Mosquito vs water cooling

-

I have a single watercooled v6 heat break that I got from a guy in Germany on mine. I like it as even with doing a 20 hour print the radiator fan never runs so the printer is virtually quiet other than the stepper motor noise. I also have a berd air style part cooling which gets rid of all of the fans other than the ones inside the base of the machine. I can say anything about the mosquito, but I personally like the water cooling

-

I hav one roll of petg. I won't name the brand because one roll might just be a bad roll. But it seems like it has a TG that is lower than most PLA. It has looked like heat creep twice only when printing it really slow . But what makes me think it is just bad filament is trying to remove my purge line from the heat bed after it cooled to 65c the 2in. Purge line stretched and was over 10in long after removing it..

-

@jens55 Interesting that this has come up. I'm currently working on an experimental 6 input mixing hot end which uses 6 Mosquito heat breaks (see my blog). The heat breaks are very efficient due to the extremely thin wall tubes. Because the heat breaks are not structural elements, the tubes can be very much thinner than conventional heat breaks. I believe the cross sectional area of the Mosquito heat breaks is about 15% of an E3D V6, so very little heat finds its way past the heat break.

This works well when filament is moving forward, as in a conventional single input, hot end. BUT, (and it's a big BUT), when filament is static, as in a multi input hot end, heat can be conducted up through the filament itself. In this situation, it doesn't matter how efficient a heat break is because the filament itself bridges the that heat break.

I have more testing to do, but I'm beginning to come to the conclusion that the only way to prevent heat breaks from blocking when the filament is static for a long time, is to use PTFE lined heat breaks. Of course, this will limit temperatures and thus filament types.

It is possible that a water cooled solution might provide a steep enough temperature gradient to prevent blockage in the heat break, but I wouldn't want to put money on it. -

Ian, I'm using a water cooling system with a custom hotend using this:

and I have no trouble at all by leaving the filament heated.

So, I think it would worth the effort to adapt a water cooling system on the Mosquito. It can be very simple: mine is made out of an aluminium bloc, cut, drilled and taped by hand (I don't have all your nice tools

).

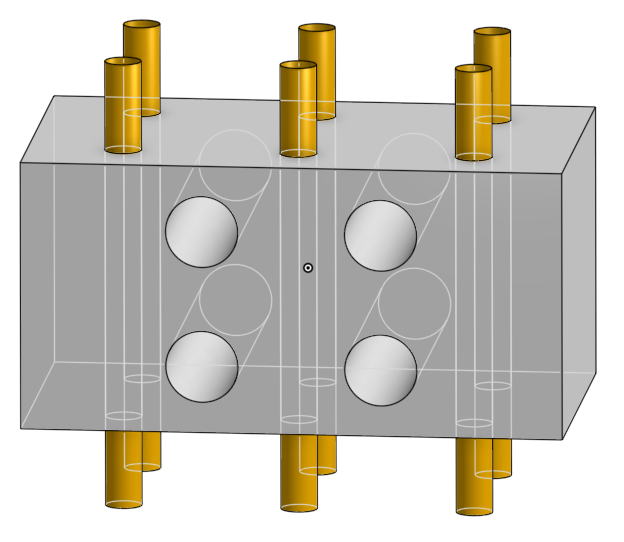

).With your setup, a large copper bloc with 6 precise holes for the heatbreaks (so there is a good thermal conduction), and 2 taped holes for the water can do the trick.

-

@fma Thanks. But I'm not sure how that helps. I have 6 inputs which currently take 6 Mosquito heat breaks. These then feed filament into a "combining block", with a single output and then through a mixing chamber and finally, exiting through a single nozzle. So a water cooling solution would need 6 filament inputs (which can be bowden clips) and 6 outputs. But how do I connect 6 outputs of a cooling block to 6 inputs of a combining block with heat breaks in between? The only way I can think of is to use compression fittings and tubes with nuts and olives at each end, but that makes the entire hot end very big and heavy because the tubes have to be spaced far enough apart to accommodate the compression fittings.

-

Design a part that uses internal coolant paths and contact Renishaw AM group in UK. They can print your design in your choice of materials. Their prices are reasonable.

-

Ian, the idea is to make a simple bloc with 6 vertical holes and have the 6 heatbreak tubes go through (they need to be precisley drilled to have a good thermal contact). Then, you make horizontal holes (between the heatbreak holes), to make a path for the water. These holes can be through the entire bloc, and using external tubes to make the links.

Looking at your pictures, this would require to remove the heatsink on the heatbreak tubes; don't know if it is possible...

