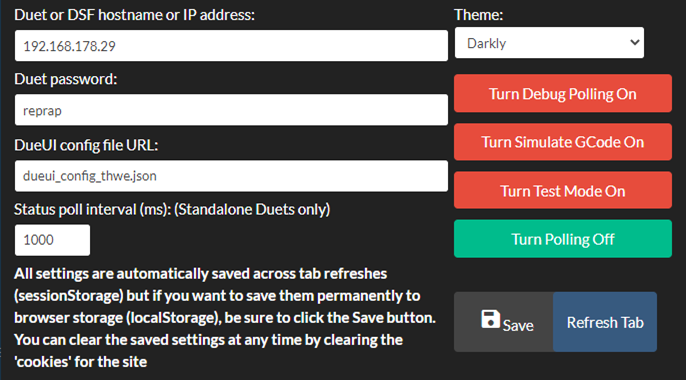

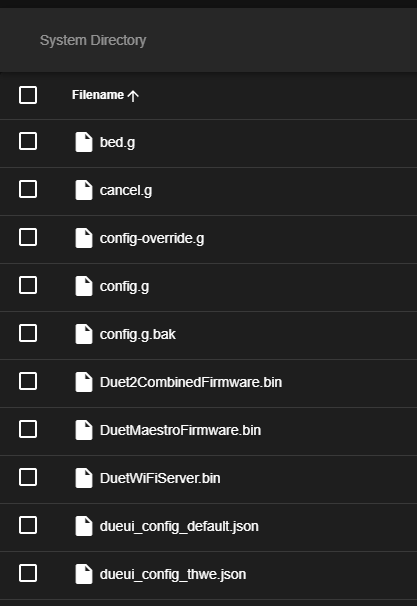

Now I could access my home network, below the files:

Attention, individual settings:

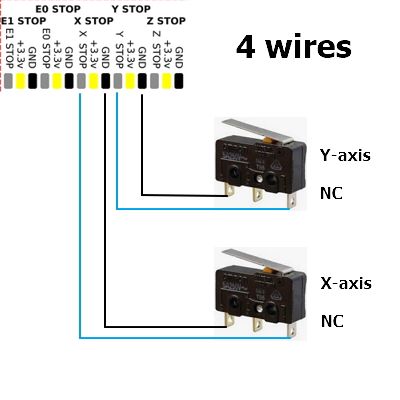

- Limit switch X -> min, Y -> min, Z -> max

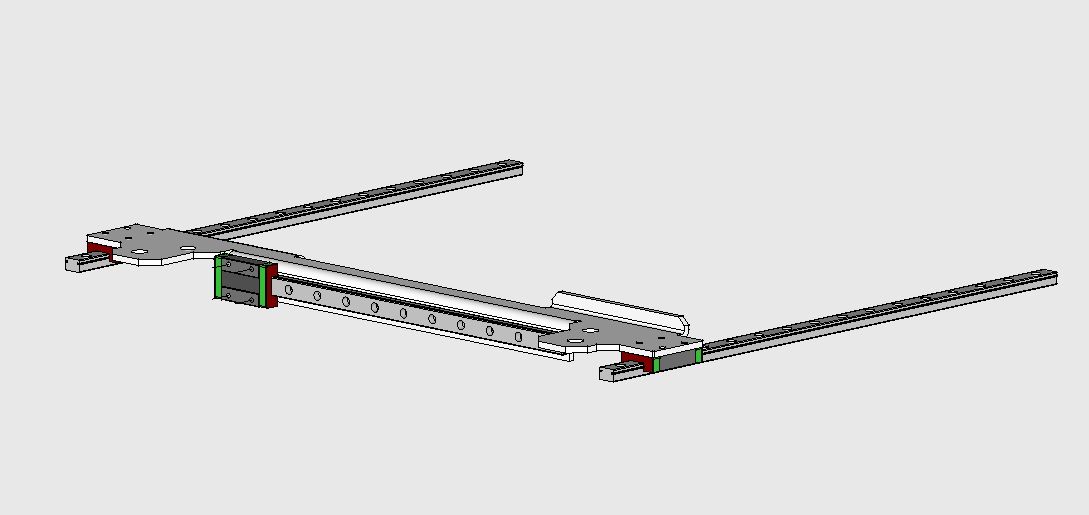

- Installation of the two limit switches as Z-MAX and and finely aligned, so that the separate positioning (line 13 in homez.g) is not necessary for me - but can be aligned in the line exactly -> thus is an automatic heights - Alignment of the two nuts of the ball screw (Z-axis) given.

