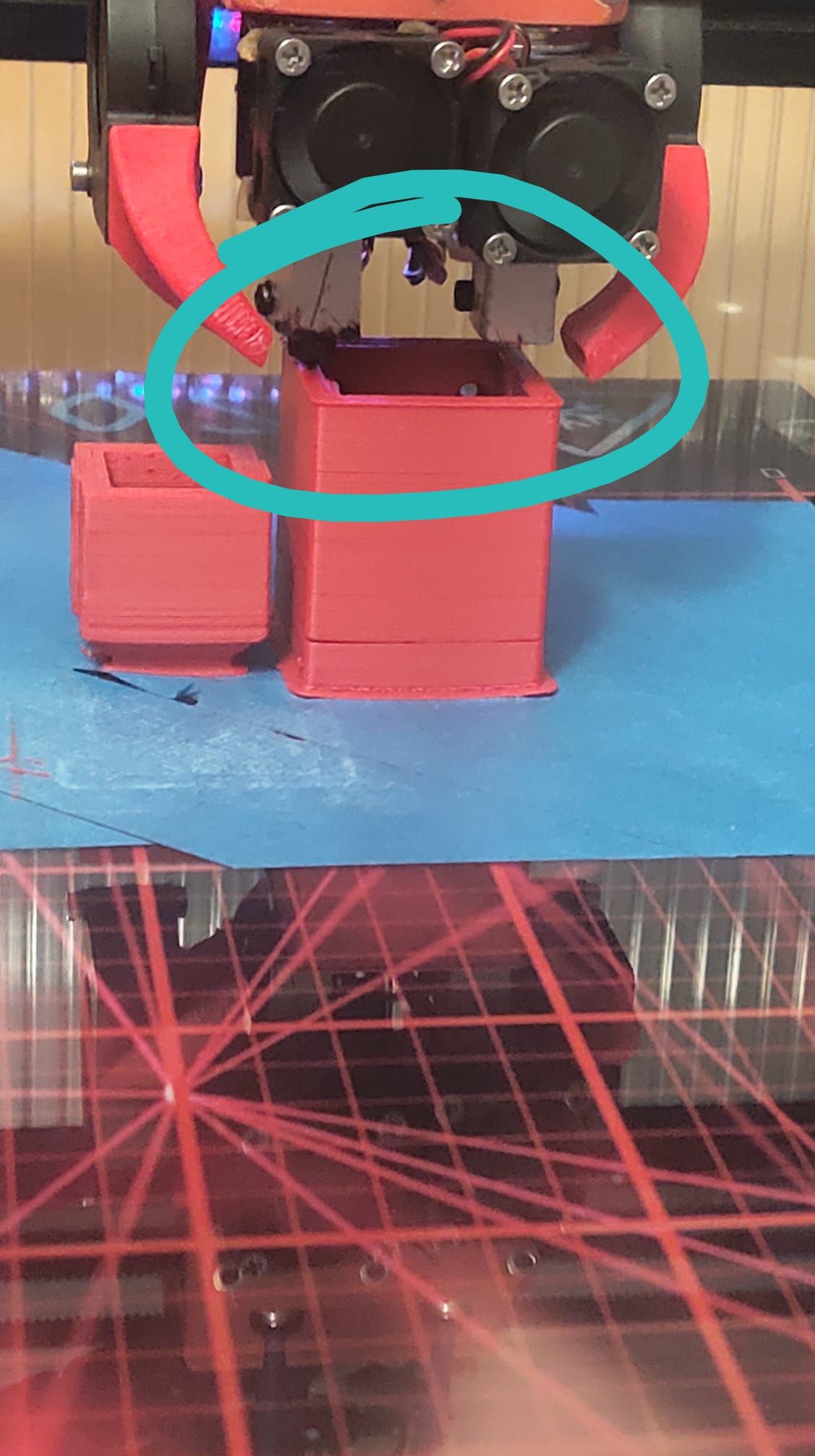

Turning of the SSR heated bed immediately kicks the printed part

-

Not sure what happened here but when I just turned off the SSR heated bed from110 Cdeg and this happens.(ABS, enclosure)

I thought it is shifted printing but seems it is not.

