Parts are coming out too small...

-

I would first start with making sure your steps/mm are correct in the firmware. One thing you can do if you think you do have them set correctly is to fine tune them with this formula:

A = current steps per mm

B = Actual steps movedA(100/B)

I will use the X axis as an example.

-

- Set your starting position in a spot where you can easily measure between two points on the X axis, if you have calipers even better and 0 out the starting distance.

-

- Tell the printer to move the X axis 100mm and then measure the distance that it actually moved, this will be the "B" number of the formula below. This will give you a new steps/mm that you enter in the firmware.

Repeat the steps for Y axis and Z axis and even your extruder. For the extruder just make a mark on your filament at 110mm above where it enters the extruder once it has finished extruding measure the distance to the mark. Take that measurement and subtract 10, if it is positive you are not extruding enough, negative, extruding to much, zero you are right on.

-

-

@dakingofhearts2003 when you say smaller how much are we talking? .1mm or 1mm?

-

@alankilian @alankilian I have the duet wifi and it is a qidi tech 1 which is a flashforge clone. I am using the lastest version of the firmware it always has printed since i configured it but the parts are inaccurate since i changed boards.

; Configuration file for Duet WiFi (firmware version 3)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool v3.1.4 on Sat Jul 25 2020 12:56:48 GMT-0400 (Eastern Daylight Time); General preferences

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

M550 P"Qidi nova" ; set printer name; Network

M552 S1 ; enable network

M586 P0 S1 ; enable HTTP

M586 P1 S0 ; disable FTP

M586 P2 S1 ; disable Telnet; Drives

M564 H0 ; allow not homed axis movement

M569 P0 S1 ; physical drive 0 goes forwards

M569 P1 S0 ; physical drive 1 goes forwards

M569 P2 S1 ; physical drive 2 goes backwards

M569 P3 S0 ; physical drive 3 goes forwards

M584 X0 Y1 Z2 E3 ; set drive mapping

M350 X32 Y32 Z32 E32 I1 ; configure microstepping with interpolation

M92 X160.00 Y160.00 Z800.00 E909.59 ; set steps per mm

M566 X800.00 Y800.00 Z20.00 E400.00 ; set maximum instantaneous speed changes (mm/min)

M203 X40000.00 Y40000.00 Z200.00 E2200.00 ; set maximum speeds (mm/min)

M201 X4500.00 Y4500.00 Z200.00 E1000.00 ; set accelerations (mm/s^2)

M906 X800 Y700 Z500 E950 I15 ; set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout; pressure advance ;set pressure advance for direct drive nova hotend

M572 D0 S0.04; Axis Limits

M208 X0 Y0 Z0 S1 ; set axis minima

M208 X225 Y145 Z165 S0 ; set axis maxima; Endstops

M574 X2 S1 P"xstop" ; configure active-high endstop for high end on X via pin xstop

M574 Y1 S1 P"ystop" ; configure active-high endstop for low end on Y via pin ystop

M574 Z0 ; configure Z-probe endstop for low end on Z

M558 P9 H5 F500 T4000 X0 Y0 Z1 :set probe type and mode. not using on xy but using it on z axis; Z-Probe

M950 S0 C"exp.heater3" ; create servo pin 0 for BLTouch

M558 P9 C"^zprobe.in" H5 F6000 T6000 ; set Z probe type to bltouch and the dive height + speeds

G31 P50 X-49.41 Y8.53 Z4.207 ; set Z probe trigger value, offset and trigger height

M557 X10:205 Y10:145 S10 ; define mesh grid; autosave 911

M911 S21.0 R23.0 P"M913 X0 Y0MG91 M83 G1 Z3 E-5 F1000; Heaters

M308 S0 P"bedtemp" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin bedtemp

M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0

M307 H0 B1 S1.00 ; enable bang-bang mode for the bed heater and set PWM limit

M140 H0 ; map heated bed to heater 0

M143 H0 S120 ; set temperature limit for heater 0 to 120C

M308 S1 P"e0temp" Y"thermistor" T100000 B4138 ; configure sensor 1 as thermistor on pin e0temp