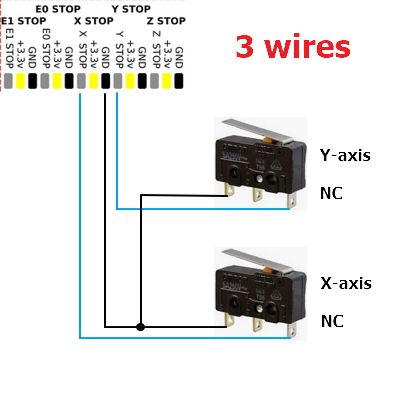

- Assignment of the two limit switches see my wiring diagram as already posted

Documentation: https://duet3d.dozuki.com/Wiki/Gcode#Section_M584_Set_drive_mapping

config.g

; ############## config.g -> configuration file of the Duet WiFi for my CoreXY - PULLEYX (thwe) ##############

;

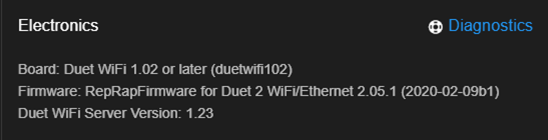

; Firmware Electronics: 1.04

; Board ID: 08DGM-9T6BU-FG3S0-7JKD0-3SN6T-KU6BH

;Firmware Name: RepRapFirmware for Duet 2 WiFi/Ethernet

;Firmware Electronics: Duet WiFi 1.02 or later

;Firmware Version: 2.03beta2 (2019-02-16b1)

;WiFi Server Version: 1.23beta1

;Web Interface Version: 1.22.6

; ############## General preferences ##############

M667 S1 ; Switch to CoreXY mode

G90 ; Send absolute coordinates...

M83 ; ...but relative extruder moves

M555 P1 ; Set firmware compatibility to look like RepRapFirmare

; ############## Network - Connect to a wifinet ##############

M552 S0 ; Disable network

M550 PDUTH-PULLEYX ; Set machine name

;M551 Pxxxxxxx ; Set password

M552 S1 ; Enable network

M586 P0 S1 ; Enable HTTP

M586 P1 S0 ; Disable FTP

M586 P2 S0 ; Disable Telnet

; ############## Drives ##############

M569 P0 S1 ; Drive 0 -> X -> goes forwards

M569 P1 S1 ; Drive 1 -> Y -> goes backwards

M569 P2 S0 ; Drive 2 -> Z1 -> goes forwards (right one, viewd from ahead)

M569 P3 S0 ; Drive 3 -> Z2 (U) -> goes forwards (right one, viewd from ahead)

M569 P4 S1 ; Drive 4 -> EXTRUDER -> goes forwards

; ############## Dual Z-Drives ##############

M584 X0 Y1 Z2:3 U3 E4 P3 ; Driver 0 = X, 1 = Y, 2+3 = Z, 3 = U, 4 = Extruder, 3 axis visible

; ############## Drives setting ##############

M350 X16 Y16 Z16 U16 I1 ; Configure microstepping with interpolation

M350 E16 I1 ; Configure microstepping with interpolation

M92 X66.667 Y66.667 Z800 U800 ; Set axis steps per mm

M92 E408 ; Set extruder steps per mm

M566 X600 Y600 Z240 U240 E240 ; Set maximum instantaneous speed changes/jerk (mm/min)

M203 X18000 Y18000 Z2100 U2100 E6000 ; Set maximum speeds (mm/min)

M201 X2000 Y2000 Z600 U600 E3000 ; Set accelerations (mm/s^2)

M906 X2000 Y2000 Z2000 U2000 E2000 I30 ; Set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout

; ############## Axis Limits ##############

M208 X0.00 Y-5.00 Z0.00 U0.00 S1 ; Set axis S1 = minimum

M208 X276.00 Y305.00 Z280.00 U280.00 S0 ; Set axis S0 = maximum

; ############## Endstops ##############

M574 X1 Y1 Z2 U2 S1 ; X0 = without endstop, 1 = min endstop, 2 = max endstop, S1 = active high (NC), S0 active low (NO)