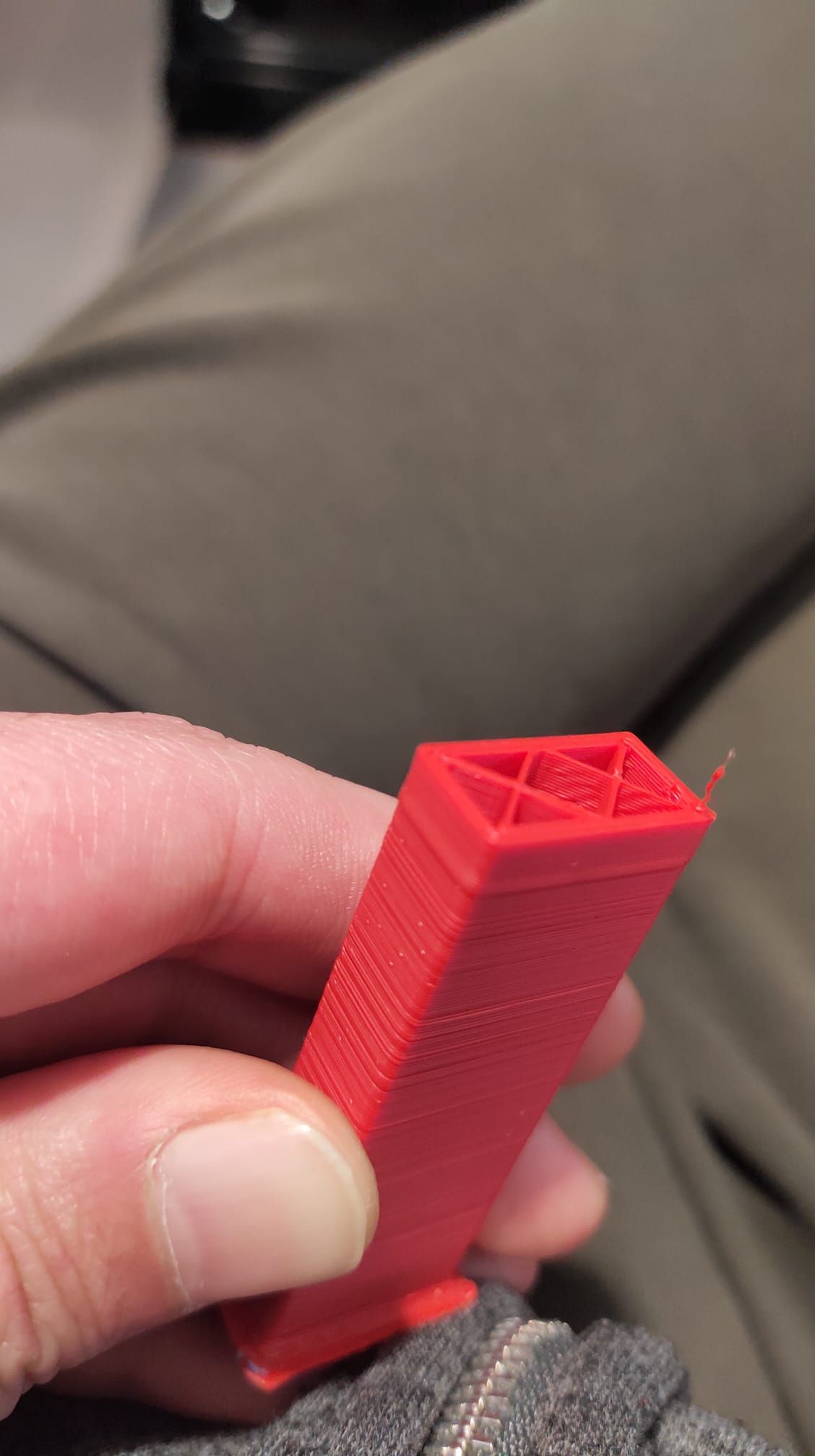

I will take another photo when the printing finish.

-

Last layers expanded inside and outside after heatbed shutdown. How could this be? What is it do the with ssr heated bed?

-

I don't see how turning off the heated bed would cause an issue like this.

Please, can you post the GCODE for the model?It does not look like typical overextrusion which leaves messy, blobby outer layers.

This looks like that's what the model geometry is. -

Yes I don't see any reason as well. It is SSR so there is no load on the board.

Dimensional accuracy is correct at top. There is only a few layers shifted inner/outer when I turned of the heated bed.

I will try to print again to replicate this.

I can upload the Gcode but here is the preview.

