X30000.00 Y30000.00 Z1000:1000 U1000 E1800.00:1800.00 ; set maximum speeds (mm/min) M201 X5000.00 Y5000.00 Z250:00:250.00 U250.00 E250:250 ; set accelerations (mm/s^2) M906 X2000 Y2000 I0 ; set motor currents (mA) and motor idle factor in per cent M906 E800:800 I50 M84 S30 ; Set idle timeout ; Axis Limits M208 X0 Y0 Z0 S1 ; set axis minima M208 X800 Y800 Z760:760 S0 ; set axis maxima ; Endstops M574 X1 S1 P"xstop" ; configure active-high endstop for low end on X via pin xstop M574 Y1 S1 P"ystop" ; configure active-high endstop for low end on Y via pin ystop M574 Z2 S1 P"e0stop" M574 Z1 S2 ; configure Z-probe endstop for low end on Z ; Z-Probe M950 S0 C"exp.heater7" ; create servo pin 0 for BLTouch M558 P9 C"^zprobe.in" H5 F120 T6000 ; set Z probe type to bltouch and the dive height + speeds G31 P500 X0 Y0 Z2.5 ; set Z probe trigger value, offset and trigger height M557 X15:785 Y15:785 S20 ; define mesh grid ; Heaters M308 S0 P"bedtemp" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin bedtemp M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0 M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit M140 H0 ; map heated bed to heater 0 M143 H0 S180 ; set temperature limit for heater 0 to 180C M308 S1 P"spi.cs1" Y"rtd-max31865" ; configure sensor 1 as thermocouple via CS pin spi.cs1 M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1 M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit M143 H1 S400 ; set temperature limit for heater 1 to 400C M308 S2 P"spi.cs2" Y"thermocouple-max31856" ; configure sensor 2 as thermocouple via CS pin spi.cs2 M950 H2 C"e1heat" T2 ; create nozzle heater output on e1heat and map it to sensor 2 M307 H2 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit M143 H2 S400 ; set temperature limit for heater 2 to 400C ; Fans M950 F0 C"fan0" Q500 ; create fan 0 on pin fan0 and set its frequency M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off M950 F1 C"fan1" Q500 ; create fan 1 on pin fan1 and set its frequency M106 P1 S1 H1 T45 ; set fan 1 value. Thermostatic control is turned on M950 F2 C"fan2" Q500 ; create fan 2 on pin fan2 and set its frequency M106 P2 S1 H2 T45 ; set fan 2 value. Thermostatic control is turned on ; Tools M563 P1 D0 H1 F0 ; define tool 1 G10 P1 X0 Y0 Z0 ; set tool 1 axis offsets G10 P1 R0 S0 ; set initial tool 1 active and standby temperatures to 0C ; Custom settings are not defined ; Miscellaneous M575 P1 S1 B57600 ; enable support for PanelDue M911 S10 R11 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; set voltage thresholds and actions to run on power lossand here the bed.g

; bed.g ; called to perform automatic bed compensation via G32 ; ; generated by RepRapFirmware Configuration Tool v3.2.3 on Sun Feb 28 2021 15:17:04 GMT+0100 (Mitteleuropäische Normalzeit) M561 ; clear any bed transform G29 ; probe the bed and enable compensation ;G28 ; home ;M401 ; deploy Z probe (omit if using bltouch) ;G30 P0 X20 Y100 Z-99999 ; probe near a leadscrew, half way along Y axis ;G30 P1 X180 Y100 Z-99999 S2 ; probe near a leadscrew and calibrate 2 motors ;M402 ; retract probe (omit if using bltouch) ;also copied from instructionsI don´t think the gcode in your guide is too easy to understand. Maybe you have some tips for me. For now, BL Touch is disabled, as i am missing some resistors to getting the 3.3V Signal output.

-

Duet2 + Breakout Board with external stepper driverposted in Duet Hardware and wiring

Hey guys,

i´m pretty new when it comes to duets and building printers in general but I´m currently working on a project that uses a dual z axis motors (Nema23 , 4,2A) with external stepper drivers (DM542T).

I have problems to make the motors run. I tried it with an Arduino setup and wired all neg inputs in parallel and connected it to the Arduino (also the ENA+) and it worked just fine. Sadly i cannot manage to get the integration of the drivers in the config.g file.What is the output voltage of the breakout boards PUL+ signal? The driver demands a 2k Ohms resistor with 24V signals.

Also what is the max current and e steps I should set for an external driver in the config.g ?

I used the guide of a dude named betrue3d.dk to set the z axis up, but it didn´t work.

Do i need to use things like "Taa:bb:cc:dd (firmware 1.21 and later) Minimum driver step pulse width, step pulse interval, direction setup time and direction hold time, in microseconds" value when setting up an external driver? I don´t seem to understand the instructions there.

It would be nice to get your help. Thanks!