; ############## Z-Probe ##############

;M558 P8 I1 H5 R0.3 F300 T6000 ; Set Z probe Piezo-Orion:

M558 P1 X0 Z0 ; Set Z probe Mini IR Probe:

; P8 = switch by default (normally closed)unfiltered / I1 = invert sw reading / H5 = dive height /

; R0.3 = Z probe recovery time after triggering / F300 = probing speed(mm/min) / T2000 = Travel speed(mm/min)

;G31 P500 Z-0.10 ; Set current probe status to Piezo Orion, P500 = trigger value

G31 P500 Z2.04 ; Set current probe status to Mini IR Probe, P500 = trigger value

; ############## Define mesh grid ##############

M557 X20:270 Y25:275 S31.25 ; Define mesh grid

; ############## Define position of the leadscrews ##############

M674 X-41:331 Y150:150 S0.5 ; Define position of the leadscrews, S = maximum correction

; ############## Heater 0 - bed ###

M307 H0 B0 S1.00 V23.9 A145.0 C635.0 D0.50 ; Set heating process parameters, disable bang-bang, pwm limit 100%, voltage, pid parameters

M305 P0 S"Bed" T100000 B4138 C0 R4700 ; Set thermistor + ADC parameters for heater 0

M143 H0 S110 ; Set temperature limit for heater 0 to 110C

; ############## Heater 1 - nozzle ###

M307 H1 A425.0 C231.0 D3.5 S0.60 V24.1 B0 ; Set heating process parameters, disable bang-bang, pwm limit, voltage, pid parameters

M305 P1 S"Noz" T100000 B4725 C7.06e-8 ; Set thermistor + ADC parameters for heater 1

