What would you build if you were starting again now?

-

I have what started out a long time ago as a cr-10 and after lots of tinkering and the great help from the BLV Prusia i3 project I finnally have a printer doing reasonably good prints.......

So needless to say I want to change it as I feel the original design is lacking a lot of stability and could be better but its been a great learning experience.

So while looking around at options I noticed the BLV cube coreXY and that seems like a good direction to go in then I spotted the cross gantry type like Annex K2..

As I still very much consider myself a newbie I thought I would throw it out to you knowledgeable folks as I would prefer to build it right from the start rather than going through the pain of trying to sort out inherent design flaws to get it sorted after.

So build volume of 300x300x300mm ( or greater) has to be enclosable as although I mainly print PETG I would like all options open and enclosed makes sense to minimise external factors.

Speed would always be nice but less important than quality prints.

While I have no problem DIY for everything a kit is always welcome.

With the knowledge you now have if you were building a new machine what geometry and machine type you build?

-

I built a Chinese kit based on the "crossed axes" approach.

I made several modification but not to the basic mechanism.

It worked very well.

It included an enclosure but it's build area is appx 200 x 200 x200 which does not meet your requirements.

I liked the approach enough that the HyperEvolution I was going to build is being redesigned to see if frame can be adapted to such an approach. So far the design is based on four steppers, two X and two Y.

I also built from scratch a printer based on the "MarkForged" approach. Like a CoreXY the steppers are all mounted to the frame but my design required two Y steppers instead of one. With three steppers there are three belts but they are a good deal shorter than the belts on a CoreXY.

I just finished a CoreXY kit but it is my least favorite to date.

Frederick

-

CroXY if it needs to be cross gantry, RatRig V-Core 3 otherwise. To be taken with a grain of salt since I don't seem to need large printers.

-

I have a RailCore and a Voron 2.4.

I have had less issues with the RailCore than the Voron.(Voron is stripped ready to be something else.)

So If I had to do it all again. RailCore, Annex or CroXY build.

Before I chose the RailCore I was looking at the BLV CoreXy.Control board, this is my own opinion from my experiences.

Duet all the way with RRF.

Had the Marlin boards, Dual SKRs with a Pi running Klipper.

IMO the only one I have less hassle with is the Duet family.My 2p worth

-

@paulhew said in What would you build if you were starting again now?:

I have had less issues with the RailCore than the Voron

What kind of issue did you have with the Voron 2.4?

-

I'm far from an experienced 3D person, having only just gotten my printer up and running a few weeks ago. but I'm replying anyway because it's based upon a BLV CubeXY frame.

I started with just the aluminum bits of the BLV frame, adding a third Z axis. Already I can say it's absolutely awesome to be able to enter G32 and have it perfectly leveled. Between that, a Duet3 6HC, Tool Board, Bondtech LGX and Mosquito hot end, I'm blown away by the print quality right out of the gate, even before doing any fine tuning. Still a big learning curve but I wouldn't change anything at this point.

I chose the 375x375 bed to somewhat future proof it, so that good size parts cand be made. An open frame clock may be first on the list, though it remains to be seen how well 3D-printed gears work, both in terms of accuracy and wear qualities.

One advantage to getting into the 3D printer hobby so late in the game is that much of what really works well has already been figured out.

-

Railcore or Voron. Jubilee if tool changing is what you're after.

-

Thanks all, interesting.

So coreXY is the recomendation of all. I am surprised the cross gantry didnt get more support as it seemed like an interesting way to go and I was thinking it would likely be more stable.

Other than that it looks like everyone recommends what they have ,pretty much ,so it looks like you are all happy with what you are using which I guess says a lot about how far things have come over the last few years

-

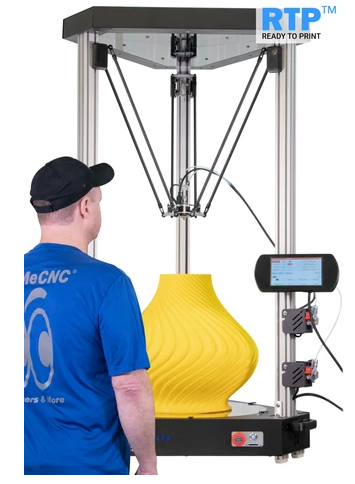

I would build my large delta all over again. In its present incarnation it's been almost hassle-free, which I can't say for any of my other printers. But I am looking forward to fitting it with a larger and CAN-connected Smart Effector carrying an Orbiter extruder.

-

@opentoideas

if you wanna build futureproof, go for a # hash-style printer. It is cross-gantry like the CroXY, but with 4 toolheads, so you can make use of the upcoming multi-stream gcode feature.

Even better if you design a printer with 4 independent tools working synchronously@all

why has no one mentioned a Delta? 300x300 build volume isn't too hard to build (OK dc42 has beaten me) -

@o_lampe said in What would you build if you were starting again now?:

a # hash-style printer

I guess you mean https://youtu.be/tzf8903FvCs

Looks interesting!Ian

-

This post is deleted! -

@dc42 said in What would you build if you were starting again now?:

I would build my large delta all over again. In its present incarnation it's been almost hassle-free, which I can't say for any of my other printers. But I am looking forward to fitting it with a larger and CAN-connected Smart Effector carrying an Orbiter extruder.

Is something like this in development? Sounds interesting.

-

@snimax said in What would you build if you were starting again now?:

@dc42 said in What would you build if you were starting again now?:

I would build my large delta all over again. In its present incarnation it's been almost hassle-free, which I can't say for any of my other printers. But I am looking forward to fitting it with a larger and CAN-connected Smart Effector carrying an Orbiter extruder.

Is something like this in development? Sounds interesting.

It's planned, but there are more important pieces of hardware for us to develop first.

-

@opentoideas said in What would you build if you were starting again now?:

So coreXY is the recomendation of all

All?

Unless requested I won't be building a CoreXY again.

Frederick

-

Speaking of deltas, (I have a SeeMeCNC Rostock Max V3.2 which uses a Duet2/Ethernet)

SeeMeCNC build a 300mm Delta for US$1,500 and a 500mm !!! Delta for US$4,500. Both use Duet.

-

@droftarts said in What would you build if you were starting again now?:

I guess you mean https://youtu.be/tzf8903FvCs

Looks interesting!I like its symmetry.

-

It depends on what you're interested in. If you just want a machine that prints with minimal effort and you have the funds, buy a proven machine/kit.

If you're interested in the details of how the machines work and maximizing some specific types of performance, I would design and build from scratch. It takes time but you learn a lot along the way, including modeling in CAD, mechanical design, machining, where to buy parts, etc.

-

@mrehorstdmd

And 2 or 3 years later with the 2. gen of that machine it will be reliable... -

I would make a few small iterative changes to my current design. Actually, I will be making printer number two soon with a few changes:

Drive the Y axis only by one side instead of both. Currently I use a ridiculously long primary belt to drive both sides of the Y axis. This causes unnecessary backlash because the primary is as long as the secondaries (lol. I know now.) I will just use a short primary like on X. Hopefully this immediately solves the backlash on Y (it's in the order of <100 microns of backlash)