-

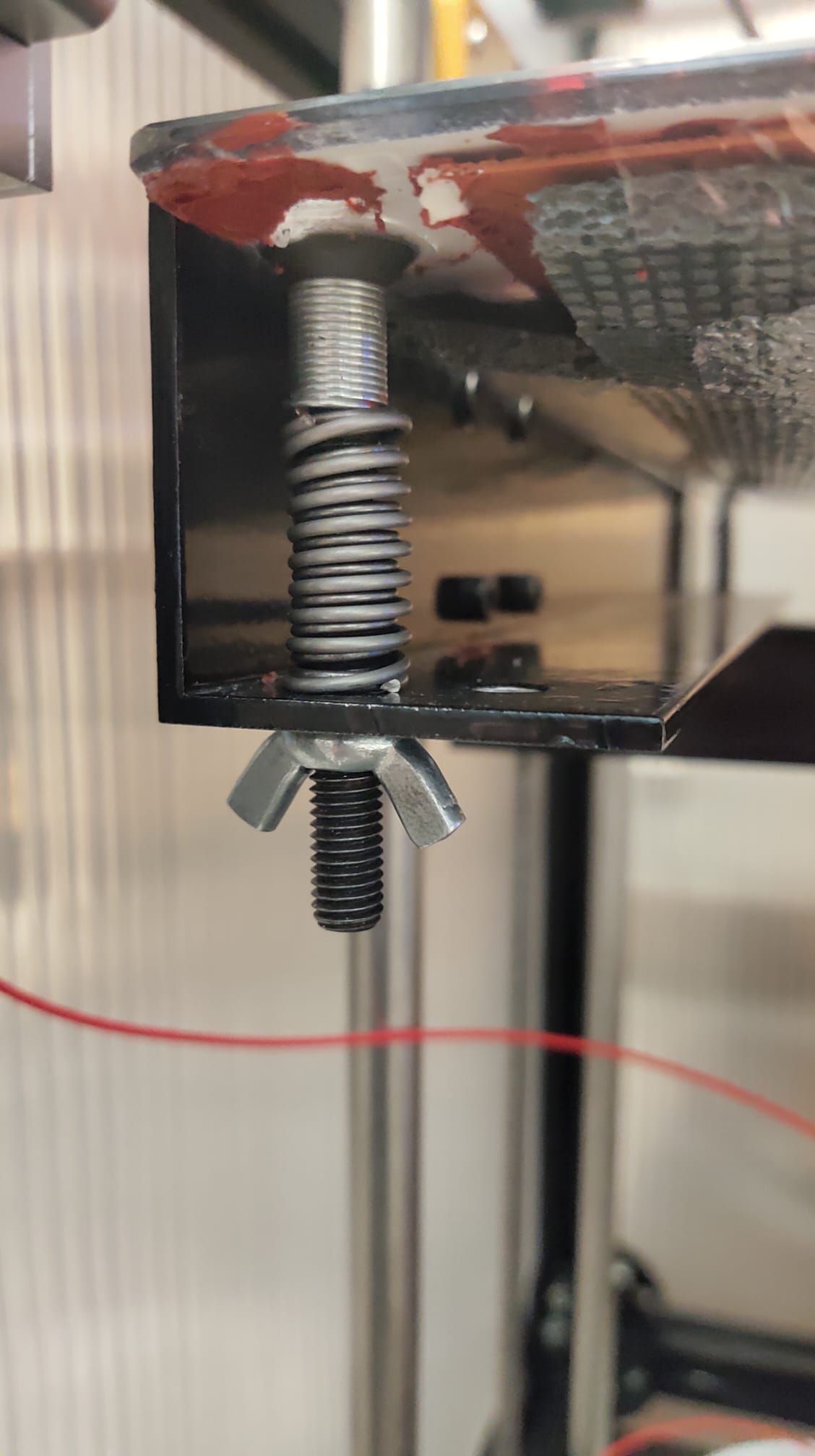

@secure could simply be thermal expansion? If your bed bows downwards when hot, maybe it just bowed back up when you turned it off and it started to cool. That means the effective later height would reduce and look like overextrusion.

Depending on your bed/heater type, some pcb type heaters also expand/contract when powered on/off so could be that? -

@engikeneer I think this is the right answer.

Get the bed to 110 degrees, take a piece of paper and position it under the nozzle, then lower the nozzle until it just starts to grab the piece of paper. Then turn of the bed and move the paper around a bit. Probably you will feel the friction increase.

You can also try to print on the 'edge' of the printbed and see whether that makes a difference

-

No I have seen this live. It is not a thermal expansion. Turned off the heated bed and immediately I had seen over extrusion.

I have over extrusion problems on that printer that I couldn't find an easy fix. May be I need to change the bulldog extruder.

-

@secure It seems unlikely to be an extruder problem. Is the problem repeatable? Will shutting off the bed heater cause this effect on any print at any Z position? What happens if you turn the heater back on? And then off again?

Is the bed heater powered by the same power supply that powers the controller board? Are there any off-controller board motor drivers?