-

@fma The tubes need to be water tight where they pass through the water filled cold block. Yet at the same time, I need to screw them into the hot block. So they need be able to rotate in that water filled chamber as they get screwed into the hot block, yet somehow that needs to be a water tight joint. The Mosquito tubes themselves have very thin walls and are easily damaged (I know from experience). I have no idea how Slice Engineering manage to fit those copper heat sinks onto those very thin wall tubes. They must be a press fit with some sort of mandrel or internal support to the tubes to prevent them buckling. They probably heat the copper parts too. Or maybe they use some sort of secret adhesive. Either way, I have no idea how I could remove the copper parts so using the Mosquito heat breaks would be out of the question. But I still have no idea how I could join a 6 input cold block to 6 input hot block with short heat breaks sections between the two.

-

My solution is a mix of mosquito style and water cooling. I used a silicon tube (like Marc Peltier) to circulate water around the heat-brake. See the post here: https://groups.google.com/d/msg/deltabot/n3PImRPtmOo/i8WCxQ1kBgAJ

I punctured the silicon tube with a smaller (than the heat-brake) dimeter steel tube. I also noticed that I had to put another peace of tube under the one I was puncturing. Puncturing against a hard surface did not produce watertight holes. I used the same tubes for the standoffs.

I have been running the setup for months now with no leaks.

Maybe you could use a single tube too cool several heat-brakes?

-

The holes for the heatbreaks and the holes for the water are distinct, so no problems with water tight stuff.

The water does not need to touch the heatbreaks; it only need to cool down the aluminium (or, better, the copper) bloc, which in turn turns the heatbreaks, and drain heat from them.

This is my setup, with a stainless steel heatbreak, which does not have as good thermal transfert as copper tubes, so it should work much better in this later case.

If it is not possible to remove the heasinks, you need to make your own heatbreaks, without heatsink. This way, you can make them thicker, with print for a key in order to be able to screw them on your block.

-

@fšk said in Mosquito vs water cooling:

My solution is a mix of mosquito style and water cooling. I used a silicon tube (like Marc Peltier) to circulate water around the heat-brake. See the post here: https://groups.google.com/d/msg/deltabot/n3PImRPtmOo/i8WCxQ1kBgAJ

I punctured the silicon tube with a smaller (than the heat-brake) dimeter steel tube. I also noticed that I had to put another peace of tube under the one I was puncturing. Puncturing against a hard surface did not produce watertight holes. I used the same tubes for the standoffs.

That's the Zatsit solution. I'm still waiting for it (I only ordered the water cooling tube/puncher)...

-

@fma Ahh, I see now what you mean. I'll have to give that some thought.....

-

@deckingman in your case you could cool down your stagnant hot ends when not in use. It will add time to your print as you would need to re heat your tools before you can use them but that might be more desirable than failed prints.

-

@baird1fa said in Mosquito vs water cooling:

@deckingman in your case you could cool down your stagnant hot ends when not in use. ..................

No I can't. It's a mixing hot end - 6 inputs, single output. So only 1 heater.

-

Well that certainly blew up while I was sleeping .... some VERY interesting stuff though.

deckingman, I read through your last two blog entries and saw that my issues are not that uncommon and that doing a 6 input hotend would literally drive me insane! Kudos to you for sticking with it, I wouldn't have the patience!

There is a lot of stuff here to digest - thank you all for posting your thoughts! -

@jens55 said in Mosquito vs water cooling:

Does the mosquito hotend have a substantial advantage over a water cooled Chimera setup?

-

mosquito creators mentioned they have a watercooling block for mosquito already designed (it's not on the shop but you can possibly order it from them)

-

you are comparing 2 head vs 1 head hotend.

Water-cooled chimera should IMHO have better heat creep performance than air-cooled mosquito but really, the question is what you want to achieve? Do you want to upgrade - why? What problem you are trying to solve? Do you want a "new extruder for new printer" so you are deciding to get new mosquito or new chimera? Do you need dual output? etc etc... What materials do you want to print? Enclosed or not? ABS and "hotter" (HIPS, ASA, PETG, PA ...) you can print with mosquito without any cooling (fan of course helps), so, not even a fan on the original heatsink required, if you are not in a heated chamber... If you have heated chamber any water-cooled solution is better than air-cooled solution as there's no effective cooling in the heated chamber using "local" air, and bringing "outside" air complicates things way more than introducing water.

-

-

@arhi said in Mosquito vs water cooling:

@jens55 said in Mosquito vs water cooling:

Does the mosquito hotend have a substantial advantage over a water cooled Chimera setup?

-

mosquito creators mentioned they have a watercooling block for mosquito already designed (it's not on the shop but you can possibly order it from them)

-

you are comparing 2 head vs 1 head hotend.

