Coming soon: Accelerometer Support

-

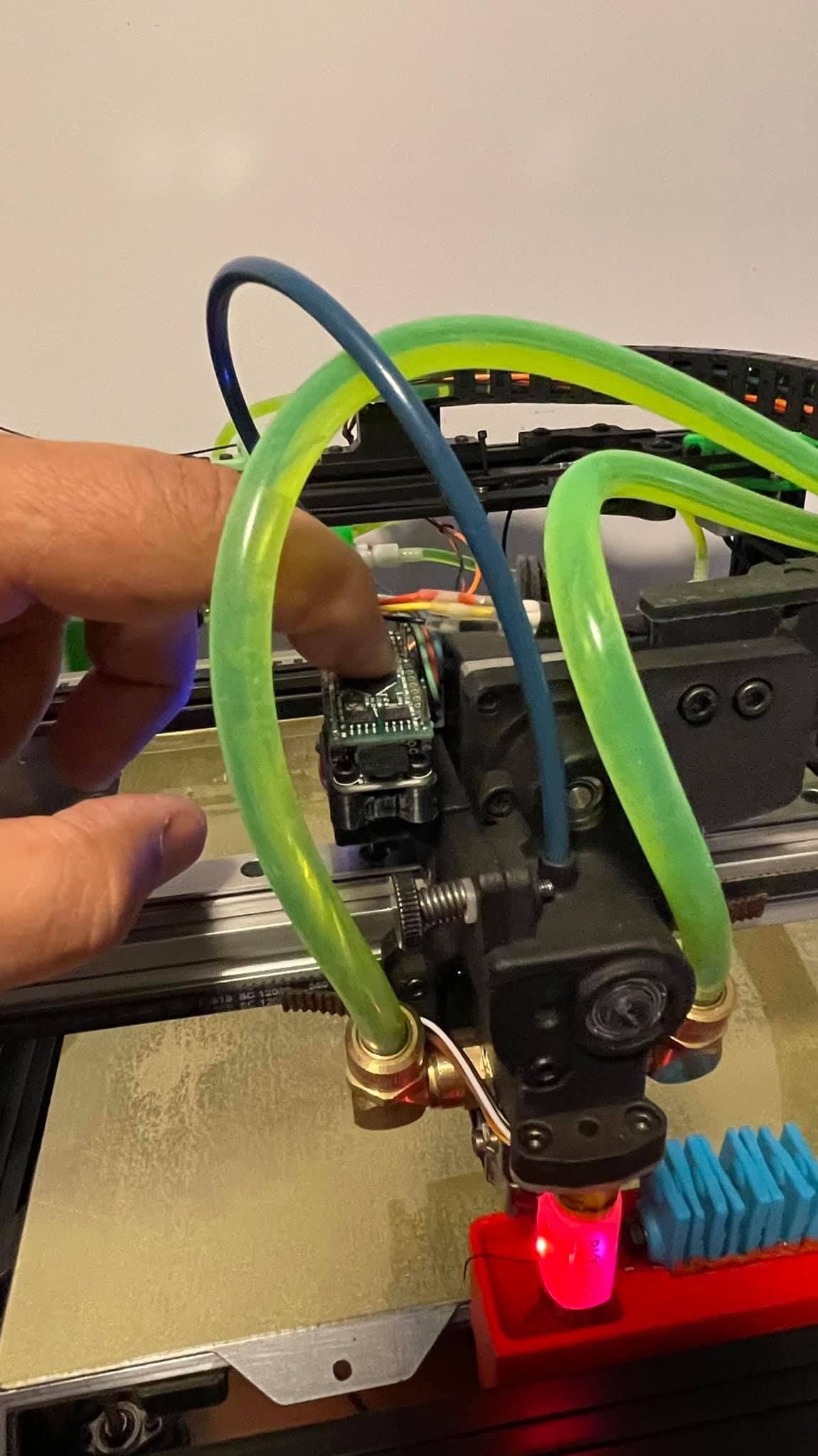

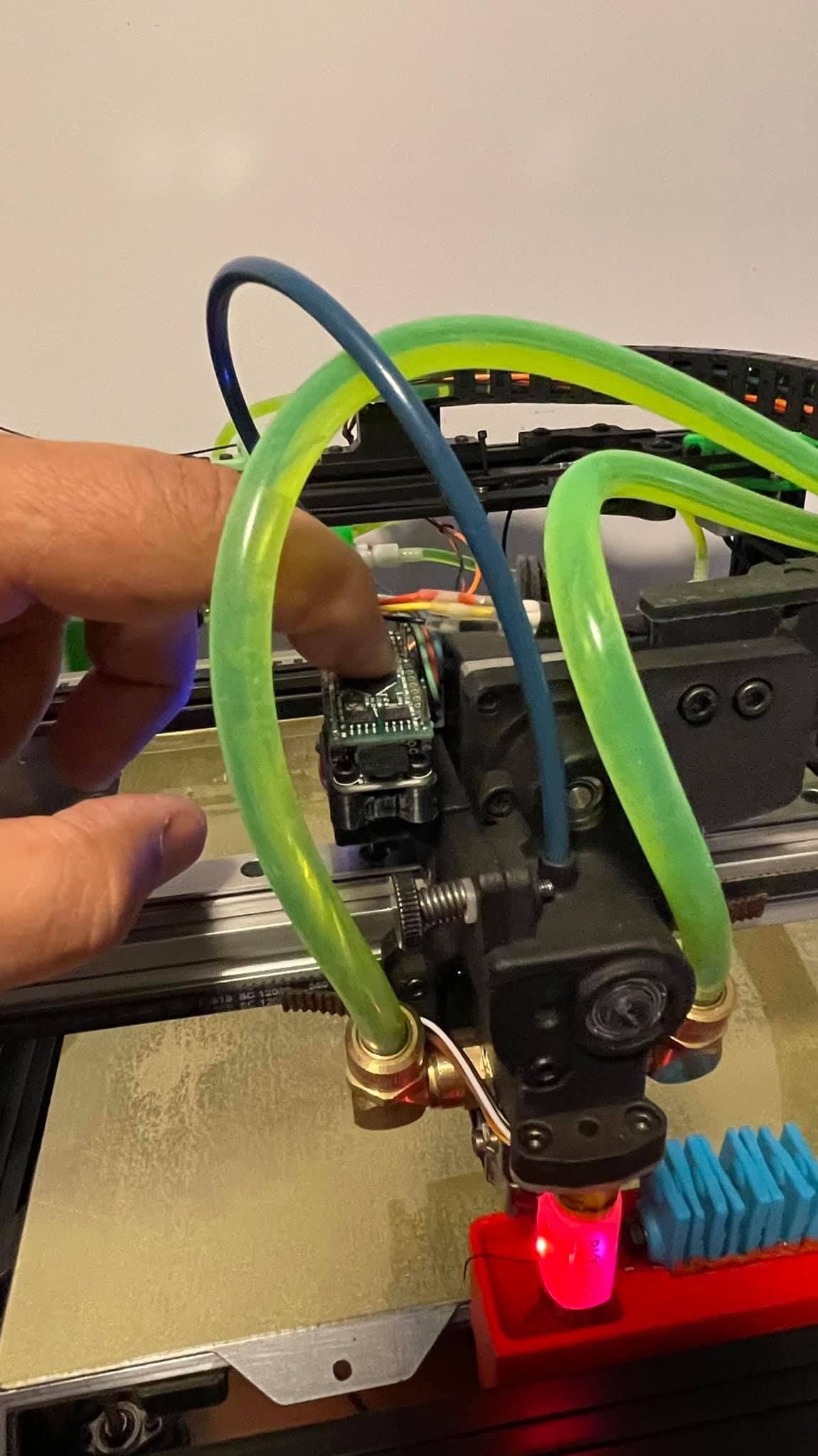

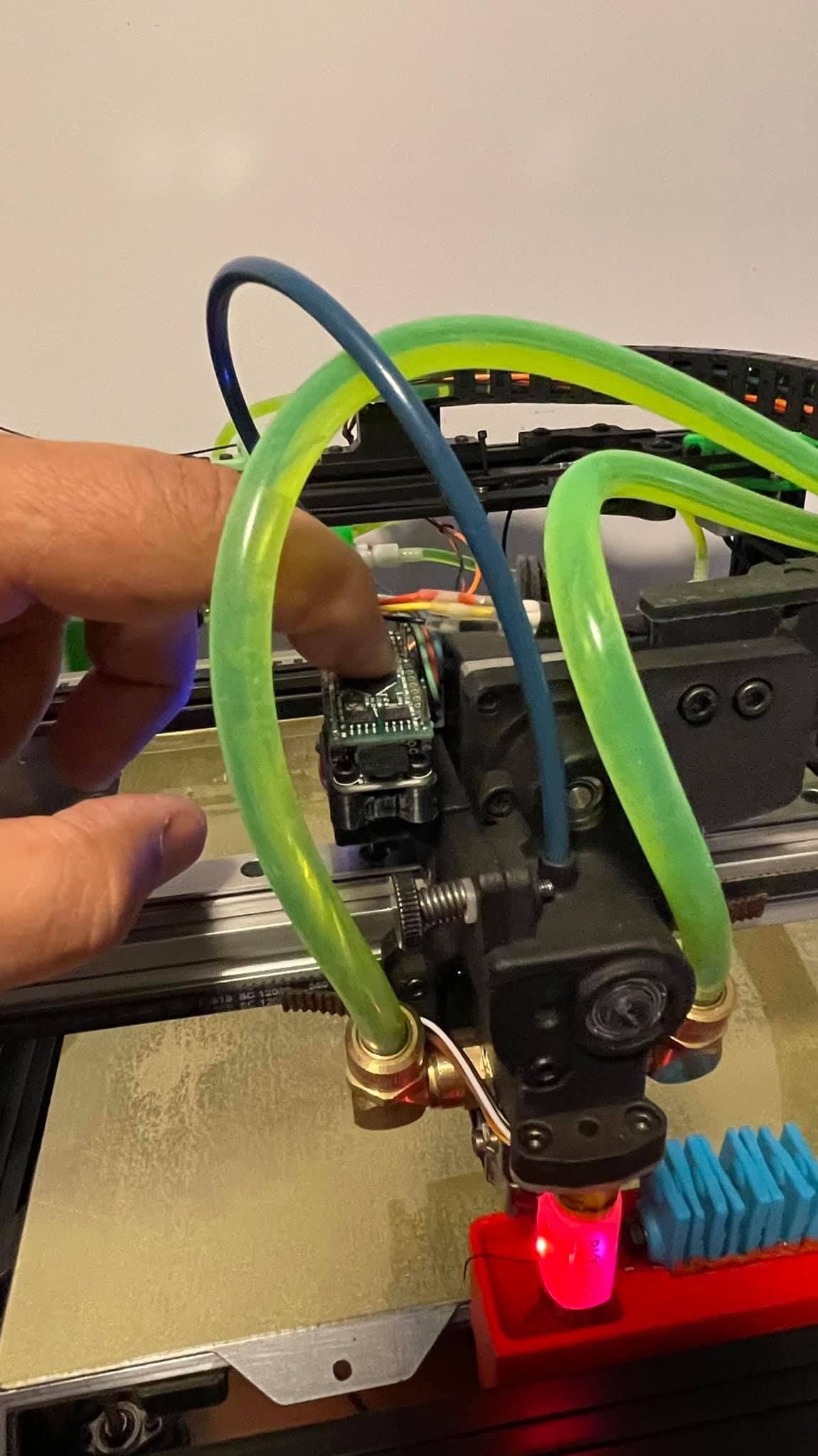

My soon to be installed Sammy/LIS3DH combo.

-

@nuramori said in Coming soon: Accelerometer Support:

My soon to be installed Sammy/LIS3DH combo.

That's nice, I've got an order in for a couple of duet Sammy boards from Germany. Looking forward to having a play with my Duet 3 mini.

-

So would the accelerometer be mounted to the frame or motor? Does its position matter for it to read any ringing frequency.

This article is interesting:

https://www.omega.com/en-us/resources/accelerometershttps://www.pcb.com/resources/technical-information/mounting

-

@aprz said in Coming soon: Accelerometer Support:

So would the accelerometer be mounted to the frame or motor?

It would be mounted on the print head. For a bed slinger, you would also need to take measurements with it mounted on the bed.

-

@aprz This is how/where I'm mounting mine...

-

@nuramori

I like your silicone-sock wiper

-

@dc42 said in Coming soon: Accelerometer Support:

@aprz said in Coming soon: Accelerometer Support:

So would the accelerometer be mounted to the frame or motor?

It would be mounted on the print head. For a bed slinger, you would also need to take measurements with it mounted on the bed.