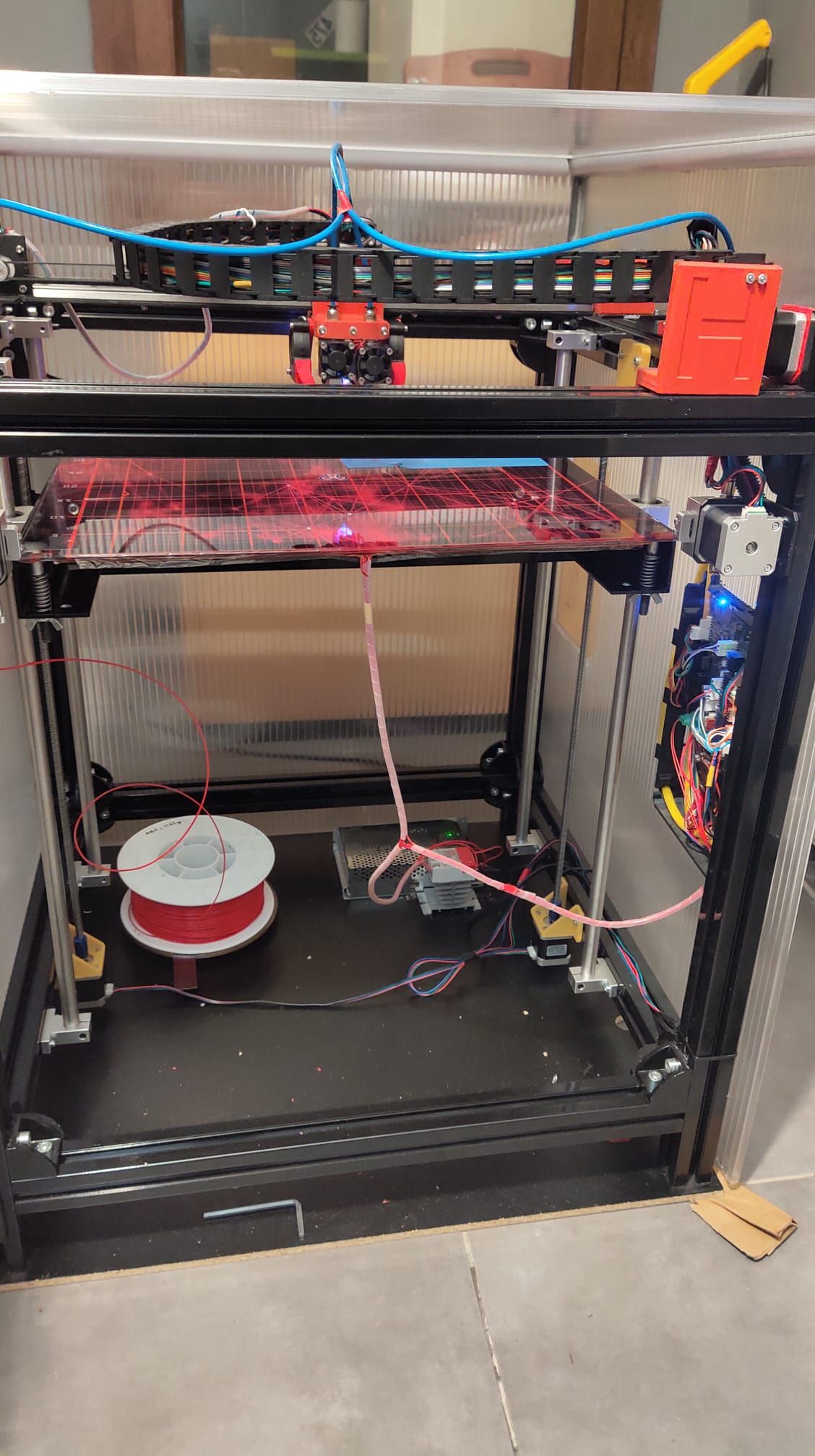

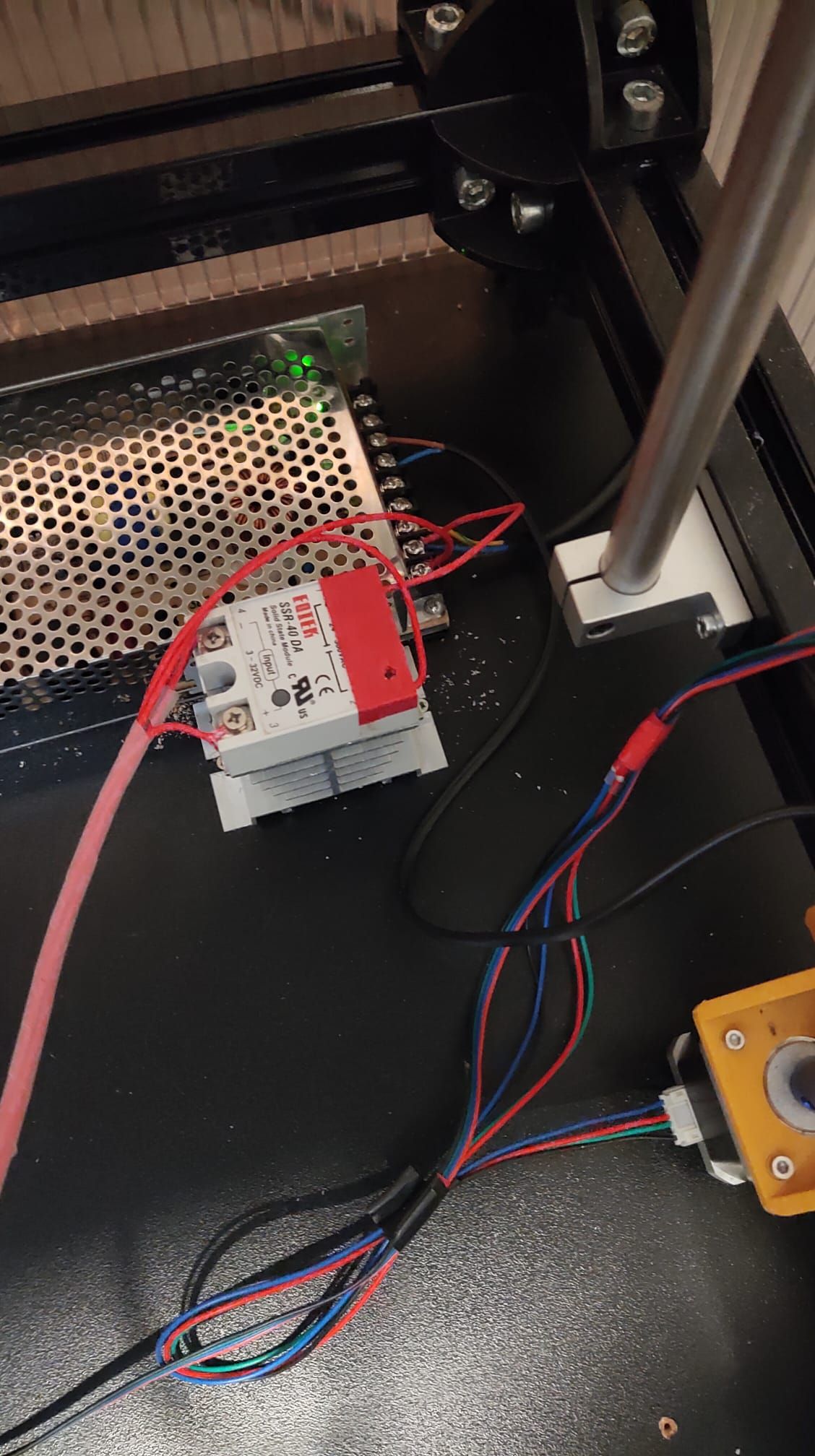

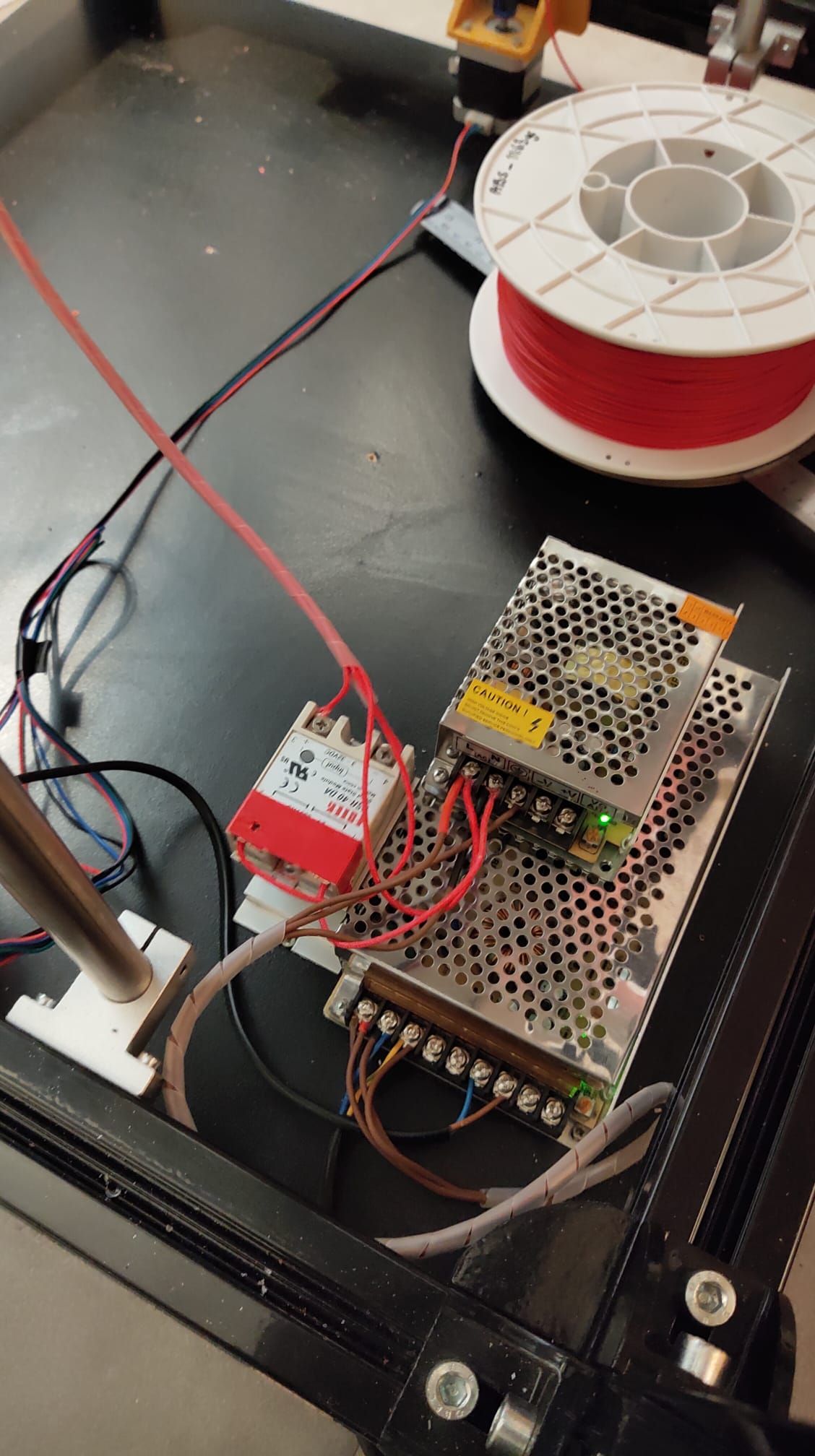

A wiring diagram and some photos of the printer might be helpful...

-

@secure said in Turning of the SSR heated bed immediately kicks the printed part:

Turned off the heated bed and immediately I had seen over extrusion.

You've seen overextrusion, because the layer height was wrong immediately after the SSR switched off.

You seem to have something like a bimetall effect in your bed mounts or glass plate. -

Interesting but it is repeated. I turned off the heater at 100 degC and 4-5 layer expanded/overextruded/shifted while the heated bed is still at 95 cdeg. I think it is nothing to do with temperature. Heater powered by 220 AC outlet nothing to do with the board. I will try PID tuning again anycase.

; Heaters M308 S0 P"bedtemp" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin bedtemp M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0 M307 H0 B0 R0.577 C501.4 D8.08 S1.00 V24.0 ; enable bang-bang mode for the bed heater and set PWM limit M140 H0 ; map heated bed to heater 0 M143 H0 S120 ; set temperature limit for heater 0 to 120CHere some photos of the printer.