M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1

M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit; Fans

M950 F0 C"fan0" Q500 ; create fan 0 on pin fan0 and set its frequency

M106 P0 S1 H0:2 ; set fan 1 value. Thermostatic control is turned on

M950 F1 C"fan1" Q500 ; create fan 1 on pin fan1 and set its frequency

M106 P1 S1 H0:1 T45 ; set fan 1 value. Thermostatic control is turned on

M950 F2 C"fan1" Q500 ; create fan 2 on pin fan1 and set its frequency

M106 P2 S1 H0:1 T45 ; set fan 2 value. Thermostatic control is turned on; Tools

M563 P0 S"Extruder" D0 H1 F0 ; define tool 0

G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets

G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0CM501

M500

M564 H0

; Custom settings are not defined -

@3dpmicro

image url)

image url)one comes out the right size on my tevo but the duet board died and before that would always disconnect so im about to throw one of my old boards with marlin on it in it. I'd like to get this one right first though...

-

@dakingofhearts2003 said in Parts are coming out too small...:

M350 X32 Y32 Z32 E32 I1 ; configure microstepping with interpolation

M92 X160.00 Y160.00 Z800.00 E909.59 ; set steps per mmHow did you calculate the X and Y steps per mm? Is your Z steps per mm correct?

Taking a stab, but 20mm/24.2mm=83%. 160steps/mm / 200steps/mm=80%.

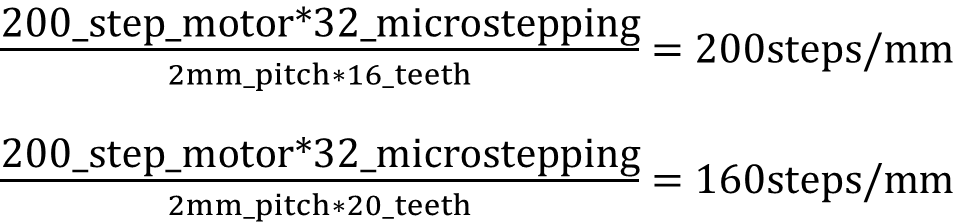

Are you sure you've properly calculated the X and Y steps per mm? I think its likely you have 16 teeth pulleys instead of 20 teeth (or an equivalent mistake).

-

@sebkritikel i tried the old numbers from the makerbot and used the 80 80 400 standard of marlin. the old makerbot numbers just made it print off the bed and etc. the marlin standard made the parts come out undersized

-

@dakingofhearts2003 said in Parts are coming out too small...:

@sebkritikel i tried the old numbers from the makerbot and used the 80 80 400 standard of marlin. the old makerbot numbers just made it print off the bed and etc. the marlin standard made the parts come out undersized

Thanks for the update!

Take a look at those formulas I posted - it’s fairy straight forward. Looks like your motors are 1.8deg motors, so 200 steps/rev (360/1.8). Per your M350, you have 32x micro stepping. Your belt pitch is likely 2mm.

In your case the ‘80 80 400’ “standard” doesn’t work as you have 32x microsteping. Had you selected 16x, bam, the ‘80 80 400’ would likely have worked.

However, those numbers aren’t working for you, and ~20% is fairly significant to be attributed to the extruder. The last variable in the equation is the pulley size/setup... double check that.

Plugging numbers into config.g willy nilly can get you far, but it’s always good to fall back on documented formulas to work out issues like this.

-

@sebkritikel when i did the extruder calibration it was correct. I did make a start mark on the bed and did a 50mm in the x direction and i measured 42.17. I didnt know i was going to need to be an engineer to change boards and firmware i see why people buy prusas now cause im sick of tinkering and wasting filament...

-

@dakingofhearts2003 well let me know if you need more help. Bummed to hear I didn’t get you pointed in the right direction.

-

@sebkritikel i think im going back i'm just tired of it...

-

@dakingofhearts2003 said in Parts are coming out too small...:

one comes out the right size on my tevo but the duet board died and before that would always disconnect

@dakingofhearts2003 said in Parts are coming out too small...:

I didnt know i was going to need to be an engineer to change boards and firmware i see why people buy prusasI can partly understand your frustration, as RRF and Duet boards are getting more and more sophisticated

They offer more options, but also ask more from the user. Like reading manuals and listen to experienced users....