Issues with pressure advance since RRF 3.4

-

@gnydick said in Issues with pressure advance since RRF 3.4:

@dc42 why don't you just generate the move list from a 3.3 system and from a 3.4 system for the same gcode and output it to text files and diff them?

Because none of the prints I and others have tried show any difference between 3.3 and 3.4. Nobody has produced a print and machine settings that shows a difference. If somebody ever does, then I will be able to use the method you suggested or another method to see what has changed.

-

I personally believe that the changes must have happened before 3.3 ... or that the observed issue isnt due to a change in firmware but a change in perception of acceptable corner bulging due to the performance of non-RRF systems.

A decent way to bisect this is to take a Duet2 board, and go back all the way to RRF 2.0.3, and then work through at least 3.0, 3.1.1, 3.2.2, 3.3 to see whether my hypothesis holds.

But I wouldn't ask anyone to lose a week of their life to do this...

-

@oliof I think you are likely correct. Pressure advance is not a compete solution to corner bulging because there are other factors at play. I have to compensate for one of those other factors separately from PA.

Accuracy of perimeters in general (including reduced corner bulging) is better if you select "External perimeters first" in the slicer. Doing so might make printing steep overhangs more difficult, but I am not aware of any other disadvantages. I have been printing external perimeters first for years.

-

@dc42 why wait? I would do what I'm suggesting over and over with lots of different gcode files.

In fact, I would make that part of the release process to validate.

-

I've printed test files with 3.2.2, 3.3 and 3.4.4 and have no been able to see a difference

-

@dc42 thanks for the additional insight! It may also be a bit slicer dependent. I remember KISS Slicer for example is doing a slight inwards bend before steep angles; other slicers may not do this.

-

I already tested different slicers and settings also different RRF versions.

Only thing that helped with my machine was connecting Klipper (Pi).

I suspect that PA smooth time is the factor (feature) that is RRF missing to improve this.But the reasons why my bedslinger (also RRF with Duet 3 Mini) produces better corners? I don't know. My Voron (printer with the issues) uses a different kind of hotend which is also not compatible with the PID algorithm RRF uses as PID tuning only works when calibrating the hotend as heater and not as a tool But that's another issue I already reported in another thread.

-

I can conclusively report that Input Shaping interferes with Pressure Advance. Didn't know if anyone else has been able to confirm on their prints.

-

@gnydick I've also seen issues with input shaping + pressure advance, though I'm always open to having done something wrong on my end. At the risk of hijacking a closely-related-but-not-quite-the-same thread, you can see the artifact show up as an indentation before and after turns in the photo below. I wasn't able to remove it with any amount of tuning.

- gcode here.

- Ringing tower model here.

- Config files for the machine when the above was printed in this commit. (Newer repo state is a bit different; I'm converting to closed loop.)

- If you want to re-slice for your machine, the PrusaSlicer layer change script, designed for 0.25mm layer height, is:

{if layer_num== 1} M593 P"none" ; no input shaping M572 D0 S0 ; no PA {elsif layer_num== 60} M593 P"ei3" F42 S0.1 ; enable input shaping M572 D0 S0 ; no PA {elsif layer_num== 120} M593 P"none" ; no input shaping M572 D0 S0.09 ; enable PA {elsif layer_num== 180} M593 P"ei3" F42 0.1 ; enable input shaping M572 D0 S0.09 ; enable PA {endif} -

@gnydick said in Issues with pressure advance since RRF 3.4:

I can conclusively report that Input Shaping interferes with Pressure Advance. Didn't know if anyone else has been able to confirm on their prints.

… which is why we recommend tuning pressure advance AFTER tuning input shaping.

Ian

-

@droftarts Yes, I've heard this before and followed this instruction.

First, I tuned IS with PA off, arriving at

M593 P"ei3" F42.Second, I printed this calibration print with input shaping held constant and PA values varied from 0.00 at the far right (bottom of the print) to 0.14 at the far left, incrementing every 5mm.