-

@o_lampe said in Turning of the SSR heated bed immediately kicks the printed part:

@secure said in Turning of the SSR heated bed immediately kicks the printed part:

Turned off the heated bed and immediately I had seen over extrusion.

You've seen overextrusion, because the layer height was wrong immediately after the SSR switched off.

You seem to have something like a bimetall effect in your bed mounts or glass plate.Sorry I don't understand. What do you mean? It is going back to normal after a few layers

-

@secure

You appear to have the logic level control wire to the SSR bundled with the high current heater wire; that could be spiking the controller - try separating them?Tip: Where possible always twist the pairs of wires to heaters, controls and sensors etc. separately from each other, to minimise possible crosstalk.

-

@rjenkinsgb said in Turning of the SSR heated bed immediately kicks the printed part:

@secure

You appear to have the logic level control wire to the SSR bundled with the high current heater wire; that could be spiking the controller - try separating them?Tip: Where possible always twist the pairs of wires to heaters, controls and sensors etc. separately from each other, to minimise possible crosstalk.

Yes, spiking is my suspect too. This is my first thing to do.

I'll add another small PSU for 12V leds&fans and source the heated bed AC from this PSU.Thanks for the tip too. I'm very bad on wiring this printer. All my connectors loose.

-

Back again!

I made a quick change and added another PSU and separate board output and heater output. Nothing changed.

I have measured AC outlet; 240 @ 50 hz. / PSU output 24.4 volt (stable) / Board input connector 23.6 volt (stable)

Board Vin voltage while printing took my attention. It is not stable and jumps between 22.4v to 24 volt.

I stopped printing and vin voltage becomes stable at 24.1 volt. Turned on hotend 1 and Vin dropped to 23.3 v.

I will check all my wirings again. There could be loose connection as I believe there shouldn't be a drop in voltage like this. -