M143 H1 S275 ; Set temperature limit for heater 1 to 245C

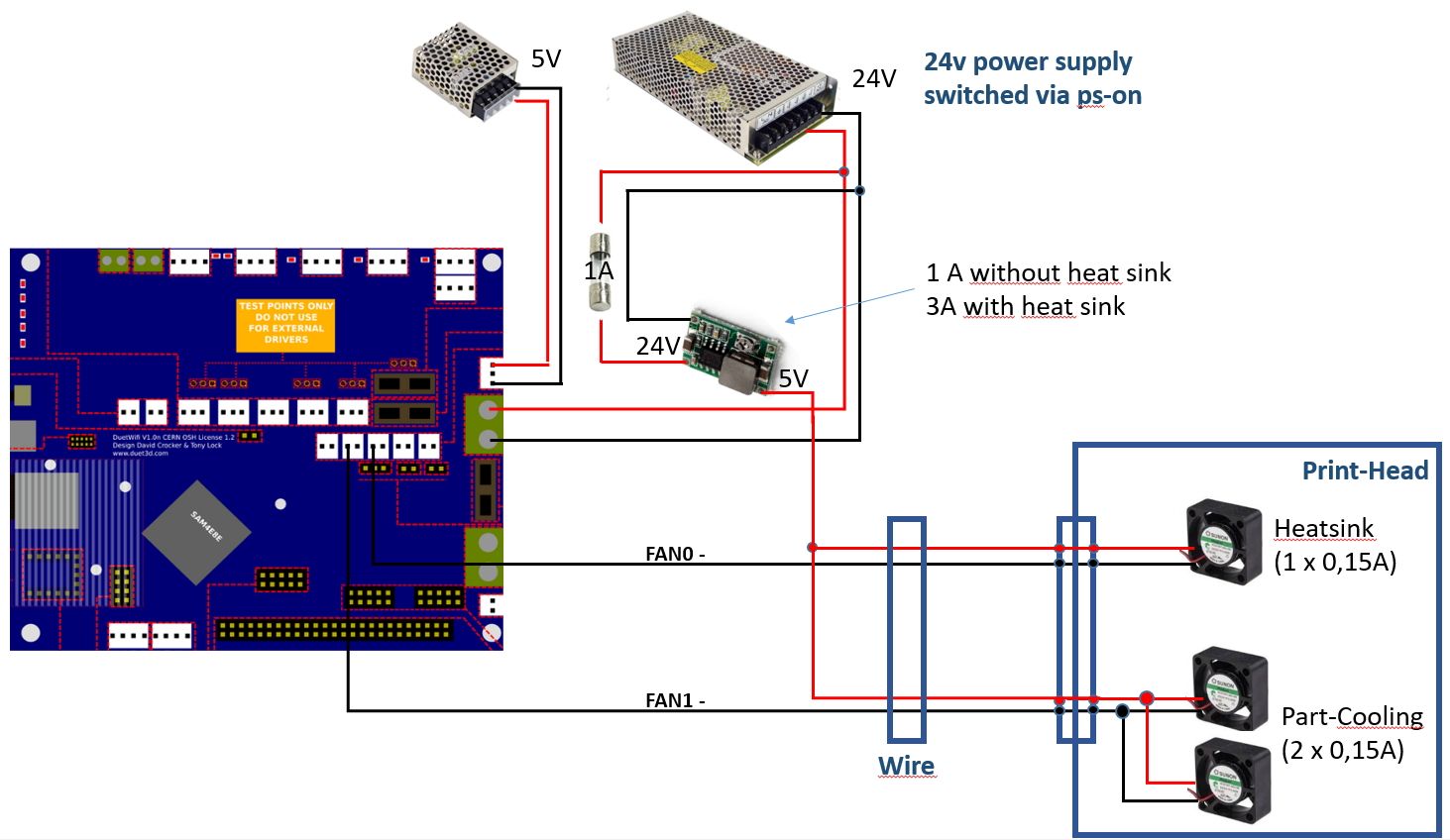

; ############## Fans ##############

M106 P0 S0.00 L0 I0 F500 H-1 C"PartFan" ; Set fan 0 value, PWM signal inversion and frequency, Thermostat control off

M106 P1 T30:80 H1 ; Sets fan 1 up thermostatic fan depending H1 (T) in proportional mode

M106 P2 S0.02 B0 L0 C"Lights" ; LED strip to P2 PWM fan outputs

; ############## Tools ##############

M563 P1 D0 F0 H1 S"Noz" ; Define tool 1 with fan 0, drive 0, heater 1

G10 P1 X0 Y0 Z0 ; Set tool 1 axis offsets

G10 P1 R0 S0 ; Set initial tool 1 active, standby temperature to 0C, temperature to 0C

; ############## Automatic power saving ##############

M911 S10 R11 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; Set voltage thresholds and actions to run on power loss

; ############## Custom settings ##############

M81 ; 24VDC power supply OFF at starting

M912 P0 S-1.9 ; Calibrating the CPU temperature

M593 F66 ; Configure Dynamic Acceleration Adjustment (DAA), cancel ringing at 48Hz

;M572 D0 S0.15 ; Set extruder pressure advance (Bowden extruders S value between 0.1 and 0.25)

;M592 D0 A0.01 B0.0005 ; Configure nonlinear extrusion for drive 0

; ############## Miscellaneous##############

M501 ; Load saved parameters from non-volatile memory

; END OF FILE

homez.g

; ############## homez.g -> called to home the Z axis ##############

G91 ; relative positioning

M584 Z2 U3 P4 ; Split Z into 2 (Z+U)

G1 S1 Z999 U999 F600 ; Move the bed down in the Z direction. S1 to stop if endstop is triggered

G1 S2 Z-3 U-3 F600 ; Move the bed up 3mm in the -Z direction, ignore if axis are not homed

G1 S1 Z9 U9 F120 ; Move slowly in the +Z direction again to stop exactly at the homing switch

M400 ; Wait for current moves to finish

G4 P100

G1 S2 Z0.00 U0.00 F200 ; Compensation the limit switch from z-axis drive 2 (!!can be adjusted here!!)

G4 P100

M584 Z2:3 P3 ; Join U to Z again

G4 P200

G1 S2 Z-3.66 F240 ; move to position, ignore endstops also if axis has not been homed

G4 P200

G92 Z280.00 ; set position of Z relativ to the bed (!!must be adjusted here!!)

G4 P200

G90 ; Back to absolute mode

G1 S2 Z270 F900

; End of file