Note how the pre- and post-seam artifact is not present when PA is zero on the right-hand side when PA is off. The artifact I am referring to the horizontal line / thin section that measures around 4mm before and after the seam, and the corners. It's present for any PA values from way too low to way too high as long as IS is enabled, and absent if PA is off. Apologies for my photography.

Did I misunderstand something? What else could I have done?

-

@droftarts, makes no difference.

-

I had this issue for nearly two years... No problem with marlin firmware.

Tried everything. Changed Steppers, different extruders, hotends, bowden tubes.... I had to use a PA value of 0.4 with a 5cm bowden.

New Year, new (last) try. Had already a bambu lab printer in the basket. Instead, I ordered an Malow NF Sunrise extruder. Thought, this has to work. It's a all in one solution.

First print yesterday without calibration a PA value of 0.04 with perfect corners.

-

It seems some extruder / hotends cause issues with the PA implemenation we have atm with RRF.

With Klipper you also would need to play around with "PA smooth time" so PA does work properly. Maybe we'll see such implementation in RRF anytime soon. -

@Monteaup, you show two cubes in your photo. What is the difference in print settings between the two?

Can you post a more detailed close up photo of the seam that you say is present for any PA values?

PA doesn't fully address the problem of over-extrusion in corners. I am looking to address this separately.

-

@evan38109 said in Issues with pressure advance since RRF 3.4:

@droftarts Yes, I've heard this before and followed this instruction.

First, I tuned IS with PA off, arriving at

M593 P"ei3" F42.Second, I printed this calibration print with input shaping held constant and PA values varied from 0.00 at the far right (bottom of the print) to 0.14 at the far left, incrementing every 5mm.

Note how the pre- and post-seam artifact is not present when PA is zero on the right-hand side when PA is off. The artifact I am referring to the horizontal line / thin section that measures around 4mm before and after the seam, and the corners. It's present for any PA values from way too low to way too high as long as IS is enabled, and absent if PA is off. Apologies for my photography.

Did I misunderstand something? What else could I have done?

This is a great photo and example of some strange interaction between PA and IS. Something isn't right.

-

@CCS86 I mean...maybe? If I'm betting on something being wrong, I bet it's me, not RRF.

Have you seen the same thing? It should be easy to recreate, just print a one-wall cube with the seam on the side while both IS and PA are enabled vs. not enabled. Make sure to disable any kind of dynamic speed control in the slicer. (e.g., "Slow down if layer print time is below...")

-

@dc42 said in Issues with pressure advance since RRF 3.4:

@Heartleander81 said in Issues with pressure advance since RRF 3.4:

@R4ffers oh yes.

@dc42 is there also something like pressure advance smooth time under RRF? A few clippers have the problem with the high smooth time, but those who have problems are mostly DirectDrive extruder users. Maybe that's an approach you can follow.No, there isn't anything similar. I will look into that Klipper feature.

Hi @dc42, just wanted to +1 this feature.

I run a delta / duet WiFi with a ~400mm bowden and 0.325 pressure advance, with input shaping. The print quality is excellent.

However, when I turn up the print speed/acceleration, I also need to increase extruder jerk - as expected with pressure advance. EXYZ all cope fine - no skipped steps or filament stripping - however on short zig-zag movements it tends to jerk rapidly back and forth which creates some noise (and the extruder is/was fixed to the frame).

As a result, I have switched to a suspended/lying extruder so that I can turn pressure advance down and maintain higher print speed but I see this as a temporary solution.

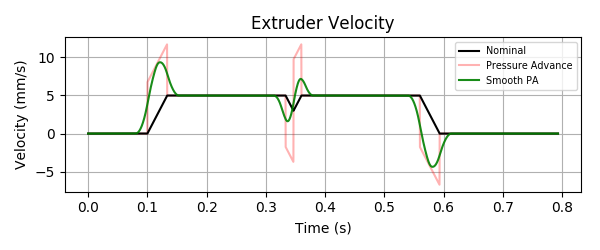

If smooth pressure advance is anything like the graphs here it looks like it might help to resolve this issue

Do you think it would have any benefits for this scenario?

-

-

I'd say it's a 80% improvement to before and compared to my printers with Klipper or Bambu X1.

So it was definitely a step in the right direction.