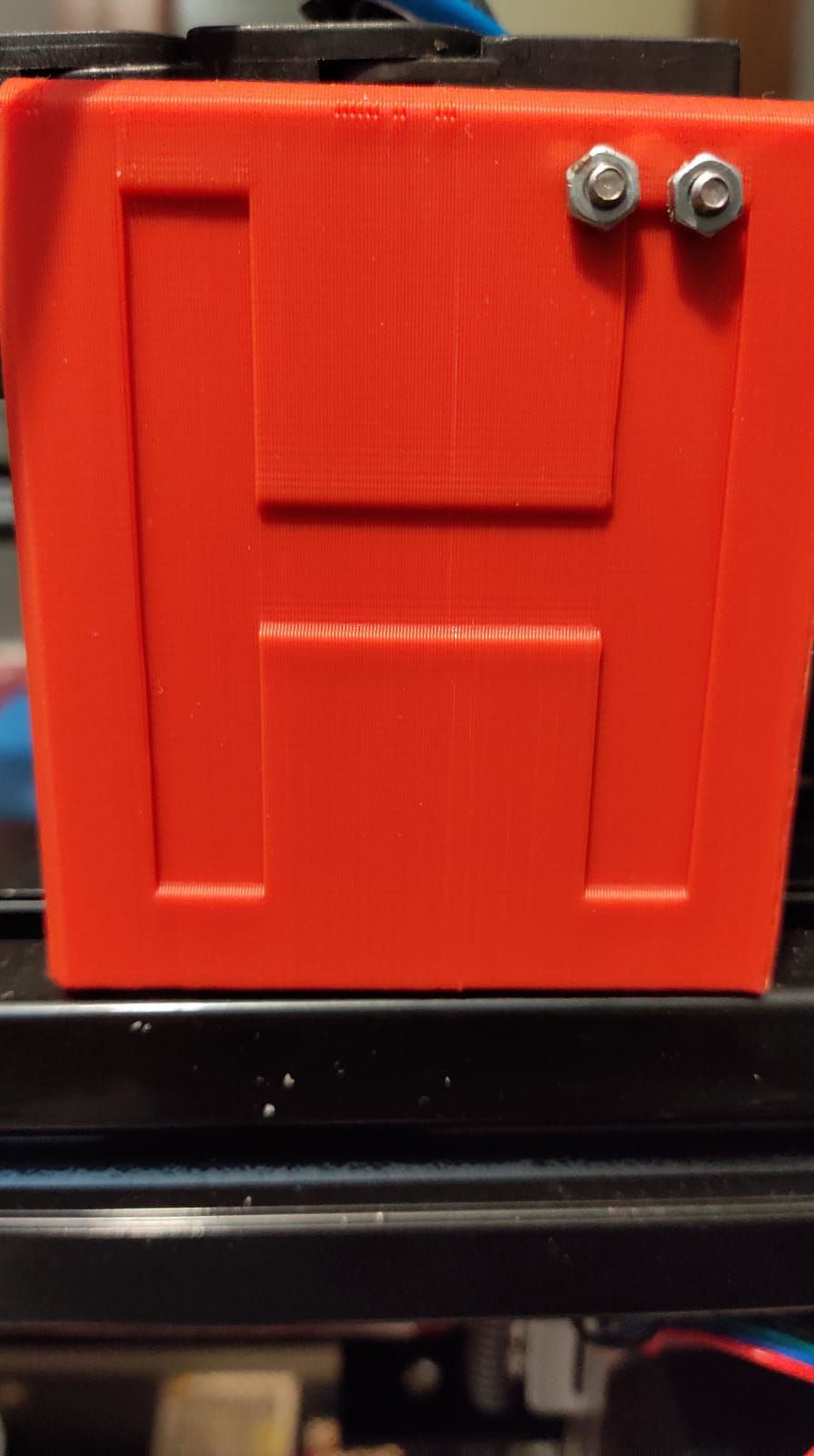

@secure, I think you have more fundamental errors than the what you suspect is caused by the heated bed. You are correct that voltage should not fluctuate like that - it should be rock steady with a decent power supply (Meanwell but not a Meanwell clone)