@dc42 Given the bed on a bed slinger increases in mass during a print would it be beneficial to alter the ringing frequency during the print to account for the print mass?

If so I guess we could embed input shaping gcode in the print file or something like that.

Perhaps enter the total print mass at the start of a print and profile the shaping based on % complete and a survey of frequencies across a print mass range.

Interesting

stuff...

stuff... -

@cncmodeller the amount of filament used is known already so it wouldn't be too difficult to track that to mass being added

-

@nuramori said in Coming soon: Accelerometer Support:

@aprz This is how/where I'm mounting mine...

@Nuramori given these don't need to be a permanent fit, are you fitting a plug at the print head to remove it after doing the resonance survey? I will be as I have a moving bed and will also be using the board to characterise my other printers too.

Therefore:

Should I be adding ballast to account for the loss of mass. Probably not unless the print head is very light?

Also should we be terminating the disconnected wire's at the connector to reduce EMF back to the Duet?

Really looking forward to trying this out.

-

@cncmodeller said in Coming soon: Accelerometer Support:

Also should we be terminating the disconnected wire's at the connector to reduce EMF back to the Duet?

When you uninstall it, you also comment out the sensor definition. The pins involved will no longer be 'observed' by RRF

-

@o_lampe said in Coming soon: Accelerometer Support:

@cncmodeller said in Coming soon: Accelerometer Support:

Also should we be terminating the disconnected wire's at the connector to reduce EMF back to the Duet?

When you uninstall it, you also comment out the sensor definition. The pins involved will no longer be 'observed' by RRF

Yeah thinking about it I'm just going to have a temporary loom as well so it'll all get removed all the way back to the Duet.

-

@cncmodeller

Imagine we'd have to terminate all unused I/O pins on the boards

-

@o_lampe said in Coming soon: Accelerometer Support:

@cncmodeller

Imagine we'd have to terminate all unused I/O pins on the boards

As I understand it there is a difference between unused pins and unterminated flying wires that are still connected. Unterminated wires would just act as an antenna to draw electromagnetic interference into the Duet.

-

@o_lampe said in Coming soon: Accelerometer Support:

@cncmodeller

Imagine we'd have to terminate all unused I/O pins on the boards

No need.

-

@cncmodeller given my liquid cooled head which is not what I’d call light, the 2-5 grams I’m adding is t something I’m going to fuss over, and I plan on just leaving it on the head. I have a toolboard on the back of the print head, so the wiring is short and sweet.

-

@nuramori said in Coming soon: Accelerometer Support:

@aprz This is how/where I'm mounting mine...

I like your cooling system.

-

@cncmodeller, looking at your picture, the accelerometer is close to the rail and far from the nozzle. I would think that you want to measure the accelerations of the nozzle which can be different due to mechanical flex and play.

(I am not an expert, just speculating).

-

-

@cncmodeller, that would something interesting to try, the effect of the position of the accelerometer on the measurement results.

BTW, as for same uniform accelerations on a stiff object, you don't want to be near the bow of the ship when the sea is rough.

-

@zapta said in Coming soon: Accelerometer Support:

I would think that you want to measure the accelerations of the nozzle which can be different due to mechanical flex and play.

that's why I really like the klipper idea of using el-cheapo ADXL345 board (0.74EUR + free shipping on all for e.g.) is like 2 gramms, you can stick it directly to your nozzle with some double tape (or very close to it)

on the other side LIS3DH that is (will be) used with RRF (I understand why, it is a better chip IMHO) is zero stock on digikey, mouser .... now I do have some LIS3DH too and they are great as they can send bigger chunks of data if I remember correctly but I really hate they are not on stock at any of my suppliers and that all the boards I have it on (and that I can buy it on) are 4-5 times bigger than small boards ADXL345 comes on

@o_lampe copter needs a kalman so as many sensors as you can pull to work together to get to proper data. here you are interested in very short and very simple measurement so no need for additional sensors..

with a growing flat spot on a ball

for this you normally need a very different accelerometer probe and they cannot be mounted on the hotend but on the rail ... this equipment that detect balls that are starting to deteriorate start, used, at a price of a good brand name printer

... el cheapo accelerometer attached to a plastic carriage will not be detecting a flat spot on a ball in the bearing

... el cheapo accelerometer attached to a plastic carriage will not be detecting a flat spot on a ball in the bearing