Water-cooled chimera should IMHO have better heat creep performance than air-cooled mosquito but really, the question is what you want to achieve? Do you want to upgrade - why? What problem you are trying to solve? Do you want a "new extruder for new printer" so you are deciding to get new mosquito or new chimera? Do you need dual output? etc etc... What materials do you want to print? Enclosed or not? ABS and "hotter" (HIPS, ASA, PETG, PA ...) you can print with mosquito without any cooling (fan of course helps), so, not even a fan on the original heatsink required, if you are not in a heated chamber... If you have heated chamber any water-cooled solution is better than air-cooled solution as there's no effective cooling in the heated chamber using "local" air, and bringing "outside" air complicates things way more than introducing water.

As mentioned in the original post, I seem to have a heat creep issue when printing two materials. I am printing PLA on one extruder and PETG on the second extruder. This is a chimera (clone) setup with two Volcano (clone) heat blocks. I can print either PLA or PETG but if I print a model with both materials then I have feeding issues when the extruder is switched ie after one extruder has set dormant for a bit.

-

-

@jens55 said in Mosquito vs water cooling:

As mentioned in the original post, I seem to have a heat creep issue when printing two materials.

Ian has that pretty good explained on his blog and also here in this thread. The heat will travel trough the filament, not much you can do about that except push filament forward. Could be interesting to test cooling with chiller and not just room temp water if dropping heatbreak to 4-5C would change anything (make it crack or actually stop the heat creep who knows

)

)This is a chimera (clone) setup with two Volcano (clone) heat blocks.

I had a chance to compare kraken from e3d and kraken from bigtree (or it was the green.. / blue .. don't remember, but "reputable" PRC 3d printing part seller/manufacturer) and well "huuuuuuge" difference. I never saw chimera in person but I think it uses the same heatbreak as kraken right? when you plug the input hole on the heatsink and on the output of the heatbreak and try to push it in the heatsink it refuses to go in, behaves like a syringe, the fit is super precise/tight. On the other hand, the PRC one had at least half a mm play so heat transfer on the PRC ona was way worse. It can probbly be improved with some copper tape and heat greese but.. So what I'm trying to say, did you try measuring the temperatures on the heatbreaks, how cold can that heatsink keep them?

I did some experiments back in the day when I was planning to make a multi nozzle water cooled hotend by using a "very small heater block" (actually no block at all, I machined aluminium nozzle and wrapped the glass insulated khantal wire) - this gave very small thermal mass but with a very strong heater (150W). This way a part cooling fan would cool the nozzle quickly and strong heater would heat it up super quick so you could just turn the hotend off when you stop printing. It worked "ok-ish" but I had so many issues machining it (my lathe is not very good), aluminium is not a very good material for the nozzle (the orifice was waring off even with non abrasive materials) and it was very unsafe as 150W can easily melt that aluminium nozzle if anything bad happens, and since bad things did happen (luckily I never let it alone as I did not trust it so it was always monitored) I decided not to persue that path... but something like that could be done properly. Anyways imo the only "dual material" system that works is 2 separate extruders, I seen it done in different ways, 2 separate X motors, same Y rail etc etc.. you move the idle tool out of the way, you push a little bit of filament trough every now and then, have a nice string removal when engaging and that works ... check out BCN3D for e.g. (never tried those but first google result when I looked for that type of printer with dual heads)

-

@deckingman said in Mosquito vs water cooling:

But I still have no idea how I could join a 6 input cold block to 6 input hot block with short heat breaks sections between the two.

I don't think there is an easy solution.

@fma is right about the heatsink though.Wrote a long reply, then had an idea.

Have the cooling channels intersect the holes for the heatbreaks, but also cut o-ring retaining features inside the heatbreak holes and use o-rings to seal top and bottom. Leave some clearance in those holes, let the water act as your thermal interface. At that point your heatsink is mostly to just keep the water in.

You are already CNC'ing the parts, an internal o-ring groove isn't a big jump and the right size o-ring should give you a watertight seal. Assembly might be a pain, but it might work.

Might want to double up the o-rings for safeties sake... -

I am doing testing this morning and the heatsink (chimera clone) is hovering around 40C with both extruders running. This is looking pretty good to me. I am currently running a test model that alternates between materials and I have not run into my previous issue.

The issue before was that a single material was running for about 45 minutes before the second material came into play .... but thinking about it, it shouldn't (in theory) have caused issues because the standby temperature was pretty low.

I also have a lot of material extruded during the time when one extruder goes to standby and the other extruder warms up (the 0.4 mm nozzle extrudes a string about 100 mm long !!!). I have yet to come up with a good way of getting that crap out of the way. In any which case, I do an extra prime with a nozzle switch to replenish this material and this was the point when the system had issues. This morning I reduced the feed speed from 15 mm/sec to 5 mm/sec during this extra prime phase and there is a good possibility that the speed caused the extruder to wear a divot into the filament and then subsequently not feed right.

So far my test print is running fine and I am feeling optimistic about things.