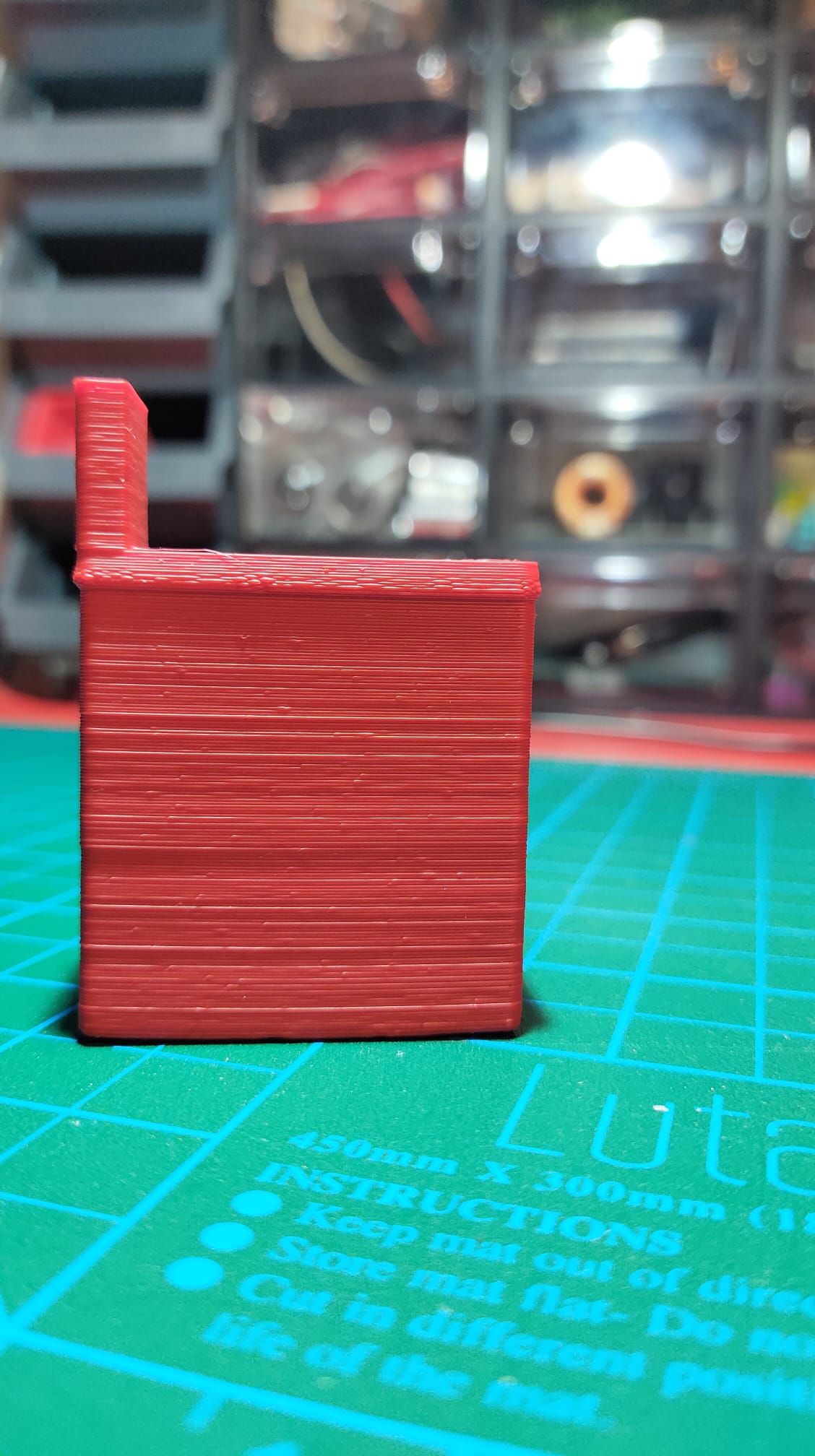

This might possibly be the reason why the rest of the print looks quite crappy (sorry). The walls are all over the place and are just terrible.

I would try replacing the power supply first .... but I am afraid that there might be other gremlins at work that cause the poor walls. I suppose they could be just over extruded .... hard to tell from here. -

@jens55 said in Turning of the SSR heated bed immediately kicks the printed part:

@secure, I think you have more fundamental errors than the what you suspect is caused by the heated bed. You are correct that voltage should not fluctuate like that - it should be rock steady with a decent power supply (Meanwell but not a Meanwell clone)

This might possibly be the reason why the rest of the print looks quite crappy (sorry). The walls are all over the place and are just terrible.

I would try replacing the power supply first .... but I am afraid that there might be other gremlins at work that cause the poor walls. I suppose they could be just over extruded .... hard to tell from here.Yes it is crappy I have some errors and trying find the possible causes.

I think it is hardware related error because I had recently(3 weeks ago) printed this part with the same printer.

Not a Meanwell but I have 1300 watt @24 volt PSU lying around here. I don't think it is related with PSU because it's voltage output is stable. I had changed a lot of things on that printer for the last 3 weeks. One another suspect is the twisted CAT7 23 awg cables that I used to for heat cartidges. Like @rjenkinsgb said I may need to rewire those cables. Thanks for the inputs.

-

Yes it is crappy I have some errors and trying find the possible causes.

I think it is hardware related error because I had recently(3 weeks ago) printed this part with the same printer.That's a night and day quality difference!

Not a Meanwell but I have 1300 watt @24 volt PSU lying around here. I don't think it is related with PSU because it's voltage output is stable.

What do you mean the output is stable .... you said "Board Vin voltage while printing took my attention. It is not stable and jumps between 22.4v to 24 volt."

If Vin varies at the board but not on the power supply then you have either severely undersized wiring or bad connections on the wiring which I assume you checked as soon as you noticed the fluctuations.I had changed a lot of things on that printer for the last 3 weeks. One another suspect is the twisted CAT7 23 awg cables that I used to for heat cartidges. Like @rjenkinsgb said I may need to rewire those cables. Thanks for the inputs.

Yes, 23 gauge is iffy but might work if it's a 24V / 40W heater .... if it is a 12V heater then 23 ga is not heavy enough.

-

Further thought - the crappy wall finish could very well be related to an undersized extruder heater wire.

-

@secure said in Turning of the SSR heated bed immediately kicks the printed part:

Yes, spiking is my suspect too. This is my first thing to do.

I'll add another small PSU for 12V leds&fans and source the heated bed AC from this PSU.You still have the SSR control wire bundled in with the power wires; that's a no-no - small signal wires need some form of isolation, eg. distance, screening, twisting etc., to separate them from power wires anywhere it is physically possible.

-

@secure

Can you separate the input lines of the two PSUs? maybe using UPS, if you can pull an extension cable from your neighbor's garage it's better

just for what causes this feedback, reading the various posts the only point in common is the AC line ....